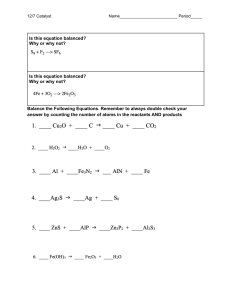

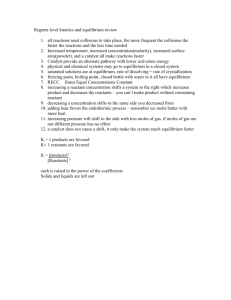

INDIAN CHEMICAL ENGINEER © 2014 Indian Institute of Chemical Engineers Vol. 57 No. 2 June 2015, pp. 177–196 Print ISSN: 0019-4506, Online ISSN: 0975-007X, http://dx.doi.org/10.1080/00194506.2014.975761 Kinetics of Esterification of Acetic Acid and Ethanol with a Homogeneous Acid Catalyst C. Beula and P.S.T. Sai* Department of Chemical Engineering, Indian Institute of Technology Madras, Chennai, India Abstract: In the present work, esterification reaction between acetic acid and ethanol was conducted in an isothermal batch reactor in the presence of a homogeneous acid catalyst sulphuric acid. The progress of the reaction was monitored by following the concentration of water measured using Karl Fischer titrator. The variables include the mole ratio of reactants, reaction temperature and catalyst concentration. The mole ratio of alcohol to acid was varied from 1 to 5, the reaction temperature between 20°C and 60°C and the catalyst concentration was varied from 1 to 10 weight per cent. The operating conditions for better yield of ester were identified. The experimental data were analysed by an integral method of analysis to obtain the order of the reaction. The reaction rate constants, frequency factor and activation energies have been determined. The kinetic model derived from the mechanism fits the experimental data satisfactorily. The activity coefficients of the system calculated using UNIFAC and modified UNIFAC models deviated from ideality. Both activity- and concentration-based model fits were plotted, which showed the importance of activity coefficient in the rate equation. The present work was also extended to exploit the scope of ionic liquid as a catalyst for the esterification reaction. But it was observed that the reaction is very slow and the amount of catalyst required is high to enhance the yield. Keywords: Esterification, Homogeneous catalysis, Kinetics, Mechanism, Activity coefficient. 1. Introduction Esters of carboxylic acid are fine chemicals which have applications in various areas such as perfumery, flavours, pharmaceuticals, solvents, plasticisers, etc. and are also used as an intermediate for many industries [1, 4]. The use of esters as biofuel is very significant in the present scenario of rising price of crude oil and environmental concerns. There are several *Author for Correspondence. Email: psts@iitm.ac.in 178 B EULA AND SAI routes by which esters can be synthesised. The most widely used method is direct esterification of carboxylic acids with alcohol in the presence of a mineral acid catalyst [1]. 0 RCOOH þ R0 OH ! RCOOR þ H2 O where R and R′ are either alkyl or aryl groups. Esters formed from simple hydrocarbon groups are colourless,volatile liquids with pleasant aroma and are responsible for giving fragrance to flowers and fruits. These unique features make unbounded applications of esters. Esterification is a very slow and highly reversible reaction. The limiting conversion of the reactants is determined by the equilibrium. The equilibrium constants of esterification reaction are in the range of 1–10, which shows that considerable amounts of reactants exit in the equilibrium mixture [2]. Being a reversible reaction, equilibrium constant or the conversion of the reaction can generally be improved by the following methods (1) using alcohol in large excess, (2) using a dehydrating agent, (3) removal of water by physical means such as distillation and (4) addition of a catalyst. Since the limiting step in the esterification reaction is the protanation of carboxylic acid, both homogeneous and heterogeneous acids can catalyse the reaction. Since the present study is concerned with homogeneous catalysis, the catalysts in this category are mineral acids such as sulphuric acid, hydrochloric acid, hydrogen iodide and strong organic acids such as formic acid [2]. Considering the enormous uses of acetate ester, carboxylic acid selected for the present study is an acetic acid. The esterification of acetic acid with methanol has been widely studied. But investigations with acetic acid, ethanol and sulphuric