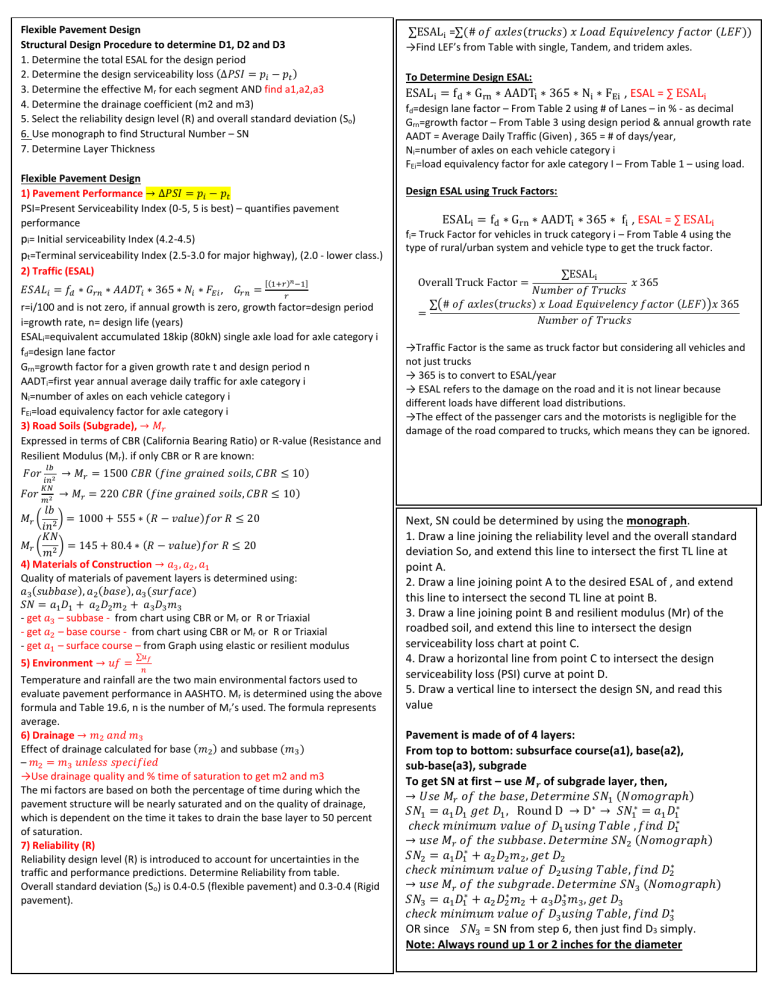

Flexible Pavement Design Structural Design Procedure to determine D1, D2 and D3 1. Determine the total ESAL for the design period 2. Determine the design serviceability loss (∆𝑃𝑆𝐼 = 𝑝𝑖 − 𝑝𝑡 ) 3. Determine the effective Mr for each segment AND find a1,a2,a3 4. Determine the drainage coefficient (m2 and m3) 5. Select the reliability design level (R) and overall standard deviation (So) 6. Use monograph to find Structural Number – SN 7. Determine Layer Thickness Flexible Pavement Design 1) Pavement Performance → ∆𝑃𝑆𝐼 = 𝑝𝑖 − 𝑝𝑡 PSI=Present Serviceability Index (0-5, 5 is best) – quantifies pavement performance pi= Initial serviceability Index (4.2-4.5) pt=Terminal serviceability Index (2.5-3.0 for major highway), (2.0 - lower class.) 2) Traffic (ESAL) 𝐸𝑆𝐴𝐿𝑖 = 𝑓𝑑 ∗ 𝐺𝑟𝑛 ∗ 𝐴𝐴𝐷𝑇𝑖 ∗ 365 ∗ 𝑁𝑖 ∗ 𝐹𝐸𝑖 , 𝐺𝑟𝑛 = [(1+𝑟)𝑛 −1] 𝑟 r=i/100 and is not zero, if annual growth is zero, growth factor=design period i=growth rate, n= design life (years) ESALi=equivalent accumulated 18kip (80kN) single axle load for axle category i fd=design lane factor Grn=growth factor for a given growth rate t and design period n AADTi=first year annual average daily traffic for axle category i Ni=number of axles on each vehicle category i FEi=load equivalency factor for axle category i 3) Road Soils (Subgrade), → 𝑀𝑟 Expressed in terms of CBR (California Bearing Ratio) or R-value (Resistance and Resilient Modulus (Mr). if only CBR or R are known: 𝐹𝑜𝑟 𝑙𝑏 𝑖𝑛2 𝐾𝑁 To Determine Design ESAL: ESALi = fd ∗ Grn ∗ AADTi ∗ 365 ∗ Ni ∗ FEi , ESAL = ∑ ESALi fd=design lane factor – From Table 2 using # of Lanes – in % - as decimal Grn=growth factor – From Table 3 using design period & annual growth rate AADT = Average Daily Traffic (Given) , 365 = # of days/year, Ni=number of axles on each vehicle category i FEi=load equivalency factor for axle category I – From Table 1 – using load. Design ESAL using Truck Factors: ESALi = fd ∗ Grn ∗ AADTi ∗ 365 ∗ fi , ESAL = ∑ ESALi fi= Truck Factor for vehicles in truck category i – From Table 4 using the type of rural/urban system and vehicle type to get the truck factor. ∑ESALi 𝑥 365 𝑁𝑢𝑚𝑏𝑒𝑟 𝑜𝑓 𝑇𝑟𝑢𝑐𝑘𝑠 ∑(# 𝑜𝑓 𝑎𝑥𝑙𝑒𝑠(𝑡𝑟𝑢𝑐𝑘𝑠) 𝑥 𝐿𝑜𝑎𝑑 𝐸𝑞𝑢𝑖𝑣𝑒𝑙𝑒𝑛𝑐𝑦 𝑓𝑎𝑐𝑡𝑜𝑟 (𝐿𝐸𝐹))𝑥 365 = 𝑁𝑢𝑚𝑏𝑒𝑟 𝑜𝑓 𝑇𝑟𝑢𝑐𝑘𝑠 Overall Truck Factor = →Traffic Factor is the same as truck factor but considering all vehicles and not just trucks → 365 is to convert to ESAL/year → ESAL refers to the damage on the road and it is not linear because different loads have different load distributions. →The effect of the passenger cars and the motorists is negligible for the damage of the road compared to trucks, which means they can be ignored. → 𝑀𝑟 = 1500 𝐶𝐵𝑅 (𝑓𝑖𝑛𝑒 𝑔𝑟𝑎𝑖𝑛𝑒𝑑 𝑠𝑜𝑖𝑙𝑠, 𝐶𝐵𝑅 ≤ 10) → 𝑀𝑟 = 220 𝐶𝐵𝑅 (𝑓𝑖𝑛𝑒 𝑔𝑟𝑎𝑖𝑛𝑒𝑑 𝑠𝑜𝑖𝑙𝑠, 𝐶𝐵𝑅 ≤ 10) 𝑙𝑏 𝑀𝑟 ( 2 ) = 1000 + 555 ∗ (𝑅 − 𝑣𝑎𝑙𝑢𝑒)𝑓𝑜𝑟 𝑅 ≤ 20 𝑖𝑛 𝐾𝑁 𝑀𝑟 ( 2 ) = 145 + 80.4 ∗ (𝑅 − 𝑣𝑎𝑙𝑢𝑒)𝑓𝑜𝑟 𝑅 ≤ 20 𝑚 4) Materials of Construction → 𝑎3 , 𝑎2 , 𝑎1 Quality of materials of pavement layers is determined using: 𝑎3 (𝑠𝑢𝑏𝑏𝑎𝑠𝑒), 𝑎2 (𝑏𝑎𝑠𝑒), 𝑎3 (𝑠𝑢𝑟𝑓𝑎𝑐𝑒) 𝑆𝑁 = 𝑎1 𝐷1 + 𝑎2 𝐷2 𝑚2 + 𝑎3 𝐷3 𝑚3 - get 𝑎3 – subbase - from chart using CBR or Mr or R or Triaxial - get 𝑎2 – base course - from chart using CBR or Mr or R or Triaxial - get 𝑎1 – surface course – from Graph using elastic or resilient modulus 𝐹𝑜𝑟 ∑ESALi =∑(# 𝑜𝑓 𝑎𝑥𝑙𝑒𝑠(𝑡𝑟𝑢𝑐𝑘𝑠) 𝑥 𝐿𝑜𝑎𝑑 𝐸𝑞𝑢𝑖𝑣𝑒𝑙𝑒𝑛𝑐𝑦 𝑓𝑎𝑐𝑡𝑜𝑟 (𝐿𝐸𝐹)) →Find LEF’s from Table with single, Tandem, and tridem axles. 