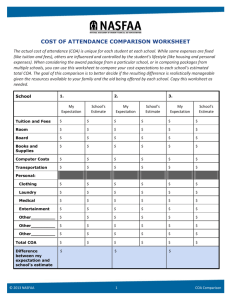

Kinetic parameterization and model construction of Mycobacterium Tuberculosis Pantothenate Kinase De Vries, H., Mocke, L., Snoep, J.L. Department of Biochemistry – Systems Biology, Stellenbosch University Abstract The bacterial disease tuberculosis, which is caused by the bacillus Mycobacterium tuberculosis, poses a large threat to the global health sector as many of its pathogenic strains are resistant to current drug treatments. Furthermore, the combinatory effect of tuberculosis and HIV increases the risk of death. Thus, new drug strategies must be developed to decrease the effect tuberculosis has on the global health sector. Such a drug target is presented in the Coenzyme A synthesis pathway of Mycobacterium tuberculosis. Disruption of the synthesis of such an essential co-factor could lead to the disruption of its central metabolism. In this project the enzyme Pantothenate Kinase of the pathogen Mycobacterium tuberculosis, was kinetically characterized by constructing a parameterized rate equation and a mathematical model with the eventual aim of kinetically characterizing the entire CoA synthesis pathway. This will enable the model to predict the control distribution the enzymes have over the pathway, which could lead to the identification of a suitable enzyme as a drug target. Pantothenate kinase had a Vmax of 7.70 µM/min/mgprotein. The enzyme was inhibited in a non-competitive manner by CoA and Acetyl-CoA with ki-values of 2.55 x 10-2 mM and 9.14 x 10-2 mM respectively. The mathematical model could predict basic changes in the metabolite concentration over time with CoA present/absent; however, with Acetyl-CoA present, the in vitro changes in metabolite concentrations differed from the model prediction. Keywords: Mycobacterium Tuberculosis, Pantothenate Kinase, Enzyme kinetics, Mathematical Modeling 1. Introduction Tuberculosis (TB) is a bacterial disease that is caused by the bacillus Mycobacterium tuberculosis. TB is primarily a pulmonary disease spreading through aerosol droplets. However, progression of the disease is immune dependent and could lead to the M.tuberculosis spreading to several organs [1]. According to the World Health Organization it ranks among the top 10 causes of death worldwide. In 2019 an estimate of 10 million people was infected with TB of which 1.4 million succumbed to the disease. Of the 1.4 million deaths 208 000 were HIV-positive [2]. HIV1 is an immunodeficiency disease which causes an individual to become susceptible to many viral/bacterial infections, such as TB [3]. Several drug treatment strategies have been used to treat TB; however, Multi-Drug-Resistant (MDR) M.tuberculosis and extensively drug resistant (XDR) M.tuberculosis strains have become a large concern. MDRTB strains are resistant to many of the first- and second-line TB drugs. They require an extensive treatment plan that uses a combination of first- and second-line TB drugs to cure the disease, however treatment success rates for MDR-TB are only at 58% and even lower for XDR-TB [4]. Thus, new drug strategies must be implemented 1 Human Immunodeficiency Virus 1 to combat MDR- and XDR-TB. Several drug targets, targeting several important M.tuberculosis systems have been identified [5, 6]. The Coenzyme A (CoA) biosynthesis pathway has been identified as a potential drug target [6]. CoA is an essential co-factor involved in many metabolic processes such as fatty acid synthesis, breakdown, and the citric acid cycle [7]. According to a survey performed on the BRENDA database of enzymes, CoA and its derivates act as co-factors for approximately 9% of all known enzymes across all organisms [8]. Furthermore, nearly all organisms are required to synthesize CoA de novo [8]. Thus, if the de novo synthesis of CoA in M.tuberculosis is