acid as a catalyst are limited. In addition, ethanol (CH3CH2OH) is a simple alcohol and it reacts very fast as they are relatively small and contain no carbon atom side chains which would hinder their reaction. It also has several advantages such as renewable characteristics, non-toxicity and are safer to handle and store, etc. [3]. So the system of the present work on esterification is acetic acid with ethanol using sulphuric acid as catalyst. Nada et al. [4] had studied the kinetics of acetic acid with ethanol in the presence of sulphuric acid catalyst. They ignored the occurrence of backward reaction. As the esterification is highly reversible, the reverse reaction must be taken into account for obtaining good kinetics. For the optimisation of an industrial process, reaction kinetics should be well determined. The design of the reactor should be based on rate equation, which depends on the conditions inside the reactor [2]. Chemical reactions reflect the tendency of a system to approach equilibrium. The dynamics towards equilibrium are reflected in the rate of chemical reactions, which concern the role of activity coefficient in the rate equation. Reaction rate depends on concentrations only in the case of ideal reaction mixture [5]. The selected system shows a strong non-ideal behaviour due to the presence of water and ethanol which is highly polar compared to non-polar ethyl acetate [4]. The present work is to establish an optimised condition to increase the rate of reaction within the reactor and also to develop the kinetics of the reaction. Nowadays ionic liquids are receiving more attention because they can function as solvents for reactants and products as well as catalyst to promote the reactions [12, 13]. Other applications include separation, electrolyte, heat storage, lubricants and additive, liquid crystal, etc. These multifunctional applications are due to the important properties such as low vapour pressure, high thermal stability and possibilities to manipulate the properties, INDIAN CHEMICAL ENGINEER Vol. 57 No. 2 June 2015 Esterification of Acetic Acid and Ethanol 179 such as density, solubility, etc., by changing the structure. In this context, few experiments were carried out using ionic liquid as a catalyst. The ionic liquids selected in this study are 1-ethyl 3-ethyl imidazolium hydrogen sulphate, 1-ethyl 3-ethyl imidazolium methyl sulphate and 1-butyl 3-methyl imidazolium methyl sulphate. 2. Experimental Procedure 2.1. Chemicals Acetic acid (99.8 wt%, Fisher Scientific), ethyl alcohol (99.9 wt%, Jiangsu Huaxi International) and concentrated sulphuric acid (98 wt%, RFCL limited) were used without further purification. Karl Fischer solution (Merck Specialties Pvt. Limited) and methanol (99.8 wt% HPLC grade, Thomas Baker) were used for the analysis. 2.2. Analysis Analysis was conducted using Karl Fischer titrator (Metrohm 870 KF Titrino plus, Switzerland) to determine the water content of the samples. The Karl Fischer Titrino is an automated titration system that carries out the titration automatically and it produces rapid, precise and reproducible results. The whole assembly constitutes Metrohm 870 KF Titrino plus, 803 Ti Stand and 100 ml capacity KF titration cell with magnetic stirrer. The increases in titration rate and volume are controlled according to the signal measured by the indication system. The sample weight was transmitted directly to the titration system via a connected balance (BSA 224S-CN d = 0.1 mg, Sartorius). The results were then transferred to a PC database. 2.3. Procedure Experiments were performed in a batch reactor which is a flat-bottomed flask of 250 ml capacity with magnetic agitation. Water at constant temperature from a thermostat is circulated through the Perspex jacket surrounding the reactor. Calculated quantity of ethanol is placed in the reactor. At zero time, a known quantity of acetic acid which is separately heated to the set temperature and calculated amounts of sulphuric acid were added into the reactor. Stirring was maintained constant throughout the experiment. Samples were pipetted out at different time intervals and the amount of water present in the sample was measured with Karl Fischer Titrator. The progress of the reaction was monitored by following the concentration of water. The experiments were carried out at temperatures between 30°C and 60°C, the different initial molar ratio of ethanol to acetic acid was in the range of 1:5 and catalyst concentrations varied from 1 to 10 wt%. 