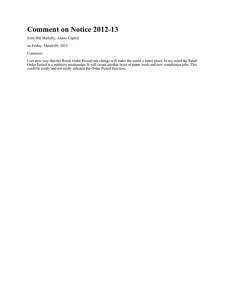

VOX Music Ltd. Andre Yager the Director of Supply Chain Operations at VOX Music Ltd., a musical instrument retailer, joined a meeting of the company’s senior management team chaired by Sylvia Wallstrom, the CEO. On the projection screen was a quote: “The past is a great place and I don't want to erase it or to regret it, but I don't want to be its prisoner either.” Mick Jagger, The Rolling Stones Wallstrom welcomed the team. She used the quote as a lead in for what she had to say about a new direction for the company. “You’ve all done a great job. VOX is a rapidly growing and very successful company, so please don’t take what I am about to say as criticism. The market is radically changing, my friends, and if we don’t change with it we’re going to die a slow and painful death. We need to turn this place on its head, and I need every one of you to help figure out how to do it. Andre, your expertise is especially needed for what I have in mind. Our distribution system will be critical to our success.” The message was not a complete surprise to the management team. They were well aware that web and mobile technology was quickly changing the retailer-customer dynamic. Customers were no longer distinguishing between online and bricks-andmortar (physical stores) channels and expected to have complete freedom to research, purchase and receive the product in the manner of their choosing, at the time of their choosing. Wallstrom went on to express the need for VOX to transition from a multi-channel operation, using separate channels to fulfill the needs of online and in-store customers, to become an integrated, omni-channel company, with seamless customer service and fulfillment no matter how the customer came into contact with the company. As Yager listened to the pitch, he began to think about the implications. He could foresee massive change. He noted, “Sitting in that meeting I began to feel overwhelmed by the task. I could see the potential for a complete overhaul of our operations. Everything from the DCs [distribution centres], to our shipping methods, to store layouts might have to be ripped apart and reconceived. It was going to be a huge effort considering that we were already scrambling. We had been growing rapidly and all our systems, including the distribution systems, were bumping up against their limits.” Company Background VOX Music Ltd. was a Canadian musical instrument retailer founded in 1978. Greg Morrison and Amy Slidell founded the company. They originally met playing in a rock band after high school, but discovered that it was very tough to find success as touring musicians. They both had had experience working in a music store and decided to try their hands at running their own store. © Supply Chain Management Association 1 VOX Music Ltd. The duo first started selling guitars and amplifiers but quickly added other lines in order to meet customer demand. Since that time, they had successfully expanded the business from one store to 21 stores across the country through a combination of organic growth and acquisition of other small retailers. In 1996 they added a rudimentary online catalogue. In 2004 they set up a division of the company to operate a full online sales website. The company’s product line included a wide variety of musical instruments and accessories: • Drums and percussion • Electric and acoustic guitars • Electric basses • Keyboards • Musical electronics (DJ equipment) • Recording equipment • Amplifiers, mixers and speakers for live sound reinforcement • School band instruments (wind, brass and percussion) • Sheet music, books and instructional DVDs Most of the items were sold in both channels (retail stores and online), but about 10% of the SKUs were offered in only one of the two channels. Some items were considered not suitable for both channels. For instance, higher end instruments were not often sold online because customers typically wanted to try the items in-store before committing to a purchase. The online store also carried a myriad of slow moving specialty items that the retail stores did not have room to stock, such as replacement parts for specific drum set hardware. Two years ago Morrison and Slidell decided to step back from the business and semiretire. They noted that online sales were growing much more rapidly (14% per year on average) than traditional store sales (2.5% on average) and felt that they needed some new leadership to take the company more firmly into the digital age (neither Morrison nor Slidell personally used social media accounts or online purchasing to any great extent). They managed to lure Sylvia Wallstrom away from a large North America wide electronics retailer, where she worked as VP Marketing, to join VOX as CEO. She was considered to be a highly innovative individual, focused on customer service and always looking for ways to keep current customers satisfied and to bring new customers to the business. Changing Customer Needs Wallstrom was well versed in the tech-enabled retail world. Online and mobile technologies had begun to radically change customers’ methods of finding product information and buying products. Wallstrom’s experience in the electronics industry showed her that customers expected a great deal of product information be available to them both online and in the store. As a result they had become better informed and more © Supply Chain Management Association 2 VOX Music Ltd. demanding. Some of her observations about trends from the electronics industry included: • • • • • • Customers were increasingly expecting to be able to view in-store inventory availability online as they didn’t want to waste time going to a store that didn’t have the product they were