disrupted, it could lead to the disruption of integral metabolic processes, leading to cell and eventual organism death. CoA is synthesized via a general 5-step pathway, where several enzymes catalyse the reactions from pantothenate to CoA (PanK, PPCS, PPCDC, PPAT, DPCK) [9, 10] (Fig.1). To identify a suitable enzyme in the pathway as a drug target, one must assess the control distribution the enzymes have over the pathway. Figure 1: The complete general 5-step CoA biosynthesis pathway. (1.6-1.7): Pantothenate phosphorylated to 4’phosphopantothenate by pantothenate kinase (PanK). (1.7-1.8): Combination of 4’-phosphopantethenate with cysteine by Phosphopantothenoylcysteine synthase (PPCS) to form phosphopantothenoylcysteine. (1.8 -1.9): Decarboxylation of phosphopantothenoylcysteine by phosphopantothenoylcysteine decarboxylase (PPCDC) to form 4’-phosphopantetheine. (1.91.10): Adenylation of 4’- phosphopantetheine by Phosphopantetheine adenylyltransferase (PPAT) to form dephospho-CoA. (1.10-1.11): In the final step of the pathway dephospho-CoA is phosphorylated by dephospho-CoA kinase (DPCK) to form CoA. (1.12-1.9): Illustrates the CoA-salvage pathway, where pantetheine is phosphorylated to 4’-phosphopantetheine by PanK to join the general 5-step pathway at 1.9 [11]. 2 Pantothenate kinase (PanK) catalyses the first and proposed rate limiting step of this pathway, converting pantothenate to 4’-phosphopantothenate with ATP as a phosphoryl donor [6]. Three different types of PanK enzymes have been characterized. Type I is mostly found in prokaryotic organisms, Type II predominantly occurs in eukaryotic organisms and Type III is found in a wide variety of phylogenetic groups, mostly in pathogenic organisms [12]. The M.tuberculosis genome contains a single copy of both Type I and Type III PanK, however, the Type III PanK has been shown to be non-essential [13]. It has also been shown that type II PanK shares little sequence homology with Type I and III PanK [13]. This creates an unique opportunity for drug development against M.tuberculosis as human hosts function with type II PanK enzymes. Thus, targeting the M.tuberculosis type I PanK (MtPanK) should have no effect on the human PanK. In most organisms CoA is synthesized via the above mentioned general 5-step pathway from pantethenate to CoA [9]. Alternatively in some organisms such as E.coli, CoA can be synthesized via the phosphorylation of pantetheine (PanSH) to 4’phosphopantetheine (PPanSH) by PanK. PPanSH is then converted to CoA via the final two enzymes in the general pathway, PPAT and DPCK. The alternative pathway is known as the CoA salvage pathway [8]. In E.coli PanK, activity is modulated by the total CoA pool, consisting of CoASH and CoA thioesters [14]. The modulation is a result of feedback inhibition as CoA is the final product of the pathway, thus if the total CoA pool is increased with the addition of external CoA, PanK activity should decrease. Kinetic characterization of MtPanK has been performed for the first and proposed rate limiting step of the classic 5-step pathway [15]. However, the MtPanK CoA salvage pathway has not been kinetically characterized. In this project a start was made to kinetically characterize MtPanK of the pathogen M.tuberculosis . The focus was on the experimental characterization of the enzyme and parameterization of a kinetic rate equation for the phosphorylation of PanSH to PPanSH in the CoA-salvage pathway, including the regulation of the enzyme by CoA and acetyl-CoA (AcCoA). Pyruvate kinase (PK)/lactate dehydrogenase (LDH) coupled assays were used to determine the initial rate kinetics of MtPanK, with which the rate equation was parameterized. CoA and AcCoA were found to be noncompetitive inhibitors of MtPanK with ki values of 2.55 x 10-2 mM and 9.14 x 10-2 mM respectively. A mathematical model was constructed for MtPanK using Wolfram Mathematica, which could predict the basic metabolic flux for the conversion of PanSH to PPanSH. The mathematical model was validated using a HPLC method developed by R.Goosen, which can quantify the in vitro concentration of all thiol-bearing metabolites in the CoA pathway [16]. This method was used to validate the model by comparing the model predicted metabolic fluxes with the experimental in vitro metabolic fluxes. This was done with no inhibitor and 0.05 mM CoA present. 