3. Results and Discussion 3.1. Variables Affecting the Rate of Reaction To enhance yield of acetic acid–ethanol esterification reaction, the probable variables affecting the rate of reaction were studied. They are temperature of reaction mixture, catalyst concentration and initial molar ratio of reactants. Before proceeding to catalysed reactions, experiments were conducted in the absence of catalyst at different temperatures. The results show that the yield of the reaction is less than 10% even at a higher temperature, as depicted in Fig. 1. This confirms that the reaction is very slow and that it needs a catalyst to enhance the rate. INDIAN CHEMICAL ENGINEER Vol. 57 No. 2 June 2015 180 B EULA AND SAI 10 9 313 K 8 323 K Conversion (%) 7 333 K 6 5 4 3 2 1 0 0 50 100 150 200 250 300 350 Time (min) Fig. 1. Effect of temperature on esterification of acetic acid and ethanol without catalyst and initial molar ratio of 1:1. Figure 2 shows the influence of temperature on ethyl acetate conversion. It was found that increasing the temperature of the reaction yields a marginal increase in conversion but the time required to reach the equilibrium conversion was reduced drastically from 5 hrs at 20°C to 20 minutes at 60°C at a constant molar ratio of reactants and concentration of the 60 Conversion (%) 50 40 30 293 K 303 K 20 313 K 323 K 333 K 10 0 0 50 100 150 200 250 300 350 Time (min) Fig. 2. Effect of temperature on esterification of acetic acid and ethanol with catalyst. Catalyst concentration 5 wt% and initial molar ratio 1:1. INDIAN CHEMICAL ENGINEER Vol. 57 No. 2 June 2015 Esterification of Acetic Acid and Ethanol Fig. 3. 181 Effect of catalyst concentration on esterification of acetic acid and ethanol at a temperature of 60°C and initial molar ratio 1:1. catalyst. The effect of catalyst concentrations was varied from 1 to 10 wt% as shown in Fig. 3. For these sets of experiments, the temperature selected was based on previous experiments and at a constant initial molar ratio of reactants. When catalyst concentration is increased, the equilibrium conversion is same for all the concentrations. But here also the time to reach the equilibrium conversion was reduced from 60 to 20 minutes, as the concentration of the catalyst was increased from 1 to 10 wt%. But the effect was negligible beyond 5 wt%. Therefore, in other experiments the catalyst concentration was fixed at 5 wt%. Among the three ways used to increase the equilibrium concentration mentioned in the Introduction section, one way is to use alcohol in excess. The experiments with a different initial molar ratio of reactants keeping all other parameter constants were conducted. The results are shown in Fig. 4. When the alcohol to acid ratio was increased from 1 to 5, the conversion was increased from 55% to 77%. This confirms the above statement. 3.2. Reaction Kinetics from Analysis of Batch Reactor Data Based on the data obtained from the above sets of experiments, the reaction kinetics were determined. The integral method of analysis was used to find the order of reaction. The analysis was started with first-order irreversible, second-order irreversible, etc. The analysis results show that data were fitted with second-order reversible reaction. In general, a secondorder reversible reaction can be written as: A þ B ! CþD INDIAN CHEMICAL ENGINEER Vol. 57 No. 2 June 2015 182 B EULA Fig. 4. AND SAI Effect of initial molar ratio of reactants on esterification of acetic acid and ethanol at a temperature of 60°C and catalyst concentration of 5 wt%. For the second-order reversible reaction the rate equation is: rA ¼ dCA ¼ k1 CA CB K2 CC CD dt ð1Þ With conditions CA0 = CB0 and CC0 = CD0 = 0, the integrated rate of expression is [7]: XAe ð2XAe 1ÞXA 1 ¼ 2k1 1 CA0t ð2Þ ln XAe XAe XA The experimental data at conditions of M = 