𝑚2 ∑𝑢𝑓 5) Environment → 𝑢𝑓 = 𝑛 Temperature and rainfall are the two main environmental factors used to evaluate pavement performance in AASHTO. Mr is determined using the above formula and Table 19.6, n is the number of Mr’s used. The formula represents average. 6) Drainage → 𝑚2 𝑎𝑛𝑑 𝑚3 Effect of drainage calculated for base (𝑚2 ) and subbase (𝑚3 ) – 𝑚2 = 𝑚3 𝑢𝑛𝑙𝑒𝑠𝑠 𝑠𝑝𝑒𝑐𝑖𝑓𝑖𝑒𝑑 →Use drainage quality and % time of saturation to get m2 and m3 The mi factors are based on both the percentage of time during which the pavement structure will be nearly saturated and on the quality of drainage, which is dependent on the time it takes to drain the base layer to 50 percent of saturation. 7) Reliability (R) Reliability design level (R) is introduced to account for uncertainties in the traffic and performance predictions. Determine Reliability from table. Overall standard deviation (So) is 0.4-0.5 (flexible pavement) and 0.3-0.4 (Rigid pavement). Next, SN could be determined by using the monograph. 1. Draw a line joining the reliability level and the overall standard deviation So, and extend this line to intersect the first TL line at point A. 2. Draw a line joining point A to the desired ESAL of , and extend this line to intersect the second TL line at point B. 3. Draw a line joining point B and resilient modulus (Mr) of the roadbed soil, and extend this line to intersect the design serviceability loss chart at point C. 4. Draw a horizontal line from point C to intersect the design serviceability loss (PSI) curve at point D. 5. Draw a vertical line to intersect the design SN, and read this value Pavement is made of of 4 layers: From top to bottom: subsurface course(a1), base(a2), sub-base(a3), subgrade To get SN at first – use 𝑴𝒓 of subgrade layer, then, → 𝑈𝑠𝑒 𝑀𝑟 𝑜𝑓 𝑡ℎ𝑒 𝑏𝑎𝑠𝑒, 𝐷𝑒𝑡𝑒𝑟𝑚𝑖𝑛𝑒 𝑆𝑁1 (𝑁𝑜𝑚𝑜𝑔𝑟𝑎𝑝ℎ) 𝑆𝑁1 = 𝑎1 𝐷1 𝑔𝑒𝑡 𝐷1 , Round D → D∗ → 𝑆𝑁1∗ = 𝑎1 𝐷1∗ 𝑐ℎ𝑒𝑐𝑘 𝑚𝑖𝑛𝑖𝑚𝑢𝑚 𝑣𝑎𝑙𝑢𝑒 𝑜𝑓 𝐷1 𝑢𝑠𝑖𝑛𝑔 𝑇𝑎𝑏𝑙𝑒 , 𝑓𝑖𝑛𝑑 𝐷1∗ → 𝑢𝑠𝑒 𝑀𝑟 𝑜𝑓 𝑡ℎ𝑒 𝑠𝑢𝑏𝑏𝑎𝑠𝑒. 𝐷𝑒𝑡𝑒𝑟𝑚𝑖𝑛𝑒 𝑆𝑁2 (𝑁𝑜𝑚𝑜𝑔𝑟𝑎𝑝ℎ) 𝑆𝑁2 = 𝑎1 𝐷1∗ + 𝑎2 𝐷2 𝑚2 , 𝑔𝑒𝑡 𝐷2 𝑐ℎ𝑒𝑐𝑘 𝑚𝑖𝑛𝑖𝑚𝑢𝑚 𝑣𝑎𝑙𝑢𝑒 𝑜𝑓 𝐷2 𝑢𝑠𝑖𝑛𝑔 𝑇𝑎𝑏𝑙𝑒, 𝑓𝑖𝑛𝑑 𝐷2∗ → 𝑢𝑠𝑒 𝑀𝑟 𝑜𝑓 𝑡ℎ𝑒 𝑠𝑢𝑏𝑔𝑟𝑎𝑑𝑒. 𝐷𝑒𝑡𝑒𝑟𝑚𝑖𝑛𝑒 𝑆𝑁3 (𝑁𝑜𝑚𝑜𝑔𝑟𝑎𝑝ℎ) 𝑆𝑁3 = 𝑎1 𝐷1∗ + 𝑎2 𝐷2∗ 𝑚2 + 𝑎3 𝐷3∗ 𝑚3 , 𝑔𝑒𝑡 𝐷3 𝑐ℎ𝑒𝑐𝑘 𝑚𝑖𝑛𝑖𝑚𝑢𝑚 𝑣𝑎𝑙𝑢𝑒 𝑜𝑓 𝐷3 𝑢𝑠𝑖𝑛𝑔 𝑇𝑎𝑏𝑙𝑒, 𝑓𝑖𝑛𝑑 𝐷3∗ OR since 𝑆𝑁3 = SN from step 6, then just find D3 simply. Note: Always round up 1 or 2 inches for the diameter Equations of Motion 𝑣 = 𝑎𝑡 + 𝑣0 , 𝐷𝑏 = Dilemma Zone (𝑣 2 − 𝑣02 ) = 𝑎(𝑥 − 𝑥0 ), 2 𝑣02 − 𝑣 2 , 𝐷 = 𝑏𝑟𝑒𝑎𝑘𝑖𝑛𝑔 𝑑𝑖𝑠𝑡𝑎𝑛𝑐𝑒. 