2. Experimental procedures 2.1 MtPanK activity assays: To determine the initial rate kinetics of MtPanK, activity assays were performed using the enzyme-coupled PK/LDH-coupled assay. This assay couples the oxidation of NADH to NAD+ with the conversion of PanSH to PPanSH. The ADP formed from the conversion of PanSH to PPanSH is used to dephosphorylate phosphoenolpyruvate (PEP) by PK, forming pyruvate. Pyruvate is then converted to lactate by LDH, which requires the oxidation of NADH to NAD+. NADH has a maximum absorbance at 340 nm, thus the decrease in absorbance at 340 nm is tracked spectrophotometrically over time. The decrease of absorbance at 340 nm is 3 directly proportional to conversion of PanSH to PPanSH, as one mole of ADP is formed per one mole of PPanSH produced. All assay mixtures contained Tris-buffer (100 mM MgCl2, 500 mM Tris, 200 mM KCl, pH 7.6), 1 mM PEP, 0.8 mM NADH, 0.04 U/µl PK, 0.04 U/µl mM LDH, 1 mM dithiothreitol (DTT) and 2 µg MtPanK. For the PanSH and ATP concentration range assays, the concentration of PanSH and ATP were varied from 0.03125 mM to 4mM and 0.15625 mM to 7 mM respectively. One was varied while the other was held at a non-rate limiting concentration. Inhibition assays were performed by adding 0.025/0.05 mM CoA or 0.1/0.25 mM AcCoA to a PanSH concentration range assay. Negative controls were added by creating a reaction mixture excluding either PanSH or ATP. All reactions were performed at 25°C in a 96-well microtiter plate. Pantethine was reduced for 15 minutes to create two molecules of PanSH using the reducing agent DTT (60 mM). The reaction was initiated by adding the reaction components to the substrates (ATP and PanSH). The initial decrease in absorbance at 340 nm was then tracked using a Spectrostar nano microplate reader in real time. The data was exported to Microsoft Excel, where it was analysed to determine the initial reaction rate for MtPanK at each substrate concentration. Reaction volumes and therefore pathlengths were equal for all assays. Each assay had a minimum of three technical repeats. 2.2 Parameterization of rate equation: 𝑣𝑃𝑎𝑛𝐾 = 𝑒𝑃𝑎𝑛𝐾×𝑉𝑚𝑎𝑥 [𝑝𝑎𝑛𝑆𝐻] [𝐴𝑇𝑃] [𝐶𝑜𝐴] [𝐴𝑐𝐶𝑜𝐴] [𝐴𝑇𝑃] [𝑝𝑎𝑛𝑆𝐻] + )(1+ )(1+ ) 𝑘𝑖𝐶𝑜𝐴 𝑘𝑖𝐴𝑐𝐶𝑜𝐴 𝑘𝑚𝐴𝑇𝑃 𝑘𝑚𝑝𝑎𝑛𝑆𝐻 (𝑘𝑚𝐴𝑇𝑃×𝑘𝑚𝑝𝑎𝑛𝑆𝐻)(1+ Eq.1 A standard Michaelis-Menten rate profile was observed, allowing the rate equation shown above to be derived for MtPanK. The rate equation describes a non-reversible Michaelis-Menten reaction, where the reaction rate for the conversion of PanSH to PPanSH is dependent on the concentration of both substrates, ATP and PanSH. Both CoA and AcCoA were inserted as non-competitive inhibitors. Wolfram Mathematica version 12.2.0.0 was used for statistical and graphical analysis of the initial rate assay data. The parameter values were determined by performing a global fit of the rate equation (Eq.1) on all initial rate data sets. 2.3 Mathematical Model: A mathematical model was constructed in Mathematica to predict the metabolic flux for the conversion of PanSH to PPanSH by using the parameterized rate equation Eq.1. The ODEs used to predict the flux are shown below: 𝑑(𝑃𝑎𝑛𝑠𝐻) = −𝑣𝑃𝑎𝑛𝐾 𝑑𝑡 𝑑(𝑃𝑃𝑎𝑛𝑆𝐻) = 𝑣𝑃𝑎𝑛𝐾 𝑑𝑡 The initial concentrations of PanSH and PPanSH were set as 0.5 mM and 0 mM respectively. MtPanK was set at 0.05 mg/ml. ATP was fixed at 5 mM. For the model predictions with inhibitor present, AcCoA and CoA were set at 0.1 mM and 0.05 mM respectively. 