Lecture 1 Macc 3 Cost and Management Accounting and new developments

advertisement

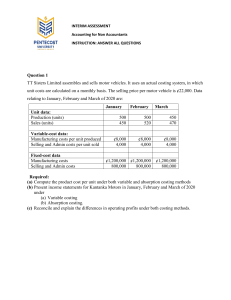

University of the Gambia BSc. In Accounting – Management accounging 3 Lecture 1: Cost and Management Accounting – New developments Lecturer: Mr. Lamin Fofana FCCA, MSc., BSc. (Hons.), MAAT - (Director of Finance and admin – Social Development Fund (SDF) Absorption and Marginal Costing _ In Absorption Costing fixed manufacturing overheads are absorbed into cost units. _ Stock is valued at absorption cost and fixed manufacturing overheads are charged in the P&L account of the period in which units are sold _ In Marginal costing fixed manufacturing overheads are NOT absorbed into cost units. _ All fixed overheads, including fixed manufacturing overheads are treated as period costs and charged in the P&L account of the period. UTG ----- ABSORPTION COSTING Absorption costing – a reminder The linking of all production costs to the cost unit to prepare a full cost per unit. Uses 1. Stock Valuation 2. Pricing decisions 3. Budgeting Traditional overhead analysis Cost Centres Overhead cost item Cost Units Steps using absorption costing The steps using absorption costing are: 1 Overhead costs are collected in various cost centres Allocation: Specific overhead costs directly relating to individual cost centres, for example, supervision, indirect materials. Apportionment: General or common overhead costs like rent, heating, electricity are incurred as a whole item by the company and therefore have to be distributed to cost centres on some sharing bases like floor area, machine hours, number of staff etc 2 Overhead absorption is achieved by means of a predetermined Overhead Absorption Rate. a. Overhead Absorption Rate = Budgeted Overheads Budgeted Level of Activity * * Activity levels generally used by examiners are number of units, labour hours or machine hours, which means overheads are charged to units on these bases. b. 2 Number of Units: Single product environment Labour Hours: Manual manufacturing operations Machine Hours: Mechanical manufacturing operations Absorbed overheads = OAR x Actual Activity Lecture 1: Cost and Management Accounting – New developments Example 1 2P2D Ltd 2P2D Ltd produces 2 products in 2 departments. Relevant product information is: Direct material cost (£) Direct labour cost in Department X (£) Time per unit in Department X (Hours) Direct labour cost in Department Y (£) Time per unit in Department Y (Hours) Budgeted number of units Product A 20 20 4 25 5 2,000 Product B 35 30 6 35 7 1,000 The labour rate is £5 per hour in each department. The Budgeted Departmental Overheads are: Department X Department Y £18,000 £6,500 Required: Calculate the cost/unit using: (a) Separate OARs for each department, based on labour hours. (b) An overall OAR, based on labour hours. (c) Discuss the differences. Criticisms of absorption costing Criticisms of absorption costing are: ● A big amount of guess work in relating overhead costs to the products. ● Inappropriate bases to link overheads to products ● Can only work in single product and simple manufacturing environments Recent changes in manufacturing The reason for the increasing inaccuracy of absorption costing is due to two basic issues: 1. Increased production complexity. 2. Increased proportion of overhead costs. Production complexity A wide variety of production processes have become more complex in recent years in a number of ways: 1. Flexible manufacturing systems allow for a number of widely differing products to be produced on the same machinery. Absorbing overhead on a simple volume base is unlikely to reflect the differing overhead costs incurred by each product. 3 2. Fast product development may mean that a number of differing iterations of the same product may be produced in quick order. With such products having differing production volumes again a volume base is unlikely to work. 3. Wider product ranges lead to a more complex cost analysis. Increased proportion of overhead costs Overheads have the substitution greater degree. rise to increased increased in importance as a percentage of total costs due to both of direct labour with indirect labour as companies mechanise to a Also the increased production complexity outlined above has given costs for such disciplines as production planning and logistics. Increased proportion of support services’ costs Activity based costing also introduces the important aspect that cost are incurred in selling and distributing a product and the cost of servicing customers are often more important than production therefore an accurate cause effect relationship should be established as to what generates the cost and what is the real impact of this cost on the volume of units sold. See supplementary notes on Lecture 1b on ABC before proceeding A revised analysis – ABC Overhead Cost Item Cost Pool Cost Unit Steps using ABC The steps involved in ABC are: 1. Identify an organisation’s activities. 2. Collect the cost of each activity into what is called cost pool (equivalent to cost centre under traditional costing). 