looking for. Customers were ordering online but asking to pickup the product in a local store in order to avoid paying shipping fees, or else to get the product the same day. This was becoming prevalent in the US market and had begun to filter into the Canadian market. Customers were also expecting the option to pay for the product when picking it up, rather than paying online, and also to be notified by email or text when the item had been set aside and ready for them. Many customers that were buying online and asking for delivery were expecting the item to ship from a local store in order to reduce delivery time and cost. In-store customers were using their mobile devices, while they were in the store, to research products on the company website. They expected sales associates to be up to speed with what was happening in the company’s online world. In-store customers, upon finding a product was out-of-stock, were asking for it to be shipped to their home from another store or DC free of charge. Customers waiting for a product delivery were often more concerned about knowing exactly when the shipment would arrive than how fast the shipment would arrive. Wallstrom’s summation of this: “In my experience customer expectations are constantly increasing. They aren’t content with the way things were. They live in a global world. They see what’s happening elsewhere and expect that we will offer the same or better. What was an order winner last year becomes an order qualifier this year as more and more retailers change their practices. We are now facing a world where the customer wants a full, uninterrupted, experience with the company. They do not distinguish between mobile, online or in-store. It happened in the electronics business and it will happen in ours!” The Musical Instrument Marketplace The bricks-and-mortar retail music instrument business was also starting to feel competitive pressures in addition to customer pressures. The two main sources were new instrument distributors that sold purely through websites, and big-box retailers that had added musical instrument lines. The typical strategy of these competitors was low cost leadership. They often purchased cheaply made instruments in bulk from Asia, and elsewhere, and made money through large volume sales rather than high margins. Their delivery times were rapid and product availability was good, but they did not typically provide a great deal of personal advice for their customers. This was attractive to people who wanted to try learning an instrument but who were not heavily committed to it or who were intimidated to step into a music store. VOX’s strategy to combat this had been to grow by acquiring some of the smaller music stores and chains across the country that had begun to struggle with the low cost competition. This helped VOX to capture market © Supply Chain Management Association 3 VOX Music Ltd. share and to reduce costs through greater purchasing volume. This approach had been successful to date. VOX Company Operations VOX Music was organized into three divisions: Retail Operations, Online Operations and Corporate Support (see Appendices I, II and III for company detail). • • • Retail Operations was the largest of the three divisions encompassing the retail store network and two warehouses (one in the Toronto area and one in the Vancouver area) focused on store replenishment. All stores and warehouses were company owned and operated. Online Operations was focused on fulfilling online customer orders. The division operated out of a company-owned distribution centre located about 20 km away from the Retail Operations’ Toronto warehouse. Corporate Support was a collection of central functions that supported both store and online operations including the executive office, corporate accounting, corporate marketing, information technology management, human resources management and supply chain operations. There were organizational and information linkages between Retail Operations and Online Operations. However, the two divisions were run largely as separate profit centres and had developed their own cultures (for instance Retail used the term warehouse, while Online used the term distribution centre). Each division had been responsible for developing its own approach to operating and marketing, although the national marketing campaigns and product selection were done cooperatively and coordinated through the Corporate Support division. The operating divisions also had slightly different sets of KPIs (see the appendix for examples). Bricks-and-Mortar Store Operations Each store was laid out to display product groupings (guitars, drums, keyboards etc.) and allow customers to try out instruments. The surroundings were pleasant with wood accents, artful displays and effective lighting. There were several sound-isolated rooms where customers could play instruments free from other noise. Typically one of each model of instrument was available on the floor for demonstration purposes. Customers could access many of the instruments without assistance from a sales associate (except for band instruments, small electronics and microphones which were kept in locked display cases) but the associates walked the floor offering assistance. The associates were all musicians (it was one of the prerequisites of becoming an employee) and were well trained to answer questions and demonstrate each instrument in their area of expertise. Approximately 10% of the approximately 5,000 ft2 of space in each store was used as a storeroom for extra stock. In most stores these spaces were crammed from floor to ceiling and not always well organized. Sales associates often had trouble locating items © Supply Chain Management Association 4 VOX Music