4 2.4 Model validation – HPLC: To validate the constructed mathematical model a time-course experiment was set up using high-performance liquid chromatography (HPLC). This method was developed by R.Goosen and uses a thiol-derivation agent CPM to allow for the detection and quantification of compounds containing a thiol group [16]. In this project this method was used to track the conversion of PanSH to PPanSH by measuring the amount of PanSH and PPanSH present in samples taken at different time points. The effect of CoA and AcCoA on the conversion from PanSH to PPanSH was also investigated. The sample preparation and subsequent HPLC analysis was performed according to the method developed by R.Goosen [16]. All HPLC reaction master mixtures contained Tris-buffer (100 mM MgCl2, 500 mM Tris, 200 mM KCl, pH 7.6), 2 mM PEP, 0.04 U/µl PK, 0.02 mg/ml MtPanK, 0.5 mM PanSH and 5 mM ATP. MilliQ was used to prepare stocks, buffers, and mixtures. All reactions were performed at 25 °C. Pantethine was reduced using TCEP (2 mM). The reaction was initiated by adding both substrates (ATP and PanSH) simultaneously. For the reactions containing inhibitor, CoA (0.05 mM) or AcCoA (0.1 mM) were added. At specific timepoints aliquots were removed and added to 90% TCA to stop the reaction. Reactions were then neutralized with NH4OAc (2.25 mM). This was followed by centrifugation of the samples at 10 000 g for 10 minutes. Supernatants were removed, whereafter CPM (0.23 mM) was added, the derivation mixture was left to derivatize overnight. For the HPLC analysis an Agilent 1100 series, with an in-line FLD fluorescence detector was used. Chemstation software package was used to analyse the HPLC data. A reference standard for PanSH and PPanSH was produced by Leanie Mocke (PhD). The HPLC data and reference standard were produced using the combination of a Supelcosil LC-DP Supelguard Cartridge and a Supelcosil LC-DP HPLC. The integration event HPLC data was converted to PanSH and PPanSH concentrations, which was then graphically compared to the mathematical model flux predictions using Mathematica. 3. Results and Discussion 3.1 Initial rate kinetics: In phase 1 of the project the initial rate kinetics of MtPanK were determined using PK/LDH-coupled assays. The regulation of the enzyme by CoA and AcCoA was investigated. The rate equation Eq.1 was constructed and parameterized using the data collected from all the PK/LDH-coupled assays (Table 1). Table 1:Kinetic parameters for MtPanK. The parameters were determined by fitting Eq.1 on all the initial rate assay data sets. The standard error represents the standard error of the parameters calculated from the global fit. kmATP kmPanSH kiCoA kiAcCoA Estimate and Std error 1.65801 ± 0.27 0.347962 ± 0.036 0.0254922 ± 0.0034 0.0913536 ± 0.013 Unit mM mM mM mM Vmax 7.69794 ± 0.41 µM/min/mgprotein 5 As shown in Fig.2(A-C) the reaction rate increases with the increase in substrate concentration. The maximal reaction rate for MtPanK was calculated as 7.70 µM/min/mgprotein. In Fig.2(A&B) it is shown that the Vmax decreases with the addition of increasing concentrations of inhibitor, however Km remains unchanged, thus, CoA and AcCoA acts as a non-competitive inhibitors. CoA and AcCoA inhibits MtPanK with ki-values of 2.55 x 10-2 mM and 9.14 x 10-2 mM respectively, thus CoA is a more potent inhibitor of MtPanK, compared to AcCoA. PanSH presented a lower km value compared to ATP, which indicates that PanSH binds to MtPanK with higher affinity. You must compare your parameter values to values found for other panKs. B A C Instead of substrate, state e.g. ATP, PanSH Figure 2: Solid lines represent rate profiles obtained from the global fit of the rate