2𝑔(𝑓 ± 𝐺) 𝑏 1 𝑥 = 𝑎𝑡 2 + 𝑣0 𝑡 + 𝑥0 2 𝑎2 = 𝑣02 𝑣02 𝑣0 𝑤+𝑙 , 𝑥𝑐 = 𝑣0 𝛿2 + ∗ , 𝜏𝑚𝑖𝑛 = 𝛿2 + ∗ + 2(𝑥 − 𝑣0 𝛿2 ) 2𝑎2 2𝑎2 𝑣0 2𝑥 𝑎1 = (𝜏−𝛿 2 1) + 2(𝑤+𝐿−𝑣0 𝜏) (𝜏−𝛿)2 , τ𝑚𝑖𝑛 = δ2 + v0 2a∗2 + w+L v0 Vertical Curve Crest 𝐿𝑚𝑖𝑛 = 2𝑆 − 200(√ℎ1 +√ℎ2 ) |𝐴| 2 (𝑆 ≥ 𝐿), 𝐿𝑚𝑖𝑛 = |𝐴|𝑆 2 200(√ℎ1 +√ℎ2 ) 2 (𝑆 ≤ 𝐿), 𝐴 = |𝐺2 − 𝐺1 | [𝑎𝑛𝑠𝑤𝑒𝑟 𝑖𝑛 %]. 𝑇𝑜 𝑓𝑖𝑛𝑑 𝐿𝑚𝑖𝑛 → 𝑠𝑝𝑒𝑒𝑑, 𝑆𝑆𝐷, 𝑆 < 𝐿 𝑜𝑟 𝑆 𝐿, 𝐿𝑚𝑖𝑛 (𝑓𝑡) 𝐿 𝐿 𝐿 𝑇𝑜 𝑠𝑜𝑙𝑣𝑒 𝑣𝑒𝑟𝑡𝑖𝑐𝑎𝑙 𝑐𝑢𝑟𝑣𝑒 → 𝐴, 𝐾 𝑓𝑟𝑜𝑚 𝑡𝑎𝑏𝑙𝑒, 𝐿 = 𝐾𝐴, 𝑆𝑡𝑎. 𝐵𝑉𝐶 = 𝑆𝑡𝑎. 𝑃𝑉𝐼 − , 𝑆𝑡𝑎. 𝐸𝑉𝐶 = 𝑆𝑡𝑎. 𝑃𝑉𝐼 + , 𝐸𝑙𝑒𝑣. 𝐵𝑉𝐶 = 𝐸𝑙𝑒𝑣. 𝑃𝑉𝐼 + 𝑔1 , 2 2 2 𝐿 𝐿𝐺1 2 𝐺1 −𝐺2 𝐸𝑙𝑒𝑣. 𝐸𝑉𝐶 = 𝐸𝑙𝑒𝑣. 𝑃𝑉𝐼 + 𝑔2 , [ 𝑋ℎ𝑖𝑔ℎ = , 𝑌ℎ𝑖𝑔ℎ = 𝐿𝐺12 200(𝐺1 −𝐺2 ) ] 𝑓𝑜𝑟 𝑆𝑎 𝑎𝑛𝑑 𝐶𝑟, 𝑃𝑒𝑙𝑒 = [𝑉𝑃𝐶𝑒𝑙𝑒 + ( 𝐺1 100 𝑥 2 ) 𝑥] + 𝑦, 𝑦 = 4𝐸 ( ) , 𝐸 = 𝐿 𝐴𝐿 800 Vertical Curve Sag Same steps as Vertical Curve Crest except 𝐿𝑚𝑖𝑛 is found differently. 𝐿𝑚𝑖𝑛 = 2𝑆 − CHAPTER 3 – Traffic Stream Flow Models 𝑞 = 𝑓𝑙𝑜𝑤, 𝑘 = 𝑑𝑒𝑛𝑠𝑖𝑡𝑦, 𝑣, 𝑢 = 𝑠𝑝𝑒𝑒𝑑, ℎ = 𝑡𝑖𝑚𝑒 ℎ𝑒𝑎𝑑𝑤𝑎𝑦, 𝑆 = 𝑠𝑝𝑎𝑐𝑖𝑛𝑔 1⁄2 (𝑣 2 − 𝑣02 ) = 𝑎(𝑥 − 𝑥0 ) (𝑎 = 𝑎𝑐𝑐𝑒𝑙𝑒𝑟𝑎𝑡𝑖𝑜𝑛, 𝑣 = 𝑠𝑝𝑒𝑒𝑑, 𝑥 = 𝑝𝑜𝑠𝑖𝑡𝑖𝑜𝑛) 2 𝑥𝑙 = 𝑣 ⁄2𝑑 (𝑑𝑙 = 𝑑𝑒𝑐𝑒𝑙𝑒𝑟𝑎𝑡𝑖𝑜𝑛 𝑙𝑒𝑎𝑑𝑒𝑟) 𝑙 2 𝑥𝑓 = 𝑣 ∗ 𝛿 + 𝑣 ⁄2𝑑 (𝑑𝑓 = 𝑑𝑒𝑐𝑒𝑙𝑒𝑟𝑎𝑡𝑖𝑜𝑛 𝑓𝑜𝑙𝑙𝑜𝑤) 𝑓 𝑥𝑓 = 𝑆 + 𝑥1 − 𝑁𝐿 − 𝑥0 , 2 (𝑁 = 𝑛𝑢𝑚𝑏𝑒𝑟 𝑜𝑓 𝑐𝑎𝑟𝑠, 𝐿 = 𝑙𝑒𝑛𝑔𝑡ℎ 𝑜𝑓 𝑐𝑎𝑟) 2 200(ℎ+𝑆𝑡𝑎𝑛𝛽) 𝐴 (𝑆 > 𝐿), 𝐿𝑚𝑖𝑛 = 𝐴𝑆 2 200(ℎ+𝑆𝑡𝑎𝑛𝛽) (𝑆 < 𝐿), Horizontal Curve 5729.6 1719 ∆ 𝑅(𝑓𝑡) = , 𝑅(𝑚) = , , 𝑇 = 𝑅𝑡𝑎𝑛 ( ), 𝐷𝑎 𝐷𝑎 2 𝐿= 𝑅∆𝜋 180 = 100∆ D ,, ∆ ∆ ∆ 𝐿𝐶 = 2𝑅𝑠𝑖𝑛 ( ) , 𝑀 = 𝑅 (1 − 𝑐𝑜𝑠 ( )) , 𝐸 = 𝑅 (sec ( ) − 1) , 2 2 2 𝑆 = 𝑣 ∗ 𝛿 + 𝑣 ⁄2𝑑 − 𝑣 ⁄2𝑑 + 𝑁𝐿 + 𝑥0 𝑓 𝑙 Stopping Sight Distance 𝑆 = 1⁄𝑘 = ℎ ∗ 𝑢 , 𝑣02 − 𝑣 2 𝑣02 − 𝑣 2 (ℎ 𝑖𝑠 ℎ𝑒𝑎𝑑𝑤𝑎𝑦(𝑠), ℎ 𝑖𝑠 𝑐𝑜𝑛𝑠𝑡. 𝑠𝑝𝑎𝑐𝑖𝑛𝑔, 𝑆 𝑖𝑠 ℎ𝑒𝑎𝑑𝑤𝑎𝑦(𝑚), 𝑢 𝑖𝑠 𝑚𝑒𝑎𝑛 𝑠𝑝𝑒𝑒𝑑) (𝑢𝑝ℎ𝑖𝑙𝑙), (𝑑𝑜𝑤𝑛ℎ𝑖𝑙𝑙) 𝐷 = 𝐷 = 1 𝑏 𝑏 ℎ = ⁄𝑞 2𝑔(𝑓 + 𝐺) 2𝑔(𝑓 − 𝐺) 1 𝑇𝑖𝑚𝑒 𝑀𝑒𝑎𝑛 𝑆𝑝𝑒𝑒𝑑: 𝑢𝑖 = ⁄𝑁 ∗ ∑𝑣𝑖 𝑓 = 0.6 𝑑𝑟𝑦, 0.3 𝑤𝑒𝑡 𝐷𝑏 = 𝑐𝑜𝑠𝛼, 𝐺 = 𝑡𝑎𝑛𝛼 1 𝐷 𝑆𝑆𝐷 = 𝑣 ∗ 𝛿 + 𝐷𝑏 , 𝛿 = 𝑅𝑒𝑎𝑐𝑡𝑖𝑜𝑛 𝑡𝑖𝑚𝑒 𝑆𝑝𝑎𝑐𝑒 𝑀𝑒𝑎𝑛 𝑆𝑝𝑒𝑒𝑑; 𝑢𝑠 = 1⁄1 1 𝑡𝑎𝑣𝑔 = ∗ ∑ 𝑁 𝑣𝑖 ∑ Curvilinear Motion 𝑁 𝑣𝑖 𝑞 = 𝑢 ∗ 𝑘 (𝑞 = 𝑓𝑙𝑜𝑤, 𝑢 = 𝑚𝑒𝑎𝑛 𝑠𝑝𝑒𝑒𝑑, 𝑘 = 𝑐𝑜𝑛𝑐𝑒𝑛𝑡𝑟𝑎𝑡𝑖𝑜𝑛) 𝑣2 𝑒 + 𝑓𝑆 = (1 − 𝑓𝑠 𝑒), 𝑒 = 𝑡𝑎𝑛𝛽, 𝑒𝑓𝑆 = 0 𝑓𝑜𝑟 𝑡𝑦𝑝𝑖𝑐𝑎𝑙 ℎ𝑖𝑔ℎ𝑤𝑎𝑦 1 𝑢2 𝑢2 𝑔𝑅 𝑈𝑛𝑖𝑓𝑟𝑜𝑚 𝐹𝑙𝑜𝑤: 𝑘 = = 1⁄(𝑢𝛿 + − + 𝑁𝐿 + 𝑥0 ) 𝑆 2𝑑𝑓 2𝑠𝑑𝑙 𝑢 𝑞 =𝑢∗𝑘 = = 𝑘 ∗ 𝑢(𝑘) Regime Decelerating of leading Decelerating of following ⁄(𝑢𝛿 + 𝑢2 − 𝑢2 + 𝑁𝐿 + 𝑥 ) 0 A ∞ dn 2𝑑𝑓 2𝑠𝑑𝑙 B de dn 𝑆𝑡𝑎𝑡𝑖𝑜𝑛𝑎𝑟𝑦 𝑂𝑏𝑠𝑒𝑟𝑣𝑒𝑟 𝑎𝑛𝑑 𝑀𝑜𝑣𝑖𝑛𝑔 𝑉𝑒ℎ𝑖𝑐𝑙𝑒; 𝑞 𝑁0⁄ C ∞ de = 𝑇 (𝑁0 𝑖𝑠 # 𝑣𝑒ℎ𝑖𝑐𝑙𝑒𝑠, 𝑞 𝑖𝑠 𝑓𝑙𝑜𝑤, 𝑇 𝑖𝑠 𝑡𝑖𝑚𝑒 ) D Dec of leading = Dec of following 𝑁𝑝 𝑂𝑏𝑠𝑒𝑟𝑣𝑒𝑟 𝑚𝑜𝑣𝑒𝑠, 𝑡𝑟𝑎𝑓𝑓𝑖𝑐 𝑠𝑡𝑜𝑝𝑝𝑒𝑑; 𝑘 = ⁄𝐿 , 𝑁𝑝 = 𝑘𝑉𝑇 E No Braking ( 𝑘 𝑖𝑠 𝑐𝑜𝑛𝑐𝑒𝑛𝑡𝑟𝑎𝑡𝑖𝑜𝑛 𝑁𝑝 = #𝑝𝑎𝑠𝑠𝑒𝑑, 𝐿 = 𝑙𝑒𝑛𝑔𝑡ℎ, 𝑉 = 𝑠𝑝𝑒𝑒𝑑, 𝑇 = 𝑡𝑖𝑚𝑒) 𝑂𝑏𝑠𝑒𝑟𝑣𝑒𝑟 𝑚𝑜𝑣𝑒 𝑤𝑖𝑡ℎ 𝑠𝑡𝑟𝑒𝑎𝑚; 𝑁𝑒𝑒𝑑 𝑡𝑤𝑜 𝑟𝑢𝑛𝑠 𝑓𝑜𝑟 𝑏𝑜𝑡ℎ 𝑣𝑎𝑟𝑖𝑎𝑏𝑙𝑒𝑠 𝑣𝑎𝑟𝑦𝑖𝑛𝑔 𝑠𝑝𝑒𝑒𝑑𝑠. 2𝑒𝑞𝑛′ 𝑠 Passing Sight Distance 𝑀 = 𝑀0 − 𝑀𝑝 = 𝑞𝑇 − 𝑘𝑉𝑇 (𝑀𝑜 𝑖𝑠 # 𝑜𝑣𝑒𝑟𝑡𝑎𝑘𝑖𝑛𝑔, 𝑀𝑝 𝑖𝑠 #𝑝𝑎𝑠𝑠𝑒𝑑) 𝑎𝑡 2𝑑 𝑀⁄ = 𝑞 − 𝑘𝑉, 𝑀𝑤⁄ = 𝑞 − 𝑘𝑉 , 𝑀𝑎⁄ = 𝑞 − 𝑘𝑉 , 𝑞 = (𝑀𝑤 + 𝑀𝑎 )⁄ 𝑑1 = 1.47𝑡 [𝑣 − 𝑚 + ( 1 )] , 𝑑2 = 1.47𝑉𝑡2 , 𝑑4 = 2 , 𝑑3 𝑖𝑠 𝑔𝑖𝑣𝑒𝑛. 𝑤 𝑎 2 3 𝑇 𝑇𝑤 𝑇𝑎 (𝑇𝑤 + 𝑇𝑎 ) 𝑀𝑤 𝑞 𝐿 Lateral Displacement 𝑆𝑝𝑎𝑐𝑒 𝑀𝑒𝑎𝑛 𝑆𝑝𝑒𝑒𝑑; =𝑞− ( ) 𝑇𝑤 𝑢 𝑇𝑤 𝜃𝑖𝑠 𝑎𝑛𝑔𝑙𝑒 𝑜𝑓 𝑑𝑖𝑠𝑝𝑙𝑎𝑐𝑒𝑚𝑒𝑛𝑡, 𝑎 𝑖𝑠 𝑎𝑐𝑐𝑒𝑙. , 𝑑𝜃 𝑣𝑎 𝐿 𝑀𝑤 𝑀𝑤 𝑙 𝑖𝑠 𝑙𝑒𝑛𝑔𝑡ℎ 𝑡𝑜 𝑑𝑖𝑠𝑝𝑙𝑎𝑐𝑒. , = 2 2 ( ) 𝑄𝑢𝑎𝑛𝑡𝑖𝑡𝑦; = 𝑡𝑎𝑣𝑔 = 𝑇𝑎𝑣𝑒 = 𝑇𝑤 − , 𝑇𝑤 − 𝑇𝑎𝑣𝑒 = 𝑑𝑡 𝑎 +𝑙 𝑢 𝑞 𝑞 𝑣 𝑖𝑠 𝑠𝑝𝑒𝑒𝑑 (𝑇𝑤 𝑖𝑠 𝑡𝑖𝑚𝑒 𝑡𝑟𝑎𝑣𝑒𝑙 𝑑𝑖𝑟𝑒𝑐𝑡𝑖𝑜𝑛, 𝑀𝑤 𝑖𝑠 𝑐𝑜𝑢𝑛𝑡 𝑑𝑢𝑟𝑖𝑛𝑔 𝑟𝑢𝑛, 𝑞 𝑖𝑠 𝑓𝑙𝑜𝑤) Super-elevation Design (−𝑀𝑤 ); 𝑇𝑎𝑣𝑒 > 𝑇𝑤 (𝑇𝑒𝑠𝑡 𝑓𝑎𝑠𝑡𝑒𝑟 𝑡ℎ𝑎𝑛 𝑎𝑣𝑒𝑟𝑎𝑔𝑒) (+𝑀𝑤 ); 𝑇𝑎𝑣𝑒 < 𝑇𝑤 (𝑇𝑒𝑠𝑡 𝑠𝑙𝑜𝑤𝑒𝑟 𝑡ℎ𝑎𝑛 𝑎𝑣𝑒𝑟𝑎𝑔𝑒) 𝑣2 𝑒 + 𝑓 = 𝑀𝑤 = 0 (𝑇𝑒𝑠𝑡 𝑖𝑠 𝑎𝑣𝑒𝑟𝑎𝑔𝑒) 𝑆 𝑔𝑅 𝐿 𝑢= (𝑎𝑣𝑒𝑟𝑎𝑔𝑒 𝑠𝑡𝑟𝑒𝑎𝑚 𝑠𝑝𝑒𝑒𝑑) 𝑇𝑎𝑣𝑒 𝑆ℎ𝑜𝑐𝑘𝑤𝑎𝑣𝑒𝑠: 𝑞𝑏 − 𝑞𝑎 𝑢𝑠𝑤 = ( ) 𝑘𝑏 − 𝑘𝑎 (𝑞𝑏 𝑖𝑠 𝑓𝑙𝑜𝑤 𝑒𝑛𝑑, 𝑞𝑎 𝑖𝑠 𝑓𝑙𝑜𝑤 𝑠𝑡𝑎𝑟𝑡, 𝑘𝑏 𝑖𝑠 𝑐𝑜𝑛𝑐. 