ACCA – MA/FMA

MANAGEMENT ACCOUNTING

STUDY NOTES

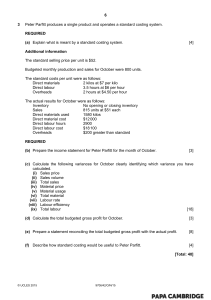

Contents

Sr. #

TOPICS

Page #

1.

COST CLASSIFICATION

01

2.

MATERIALS

16

3.

LABOUR

33

4.

OVERHEADS

48

5.

ABSORPTION AND MARGINAL COSTING

58

6.

OTHER COSTING TECHNIQUES

65

7.

JOB AND BATCH COSTING

75

8.

SERVICE COSTING

80

9.

PROCESS COSTING

83

10.

BUDGETING

90

11.

INVESTMENT APPRAISAL

109

12.

STANDARD COSTING

122

13.

STATISTICAL TECHNIQUES

138

14.

COST REDUCTION

162

15.

PERFORMANCE MEASUREMENT

167

16.

MANAGEMENT INFORMATION

192

17.

SPREADSHEET

217

18.

SUMMAZISING AND ANALYZING DATA

227

Cost Classification

MA/FMA Study Notes

COST CLASSIFICATION

❖ This Chapter Covers:

✓ COST

✓ COST UNIT

✓ COST CENTRE

✓ COST OBJECT

✓ DIRECT AND INDIRECT COST

✓ PRIME COST, PRODUCTION COST AND TOTAL COST

✓ FUNCTIONAL CLASSIFICATION

✓ PRODUCT AND PERIOD COST

✓ CONTROLLABLE AND UNCONTROLLABLE COST

✓ COST CLASSIFICATION BY BEHAVIOUR

✓ ANALYSING COST INTO FIXED AND VARIABLE ELEMENT

✓ APPLYING HIGH LOW METHOD

✓ OTHER COST CLASSIFICATIONS

Page 1

Cost Classification

MA/FMA Study Notes

Cost Accounting: “Cost accounting involves applying a set of principles, method and techniques to determine and

analyse costs within the separate units of a business”.

This involves: The establishment of budgets, standards costs and actual costs of operations, processes, activities or

products and the analysis of variances, profitability or the social use of funds.

Cost: “Any outflow of an item of value against which some benefit is received is called cost”.

Examples of cost can be:

1. Staff salaries e.g. baker’s salary, sales person salary etc.

2. Cost of all baking material like flour, sugar, chocolate etc.

3. Fuel cost

4. Transportation cost

5. Advertisement cost, etc.

Cost types differ from business to business. The larger the business, the more cost types that business might have.

Why organisations need costing systems?

An organisation’s costing system is the foundation of the internal financial information system for managers. It

provides the information that management needs to plan and control the organisation’s activities, and to make

decisions about the future. Examples of the type of information provided by a costing system are:

▪ Actual cost of unit for the latest period.

▪ Actual costs of operating a department for the latest period.

▪ The forecast costs to be incurred at different levels of activity.

Cost unit: “A unit of product or service with which cost is attached”.

For example;

▪ A table or a chair for furniture manufacturer,

▪ Room in a hotel,

▪ Batch of 1,000 sheets,

▪ Patient per night, etc.

Unit Cost: “All expenses carried out to make one unit of a product is called a cost of that unit or unit cost or cost per

unit”.

Cost Center: “A cost center is a production or service location, function, activity or item of equipment for which costs

are accumulated and analysed”. A cost centre is used as a ‘collecting place’ for costs. The cost of

operating the cost centre is determined for the period, and then this total cost is related to the cost

units which have passed through the cost centre.