1 and at different temperatures were tested using Equation (2). Figure 5 shows that the model fits the experimental data well and the estimated parameters are shown in Table 1. In Equation (1) with conditions CA0 ≠ CB0 and CC0 = CD0 = 0, the rate of expression is: ln f2XA ½ðM þ 1ÞXAe M ½ðM þ 1ÞXAe 2 XAe ZgfðM þ 1ÞXAe 2 þ XAe Zg k1ZCA0t ¼ f2XA ½ðM þ 1ÞXAe M ½ðM þ 1ÞXAe 2 þ XAe ZgfðM þ 1ÞXAe 2 XAe Zg XAe ð3Þ where M ¼ and qffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffi Z ¼ ½ðM þ 1Þ2 XAe 2 4MðMXAe þ XAe MÞ h i f2XA ½ðMþ1ÞXAe M½ðMþ1ÞXAe 2 XAe ZgfðMþ1ÞXAe 2 þXAe Zg The plot of Y = ln f2X versus time for M = 1, 2 2 A ½ðMþ1ÞXAe M½ðMþ1ÞXAe þXAe ZgfðMþ1ÞXAe XAe Zg CB0 CA0 2, 3 and 5 (Fig. 6). The plots are straight lines passing through the origin which that h confirms i A0 the reaction is a second-order reversible reaction. The slope of the lines are K1XZC . Figure 6 Ae INDIAN CHEMICAL ENGINEER Vol. 57 No. 2 June 2015 Esterification of Acetic Acid and Ethanol Fig. 5. 183 Test of the rate equation, Equation (2) at M = 1 and catalyst concentration of 5 wt%. also shows that the model fits the experimental data quite well. The estimated parameters k1, k2 & K are shown in Table 2. Forward reaction and backward reaction activation energies were calculated from Arrhenius plot (Fig. 7), and are E1 = 65.6 KJ/mol and E2 = 59.3 KJ/ mol, respectively. These high values of the activation energy indicate that a massive fraction of reactant molecules are not able to react under this condition. 4. Mechanism 4.1. Reaction Kinetics from Mechanism The overall esterification reaction of acetic acid with ethanol in the presence of concentrated H2SO4 can be written as: Hþ CH3 COOH þ CH3 CH2 OH ! CH3 COO CH2 CH3 þ H2 O ð4Þ Table 1. Values of the rate and equilibrium constants at M = 1 and different temperatures Temperature, oC k1, cm3/(mol.min) k2 cm3/(mol.min) Kact 2.24 6.09 10.01 25.65 1.76 4.61 6.70 16.44 1.27 1.32 1.50 1.55 30 40 50 60 INDIAN CHEMICAL ENGINEER Vol. 57 No. 2 June 2015 184 B EULA Fig. 6. AND SAI Test of the rate equation, Equation (3) at temperature of 60°C and catalyst concentration of 5 wt%. The hydrogen ions acting as a catalyst in this reaction are created through the decomposition of H2SO4 which can be represented as: þ H2 SO4 ! HSO4 þ H ð5Þ To derive the rate of expression for the above esterification reaction, a detailed knowledge of the mechanism is necessary. The reaction of acetic acid and ethanol catalysed by an acid has proposed the following mechanism [6]: +O O H 3C C OH + H + H 3C C H (6) OH Table 2. Values of the rate and equilibrium constants at 60°C and at different initial molar ratio of reactants (M) M k1, cm3/(mol.min) k2 cm3/(mol.min) Kact 1 2 3 5 25.65 22.35 12.68 9.41 16.44 22.35 14.68 15.44 1.55 1.00 0.87 0.61 INDIAN CHEMICAL ENGINEER Vol. 57 No. 2 June 2015 Esterification of Acetic Acid and Ethanol +O H 3C H C 185 OH OH + H 3C C H2 OH H 3C H2 C H 3C OH (7) H2O (8) C OH + OH OH H 3C H 3C C OH H 3C H2 C O + H O H 3C H 3C H2 C H 3C C H2 C + C O H + CH3-COO-CH 2CH 3 H + (9) O H2SO4 H + – + HSO4 (10) The nucleophilic substitution in Step (7) is generally believed to be the rate determining step, where as the protonation Step (6), Step (8) and Step (9) are assumed to be fast. Step (10) is the catalyst regeneration step. Steps (7)–(9) can be combined into a single pseudo step for determining the kinetics. So the simplified mechanism can be written as: O k1 CH3-C-OH H INDIAN CHEMICAL ENGINEER k-1 OH CH3-C-OH (11) Vol. 57 No. 2 June 2015 186 B EULA AND SAI Fig. 7. Plot of -lnk vs. 1/T for determination of activation energy. OH CH3-C-OH H 3C k2 CH 2OH k-2 O CH3-CO-CH2CH3 H 2O H (12) The rate of esterification reaction based on rate limiting Step (12) can be expressed as: þ r ¼ k2 C þ A C B k2 C E C H2 O C H ð13Þ where A = CH3COOH, A+ = CH3C(OH)2, B = CH3–CH2OH and E = CH3–COO– CH2–CH3. The concentration of the intermediate is obtained by applying steady state approximation rule [7] to Step (11): K1 ¼ Cþ A C CH 3 COOH :C þ H ð14Þ Substitution of Step (14) in (13) gives: 2 3 C :C E H O 4 h 2i 5 r ¼ k2 K1 C þ H C CH 3 COOH :C B K1 kk22 ð15Þ The product of K1*(k2/k−2) is the product of the