𝑒𝑛𝑑, 𝑘𝑎 𝑖𝑠 𝑐𝑜𝑛𝑐. 𝑠𝑡𝑎𝑟𝑡) (+)𝑢𝑠𝑤 𝑖𝑠 𝑖𝑛 𝑑𝑖𝑟𝑒𝑐𝑡𝑖𝑜𝑛 𝑜𝑓 𝑠𝑡𝑟𝑒𝑎𝑚 𝑓𝑙𝑜𝑤, (−)𝑢𝑠𝑤 𝑖𝑠 𝑢𝑝𝑠𝑡𝑟𝑒𝑎𝑚 𝑑𝑖𝑟𝑒𝑐𝑡𝑖𝑜𝑛, 𝑢𝑠𝑤 = 0 𝑖𝑠 𝑠𝑡𝑎𝑡𝑖𝑜𝑛𝑎𝑟𝑦 Level of Service (Freeway) Step 1: Compute FFS → 𝐹𝐹𝑆 = 𝐵𝐹𝐹𝑆 − 𝑓𝐿𝑊 − 𝑓𝐿𝐶 − 𝑓𝑁 − 𝑓𝐼𝐷 , FFS = Free Flow Speed, BFFS = base free-flow speed, 110 km/h (urban), 120 km/h (rural) Adjustments: fLW=Lane Width , fLC=right shoulder Lateral Clearance, fN=Number of Lanes ( rural freeway - fN = 0) , fID=Interchange density Step 2: Compute vp→ 𝑣𝑝 = 𝑉 𝑃𝐻𝐹∗𝑁∗𝑓𝑝 ∗𝑓𝐻𝑉 , 𝑓𝐻𝑉 = 1 1+𝑃𝑇 (𝐸𝑇 −1)+𝑃𝑅 (𝐸𝑅 −1) vp=15 min passenger car equivalent flow rate (pc/h/ln), PHF=Peak hour factor, 𝑃𝐻𝐹 = 𝐻𝑜𝑢𝑟𝑙𝑦 𝑣𝑜𝑙𝑢𝑚𝑒 4∗𝑝𝑒𝑎𝑘 15 min 𝑣𝑜𝑙𝑢𝑚𝑒 (Typically b/w 0.8 & 0.95) V = 𝑀𝑎𝑥 15 min 𝑓𝑙𝑜𝑤 𝑟𝑎𝑡𝑒 PHF V=hourly peak vehicle volume in one direction (veh/h), N=Number of travel lanes in one direction, fp=Driver population factor (0.85-1.0, use 1 for commuter traffic) fHV=Heavy vehicle adjustment factor PT=% of trucks (in decimal), PR=% of recreation vehicles (in decimal), ET=Truck adjustment Factor, ER=Recreation vehicle adjustment Factor ET and ER depend on type of terrain (Level, Rolling, Mountainous) For upgrades, ET and ER also depend on upgrade (%)and length(km), For Downgrades, ET depends on downgrade%) and length, but ER is treated as a level terrain Step 3: Average passing car speed (S) Use 𝒗𝒑 and FFS Curve in Curve to find average passenger car speed (S) OR Use: For 90 < FFS ≤ 120 km/h and (3100 – 15FFS) < vp ≤ (1800 + 5FFS) 𝑣𝑝 +15𝐹𝐹𝑆−3100 2.6 1 𝑆 = 𝐹𝐹𝑆 − [28 (23𝐹𝐹𝑆 − 1800) ( 20𝐹𝐹𝑆−1300 ) 𝑣𝑝 𝑆 ] Vp = flow rate (pc/km/ln), S = average passenger-car speed (km/h) Step 5: Compute LOS using Table or Graph for Freeway * compare the calculated D with the density range in Table 1 – Freeway – LOS + When comparing – Choose lower LOS at all times ! ** the only difference between upgrade and downgrade is the 𝑓𝐻𝑉 factor – The effect of heavy trucks is more severe in the upgrade section which means that LOS of Upgrade will be less than LOS of Downgrade. Find Capacity - Use LOS E and find Vp in PC/hr/lane using FFS limits in table V PHF∗N∗fp ∗fHV → vp ∗ 𝑁 ∗ 𝑓𝑝 ∗ 𝑓𝐻𝑉 = V PHF V Then, Hourly Volume = ∗ 𝑃𝐻𝐹 PHF Find Number of Lanes – Using the LOS and the FFS – determine the vp and then use 𝑁= V vp ∗PHF ∗𝑓𝑝 ∗𝑓𝐻𝑉 , V PHF & No passing Zone 𝑉 1 ,𝑓 = , 𝑃𝐻𝐹 ∗ 𝑓𝐺 ∗ 𝑓𝐻𝑉 𝐻𝑉 1 + 𝑃𝑇 (𝐸𝑇 − 1) + 𝑃𝑅 (𝐸𝑅 − 1) 𝐻𝑜𝑢𝑟𝑙𝑦 𝑣𝑜𝑙𝑢𝑚𝑒 𝑃𝐻𝐹 = 4 ∗ 𝑝𝑒𝑎𝑘 15 min 𝑣𝑜𝑙𝑢𝑚𝑒 vp=Passenger car equivalent flow rate for peak 15min period, V=hourly volume (vph), fHV=adjustment factor for heavy vehicles, fG=grade adjustment for level or rolling terrain PT and PR = Decimal partition of trucks (buses) and RV’s in traffic, ET and ER = Passenger car equivalent 𝑣𝑝 = To calculate 𝒗𝒑 → Estimate vp using PHF, use 𝑣𝑝 = 𝑉 𝑃𝐻𝐹 calculated value of Then, calculate BPTSF & fd/np AND find PTSF and get LOS from table , D=Density (pc/Km/ln) Find max 15 min flow rate - vp = 