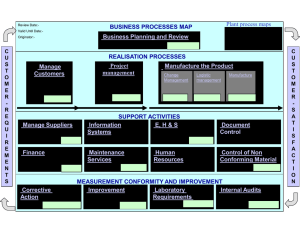

Advanced Product Quality Planning (APQP) Home » Advanced Product Quality Planning (APQP) APQP APQP Consulting APQP Training APQP Support APQP – Advanced Product Quality Planning – ⇓ Introduction to APQP ⇓ What is APQP ⇓ Why Implement APQP ⇓ When to Apply APQP ⇓ How to Implement APQP Introduction to Advanced Product Quality Planning (APQP) Complex products and supply chains present plenty of possibilities for failure, especially when new products are being launched. Advanced Product Quality Planning (APQP) is a structured process aimed at ensuring customer satisfaction with new products or processes. APQP has existed for decades in many forms and practices. Originally referred to as Advanced Quality Planning (AQP), APQP is used by progressive companies to assure quality and performance through planning. Ford Motor Company published the first Advanced Quality Planning handbook for suppliers in the early 1980’s. APQP helped Ford suppliers develop appropriate prevention and detection controls for new products supporting the corporate quality effort. With lessons learned from Ford AQP, the North American Automotive OEM’s collectively created the APQP process in 1994 and then later updated in 2008. APQP is intended to aggregate the common planning activities all automotive OEM’s require into one process. Suppliers utilize APQP to bring new products and processes to successful validation and drive continuous improvement. There are numerous tools and techniques described within APQP. Each tool has potential value when applied in the correct timing. Tools that have the greatest impact on product and process success are called the Core Tools. The Core Tools are expected to be used for compliance to IATF 16949. There are five basic Core Tools detailed in separate guideline handbooks, including Advanced Product Quality Planning (APQP). The other Core Tools are: Failure Mode and Effects Analysis (FMEA) Measurement Systems Analysis (MSA) Statistical Process Control (SPC) Production Part Approval Process (PPAP) What is Advanced Product Quality Planning (APQP) APQP is a structured approach to product and process design. This framework is a standardized set of quality requirements that enable suppliers to design a product that satisfies the customer. The primary goal of product quality planning is to facilitate communication and collaboration between engineering activities. A Cross Functional Team (CFT), involving marketing, product design, procurement, manufacturing and distribution, is used in the APQP process. APQP ensures the Voice of the Customer (VOC) is clearly understood, translated into requirements, technical specifications and special characteristics. The product or process benefits are designed in through prevention. APQP supports the early identification of change, both intentional and incidental. These changes can result in exciting new innovation supporting customer delight. When not managed well they translate to failure and customer dissatisfaction. The focus of APQP is utilization of tools and methods for mitigating the risks associated with change in the new product or process. APQP - Concurrent Process Why Implement Advanced Product Quality Planning (APQP) APQP supports the never ending pursuit of continuous improvement. The first three sections of APQP focus on planning and prevention and make up 80% of the APQP process. The fourth and fifth sections support the remaining 20% of APQP and focus on validation and evidence. The fifth section specifically allows an organization to communicate learnings and provide feedback to develop standard work and processes. A list of APQP benefits are: Directing resources by defining the vital few items from the trivial many Promote early identification of change Intentional (what is being changed on purpose to bring value to the customer) Incidental (environments, customer usage, degradation and interfaces) Avoid late changes (post release) by anticipating failure and preventing it Fewer design and process changes later in the product development process On-time quality product at lowest cost Multiple options for mitigating the risk when found earlier Higher capability of verification and validation of a change Late Failure Mode Discovery Improved collaboration between Design of the Product and Process Improved Design for Manufacturing and Assembly (DFM/A) Lower cost solutions selected earlier in the process Legacy capture and reuse, advancement of Tribal Knowledge and standard work creation and utilization Early Failure Mode Discovery When to Apply Advanced Product Quality Planning (APQP) APQP facilitates communication between the supply chain and the organization / customer. Requirements that translate into more detailed specifications are clarified and decomposed to more detail as the process continues. APQP is used in 2 ways: 1. New Product Introduction (NPI) Support: APQP supplements product development processes by adding a focus on risk as a substitute for failure. This allows the team to take action on the risk instead of having to wait for failure to occur in testing or worse, in the hands of the customer. APQP utilizes risk based tools that focus on all aspects of product and process design, service, process quality control, packaging and continuous improvement. Each application of APQP may be unique to a previous application because of the percentage of new content, changes to current off-the-shelf technology or past failure history. 