Ltd. that the computer indicated were in the store. However, most of the associates were much more interested in helping customers with instruments than tracking down missing stock and organizing back rooms. Items not in stock were ordered from the central warehouse with a lead-time of at least one week, but more often between three and six weeks. The customer paid the shipping charges for any items that were shipped directly to them. In the past, associates had been allowed to locate out of stock SKUs at another store and have them transferred to their store for a customer to try. However this ability had been restricted in order to keep transportation costs under control. It was now only allowed if a customer paid a nonrefundable deposit of 25% of the price of the item, which has meant some customers chose to buy from competitors instead. Occasionally SKUs were transferred between the retail and online divisions. The revenue for these items was attributed to the division that completed the sale of the product, regardless of which division originally ordered the product. However, there was no clear policy for cost attribution. Supply Chain Operations The supply chains for the two divisions were operated semi-independently. The corporate supply chain operations department, managed by Yager, was responsible for, as he put it, “feeding” the other two divisions. This included supplier selection, supplier management, supplier development, ordering and inbound transportation to the company warehouses/DCs. The department also arranged company-wide agreements for items such as outbound transportation (all transportation was done by third parties). Yager and his staff also provided supply chain advice and guidance to the staff in each of the divisions. Each division was responsible for demand forecasting, warehouse/DC operation, and coordination with outbound transportation providers to get product delivered to stores and to end customers. Over the last several years the company had instituted a program to drive costs out of the supply chain. A great deal of effort was expended to look for efficiencies. The goal was to achieve high inventory turns, low safety stock and low transportation costs. Retail Distribution Centre Operations These two warehouses were set up solely to support the movement of goods from the suppliers to the stores. The Toronto warehouse was 300,000 ft2 and the Vancouver warehouse was 1/3 of that size. The warehouses were designed mainly to handle carton and pallet sized product. Small unit orders from the stores were most often recombined into cartons and pallets for regular outgoing shipments via truck. Although the retail division had considered the use of RFID for product tracking they had not implemented it and relied on barcoding. © Supply Chain Management Association 5 VOX Music Ltd. The Toronto warehouse was considered the main retail division warehouse and was full to overflowing much of the time. This problem was compounded several times per year. The first was August, as there was an upsurge in demand by students starting music lessons in September. The second was in November and December before the Christmas rush. The Vancouver warehouse, which had been recently inherited during the purchase of a retail chain in that area, was not used to its potential partially due to staff unionization issues. It was the only unionized portion of the VOX company. As part of the efficiency improvement efforts, the retail operations division management had made the decision to eliminate some slow moving items from the product list. This had freed up some space in the warehouses but had caused customer complaints. Customers were confused as to why they could order the products online, but not get them through the stores. The division had also implemented risk pooling on some items with highly variable demand, by keeping much of the stock for those items at a warehouse, rather than at store level, until demand patterns began to emerge. This had increased the demand for warehouse space. The warehouse manager, when asked what kept him up at night, indicated that he had had an increasing number of complaints from stores about lead times and inaccurate shipments. He also mentioned that store managers were frustrated that they knew there was stock in the system somewhere, but they couldn’t always get ahold of it to sell it to interested customers. Online Distribution Centre Operations The online division DC was a 350,000 ft2 pick, pack and ship operation. Incoming product arrived in pallets, which were broken down and stored. Smaller items were placed in racked bins for easy picking access. Larger items, such as boxed drumsets and keyboards, were stored in racking. The order pickers used mobile computers with an electronic pick list and bar code scanner to track the products selected. The smaller items needed for customer orders were picked into mobile bins and then combined into boxes at a packing station. Many of the orders involved a combination of related products. For example customers ordering a microphone often also ordered a microphone stand and an XLR cable (a cable used only for microphones). All orders were shipped out using a courier service or the post office depending on the customer’s desired level of delivery service. Shipping was free for customers with orders over $250. The DC was operating near capacity. It was estimated that if growth continued at the recent rate that capacity would be reached in nine to twelve months. The management of the DC was exploring options to expand but, in general, was happy with the performance of the DC and its staff. © Supply Chain Management Association 6 VOX Music Ltd. Information Technology Each of the operating divisions used