equilibrium constant of Steps (11) and (12) which equals the equilibrium constant of the overall reaction, KE. Also the product K1k2 can INDIAN CHEMICAL ENGINEER Vol. 57 No. 2 June 2015 Esterification of Acetic Acid and Ethanol 187 be grouped as a single constant k2′. Thus, Step (15) becomes: r¼ k20 CHþ CE :CH2 O CCH3 COOH :CB KE ð16Þ from Step (5), CH+ ≈ CH2SO4. Also the concentration of H2SO4 for a particular set of reaction can be taken as a constant. So k2′.CH2SO4 can be groped into a single constant k′. Therefore, Equation (16) can be modified into: CE :CH2 O r ¼ k CCH3 COOH :CB KE 0 ð17Þ The above rate of expression shows that the reaction is second order in both forward and backward directions, and the rate of reaction depends on the concentrations of reactants and products. Fig. 8. (a) Model fit at a temperature of 30°C, M = 1 and catalyst concentration of 5 wt%. (b) Model fit at a temperature of 40°C, M = 1 and catalyst concentration of 5 wt%. (c) Model fit at a temperature of 50°C, M = 1 and catalyst concentration of 5 wt%. (d) Model fit at a temperature of 60°C, M = 1 and catalyst concentration of 5 wt%. INDIAN CHEMICAL ENGINEER Vol. 57 No. 2 June 2015 188 B EULA Fig. 9. (a) Model fit at M = 1, temperture 60°C and catalyst concentration of 5 wt%. (b) Model fit at M = 2, temperture 60°C and catalyst concentration of 5 wt%. (c) Model fit at M = 3, temperture 60°C and catalyst concentration of 5 wt%. (d) Model fit at M = 5, temperture 60°C and catalyst concentration of 5 wt%. AND SAI 4.2. Fit of the Kinetic Model In the experimental data, the temperature variation was from 30°C to 60°C; M = 1 and catalyst concentration of 5 wt% and parameters from Table 1 were well fitted to model (17). The results are illustrated in Fig. 8a–d. The model was also well fitted to the batch reactor data at temperature 60°C, catalyst concentration of 5 wt%, M = 1–5 and parameters from Table 2. The fits are depicted in Fig. 9a–d. 5. Activity Coefficients The equilibrium constants presented in the rate of expression (17) are based on the concentration of the reactants and products. Concentration-based equilibrium constants are applicable only to ideal systems. For the non-ideal case, the values of the equilibrium constants are dependent on the conditions in the liquid phase, such as the concentration of the species and the ionic strength of the solution [2]. The concentration-based equilibrium constant KC is related to true thermodynamic constant Kact through activity-based constant INDIAN CHEMICAL ENGINEER Vol. 57 No. 2 June 2015 Esterification of Acetic Acid and Ethanol 189 Kγ. For example, a second-order reversible reaction can be written as: A þ B ! CþD The true thermodynamic constant Kact is defined by: Kact ¼ CC CD cC cD CA CB cA cB Also KC and Kγ are defined as: KC ¼ CC CD CA CB Kc ¼ and cC cD cA cB Therefore, Kact = KC.Kγ. Thus, the concentration-based rate constant KC is obtained by KC = Kact/Kγ.Kact is determined from experimental data and Kγ is to be calculated using an approximate theory. The insertion of this KC in the rate of expression (17) yields the concentration-based model. The reaction system consists of components CH3COOH, CH3CH2OH, CH3COOCH2CH3 and H2O. The calculations of activity coefficient were done by using UNIFAC programme. Two models such as UNIFAC and modified UNIFAC were used to establish the values. By using these models, the activity coefficient of a species γi consists of combinatorial (C) and residual (R) parts [8, 9] [10]. ln ci ¼ ln cCi þ ln cRi The C part by UNIFAC model is: ln cCi Vi Vi ¼ 1 Vi þ ln Vi 5qi 1 þ ln Fi Fi The same part by modified UNIFAC model is: ln cCi ¼1 Vi0 þ ln Vi0 Vi Vi 5qi 1 þ ln Fi Fi The parameters Vi, ri, Fi and qi are the same in both models except that Vi′ is given by [14]. Vi0 ¼ P 3=4 ri 3=4 j xj r j The R part of the activity coefficient described by both UNIFAC and modified UNIFAC models and are the same, except that the temperature-dependent interaction parameter given by UNIFAC model is: wnm ¼ e T am INDIAN CHEMICAL ENGINEER Vol. 57 No. 2 June 2015 190 B EULA AND SAI Table 3. Estimated activity coefficients and KγUNIFAC at 60°C and M = 1 AcOOH XA 0.50 0.45 