GTAW Welding: Process, Equipment, and Applications

advertisement

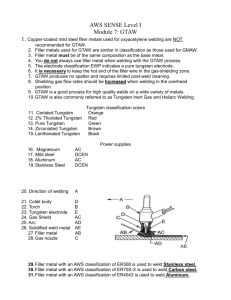

GTAW Definitions GTAW gas tungsten arc welding an electric arc between a non-consumable electrode and the work piece protected by a shielding gas TIG tungsten inert gas Inert Gas a gas that does not chemically combine or react with another substance Contamination tungsten non-consumable electrode coming into contact with the base metal. inert gas not present. both these conditions lead to not only contamination of the tungsten electrode, but also defects in the weld itself. Shielding gases inert Argon most popular Helium Argon combined with Helium GTAW Applications virtually all metals can be welded aluminum titanium stainless steels carbon steels copper mild steels magnesium GTAW Equipment GTAW Welding Process similar to oxy-fuel welding heat source is held in one hand if filler is required it is added with the other hand requires much more skills than the typical manual or semi-automatic welding non-consumable tungsten electrode generates arc tungsten electrode has a melting point of 6170 degrees Fahrenheit (the highest melting point of all the metals) the material is also the same type of material used as a filament in a regular light bulb electrode DOES NOT touch the base metal or the molten puddle the arc reaches temperatures of 11,000 degrees Fahrenheit tungsten electrode normally does not melt in these temperatures because: • it has the ability to conduct heat well • touch handle is a good heat conductor Welding Aluminum or Magnesium uses AC ( alternating current) electrons flow in one direction, stop and flow the other direction for the same period of time (60-cycle means electrons change directions 60 times per second) this constant current reversal creates base metal heating for an instant (negative electron flow), while metal cleaning the next instant (electron positive flow) heat from the arc is more evenly distributed between the tungsten and the base metal pure tungsten electrode is used (green end) Welding other materials Direct Current Electrode Negative (DCEN) (same as DCSP in SMAW) electrons flow from electrode to base metal which transfers 70% of the heat from the arc to the base metal Direct Current Electrode Positive (DCEP) (same as DCRP in SMAW) rarely used in GTAW since it produces shallow penetration and slow travel speeds this is just the opposite of SMAW and GMAW which is mostly done with DCRP electrode does not contain any flux, therefore a shielding gas is used to protect the weld if electrode comes in contact with the base metal, it will become contaminated after contamination, the electrode must be cleaned this is done on a grinding wheel (point for stainless steel, flat for aluminum) Argon is most common shielding gas setting is 20 CFH, but may be as high as 30 CFH when welding aluminum 2% thoriated tungsten electrode used (red end) Typical Current Ranges GTAW Tungsten Electrode Preparation GTAW Torch Parts Preparing to Weld Follow same precautions as GMAW and SMAW number 10 shade is required (minimum) always clean base metal prior to welding clean aluminum with aluminum brush only clean stainless steel with stainless steel brush only choose the correct filler for the base metal always wear gloves on both hands always hang torch up properly when not in use always shut off shielding gas when not in use magnetic fields can from high currents can affect pacemakers operations