𝑃𝑇𝑆𝐹 = 𝐵𝑃𝑇𝑆𝐹 + 𝑓𝑑/𝑛𝑝 , 𝐵𝑃𝑇𝑆𝐹 = 100(1 − 𝑒 −0.000879𝑉𝑝 ), PTSF=Percent spent following for both directions (%), BPTSF=Base percent time spent following for both directions (%), fd/np=adjustment in PTSF (%), - found from table using vp & Directional Split vp to estimate fG, ET and ER which will provide value of vp close to vp initially calculated. and check that new vp and old vp are in the same range. If yes, Continue, If not, use new vp and find new fG & fHV, and so on. For 90 < FFS ≤ 120 km/h and vp ≤ (3100 - 15FFS) → 𝑆 = 𝐹𝐹𝑆 Step 4: Compute the density (D) 𝐷= Level of Service (Two Lane) Capacity of two-lane highways is 1,700 pc/hr for each direction and will normally not exceed 3,200 pc/hr for both directions for long section of the highway Class I two-lane highways – LOS depends on % time spent following(PTSF) in platoons & Average travel speed (ATS). Then Compare, take lower LOS Class II two-lane highways - LOS depends only on the % time spent following (PTSF) Step 1: Compute PTSF→ = 𝑀𝑎𝑥 15 min 𝑓𝑙𝑜𝑤 𝑟𝑎𝑡𝑒 – and use vp & FFS in Graph to see whether Number of Lanes meets the required LOS →A freeway is a divided highway with full access control and two or more lanes in each direction. → An LOS is a performance measure of a highway at traffic volume less than capacity →LOS A - Free-flow operation ▪ Vehicles are completely free to manoeuvre ▪ Effects of incidents or point breaks are easily absorbed - Density (D) ≤ 7 pc/km/ln →LOS B - Free-flow operation ▪ Ability to maneuver is only slightly restricted ▪ Effects of minor incidents still easily absorbed - Density (D) ≤ 11 pc/km/ln →LOS C - Speeds at or near FFS ▪ Freedom to maneuver is noticeably restricted ▪ Queues may form behind any significant blockage. - Density (D) ≤ 16 pc/km/ln →LOS D - Speeds decline slightly with increasing flows ▪ Density increases more quickly ▪ Freedom to maneuver is more noticeably limited ▪ Minor incidents create queuing Density (D) ≤ 22 pc/km/ln →LOS E - Operation near or at capacity ▪ No useable gaps, and little room to manoeuvre ▪ Any disruption causes queuing Density (D) ≤ 28 pc/km/ln →LOS F - Breakdown in flow ▪ Queues form behind breakdown points ▪ Demand > capacity - Number of cars arriving at a point > the number discharged Step 2: Compute ATS 𝐴𝑇𝑆 = 𝐹𝐹𝑆 − 0.0125𝑣𝑝 − 𝑓𝑛𝑝 , ATS=Average travel speed for both directions of travel combined (mi/h), fnp=adjustment for the percentage of no passing zones 𝐹𝐹𝑆 = 𝐵𝐹𝐹𝑆 − 𝑓𝐿𝑆 − 𝑓𝐴 (𝑒𝑠𝑡𝑖𝑚𝑎𝑡𝑒) FFS=Free flow speed (Km/h). fLS=Adjustment for lane and shoulder width fA=Adjustment for number of access points per mile 𝑉𝑓 𝑝𝑐 𝐹𝐹𝑆 = 𝑆𝐹𝑀 + 0.0125 ∗ (𝑓𝑖𝑒𝑙𝑑 𝑚𝑒𝑎𝑠𝑢𝑟𝑒𝑚𝑒𝑛𝑡 𝑎𝑡 > 200 ), 𝑓𝐻𝑉 ℎ SFM=Mean Speed of traffic measured in the field (mi/h), Vf = observed flow rate for period when field data was obtained (veh/h) fHV = heavy-vehicle adjustment factor 𝑉 1 𝑣𝑝 = , 𝑓 = , 𝑃𝐻𝐹 ∗ 𝑓𝐺 ∗ 𝑓𝐻𝑉 𝐻𝑉 1 + 𝑃𝑇 (𝐸𝑇 − 1) + 𝑃𝑅 (𝐸𝑅 − 1) fG=grade adjustment for level or rolling terrain fG & fHV are dependant on vp, therefore, 