2. Product or Process Change (Post Release): APQP follows a product or process change outside of Product Development and assures the risk of change is managed successfully by preventing problems created by the change. How to Implement Advanced Product Quality Planning (APQP) APQP is comprised of one pre-planning stage and five concurrent phases. Once begun, the process never ends and is often illustrated in the Plan Do Study Act (PDSA) cycle. PDSA was made famous by W. Edwards Deming. Each section is aligned with analytical risk discovery tools and techniques. Finding risk in product and process development is more desirable than finding late failure. The APQP Sections are defined below: APQP - Plan Do Study Act Section 0: Pre-Planning APQP begins with assumptions, concepts and past knowledge. Bookshelf knowledge and standard work practices are listed as well as areas where significant change is expected. This section compiles the inputs into Section 1 – Plan and Define. Section 1: Plan and Define Section 1 links customer expectations, wants, needs and desires to requirements. Plan Development will assure the output of this section is satisfactory product quality. Resource planning, process and product assumptions are made. A list of preliminary special characteristics and design / reliability goals are also established. Section 2: Product Design and Development The focus in Section 2 is on product design and development. Geometry, design features, details, tolerances and refinement of special characteristics are all reviewed in a formal Design Review. Design verification through prototypes and testing are also part of this section. Tools which typically provide great benefit in this section are DFM/A, Design Failure Mode and Effects Analysis (DFMEA) and Design Verification Plan and Report (DVP&R). Section 3: Process Design and Development Section 3 explores manufacturing techniques and measurement methods that will be used to bring the design engineer’s vision into reality. Process Flow Charts, Process Failure Mode and Effects Analysis (PFMEA) and Control Plan Methodology are examples of tools used in this section. Section 4: Product and Process Validation Validation of the process quality and volume capabilities is the focus of Section 4. Statistical Process Control (SPC), Measurement Systems Analysis (MSA) and Process Capability Studies are introduced in this section. Product Part Approval Process (PPAP) is ready for submission and production begins upon approval. Section 5: Feedback Assessment and Corrective Action Section 5 explores learnings from the ongoing manufacturing process, RPN reduction, corrective actions (both internal and external), Eight Disciplines of Problem Solving (8D) and the capture of information pertinent for future use. APQP Inputs and Outputs by Section Each section of APQP depends on risk information that has previously been discovered. The information sharing assures a flow of logical risk discovery and mitigation. The detailed inputs and outputs for each section are described below: Inputs into Section 1: Voice of the Customer Market research Historical issues Team experience Business Plan and Marketing Plan Product and Process Benchmark Product and Process Assumptions Product Reliability Studies Customer Inputs as applicable Outputs of Section 1: Design Goals Reliability and Quality Goals Preliminary Bill of Material (BOM) Preliminary Process Flow Preliminary list of Special Characteristics Product Assurance Plan Gateway approval Outputs of Section 2: Design FMEA (DFMEA) Design for Manufacturing and Assembly (DFM/A) Design Verification Design Review Prototype Control Plan Engineering Drawings CAD the Master Engineering Specifications Material Specifications Change Control for Drawings New Equipment, Tooling and Facilities Requirements Special Product and Process Characteristics Gages / Testing Equipment Requirements Team Feasibility Commitment and Gateway approval Outputs of Section 3: Packaging Standards and Specifications Quality System Review Process Flow Chart Floor Plan Layout Characteristics Matrix Process FMEA (PFMEA) Pre-Launch Control Plan Process Instructions Measurement Systems Analysis (MSA) Plan Preliminary Process Capability Plan Gateway Approval Outputs of Section 4: Significant Production Run MSA Results Process Capability Studies Production Part Approval Process (PPAP) Production Validation Testing Packaging Evaluation Production Control Plan Quality Planning Sign-Off and Gateway approval Outputs of Section 5: Reduced Variation Improved Customer Satisfaction Improved Delivery Performance Effective Use of Lessons Learned Examples of Where to Incorporate APQP: Develop Requirements from Voice of the Customer (VOC) using Quality Function Deployment (QFD) Develop a Product Quality Plan integrated into Program / Project Timeline Translate percentage of new content into Product and Process Assumptions Product design activities communicating special characteristics or key characteristics to the process design activity, prior to design release This may include new geometry, shape, parts, tighter tolerances and new materials linking the DFMEA to PFMEA Develop test plans (DVP&R) Use of formal Design Review to track progress Plan, acquire and install appropriate process equipment and tooling based on design tolerances provided by the product design source Assembly and Manufacturing personnel communicating suggestions of ways to better assemble a product (DFM/A) Establish adequate Quality Controls for Special Characteristics or Key Characteristics features of a product or parameters of a process, which still risk potential failure Performing Stability and Capability studies on special characteristics to understand the variation present and predict future performance with Statistical Process Control (SPC) and Process Capability (PPK and CPK) How to Develop a Product Quality Plan (PQP) The APQP process begins with the creation of a Product Quality Plan (PQP). The PQP may be unique for each individual development. During APQP - PQP Flow Chart the planning section, a core group of personnel will review the concept design, process and product assumptions, overall goals of the project and past failures. After collecting this