equation (Eq.1) to all initial rate assay data; dots represent experimental data. Error bars represent SEM. A): Fit of the MtPanK rate equation (Eq.1) to the initial rate assay experimental data (umol/min/mgprotein) in the presence or absence of CoA, while varying PanSH (n=3). B): Fit of the MtPanK rate equation (Eq.1) to the initial rate assay experimental data (umol/min/mgprotein) in the presence or absence of Acetyl CoA, while varying PanSH (n=3). C): Fit of the MtPanK rate equation (Eq.1) to the initial rate assay experimental data (umol/min/mgprotein) with no inhibitor present, while ATP is varied (n=5). State how much enzyme was used, i.e. x ug/ml 6 3.2 Model validation: Phase 2 of the project focused on validating the predicted metabolic fluxes for the conversion of PanSH to PPanSH by constructing a mathematical model using the parameterized rate equation constructed in phase 1. The model was then validated using HPLC. The conversion of PanSH to PPanSH was measured over time. The conversion of PanSH to PPanSH is shown in Fig.3(A-C). All three graphs show an increase in PPanSH, with a simultaneous decrease in PanSH. This confirms that MtPanK is able to convert PanSH to PPanSH, which is the first step of the proposed CoA salvage pathway in M.tuberculosis. Fig.3A shows that the model could predict the in vitro metabolic flux well. However, when 0.05 mM CoA is added (Fig.3B) the model prediction for the PanSH concentration differs from the experimental data. With the addition of 0.1 mM AcCoA the model predicted metabolic fluxes were different compared to the fluxes observed in vitro, which could be due to experimental error as the experiment was only performed once. More HPLC runs should be done in future studies to fully validate the mathematical model and subsequently the rate equation (Eq.1). A B C C Figure 3:(A-C): Model predictions for the conversion of PanSH to PPanSH versus the experimental HPLC data over time. Solid lines represent model predicted values; dots represent experimental HPLC data. A): In the absence of inhibitor (n=1). B): With the addition of 0.05 mM CoA (n=1).C): With the addition of 0.1 mM AcCoA (n=1). State how much enzyme was used, i.e. x ug/ml 7 4. Conclusion: In this project the aims were to kinetically characterize MtPanK, construct a mathematical model and validate the model by HPLC analysis. The project was completed successfully as a parameterized rate equation was constructed (Eq.1). This allowed for the mathematical model to be constructed. The model was validated when no inhibitor was present and partly with the addition of CoA, however, with the addition of AcCoA, the model predicted metabolic flux differed from the in vitro metabolic flux. More HPLC validation experiments are required to fully validate the mathematical model. This project was performed as a part of a larger project, which aims to kinetically characterize and construct a mathematical model for the entire CoA synthesis pathway in M.tuberculosis . The research performed in this project confirmed the presence of the CoA salvage pathway in M.tuberculosis. The data gathered in this project showed that CoA and AcCoA are inhibitors of the CoA salvage pathway in M.tuberculosis. This information could be used in drug discovery to create CoA or AcCoA analogues which could possibly disrupt the CoA salvage pathway. The combination of disrupting the main and CoA salvage pathway could lead to the disruption of the central metabolism of M.tuberculosis. Furthermore, the knowledge gained on the CoA salvage pathway could be carried over to studies focusing on similar pathogens that also possess the CoA salvage pathway. Data availability: All data and supplementary material can be privately requested by contacting Herman de Vries at 19306520@sun.ac.za. Funding and additional