𝑣𝑝 = 𝑉 𝑃𝐻𝐹 , then determine fG & fHV, and check that new vp and old vp are in the same range. If yes, Continue, If not, use new vp and find new fG & fHV, and so on. Then, find fnp and calculate ATS and get LOS from table. Step 3: Compute LOS for Class I and Class II 1) First comparing vp with the two-way capacity of 3,200 pc/h 2) If vp is greater than capacity, the LOS is F 3) Also, if the demand flow rate in either direction (vp times directional split) is > 1700 pc/h, the LOS is F Class I uses both ATS and PTSF , Class II uses only PTSF Chapter 1 – Introduction →A transportation system may be defined as consisting of the fixed facilities, the flow entities, and the control system that permit people and goods to overcome the friction of geographical space efficiently in order to participate in a timely manner in some desired activity. →Transportation system classification: Land, Air, Water, Pipelines. Chapter 2 – Roadway Design →Braking Distance is affected by the original speed of the vehicle, the type of brake system in use, and the coefficient of friction between its tires and the road surface. → Banking or super-elevation – components of vehicle’s weight increase the resistance to the sliding tendency → Stopping distance = Braking distance + Time for perception-reaction x speed → Freeways ▪ Uninterrupted traffic flow ▪ Full control of access (access to and exit from these facilities are permitted only at controlled locations such as entrance and exit ramps) → Highways ▪ Uninterrupted traffic flow ▪ Partial control of access (access or exit may have permitted directly from or to abutting property or via a limited number of at-grade intersection) → Arterial roads: high-capacity urban roads. The primary function of an arterial road is to deliver traffic from collector roads to freeways. → Super-elevation design ▪ Normal crown: typical cross section on a tangent section (no super-elevation) ▪ Remove crown (Reverse crown): a super-elevated cross section which is sloped across the entire traveled way in the same direction and at a rate equal to the typical cross slope on tangent section (e.g. 2%) ▪Tangent runout: change from a normal crown section to a point where the adverse cross slope of the outside lane is removed (i.e. the outside lane is level) ▪Super-elevation runoff: change in cross slope from the end of tangent runout to a section that is fully super-elevated. Chapter 3 – Traffic Stream Flow Models →Traffic Flow Elements →• Flow (q) • Density/Concentration (k) • Speed (v, u) • Time Headway (h) • Space Headway or Spacing (S) → Free-flow condition: very low concentration and very high speed (speed ↑, spacing ↑, concentration ↓) → Free-flow speed, uf: maximum speed at zero concentration (when concentration approaches zero) →Concentration (k): ratio of the number of vehicles appearing on the photograph to the length of the roadway segment. →Time headway (h): difference between the time when the