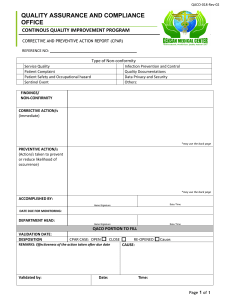

Building maintenance strategy: a new management approach R.M.W. Horner, M.A. El-Haram and A.K. Munns Building maintenance strategy 273 Construction Management Research Unit, Department of Civil Engineering, University of Dundee, Dundee, Scotland Introduction Building maintenance is a major activity in most countries. It is estimated that in the United Kingdom it currently accounts for expenditure of some £20 billion (Technology Foresight Construction Sector Panel, 1995). Accordingly, any reduction in resources applied to building maintenance will have a visible effect on the national economy. For this reason, a current research project supported by EPSRC at the University of Dundee is paying particular attention to the development of a new maintenance management approach aimed at reducing the maintenance costs of existing building stock. The easiest way to cut maintenance costs is to stop doing maintenance. This approach is simple, but the long-term results are usually very costly. Thus, the goal of the new approach is to carry out as little maintenance as possible as infrequently as possible while at the same time preserving the availability of the services facilities, the building elements and the whole building. In other words, maintenance should be carried out only when necessary to ensure the continued, safe and profitable use of the building at acceptable levels of satisfaction or when there is the possibility of extending the useful life of the elements of the building. Finding an appropriate maintenance strategy is the most difficult task facing maintenance management in determining an optimal approach to reducing the financial expenditure and total life cycle costs. This paper describes a new, systematic framework for selecting a suitable maintenance strategy for each individual item in a building. Building maintenance Building maintenance is defined as “work undertaken in order to keep, restore or improve every part of a building, its services and surrounds, to a currently accepted standard, and to sustain the utility and value of the building” (Seeley, 1976). The objectives of building maintenance are therefore (Alner and Fellows, 1990): The financial support of the Engineering and Physical Sciences Research Council is gratefully acknowledged. Journal of Quality in Maintenance Engineering, Vol. 3 No. 4, 1997, pp. 273-280. © MCB University Press, 1355-2511 JQME 3,4 274 • to ensure that the buildings and their associated services are in a safe condition; • to ensure that the buildings are fit for use; • to ensure that the condition of the building meets all statutory requirements; • to carry out the maintenance work necessary to maintain the value of the physical assets of the building stock; and • to carry out the work necessary to maintain the quality of the building. In maintaining a building, there are usually several strategic options available to management, and many alternative decisions to be considered. There is, for example, the possibility of reducing the demand for maintenance by addressing the actual cause of failure and identifying its consequences. For instance, it may be necessary to decide whether to repair or replace an item, and whether to carry out periodic maintenance at fixed intervals or simply to respond to the requests of the users. Thus, building maintenance can be divided into three strategies: • corrective; • preventive; • condition-based. Corrective maintenance Corrective maintenance is the simplest type of maintenance strategy, where an element in a building is used until it breaks down. It covers all activities, including replacement or repair of an element that has failed to a point at which it cannot perform its required function. Corrective maintenance is sometimes referred to as failure-based or unplanned maintenance. Corrective maintenance tasks often take places in an ad hoc manner in response to breakdowns or user requests (David and Arthur, 1989). Thus, corrective maintenance can be extremely expensive for two reasons: (1) The failure of an item can cause a large amount of consequential damage to other elements in the building. For example, failure of the roof could cause damage to the ceiling and the interior of the building. (2) Failure of an item can occur at a time which is inconvenient to both the user and the maintaining authority. This can make manpower and spare parts planning extremely difficult. However, corrective maintenance is still an important part of any maintenance management strategy, as we shall see later in this paper. It is from such work that we can gather vital predictive information. Preventive maintenance Preventive maintenance was introduced to overcome the disadvantages of corrective maintenance, by reducing the probability of occurrence of failure and avoiding sudden failure. This strategy is referred to as time-based maintenance, planned maintenance or cyclic maintenance. Preventive maintenance tasks are performed in accordance with a predetermined plan at regular, fixed intervals, which may be based for example on operating time. Such a strategy is frequently applied to external or internal paint work. The following are the advantages of preventive over corrective maintenance (Raymond and Joan, 1991): • maintenance can be planned ahead and performed when it is convenient to the building’s user; • maintenance costs can be reduced by avoiding the cost of consequential damage; • downtime, the time that an element of the building or the whole building is out of service, can be minimized so the habitability of the building can be increased; and • the health and safety of the user can be improved. Nevertheless, preventive maintenance has some disadvantages which must be minimized (El-Haram, 1995): • Planned maintenance is performed irrespective of the condition of the building elements. Consequently, a large number of unnecessary tasks, will be