0.40 0.35 0.30 0.25 0.23 0.20 0.17 0.14 0.12 0.10 0.05 0.00 EtOH XB EtOOAc XC H2O XD AcOOH γA EtOH γB EtOOAc γC H2O γD Kγ 0.50 0.45 0.40 0.35 0.30 0.25 0.23 0.20 0.17 0.14 0.12 0.10 0.05 0.00 0.00 0.05 0.10 0.15 0.20 0.25 0.27 0.30 0.33 0.36 0.38 0.40 0.45 0.50 0.00 0.05 0.10 0.15 0.20 0.25 0.27 0.30 0.33 0.36 0.38 0.40 0.45 0.50 1.005 0.976 0.946 0.946 0.886 0.854 0.854 0.821 0.801 0.780 0.765 0.750 0.712 0.671 0.994 1.024 1.054 1.054 1.113 1.141 1.141 1.168 1.184 1.199 1.208 1.218 1.239 1.257 1.772 1.762 1.753 1.753 1.733 1.721 1.721 1.706 1.696 1.684 1.676 1.666 1.640 1.607 1.944 1.974 2.008 2.008 2.086 2.129 2.129 2.176 2.204 2.234 2.254 2.274 2.326 2.378 3.446 3.482 3.530 3.530 3.668 3.759 3.759 3.869 3.944 4.026 4.085 4.149 4.326 4.533 Table 4. Estimated activity coefficients and KγMOD.UNIFAC at 60°C and M = 1 AcOOH XA 0.50 0.45 0.40 0.35 0.30 0.25 0.23 0.20 0.17 0.14 0.12 0.10 0.05 0.00 EtOH XB EtOOAc XC H2O XD AcOOH γA EtOH γB EtOOAc γC H2O γD Kγ 0.50 0.45 0.40 0.35 0.30 0.25 0.23 0.20 0.17 0.14 0.12 0.10 0.05 0.00 0.00 0.05 0.10 0.15 0.20 0.25 0.27 0.30 0.33 0.36 0.38 0.40 0.45 0.50 0.00 0.05 0.10 0.15 0.20 0.25 0.27 0.30 0.33 0.36 0.38 0.40 0.45 0.50 1.119 1.0885 1.0595 1.0325 1.008 0.9867 0.9792 0.9696 0.9619 0.9567 0.9547 0.9543 0.9609 0.9825 1.0785 1.1074 1.1336 1.157 1.1776 1.1954 1.2018 1.2108 1.2192 1.2272 1.2324 1.2377 1.252 1.2703 1.5699 1.5979 1.6195 1.6341 1.6412 1.6407 1.6383 1.6325 1.6241 1.6134 1.605 1.5958 1.5697 1.5413 2.2275 2.2414 2.2566 2.2729 2.2905 2.3094 2.3174 2.33 2.3434 2.358 2.3685 2.3797 2.4117 2.4518 2.898 2.971 3.043 3.109 3.167 3.212 3.226 3.240 3.245 3.240 3.231 3.215 3.147 3.028 INDIAN CHEMICAL ENGINEER Vol. 57 No. 2 June 2015 Esterification of Acetic Acid and Ethanol 191 Table 5. Estimated activity coefficients and KγUNIFAC at 60°C and M = 5 AcOOH XA 0.17 0.15 0.14 0.12 0.10 0.08 0.08 0.07 0.06 0.05 0.04 0.03 0.02 0.00 EtOH XB EtOOAc XC H2O XD AcOOH γA EtOH γB EtOOAc γC H2O γD Kγ 0.83 0.81 0.80 0.78 0.76 0.76 0.74 0.73 0.72 0.71 0.70 0.69 0.68 0.66 0.00 0.02 0.03 0.05 0.07 0.08 0.09 0.10 0.11 0.12 0.13 0.14 0.15 0.17 0.00 0.02 0.03 0.05 0.07 0.08 0.09 0.10 0.11 0.12 0.13 0.14 0.15 0.17 0.995 0.965 0.950 0.921 0.894 0.876 0.867 0.854 0.841 0.829 0.816 0.804 0.792 0.768 0.999 1.005 1.008 1.014 1.020 1.022 1.026 1.029 1.032 1.035 1.037 1.040 1.042 1.047 2.414 2.370 2.349 2.307 2.266 2.263 2.226 2.207 2.187 2.168 2.149 2.130 2.111 2.074 2.305 2.291 2.285 2.276 2.268 2.277 2.263 2.261 2.259 2.258 2.258 2.257 2.258 2.259 5.601 5.603 5.606 5.618 5.636 5.750 5.660 5.675 5.692 5.711 5.731 5.752 5.776 5.829 Table 6. Estimated activity coefficients and KγMOD.UNIFAC at 60°C and M = 5 AcOOH XA 0.17 0.15 0.14 0.12 0.10 0.08 0.08 0.07 0.06 0.05 0.04 0.03 0.02 0.00 EtOH XB EtOOAc XC H2O XD AcOOH γA EtOH γB EtOOAc γC H2O γD Kγ 0.83 0.81 0.80 0.78 0.76 0.76 0.74 0.73 0.72 0.71 0.70 0.69 0.68 0.66 0.00 0.02 0.03 0.05 0.07 0.08 0.09 0.10 0.11 0.12 0.13 0.14 0.15 0.17 0.00 0.02 0.03 0.05 0.07 0.08 0.09 0.10 0.11 0.12 0.13 0.14 0.15 0.17 1.275 1.261 1.254 1.241 1.229 1.229 1.218 1.213 1.208 1.204 1.200 1.197 1.193 1.188 1.007 1.010 1.011 1.013 1.015 1.015 1.017 1.018 1.019 1.020 1.022 1.023 1.024 1.026 1.987 1.979 1.976 1.967 1.958 1.966 1.948 1.943 1.938 1.932 1.927 1.921 1.915 1.903 2.527 2.514 2.508 2.496 2.484 2.484 2.473 2.468 2.463 2.458 2.453 2.449 2.445 2.436 3.909 3.909 3.909 3.905 3.899 3.915 3.889 3.882 3.875 3.866 3.856 3.845 3.833 3.805 INDIAN CHEMICAL ENGINEER Vol. 57 No. 2 June 2015 192 B EULA AND SAI Table 7. Summarised values of Kact, KγUNIFAC and KγMOD.UNIFAC Kact Temperature, oC 30 40 50 60 M 1 2 3 5 Fig. 10. KγUNIFAC KγMOD.UNIFAC M=1 1.27 1.32 1.50 1.55 1.55 1.00 0.87 0.61 4.06 3.97 3.88 3.80 T = 60oC 3.80 4.64 5.13 5.73 3.39 3.32 3.37 3.23 3.23 3.53 3.68 3.86 (a) Concentration-based model fit at a temperature of 30°C, M = 1 and catalyst concentration of 5 wt%. (b) Concentration-based model fit at a temperature of 40°C, M = 1 and catalyst concentration of 5 wt%. (c) Concentration-based model fit at a temperature of 50°C, M = 1 and catalyst concentration of 5 wt%. (d) Concentration-based model fit at a temperature of 60°C, M = 1 and catalyst concentration of 5 wt%. INDIAN CHEMICAL ENGINEER Vol. 57 No. 2 June 2015 Esterification of Acetic Acid and Ethanol Fig. 11. 