front of a vehicle arrives at a point on the highway and the time the front of the next vehicle arrives at the same point →h = (constant spacing) / (constant speed of operation) → h = 1/ q ** →Space headway (S): difference in position between the front of a vehicle and the front of the next vehicle Chapter 5 – Pavement Design - Part 1: Pavement materials & Types: Asphalt Strong cement, readily adhesive, highly waterproof, and durable (Asphalt Institute) Asphalt concrete Flexible pavement: maintains intimate contact with and distributes loads to the subgrade and depends on aggregate interlock, particle friction, and cohesion for stability Portland cement Rigid pavement More advantages compared to asphalt pavement in terms of strength requirement Distribution of loads to the subgrade, Portland-cement concrete slab of relatively high bending resistance Pavement Design Traffic load (Most important – thickness of pavement), Soils, Environment, Reliability Subgrade Soil Classification Resilient Modulus – Mechanical Behavior - measure of material stiffness Granular base/subbase layers: elastoplastic behavior. Designed to simulate the behavior of soils and granular materials when subjected to traffic loading within a pavement system. Similar to modulus of elasticity. Depends on Density, Gradation, fine contents, and moisture content, At low levels of moisture content: increase in the resilient modulus due to suction. At high levels of moisture content: reduction in the resilient modulus due to pore pressure. California Bearing Ratio - Relative strength of a soil with respect to crushed rock. Penetration test for evaluation of the mechanical strength of natural ground, subgrades and basecourses. Determination of the load deformation curve of the soil in the laboratory using the standard CBR testing equipment. Chapter 5 – Pavement Design - Part 2: Flexible Pavement Design Layers(bottom to top): 1. Subgrade, 2. Subbase Course, 3. Base Course, 4. Surface Course. Subgrade: natural materials, foundation of the pavement structure, certain strength properties Subbase: • A layer of granular materials that is located between the subgrade and base course • Quality of materials is superior to that of the subgrade but inferior to that of the base course • Can be omitted if the quality of the subgrade material meets the requirements of the subbase • Specifications are in terms of plasticity, gradation, and strength • Main functions: • Reduces the stresses applied on the subgrade • Serves in water drainage • Protects the base course against volume changes of the subgrade Granular base: • Usually granular materials such as crushed stone, crushed or uncrushed gravel or slag, and sand • Strict specifications for plasticity, gradation, and strength • Can be stabilized using Portland cement, asphalt, or lime when a higher strength is required or when the available materials do not meet the specifications • Main functions: • Acts as a