carried out on elements that could have remained in a safe and acceptable operating condition for a much longer time. • The condition of an element may end up worse than it was before, as a result of human error during the execution of the maintenance task. • Planned maintenance tasks are usually very demanding in terms of spare parts and labour. Condition-based maintenance Condition-based maintenance is defined as: “Maintenance carried out in response to a significant deterioration in a unit as indicated by a change in monitored parameter of the unit condition or performance” (Kelly and Harris, 1978). The condition-based maintenance concept recognizes that a change in condition and/or performance of an item is the principal reason for carrying out maintenance. Thus, the optimal time to perform maintenance is determined from a condition survey used to determine the actual state of each constituent item in a building. In this strategy, maintenance tasks are determined and planned by efficiently monitoring the building’s elements such as walls, floors, roof and service equipment such as boilers, pumps, and heating system, to identify which element or piece of equipment requires maintenance before a major failure occurs. To gain the full advantage of applying condition-based Building maintenance strategy 275 JQME 3,4 276 maintenance, the condition of an item must be monitored to identify whether there is any evidence of change from a normal to an abnormal condition. This can be done by selecting the parameter which best describes the condition of the item and monitoring changes using suitable condition monitoring tools. Condition assessments can vary from simple visual inspections to more advanced inspections using a variety of condition monitoring tools and techniques. A new approach to maintenance management Current building maintenance strategies, whether based on planned or unplanned maintenance, are most likely to be budget driven. This means that maintenance is not carried out according to actual need, but is dictated by financial priorities decided at the time or during the previous 12 months. Although theoretically the budget should be built up as a result of estimated needs, it is almost invariably based on previous years’ figures, modified for changes in the number of buildings, specially agreed programmes of planned maintenance and inflation forecasts (Spedding, 1987). Three methods are currently used for constructing a budget for estate-based management organizations; none is entirely satisfactory and each produces a different budget (Lee, 1987): (1) Base this year’s budget on last year’s expenditure with an allowance for inflation. (2) Use the Department of Environment (DoE) or other formula for calculating the maintenance element of the estate budget. (3) Use a stock condition survey to quantify the size of the maintenance task. In contrast to the way that current building maintenance strategies are selected, the new maintenance management approach is based on the failure consequences of each item in a building. Thus, the objective of maintenance management is to prevent, to minimize and to repair building defects by enhanced planning and implementation using appropriate materials and tools at the right time and minimum total life-cycle cost. The maintenance management decision diagram The maintenance management decision diagram is a logical process used to select an appropriate and cost-effective maintenance strategy for each item or group of items in a building. Its objective is to determine the best combination of maintenance strategies for a building by selecting the optimum maintenance strategy for each individual item in the building, taking into consideration health, safety and satisfaction of the user and the costs of maintenance tasks. The first step in developing the maintenance management decision diagram is to carry out a comprehensive review of all constituent items in a building. This can be done by breaking the building down into the physical elements and items of each functional system and subsystem. Engineering failure analysis provides insight into the type of failures that an item in a building is likely to experience. So each item within the building should be analysed from the point of view of failure. It is especially important to identify the consequences of failure. The engineering tool which is used to perform this task is a failure mode, effect and consequences analysis (FMECoA) (El-Haram et al., 1996). As a result of this analysis, all the constituent items in the building can be divided into two groups depending on the significance of the consequences of failure (El-Haram and Knezevic, 1995). Significant items Significant items are those whose failure affects health, safety, environment or utility (including cost). Health, safety and environmentally significant items. To determine health, safety and environmentally significant items (HSESIs), it is necessary to find out exactly how the item might affect the environment and the health and safety of the user when it fails. Niczyporuk (1994) defines a safe object as one which causes no hazard in relation to life, health or the environment. It is also defined as freedom from unacceptable risk or personal harm. Risk is the combined effect of the chances of occurrence of some undesirable failure and its consequences in a given system. Thus, HSESIs are those whose failure creates a possibility that the user could be injured or killed, or that environmental standards could be breached. Util ity significant item. An item is utility significant if the cost of maintenance is less than the cost of failure. In determining the cost of failure, it is necessary to take account of any loss of availability which may result from the failure. Thus, all items whose failure is likely to have an effect on the revenue, direct and indirect maintenance costs, quality, user satisfaction, appearance, serviceability