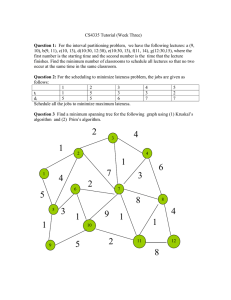

Operations Scheduling and Sequencing Single-Resource Sequencing Problem: Consider a workstation that has one maintenance mechanic to repair failed machines. We can think of the mechanic as the processor and the machines awaiting repair as the jobs. Let us assume that six machines are down, with estimated repair times given here, and that no new jobs arrive. Job (machine #) 1 2 3 4 5 6 Processing time (hours) 10 3 7 2 9 6 • We assume that jobs are ready for processing time at time zero. Using the SPT, the job sequence is 4,2,6,3,5,1. The flowtime is computed as follows: Job Sequence Flowtime 4 2 hours 2 2 + 3 = 5 hours 6 5 + 6 = 11 hours 3 11 + 7 = 18 hours 5 18 + 9 = 27 hours 1 27 + 10 = 37 hours The average flowtime for these 6 jobs is 16.67 hours (2+5+11+18+27+37 = 100/6) Average flow time was used as the criterion to minimize the average time a job spends in the workstation. The average flow time of 16.67 hours means the average time a machine will be out of service. The SPT sequencing rule maximizes workstation utilization and minimizes average job flow time and work-in-process inventory. (Try to switch 2 jobs and note the change in the average flow time. What will be the result?) Assume the following data: JOB PROCESSING TIME DUE DATE 1 4 15 2 7 16 3 2 8 4 6 21 5 3 9 Sequence by-the-numbers 1,2,3,4,5 Job Flow time Due Date Lateness Tardiness 1 4 15 -11 0 2 4 + 7 = 11 16 -5 0 3 11 + 2 = 13 8 5 5 4 13 + 6 = 19 21 -2 0 5 19 + 3 = 22 9 13 13 Average 69/5 = 13.8 0 3.6 Use the SPT rule to sequence the job Job Flow Time Due Date Lateness Tardiness 3 2 8 -6 0 5 2+3=5 9 -4 0 1 5+4=9 15 -6 0 4 9 + 6 = 15 21 -6 0 2 15 + 7 = 22 16 6 6 Average 53/5 = 10.6 -3.2 1.2 The earliest-due-date (EDD) Job Flow Time Due Date Lateness Tardiness 2 2 8 -6 0 5 2+3=5 9 -4 0 1 5+4=9 15 -6 0 2 9 + 7 = 16 16 0 0 4 16 + 6 = 22 21 1 1 Average 54/5 = 10.8 -3.0 0.2 Performance Criteria Sequence 1-2-3-4-5 Sequence (SPT) Sequence (EDD) 13.8 10.6 10.8 Average Lateness 0 3.2 3.0 Maximum Lateness 13 6 1 Average Tardiness 3.6 1.2 0.2 Maximum Tardiness 13 6 1 Average Flow Time PROJECT MANAGEMENT What is a project? - It is a temporary and often customized initiative that consists of any smaller tasks and activities that must be coordinated and completed to finish the entire initiative on time and within budget. The stages of the project life cycle 1. Define – clearly define the goal of the project, its responsibilities and deliverables, and when it must be accomplished (statement of work) 2. Plan – the steps needed to execute the project is defined. It entails breaking down a project into smaller activities and developing a project schedule. 3. Organize – involves these activities: forming a team; allocating resources; calculating costs; assessing risk, preparing project documentation, and ensuring good communications 4. Control – this stage assesses how well a project meets its goals and objectives and makes adjustments as necessary. 5. Close – closing a project involves compiling statistics, releasing and/or reassigning people, and preparing a “lessons learned” list. Three Factors Involve in Project Management Decisions 1. Resource Planning 2. Project Scheduling 3. Project Control • Resource planning includes developing time estimates for performing each activity, other resources that may be required • Project scheduling with the Critical Path Method (CPM) • Project Control - A schedule specifies when activities are to be performed. A schedule enables a manager to assign resource effectively and to monitor progress and take corrective action when necessary The Critical Path Method - The CPM is an approach to scheduling and controlling project activities. Critical Path – is the sequence of activities that take the longest time and defines the total project completion time