information: Funding and all resources used in the study were provided by the Systems biology lab – Biochemistry Deparment, Stellenbosch University. Acknowledgments: I would like to thank Prof. Snoep for being granted the opportunity to conduct this research in the JJJ lab. I would also like to thank Leanie Mocke for her constant help and supervision. Conflict of interest: The authors declare that they have no conflicts of interest with the contents of this article. References: 1. Smith, I., 2003. Mycobacterium tuberculosis pathogenesis and molecular determinants of virulence. Clin. Microbiol. Rev. 16, 463–496. https://doi.org/10.1128/CMR.16.3.463-496.2003 2. WHO, 2019. Progress report on HIV, viral hepatitis and sexually transmitted infections. Geneva, Switzerland: World Health Organization, 2019. 3. AIDSinfo | UNAIDS [WWW Document], n.d. URL http://aidsinfo.unaids.org/# (accessed 6.17.21). 4. WHO, 2021. Global tuberculosis report 2021. Geneva, Switzerland: World Health Organization, 2021. 5. Islam, M.M., Hameed, H.M.A., Mugweru, J., Chhotaray, C., Wang, C., Tan, Y., Liu, J., Li, X., Tan, S., Ojima, I., Yew, W.W., Nuermberger, E., Lamichhane, G., Zhang, T., 2017. Drug resistance mechanisms and novel drug targets for tuberculosis therapy. J. Genet. Genomics 44, 21–37. https://doi.org/10.1016/j.jgg.2016.10.002 8 6. Wellington, S., Hung, D.T., 2018. The Expanding Diversity of Mycobacterium tuberculosis Drug Targets. ACS Infect. Dis. 4, 696–714. https://doi.org/10.1021/acsinfecdis.7b00255 7. Shimizu, S., Yamada, H., 1989. Pantothenic Acid (Vitamin B5), Coenzyme A and Related Compounds, in: Vandamme, E.J. (Ed.), Biotechnology of Vitamins, Pigments and Growth Factors. Springer Netherlands, Dordrecht, pp. 199–219. https://doi.org/10.1007/978-94-009-1111-6_12 8. Strauss, E., 2010. Coenzyme A biosynthesis and enzymology, in: Comprehensive Natural Products II: Chemistry and Biology. Elsevier, pp. 351–410. https://doi.org/10.1016/b978-008045382-8.00141-6 9. Brown, G.M., Reynolds, J.J., 1963. Biogenesis of the Water-Soluble Vitamins. Annu. Rev. Biochem. 32, 419–462. https://doi.org/10.1146/annurev.bi.32.070163.002223 10. Leonardi, R., Zhang, Y., Rock, C., Jackowski, S., 2005. Coenzyme A: Back in action. Prog. Lipid Res. 44, 125–153. https://doi.org/10.1016/j.plipres.2005.04.001 11. Goosen, R., 2016. A comparative analysis of CoA biosynthesis in selected organisms: a metabolite study. Stellenbosch University. 12. Venkatraman, J., Bhat, J., Solapure, S.M., Sandesh, J., Sarkar, D., Aishwarya, S., Mukherjee, K., Datta, S., Malolanarasimhan, K., Bandodkar, B., Das, K.S., 2011. Screening, Identification, and Characterization of Mechanistically Diverse Inhibitors of the Mycobacterium Tuberculosis Enzyme, Pantothenate Kinase (CoaA). J. Biomol. Screen. 17, 293–302. https://doi.org/10.1177/1087057111423069 13. Awasthy, D., Ambady, A., Bhat, J., Sheikh, G., Ravishankar, S., Subbulakshmi, V., Mukherjee, K., Sambandamurthy, V., Sharma, U., 2010. Essentiality and functional analysis of type I and type III pantothenate kinases of Mycobacterium tuberculosis. Microbiology 156, 2691–2701. https://doi.org/10.1099/mic.0.040717-0 14. Vallari, D.S., Jackowski, S., Rock, C.O., 1987. Regulation of pantothenate kinase by coenzyme A and its thioesters. J. Biol. Chem. 262, 2468–71. 15. Björkelid, C., Bergfors, T., Raichurkar, A.K. V., Mukherjee, K., Malolanarasimhan, K., Bandodkar, B., Jones, T.A., 2013. Structural and Biochemical Characterization of Compounds Inhibiting Mycobacterium tuberculosis Pantothenate Kinase. J. Biol. Chem. 288, 18260–18270. https://doi.org/10.1074/jbc.M113.476473 16. Goosen, R., Strauss, E., 2017. Simultaneous quantification of coenzyme A and its salvage pathway intermediates in in vitro and whole cell-sourced samples. RSC Adv. 7, 19717–19724. https://doi.org/10.1039/C7RA00192D 9