3. Identify the factors which determine the size of the costs of an activity. These are called cost drivers. Activity Ordering Material handling Production scheduling Despatching 4. Possible Cost Drivers number of orders number of production run number of production run number of despatches Assign the cost of activities to products according to the product’s demand for activities. Cost Pool is an activity that consumes resources and for which overhead costs are identified and allocated. For each cost pool there should be a cost driver. Cost Driver is any factor which causes a change in the cost of an activity. 4 Example 2 Hensau Ltd Hensau Ltd has a single production process for which the following costs have been estimated for the period ending 31 December 2010: £ Material receipt and inspection costs Power costs Material handling costs 15,600 19,500 13,650 Three products - X, Y, and Z are produced by workers who perform a number of operations on material blanks using hand held electrically powered drills. The workers are paid £4 per hour. The following budgeted information has been obtained for the period ending 31 December 2009: Production quantity (units) Batches of Material Data per product unit: Direct material (square metres) Direct material cost (£) Direct labour (minutes) No. of power drill operations Product X Product Y Product Z 2,000 10 1,500 5 800 16 4 5 24 6 6 3 40 3 3 6 60 2 Overhead costs for material receipt and inspection, process power and material handling are presently each absorbed by product units using rates per direct labour hour. An activity based costing investigation has revealed that the cost drivers for the overhead costs are as follows: Material receipt and inspection: Process power: Material handling: Number of batches of material Number of power drill operations Quantity of material (square metres) handled Required (a) Prepare a summary which shows the budgeted product cost per unit for each product of X, Y, and Z for the period ending 31 December 2010 detailing the unit costs for each cost element using: (i) the existing method for the absorption of overhead costs and (ii) an approach which recognises the cost drivers revealed in the activity based costing investigation. (13 marks) (b) Explain the relevance of cost drivers in activity based costing. Make use of figures from the summary statement prepared in (a) to illustrate your answer. (7 marks) (20 marks) 5 Conditions under which ABC is most appropriate The usefulness of ABC techniques will depend on organisation, in particular the following: (1) Cost structure (2) Product mix or diversity (3) Information (4) the characteristics of the Environment. Benefits and limitations Benefits 1. More accurate product costing. 2. Is flexible enough to analyse costs by activity providing more useful costing data. 3. Provides a reliable indication of long-run variable product cost. 4. Helps understanding of cost. 5. Provides a more logical basis for costing of overhead. Limitations 1. Cost vs benefit. 2. ABC information is historic and internally. 3. Difficult to apply in practice. 4. Focuses on the allocation of cost rather than minimizing the cost incurred. 6 Example 3 Brunti plc The following budgeted information relates to Brunti plc for the forthcoming period. Products XYI (000s) YZT (000s) ABW (000s) 50 40 30 £ £ £ 45 32 Hours 95 84 Hours 73 65 Hours 2 7 5 3 4 2 Sales and production (units) Selling Price (per unit) Prime cost (per units) Machine department (machine hours per unit) Assembly department (direct labour hours per unit) Overheads allocated and apportioned to production departments (including service cost centre costs) were to be recovered in product costs as follows. ● Machine department at £1.20 per machine hour ● Assembly department at £0.825 per direct labour hour You ascertain that the above overheads could be re-analysed into 'cost pools' as follows: Cost pool £000 Machining services Assembly services 357 318 Set-up costs Order processing Purchasing 26 156 84 941 Quantity for the period Cost driver Machine hours Direct labour hours Set-ups Customer orders Suppliers' orders 420,000 530,000 520 32,000 11,200 You have also been provided with the following estimates for the period: Number of set-ups Customer orders Suppliers' orders XYI Products YZT ABW 120 8,000 3,000 200 8,000 4,000 200 16,000 4,200 Required: (a) Prepare and present profit statements using: (i) conventional absorption costing, and (5 marks) (ii) activity based costing. (9 marks) (b) Comment on why activity based costing is considered to present a fairer valuation of the product cost per unit. (6 marks) (20 marks) ACCA June 1995 Amended 7 ACTIVITY BASED BUDGETING (ABB) ● Activity based budgeting extends the use of ABC from individual product costing, for pricing and output decisions, to the overall planning and control systems of the business. ● The basic principle of ABB is that the work of each department for which a budget is to be prepared is analysed by its major activities, for which cost drivers may be identified. The budgeted cost of resources used by each activity is determined (from recent historical data) and, where appropriate, cost per unit of activity is calculated. ● Future cost can then be budgeted by d e c i d i n g on working back to the required resource input. future activity levels and