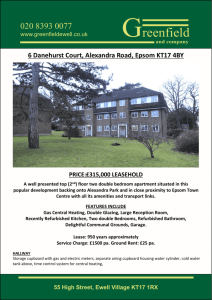

PRODUCTION PROCESS OF ALUMINIUM RADIATOR P R E PA R E D B Y : - S A I Y E D M O H . M A R U F I D N O : - D 1 9 M E 11 2 S E M E S T E R : - 7 TH G U I D E D B Y : - P R O F. A B H I S H E K S WA R N K A R BANCO PRODUCTS LTD. SEZ o Born of entrepreneurial spirit in 1961,BANCO Production Ltd. Has today carved a niche for itself as a leader in the business of engine cooling and sealing systems both for automotive and industrial applications. o BANCO Products ltd. Is engaged in the manufacturing and selling of radiators. The Company manufactures and supplies original equipment for commercial vehicles, passenger vehicles and industrial products. o We combine the power of innovation and commitment to quality to create highperformance solution for our customers. Banco is the largest manufacturer of radiator in India today. o Manufacturing Radiators for Automotive and Industrial application. Charge Air Coolers for Heavy Commercial Vehicle, Off Road Vehicle, Stationery Engine. FUNCTION OF RADIATOR IN COOLING SYSTEM Engines create a lot of heat in their operations. To prevent your engine from overheating, your car pumps coolant through your engine - fluid that receives heat, and carries it away from the engine block. The coolant takes the heat generated by your engine, and moves it to your radiator, which blows air across the liquid - cooling it down and exchanging heat with the air outside your car. The radiator works by passing your coolant through thin fins, which allow the heat to flow to the air outside your car much more easily. Sometimes, there is a fan that blows air across the radiator in order to carry the hot air out of your car. Radiators come in many different shapes, sizes, and designs, but their primary function remains the same. In essence - a radiator cools the coolant, which then cools your engine. PARTS OF ALUMINIUM RADIATOR o o o o o o Header Plate (HP) Core Channel (CC) Fins Tubes Top Tank Bottom Tank o o o o o o Oil cooler Pressure cap Gasket Plastic plug Connector Band pipe PRODUCTION PROCESS OF ALUMINIUM RADIATOR Raw Materials Storage Inspection of Raw Materials Injection Moulding Process For Tanks Core Assembly (Assembly of, tubes, fins, CC and HP) Transfer the core Assembly to the Brazing Furnace Crimping of Brazed Core Final Assembly Final Testing and Inspection of Radiator Packaging RAW MATERIALS Child parts :1. Washer Plastic tank imported & in 2. Crafts 3. Screws 4. Hex nut 5. Nut bolts Rubber parts :1. 2. 3. 4. Rubber gasket “O” Ring Silicon gasket Rubber belt house Oil coolers Aluminium foil Aluminium tubes Aluminium header plate Aluminium core channel Packaging materials INCOMING QUALITY CONTROL (IQC) An incoming inspection, also known as a receiving inspection or material inspection, validates the quality of purchased raw materials based on set acceptance criteria. It is performed by quality assurance personnel in the manufacturing facility to resolve quality issues during pre-production. Incoming inspection results follow an identification tagging system to determine required actions when an item is tagged as accepted, conditionally accepted, or rejected. INJECTION MOULDING MACHINE • Injection moulding is a common manufacturing process used to create plastic products and materials. • It involves inserting melted plastic into a mould cavity. Which has been designed into the required shape. • Banco produce radiator tanks by injection moulding machine. • Raw material of plastic tanks is nylon 66% and 33% glass field PROCESS OF MOULDING MACHING Plastic granules are sent to the dehumidifier through a vacuum loading system. Moisture content is removed from the plastic raw material in the dehumidifier. Material is transferred from dehumidifier to hopper of injection mulding machine. And then material melted down in barrel which is surrounded by the heaters. Melted material is injected into mould cavity by high pressure and then the part cooled and finally ejected Once the material has cooled sufficiently, the component can be injected and the injection cycle continues. Final Inspection of Plastic Tank CORE ASSEMBLY Core assembly parts 1. 2. 3. 4. HP (Header plate) CC (Core channel) FINS TUBE Machine for core assembly 1. UACB (Universal Auto Core Builder) 2. LMRI 3. YT-JIG STEPS FOR CORE ASSEMBLY CC Fitting on ABC. And then tubes are insert as per model design. The fins are inserted between the gaps of the two tubes. After that around 6kg pressure given by pusher to fins and tubes which are aligned to each other 5. By the application of C clamp the core channel , fins and tubes are kept bonded together . 6. The header plate is than assembled mechanically by operator . 