193 (a) Concentration-based model fit at M = 1, temperture of 60°C and catalyst concentration of 5 wt%. (b) Concentration-based model fit at M = 2, temperture of 60°C and catalyst concentration of 5 wt%. (c) Concentration-based model fit at M = 3, temperture of 60°C and catalyst concentration of 5 wt%. (d) Concentration-based model fit at M = 5, temperture of 60°C and catalyst concentration of 5 wt%. and that given by the modified UNIFAC model is [14]: wnm anm bnm T þ cnm T 2 ¼ exp T The activity coefficient depends on the composition and temperature of the mixture [2]. Therefore, the activity coefficient calculations were done for different experimental temperatures such as 30°C, 40°C, 50°C and 60°C, and compositions were varied from the beginning of the reaction to the complete conversion of the reactants. Tables 3 and 4 show the activity coefficient of acetic acid, ethanol, ethyl acetate and water system at 60°C and M = 1 by UNIFAC and modified UNIFAC model, respectively. Tables 5 and 6 give values of the activity coefficient at M = 5 and 60°C by both models. Robert Ronnback et al. [2] calculated the activity coefficient of acetic acid, methanol, methyl acetate and water system at 40°C using UNIFAC model. The same results were able to be reproduced using our UNIFAC programme. Kact, KγUNIFAC and Kγmod.UNIFAC values at different temperatures and initial molar ratios are summarised in Table 7. INDIAN CHEMICAL ENGINEER Vol. 57 No. 2 June 2015 194 Fig. 12. B EULA AND SAI Esterification of acetic acid and ethanol in the presence of ionic liquids as catalyst at a temperature of 70°C, initial molar ratio 1:5 and catalyst concentration of 10 wt%. Figures 10a–d and 11a–d are the resultant of the concentration-based model using KCUNIFAC and KCmod.UNIFAC values in Equation (17) at different experimental conditions. Figure 10 a–d shows the temperatures from 30°C to 60°C, M = 1 and catalyst concentration of 5 wt%, and Fig. 11a–d illustrates the change in initial molar ratio of reactants from M = 1–5, 60°C and 5 wt% catalyst concentration. In all these figures, significant differences can be observed between experimental and concentration-based curves. That means, the activity of the system has an important role in deriving the rate of the equation. We can also conclude that acetic acid–ethanol–ethyl acetate–water system is not an ideal system. Both UNIFAC and modified UNIFAC models were used for plotting concentration-based rate curves. It can be noticed that at M = 1 and for all temperatures, and the concentration-based rate curves by the both models show the same trend. But a significant difference can be observed between these models curves at M = 2, 3 and 5 and at high conversion. 6. Experiments with Ionic Liquids The ionic liquids selected as catalysts for the present esterification reaction is 1-ethyl 3-ethyl imidazolium hydrogen sulphate (cat I), 1-ethyl 3-ethyl imidazolium methyl sulphate (cat II) and 1-butyl 3-methyl imidazolium methyl sulphate (cat III). All the experiments were conducted at 70°C, initial molar ratio of reactants 1:5 and at catalyst concentration of 10 wt%. The experimental results are depicted in Fig. 12. The figure shows that cat I and cat III achieved an equilibrium conversion of 0.72 and 0.61, respectively, at 9 hrs and for cat II the equilibrium conversion is 0.75 at 7 hrs. Performance of the selected ionic liquids is not appreciable. INDIAN CHEMICAL ENGINEER Vol. 57 No. 2 June 2015 Esterification of Acetic Acid and Ethanol 195 7. Conclusion The esterification of acetic acid with ethanol catalysed by sulphuric acid has been studied. To enhance the yield of this esterification reaction, different variables such as temperature, initial molar ratio of reactants and catalyst concentration were selected for this study and their effect was found. At a fixed molar ratio, catalytic concentration and an increase in temperature, there was no significant enhancement in conversion. But the time to reach the equilibrium conversion was drastically reduced. When the catalyst concentration was increased, the