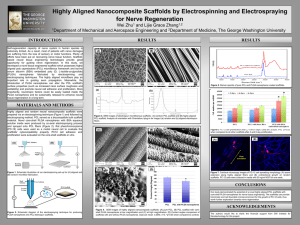

Electrospinning of Polymeric Nanofibers for Tissue Engineering Applications Presented by: Name (ID) School of Biochemical Engineering and Technology (BCET) Introduction 5- 30 kV Figure 1: Basic Electrospinning Setup Source: http://www.people.vcu.edu/~glbowlin/images/electrospinning.jpg 2 Parameters for Electrospinning Table 1: Effect of parameters on morphology of nanofibers Solution properties Control variables Ambient parameters • Viscosity/concentration • Flow rate • Conductivity/solution charge density • Field strength/ voltage • Humidity • Surface tension • Polymer molecular weight • Dipole moment and dielectric constant • Temperature • Distance between tip and collector • Needle tip design • Collector composition and geometry 3 Application in Tissue Engineering Temporary Extracellular Matrix (ECM) Figure 2: Principle of Tissue Engineering Source: http://upload.wikimedia.org/wikipedia/commons/thumb/2/27/Tissue_engineering_english.jpg/800pxTissue_engineering_english.jpg 4 Why Nanofiber Scaffolds are required? Extracellular Matrix (ECM) is composed of two main types of macromolecules 1. Ground substances (proteoglycans) Nanoscale 2. Fibrous proteins (collagens) component Epithelial cell Basement membrane Endothelium Connective tissue Fibroblast Figure 3: Extracellular Matrix (ECM) Source: http://upload.wikimedia.org/wikipedia/commons/thumb/f/f5/Extracellular_Matrix.png/800pxExtracellular_Matrix.png 5 General Properties of Scaffolds Biocompatible Ability to integrate with the host tissue Porous with a high surface-volume ratio Cell attachment, in-growth and exchange of nutrients Angiogenesis upon implantation Biodegradable Rate of degradation should be controllable to mimic the rate of neo-tissue formation 6 Types of Electrospun Scaffolds for Tissue Engineering Applications Synthetic polymer scaffolds Electrospun poly (D,L-lactide-co-glycolide) (PLGA) Most commonly used biodegradable polymer in tissue engineering Natural polymer scaffolds Composite scaffolds Functionalized scaffolds Drug delivery carriers 7 Preparation of Electrospun Nanofiber (PLGA) Preparing Poly (D,L-lactide-co-glycolide) (PLGA) solution 1 g of copolymer PLGA THF : DMF = 1:1 Tetrahydrofuran (THF) Dimethylformamide (DMF) 20 mL of organic solvent mixture 8 Process of Electrospinning Copper collecting plate Glass Syringe containing polymer solution Syringe - Fit with 18-G needle - Fix at 45o downtitled from horizontal Power Supply (18 kV) Nanofiber jet Power supply Distance of 20 cm between the plate and the needle tip Figure 4: Scheme of electrospinning apparatus 9 Objectives To explore the applications of the PLGA structure in tissue engineering To characterize properties of the structure (i.e. porosity and mechanical properties) To investigate the cell activities within nano-scale fiber-based scaffold ◦ Use two cell types: fibroblasts and bonemarrow-derived stem cells (MSCs) 10 Physical Property Characterization Porosity ◦ Pore diameter distribution ◦ Total pore volume and area ◦ Porosity of the structure Tensile property ◦ Tensile modulus ◦ Ultimate tensile stress ◦ Ultimate tensile strain Scanning Electron Microscopy (SEM) ◦ Morphology before and after cell seeding 11 Results Table 2: Porosimetry of the electrospun PLGA structure Porosity Total pore volume Total pore area 91.63 % 9.69 mL/g 23.54 m2/g Table 3: Tensile Properties of electrospun PLGA structure PLGA Cartilage Skin Tensile modulus (MPa) 323 130 15-150 Ultimate tensile stress (MPa) 23 19 5-30 Ultimate tensile strain (%) 96 20-120 35-115 12 Results (Cont’) Morphology of electrospun PLGA structure (a) (b) Figure 5: SEM morphographs of the electrospun PLGA (original magnification x 1500) (a) before cell seeding ; (b) after 3 days of cell culture. Bar = 10 µm 13 Discussion High porosity provides more structural space for cell accommodation and efficient nutrient exchange and metabolic waste between scaffold and environment. Effective mechanical properties ◦ Retain structural integrity and stability ◦ Provide sufficient biomechanical support during tissue generation and structure degradation 14 Conclusion Electrospun PLGA scaffold is suitable for tissue substitute. High porosity (i.e. surface area-to-volume ratio) is favorable for cell attachment, growth and proliferation. The structures provide effective mechanical properties suitable for soft tissue, such as skin and cartilage. A basis for future optimization of electrospun nanofibrous scaffold 15 References Quynh P. Pham, Upma Sharma Ph.D., and Antonios G. Mikos, Ph.D. Electrospinning of Polymeric Nanofibers for Tissue Engineering Applications: A Review. Mary Ann Liebert, Inc. 12, 1197, 2006. Li, W.J., Laurencin, C.T., Caterson, E.J., Tuan, R.S., and Ko, F.K. Electrospun nanofibrous structure: a novel scaffold for tissue engineering. J. Biomed. Mater. Res. 60, 613, 2002. Ma, Peter X. (May 2004). "Scaffolds for tissue fabrication". Materials Today: 30–40. http://www.people.vcu.edu/~glbowlin/research.ht ml 16 17