7. The level of the fins are maintained with the help of leveling pads. 8. The core is fitted with the help of aluminum wire (dia-0.8) and then C clamp is removed. 9. The tube flaring operation is performed using a flaring roller. 10. The final core leveling of tubes and fins is done using a leveling pad. 11. A final inspection is carried out after the entire core assembly process is over. 1. 2. 3. 4. REWORK AFTER ASSEMBLY : (IF APPLICABLE) Defects Solution Fin damage (1) Complete fin replacement after removal of c clamp (2) Fin dressing without removing of c clamp (only if fin is less damage) Tube Damage (1) Complete tube replacement after removal of c clamp (2) Repaired by nose plair ( only if less damage ) Wrong Assembly (1) Replace the component ( only if part is damage ) (2) Refitting with correct Assembly BRAZING PROCESS OF CORE ASSEMBLY • The brazing consists of the assembly of two metal parts with the aid of a filler metal having a lower melting temperature than the parts to be assembled. • Fluxes used during brazing is Nocolok flux & J.C Flux. Material of flux is Aluminum Potassium Floride. Glycol is used to give strength to flux material. • Mainly clad 4045 is used for brazing in H.P & clad 4343 is used in C.C for brazing. BRAZE CLAD ON HP AND CC BRAZE CLAD ON HEADER PLATE (HP) BRAZE CLAD ON CORE CHANNEL (CC) • For brazing applications, header plate is clad with 4343 and 7072 layers which act as the source for the filler metal during the brazing process. • The thickness of the brazing clad layer on header plate is generally 10 % of the sheet thickness both sides are clad. Brazing clad on HP For brazing applications, the core channel has one side braze clad with only 4343 layers which act as the source for the filler metal during the brazing process. Brazing clad on CC VISUAL INSPECTION OF CORE AFTER BRAZING HP to tube leak Dislodge Tube bend Tube/fin damage Fin erosion Excess flux HP crack Rhombus Core width HP/CC offset Uneven fin level Unbrazed core Wrong assembly If any defects found then it will be Repaired & Rework by operator and passed in furnance. FINAL ASSEMBLY OF RADIATOR Radiator Assembled Parts : 1. 2. 3. 4. 5. 6. 7. Core Oil Cooler Plastic Tank Pressure Cap Rubber Bush Bend Tube Frame (only if applicable) After the brazing process is done on the radiator core, the upper tank and lower tank are fitted on core by crimping machine. Oil cooler is installed inside the lower tank as per design. CONTROL PLAN OF ASSEMBLY Process Name Process Oil cooler Fitting Radiator Crimping Evaluation Measurment Tightening torque Top cylinder pressure Tool forward pressure Drain Plug Fitting Tightening torque Plug Fitting Tightening torque Dry leak test Channel set Wet leak Test Air pressure line Oil cooler connector fitting Tightening torque Dial Torque wrench Pressure Gauge O/C Connector testing ( if Channel set applicable ) Machine Display Bracket fitting (if applicable) Side Frame Assembly Tightening torque Label Pasting Final Inspection visual Packing in corrugated box Packing kit assembly visual Packing Inspection Manual Visual Torque Wrench Torque Wrench Machine Display Pressure gauge Timer Dial Torque wrench Dial Torque wrench visual visual Manual DRY LEAK TESTING The Dry leak test machine works on the principle of differential pressure . The leak can be tested by the difference between the pressure of sample workpiece and workpiece which is to be measured . In this method the air pressure is applied to the radiator which is to be tested . The pressure is applied for some particular time that time is depend upon the volume of the radiator and size of the radiator . WET LEAK TESTING The wet test is applied only if the leak is detected in the radiator in dry leak test. The simplest of the test methods, wet leak testing also called bubble immersion leak testing is typically the lowest cost method as well. In simple terms, the part under test is pressurized with air while being submerged in a liquid, typically water. The operator looks for a stream of bubbles indicative of a leakage FINAL PACKAGING OF RADIATOR For packing the radiator in corrugated box and for the Inseartion of kit they use two machine Strapping machine and Insta pack machine . Strapping machine is used for wraping the box with the wire. and Insta pack machine is use for making Thermocol buffers with the application of mixture of two chemicals in a polythene bag . REFERENCES Company production process file & Various charts. https://en.wikipedia.org/wiki/Radiator. http://www.bancoindia.com/ https://themechanicalengineering.com/radiator/ https://www.schultzautotruck.com/blog/the-importance- of-your-radiator https://haynes.com/ A book of thermal engineering “MC Graw Hill” THANK YOU