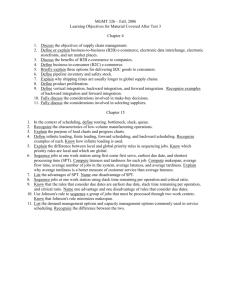

modeling.ppt

advertisement

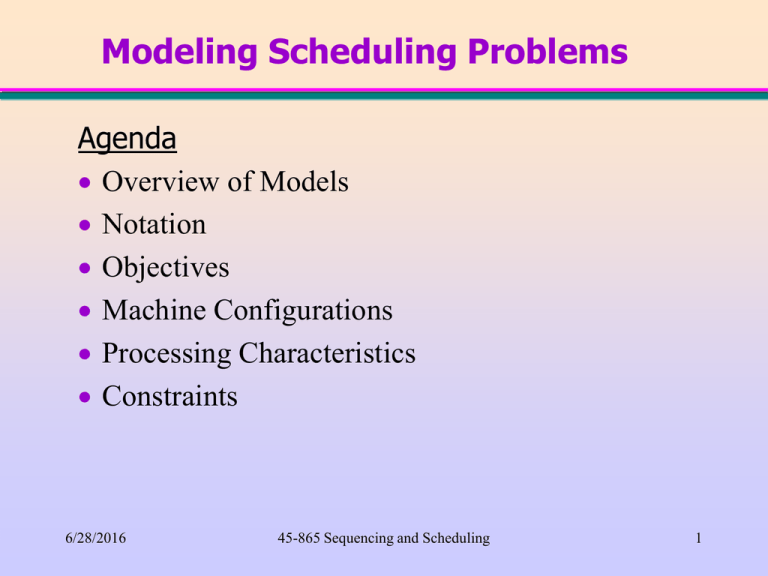

Modeling Scheduling Problems Agenda Overview of Models Notation Objectives Machine Configurations Processing Characteristics Constraints 6/28/2016 45-865 Sequencing and Scheduling 1 Overview of models Project Scheduling precedence constraints minimize makespan critical tasks can be identified Job Shop Scheduling Jobs Machine Sequence 1 1, 2, 3 2 2, 1, 4, 3 3 1, 2, 4 2 Overview of models Job Shop Scheduling minimize makespan or no of tardy jobs Mostly for make-to-order manufacturing systems Also in services Flexible Manufacturing Systems An automated material handling system controls the movement of jobs Mostly for mass production systems Maximize throughput 3 Overview of models Lot Scheduling Switching between products incurs a setup cost Minimize total inventory and setup costs Process industries, e.g. oil refinery, paper mill Reservation Systems Job start and complete times are fixed Decide to process the job or not Maximize no of jobs processed or utilization Services, e.g. hotels, car rental agencies. 4 Overview of models Timetabling Certain jobs use the same equipment and cannot be processed at the same time Minimize makespan Examples: repair shops, classroom scheduling Workforce Scheduling Assign personnel to shifts Constraints due to equipment requirements and work rules Minimize no of employees or total cost 5 Notation Input Data Processing time (pij ) Output Data Completion time (Cij or Cj) Release time (rj ) Due date (dj ) Model representation: Machine Configuration | Constraints | Objectives 6 Notation- Completion time Resources 1 1 2 4 3 3 4 2 1 2 4 3 1 Time C4 3 2 C1 C2, C3 7 Objectives Flowtime Time job j spends in the system Flow time: Fj = Cj - rj 1) Minimize average flowtime 2) Minimize maximum flowtime 8 Objectives Throughput Flow shop models or continuous processes Bottleneck machines determine output rate 1) Maximize utilization of the bottleneck 2) Minimize sum of sequence-dependent setups Makespan Determined by the last completed job Cmax = max(C1, C2, …, Cn ) 9 Objectives Due Date Related Objectives 1) Minimize maximum lateness Lateness of job j: Maximum lateness: 2) Minimize number of tardy jobs Tardiness of job j: Objective function: 3) Minimize total weighted tardiness: 10 Objectives-due date related Lj Tj dj Lateness of a job Cj dj Cj Tardiness of a job 11 Objectives Minimizing Total Cost 1) Setup Costs 2) WIP Inventory Costs min WIP min throughput time min mean flowtime 3) Finished Goods Inventory Costs 4) Personnel Costs Minimizing Total Earliness (JIT) Maximizing Robustness 12 Machine Configurations Single-Machine Parallel-Machine 13 Machine Configurations Flow Shop Job Shop 14 Processing Characteristics Sequence-Dependent Setup Times and Costs Length of setup depends on jobs sijk : setup time for processing job k after job j on machine i Costs: waste of material, labor Preemptions Interrupt the processing of a job to process another one with higher priority 15 Constraints Precedence Constraints Precedence-constraints graph contains no cycles Routing Constraints Specifies a sequence of operations for each job and the machines at which these operations must be processed 16 Constraints Material Handling Constraints Completion time Start time Storage Space Constraints Machine Eligibility Jobs Tooling and Resource Personnel Buffer Space Machines 17