information, the core team selects tools from each section, based on the value they may bring when failure prevention is discussed. The PQP is linked to the project timing plan to aid in program / project management efficiency. The tools and techniques are selected based on what risk may be present, created by the intentional and incidental change. Discovering unknown risk is desirable. Each risk is quantified and mitigation actions are developed and implemented increasing the probability of project success. Example of a Product Quality Plan The Quality-One approach depicted in the following PQP example is a matrix with calculated ratios of qualitative tools verses quantitative evidence. Since qualitative tools can be used earlier in the product development process, Quality-One expects a 3:1 qualitative to quantitative ratio. The opportunity to discuss potential issues based on change with qualitative tools should be three times greater than the actual data collected. Observed data collection happens late in Product APQP - PQP Example Development (PD) and reaction to failure may be required. Discussion of the change, using a tool and a Cross Functional Team (CFT), often results in discovering and preventing a failure early in PD. APQP is focused on predicting and preventing failure (80%) and less on detecting it (20%). The APQP Cross Functional Team (CFT) The Cross Functional Team (CFT) in APQP evolves and changes as the process progresses. Preliminary details required to begin Product Quality Planning are collected by a CFT prior to project kick-off. This process is typically short and does not involve any product or process design effort. Aspects of Pre-Planning include: Scope of the project Product and Process Assumptions Past Failure Team size, structure and experience Methods for issue resolution Space and resources required Timing of the project The CFT adds members as certain disciplines are required. Two examples of team evolution are: purchasing engagement when “make / buy” decisions are required and engagement of tool design resources when prototype and production tooling is required. APQP is performed using Collaborative Product (Process) Development (CPD). Each CFT discipline communicates with their counterparts on items which can impact quality, cost or delivery, either positively or negatively. Special Characteristics are also communicated between each CFT discipline. The earlier a product or process problem can be found, the less expensive and work intensive it will be to fix it. Working concurrently per the project timeline, the team completes the Plan and Design activity: Product Engineering (PDE) addresses Product Design and Development Process and / or Manufacturing Engineering (ME) addresses the Process Design and Development Each section has inputs, outputs and management gateway reviews. Gateways are timed to coincide with key decisions impacting project Quality, Cost or Delivery. How is APQP related to PPAP? PPAP Level Selection Product Part Approval Process (PPAP) highlights the proof or evidence collected through APQP. Validated results from the first trial run supports the assertion that quality of delivery is expected. The trial run must represent the production environment, with correct tools, machines, processes, personnel and conditions that may affect part quality. PPAP and APQP cannot be separated, as PPAP documents are the result of APQP. PPAP provides evidence that APQP has been successfully performed. Poor performance in a PPAP or a rejected sample can be attributed to poor APQP. Deliverables in PPAP are extensions of APQP Planning. The PPAP elements are listed below, note that many are the same as APQP tools or are the output results of APQP tools: Part Submission Warrant (PSW) Design Records Engineering Change Documents Customer Engineering Approval Design FMEA (DFMEA) Process Flow Process FMEA (PFMEA) Dimensional Results Performance and material test results Initial Process Capability Study Measurement Systems Analysis (MSA) Qualified Laboratory Documentation Bulk Material Requirements (if required) Control Plan Cosmetic or Visual Signoff Sample Product Master Sample Checking Aids Records of Compliance with customer specific requirements How are APQP, NPI and DFSS Related APQP, NPI, Design for Six Sigma (DFSS) and other Product Development Processes share goals and development tools. Examples of these tools can be found in our Core Competencies. APQP is often the Product Development Process that is used as a default process to support supplier engagement. DFSS is a highly focused effort reserved for high value requirements or specifications. APQP is broader in scope than DFSS and scalable to perceived risk each supplier, design or process poses on program success. Example of APQP, NPI and DFSS Relationship An Original Equipment Manufacturer (OEM) is preparing a new end user product. The product will follow the OEM NPI. Several of the subsystems and components require supplier engagement to assure that their expertise is included in product design. APQP will be used to collaborate with the suppliers. DFSS will focus on key features that are highly valuable and quite different than past products. A Six Sigma Black Belt is assigned to follow these features across all communications channels and groups. The tools used in each of these endeavors are the same. The tools may be used at differing utilization levels at the Black Belt’s discretion. Learn More About Advanced Product Quality Planning (APQP) Quality-One offers Quality and Reliability Support for Product and Process Development through Consulting, Training and Project Support. Quality-One provides Knowledge, Guidance and Direction in Quality and Reliability activities, tailored to your unique wants, needs and desires. Let us help you Discover the Value of APQP Consulting, APQP Training or APQP Project Support.