different inventory management and customer relationship management systems. This arose because the IT needs of the online operation were originally significantly different than the retail operation and, when the online channel was developed, VOX decided not to spend the money to retrofit the retail operations as well. The IT department had provided some patching to move information between the systems, but it was a workaround and prone to error. As a result, inventory visibility was poor between the two divisions and there was duplicate information for customers that used both channels. Sales associates in the stores had often found themselves providing customers inaccurate information and therefore did not trust the inventory information they had access to in the online system. Each division could track common customers, but could not see what the customer had purchased in the other division. Customers themselves could find stock availability levels for products sold online but could not see if their local store had product available. Inventory being transferred between the two divisions also became invisible while in transit. The manager of IT was well aware of the problems. “Our legacy software is older than some of our employees!” She went on to say that things would need to change as VOX was now collecting large amounts data about customer needs and opinions, especially in the online side of the business. She noted that much of the data flowing from social media was unstructured, and the company would need to develop better data analysis tools to get a complete picture of its customers and their buying habits. Wallstrom’s Final Words At the close of the management meeting Wallstrom summarized her vision for the company. She said that she saw great potential in the business. She felt that the online expansion opportunities were abundant. She was also confident that the company could penetrate its current markets more effectively by adding more brick-and-mortar stores in each current geographic area. Her longer-term plans were to tackle the US market, perhaps in five or ten years. However, Wallstrom thought the company wasn’t yet ready for the new world order in retail. “We operate a very efficient multi-channel company. But that’s the problem. We pretty much operate the two channels as separate businesses. The omni-channel approach is what customers will be expecting, and we have to move that direction. You know that old Gretzky cliché you Canadians are so fond of – skate to where the puck is going to be, not where it’s been!” The After-Meeting Meeting After the official meeting closed, Yager sat down for a coffee with the Manager of IT and the VPs of both retail and online operations, and started to brainstorm. Yager’s © Supply Chain Management Association 7 VOX Music Ltd. contribution was to lay out some of the issues and a range of potential solutions from the supply chain perspective. He proposed options running the gamut from turning the stores into pure showrooms with no inventory and then shipping all product from the DCs, to turning every store into a store/DC combo and shipping everything from the local store. He even suggested outsourcing to a 3PL but then laughed saying “but that might put me out of a job!” He summarized his thoughts. “We’ve been focusing on driving cost out of our systems to make them very efficient. This strategy change is going to force us to be much more flexible – but without losing sight of the costs. In my mind though, I don’t see a clear-cut solution yet.” After the group went silent for a few minutes Yager said, “Whatever we choose to do we need to do it carefully. This is going to be a major shift in the organization. It’s going to take time, and we still have to deal with our existing capacity issues while we figure it out.” The conversation continued for a few more minutes. The IT manager was excited as she could see the potential of implementing some cutting edge technology. The two operations VPs weren’t as enthusiastic. Their worlds were about to collide in ways that would change their jobs and the jobs of almost everybody that worked for them. The meeting left them all with more questions than answers, and they agreed to reconvene in a few days after they had all had some more time to think. © Supply Chain Management Association 8 VOX Music Ltd. Appendix I – VOX Music Ltd. Organizational Chart CEO Corporate Support Division Accounting Retail Operations Division Retail Stores Transportation and Warehousing Online Operations Division Marketing and Website Information Technology Maritimes - 4 Toronto WH Market Planning Human Resources Quebec - 4 Vancouver WH Web Infrastructure Supply Chain Operations Ontario - 6 Marketing Prairies - 4 Fulfillment Toronto DC Customer Support Centre BC - 3 © Supply Chain Management Association 9 VOX Music Ltd. Appendix II – VOX Music Ltd. Financial Summary All figures are in millions of Canadian Dollars. Corporate Support costs are allocated to each operating division. Industry average pre-tax profit is 4%. Sales COGS Gross Profit Labour Divisional Administration Corporate Support Pre-tax Profit Retail Online Operations Operations 137 92 84 57 53 35 24 14 16 6 7 Total 229 141 88 38 7 4 10 23 10 17 Appendix III – Sample KPIs for Vox Operating Divisions Retail Operations Sales in $ Gross Margin Return on Sales Sales per ft2 Average Customer Spend Stock Turnover Rate by Store and Product Group Shrinkage Number of Complaints © Supply Chain Management Association Online Operations Sales in $ Gross Margin Return on Sales Average Order Size in $ Number of Out-of-Stocks Percent of Product Returned Website Traffic (Number of Unique Visits) Customer Conversion Rate Customer Return Rate (Number Repeat Customers) 10