or availability of the building are potentially utility significant. Care should be taken to ensure that all items that have failure consequences are included in the list of significant items. Non-significant iems Non-significant items are those items whose failure has no significant effect. This means that the failure affects neither health, safety, environment nor utility. Selection of building maintenance strategy Once significant and non-significant items are identified, the next step is to select an appropriate maintenance strategy for each item in the building. Generally speaking, all three types of maintenance strategies could be applied to every item in the building, but only one will yield optimal results. The process is illustrated in Figure 1. Building maintenance strategy 277 Figure 1. Building maintenance decision diagram Condition-based maintenance (CBM) Y Is the cost of applying CBM less than the cost of applying FBM? Y N Failure-based maintenance (FBM) N Is the cost of applying TBM less than the cost of applying FBM? N Time-based maintenance (TBM) Y Is the on-line condition monitoring technique available and costeffective? Failure-based maintenance (FBM) Y Can the condition of the HSESI be monitored? Y Can the condition of the USI be monitored? N HSES items Significant items (SI) List of a building’s constituent items 278 US items Key HSES = Health, safety and environment significant US = Utility significant Time-based maintenance (TBM) N Condition-based maintenance (CBM) Non-significant items (NSI) JQME 3,4 Corrective maintenance Corrective maintenance is most likely to be the appropriate maintenance strategy for: • non-significant items; and • utility significant items whose condition cannot be monitored and for which the cost of applying time-based preventive maintenance is less than the cost of applying corrective maintenance. Preventive maintenance Time-based preventive maintenance is most likely to be the appropriate maintenance strategy for: • health, safety and environmentally significant items whose condition cannot be monitored; • health, safety and environmentally significant items whose condition can be monitored, but for which the online condition monitoring techniques either are not available or are not cost effective; and • utility significant items whose condition cannot be monitored and for which the cost of applying time-based preventive maintenance is less than the cost of applying corrective maintenance. Condition-based maintenance Condition-based maintenance is most likely to be the appropriate maintenance strategy for: • health, safety and environmentally significant items whose condition can be monitored and for which on-line condition monitoring techniques are available and cost-effective; • utility significant items whose condition can be monitored and for which condition-based monitoring techniques are available and cost-effective; and • utility significant items whose condition can be monitored and for which the cost of applying condition-based maintenance is less than the cost of applying corrective maintenance. Conclusions To determine an optimal maintenance strategy for a building, it is necessary to integrate the three types of maintenance strategy because: • not all items are significant; • not all significant items can be condition monitored; • condition monitoring techniques are not always available; and • the application of condition monitoring techniques is not always costeffective. Building maintenance strategy 279 JQME 3,4 280 This approach will allow maintenance engineers and managers to make decisions in advance about: • selecting the most cost-effective maintenance strategy for each individual item in the building; and • the optimal allocation of logistics resources such as spare parts, tools, and personnel which are needed for the execution of maintenance activities. Introducing this approach to building maintenance management is expected both to reduce building maintenance costs and to improve the health, safety and satisfaction of the user. Although the paper has proposed a new approach to building maintenance management, testing of its effectiveness at this stage is hampered by the lack of reliable failure data and maintenance cost data. References Alner, G.R. and Fellows, R.F. (1990), “Maintenance of local authority school building in UK: a case study”, Proceedings of the International Symposium on Property Maintenance Management and Modernisation, Singapore, pp. 90-9. David, W.W. and Arthur, B. (1989), “Management to maintain quality in buildings”, Proceedings of Implementation of quality in construction, Copenhagen, pp. 212-18. El-Haram, M., (1995), “Integration approach to condition-based reliability assessment and maintenance planning”, Ph D. Thesis, University of Exeter. El-Haram, M. and Knezevic, J. (1995), “Predictor based maintenance methodology”, Proceedings of the 5th International Logistics symposium, UK, pp. 187-94. El-Haram, M., Horner, R.M. and Munns, A. (1996), “Application of RCM to building maintenance strategies”, Proceedings of the 6th International Logistics symposium, UK, pp. 133-43. Kelly, A. and Harris, M.J. (1978), Management of Industrial Maintenance, Butterworths, London. Lee, R. (1987), Building Maintenance Management, William Collins Sons & Co. Ltd, London. Niczyporuk, Z.T. (1994), “Role of technical diagnostics in improvements of safety in coal mines”, Proceedings International Conference on Condition Monitoring, Swansea, UK, pp. 34-50. Raymond, C.M. and Joan, C.F. (Eds) (1991), Preventive Maintenance of Buildings, Chapman and Hall, London. Seeley, H. (1976), Building Maintenance, Macmillan Press Ltd, London. Spedding, A. (1987) (Ed.), Building Maintenance Economics and Management, E. & F. N. Spon Ltd, London. Technology Foresight Construction Sector Panel (1995), Progress Through Partnership (2): Construction, Office of Science and Technology, HMSO, February.