foundation to the surface course • Distributes the stresses on the subbase into a large area • Protects the surface course against volume changes that may take place in the subgrade Surface: The surface course is the upper course of the road pavement consists of: a mixture of mineral aggregates and asphalt. Main functions: • Transmits the wheel loads to the underlying layers within acceptable limits. • Resists abrasive forces due to traffic. • Provides skid-resistant driving surface. • Preventing the penetration of surface water into the underlying layers and withstands high tire pressures. • The thickness of the surface layer can vary from 3 in. to more than 6 in., depending on the expected traffic on the pavement. Asphalt: Natural substance that has some amazing physical properties ▪ Adhesive, elastic, able to stretch, bend and flex without breaking (cohesive) ▪ Waterproofing ▪ At air temperatures, very thick liquid (highly viscous) ▪ When heated, it becomes thinner and easier to use Properties of Asphalt Materials: Consistency ▪ Vary from solid to liquid ▪ Consistency of asphalt + associated temperature ✓ Aging and temperature sustainability ▪ When exposed to environmental elements: deterioration, loose plasticity and become brittle ▪ This natural deterioration of the asphalt material is known as weathering. ▪ Durability: resistance of the asphalt material to weathering. Asphalt Mixtures: Asphalt cement + coarse aggregate + fine aggregate + other materials ▪ Hot-mix, hot-laid/hot-mix, cold-laid/cold-mix, cold-laid ▪ Resist deformation from imposed traffic loads, be skid resistant even when wet, and not be affected easily by weathering forces ▪ Hot-mix, hot-laid asphalt mixture is produced by properly blending asphalt cement, coarse aggregate, fine aggregate, and filler (dust) at temperatures ranging from about 80 C to 160 C. ▪ Hot-mix, hot-laid asphalt mixture normally is used for high type pavement construction Asphalt Mixtures: hot-mix, cold-laid ▪ Manufactured hot and then shipped and laid immediately or stockpiled for used at a future date ▪ Small jobs ▪ Patching high-type pavement (asphalt concrete surfaced) Asphalt Mixtures: cold-mix, cold laid ▪ Emulsified asphalts and low-viscosity cutback asphalts are used to produce cold-mix asphalt mixtures. ▪ Immediately after production or stockpiled for use later General Principles of Flexible Pavement Design ▪ Multilayered elastic system • Objective: is to determine the minimum thickness of pavement layers that is enough • To Avoid overloading or overstressing the subgrade • Avoid overloading or overstressing any one or more of the pavement layers • Maintain good serviceability performance along the pavement design life Pavement structure required on top of a specific layer is expressed in terms of a Structural number (SN) which is an index number which may be converted to thickness of various flexible pavement layers through the use of layer coefficients