same result as that of temperature effect was observed. But when the molar ratio was increased the conversion of ethyl acetate was increased due to excess alcohol. A kinetic model was derived in Equation (3) using an integral method analysis to experimental data. The model is very well fitted with batch reactor data in all conditions like different temperature and initial molar ratios. Therefore, the reaction is second order in both forward and backward directions, and the kinetic parameters have been determined using this model. A study of the mechanism of this reaction was conducted. and a kinetic model based on the mechanism of reaction was derived. This model describes the reaction kinetics and it was well fitted with the experimental data. An UNIFAC programme was used to calculate the activity coefficient of this esterification system. The concentrationbased rate curves were plotted using UNIFAC and modified UNIFAC models. The results reveal that the concentration as well as the activity terms are very important while deriving the rate of expressions. As an alternative to sulphuric acid, experiments with ionic liquid as a catalyst shows that the reaction is very slow and that there was no enhancement in conversion. Nomenclature C X r t k k0 E R T K M concentration conversion rate of reaction time rate constant frequency factor activation energy gas constant temperature equilibrium constant initial molar ratio of reactants Greek Letter γ activity coefficient Subscripts A B C acetic acid ethanol ethyl acetate INDIAN CHEMICAL ENGINEER Vol. 57 No. 2 June 2015 196 D Ae A0 1 2 act B EULA AND SAI water equilibrium conversion of A initial value forward reaction backward reaction actual References [1] [2] [3] [4] [5] [6] [7] [8] [9] [10] [11] [12] [13] [14] Yadav, G.D. and Mehta, P.H., “Heterogeneous Catalysis in Esterification Reactions”, Ind. Eng. Chem., 33, pp. 2198–2208 (1994). Ronnback, R., Salmi, T., Vuori, A., Haario, H., Lehtonen, J., Sundqvist, A. and Tirronen, E., “Development of a Kinetic Model for the Esterification of Acetic Acid with Methanol in the Presence of a Homogeneous Catalyst”, Chem. Eng. Sci., 52(19), pp. 3369–3381 (1997). Pisarello, M.L., Dalla Costa, B., Mendow, G. and Querini, C.A., “Esterification with Ethanol to Produce Biodiesel from High Acidity Raw Materials. Kinetic Studies and Analysis of Secondary Reactions”, Fuel Process. Technol., 91, pp. 1005–1014 (2010). Ahamed Zeki, N.S., Al-hassani, M.H. and Al-Jendeel, H.A., “Kinetic Study of Esterification Reaction”, Al-Khwarizmi Eng. J., 6(2), pp. 33–42 (2010). Madon, R.J. and Iglesia, E., “Catalytic Reaction Rates in Thermodynamically Non-ideal Systems”, J. Mol. Catal. A Chem., 163, pp. 189–204 (2000). Clark, J., Mechanism for the esterification reaction. Available from: http://www.chemguide.co.uk/ physical/catalysis/esterify.html (2004). Levenspiel, O., Chemical Reaction Engineering, 3rd edn, John Willey & Sons, New York (1999). Poling, B.E., Prausnitz, J.M. and O’Connell, J.P., Properties of Gases and Liquids, 5th edn, McGraw-Hill, New York (2000). Sandler, S.I., Chemical, Biochemical and Engineering Thermodynamics, 4th edn, John Willey & Sons, India (2006). Rao, Y.V.C., Chemical Engineering Themodynamics, Universities Press, India (1997). Calvar, N., Gonzalez, B. and Dominguez, A., “Esterification of Acetic Acid with Ethanol. Reaction Kinetics and Operation in a Packed Bed Reactive Distillation Column”, Chem. Eng. Process., 46, pp. 1317–1323 (2007). Joseph, T., Sahoo, S. and Halligudi, S.B., “Bronsted Acidic Ionic Liquids: A Green, Efficient and Reusable Catalyst System and Reaction Medium for Fischer Esterification”, J. Mol. Catal. A Chem., 234, pp. 107–110 (2005). Pralhad, A.G., George, G. and Das, J., “Bronsted Acidic Ionic Liquid Derived from Alkyl Amines as Catalysts and Medium for Fisher Esterification: Study of Structure-Activity Relationship”, J. Mol. Catal. A Chem., 279, pp. 182–186 (2008). Gmehling, J., Li, J. and Schiller, M., “A Modified UNIFAC Model. 2. Present Parameter Matrix and Results for Different Thermodynamic Properties”, Ind. Eng. Chem. Res., 32, 178–193 (1993). INDIAN CHEMICAL ENGINEER Vol. 57 No. 2 June 2015