For example,

Type of cost centre

Examples

Service location

Stores, canteen

Function

Sales, Production

Activity

Quality control

Item of equipment

Packing machine

Page 2

Cost Classification

MA/FMA Study Notes

Cost Object: “A cost object is any activity or item for which a separate measurement of cost is desired”. It can be a

cost unit or cost center. For example the cost of a product, the cost of rendering a service to a bank

customer or hospital patient, the cost of operating a particular department or sales territory, or

indeed anything for which one wants to measure the cost of resources used.

Need to classify cost: Complete set of information of cost to make one unit of product is relevant for management

use but the individual manager will not need complete set of information. For example,

▪ Production manager will need information which relates to make the unit of product.

▪ Stores manager will need information about the cost of raw material and the quantity of products.

That is why we classify cost in different logical groups (more meaningful form) for management use. Sometimes

management has to report internal and sometimes to external bodies.

The aim of a cost classification is to find the costs incurred in the production of a cost unit. This is important for a

number of reasons:

1.

2.

3.

4.

5.

6.

Setting the selling price (so that costs can be covered and a profit can be made)

Decision making (for example if a company is selling two products and has to make a decision to stop selling

one of them, it will decide by determining which of the product is making less profit and profit of course is

determined after finding the cost).

Planning future activities (as a company has limited resources, the planning is done after determining costs)

Control of resources and cost of production (by comparing actual costs with planned costs, we can investigate

the reasons for variances)

Reporting the results of the business (it depends on knowing the costs incurred e.g. the value of stocks etc.)

Budgeting (for the upcoming period)

Cost Classification.

By Nature

By Function

Product & period

cost

Controllable &

uncontrollable cost

By Behaviour

✓ By Nature: By nature cost has three elements: material, labour and expense. It is further divided into direct and

indirect cost.

Direct costs: “A cost that can be directly identifiable with a specific cost unit or cost center is called direct costs”.

For example, Material used in production, Worker paid for making a product, etc.

Indirect costs: “A cost that cannot be directly identifiable with a specific cost unit or cost center is called indirect

cost”. It is jointly incurred and must be shared out on an equitable basis. For example, Salaries,

Rent of the building, etc.

Page 3

Cost Classification

MA/FMA Study Notes

Now we look at each element in detail:

Materials: One with which the product is manufactured, like wood used in chair. It can be direct and

indirect.

Direct Material: The material, which can be directly and easily associated / related with a particular unit of

product / service and it is economically feasible to trace it in the product. It becomes a major part of finished

good. Examples include cloth for a shirt, Paper for a book, etc.

Indirect Material: Materials that cannot be directly traceable or identifiable. It will not become a major part

of product. Also the other materials used in factory which do not become the part of product at all.

Examples are, cleaning materials, lubricants, nails, glue, buttons, etc.

▪

Labour: The payment made to workers for the work they have done is called labour cost. It can be direct

and indirect.

▪

Direct Labour: The Labour/Labour wages which is directly involved in making the product. Examples are,

labour for assembling of chair, wage of carpenter, etc.

Indirect Labour: The wages or salaries paid to the workers which are not directly involved in production,

not making the product. Examples are, maintenance worker wage, raw material storekeeper salary, factory

manager's salary, factory supervisor's salary, etc.

▪

▪

Expense: Cost incurred other than materials and labour is called expenses. These can be direct and indirect.

Direct Expenses: Expenses which are specifically incurred for the job. Examples are special tools for a job,

hire of machinery for production, cost of special designs, etc.

Indirect Expenses: The expenses which are not specific to the production but without those, production

cannot be possible. These are intangible expenses. Examples are, factory rent and rates, factory electricity

bills, machine depreciation, factory repairs and maintenances, etc.

Sum of all direct costs is

called Prime cost

Accumulated under

single head called

‘Overheads’

Cost

Direct costs

Indirect costs

Direct Material

Direct Labour

Direct Expense

Indirect Material

Indirect Labour

Indirect Expense

Prime costs = Direct Materials + Direct Labour + Direct Expense

Production overheads = Indirect Material Cost + Indirect Labour Cost + Indirect Expenses

Page 4

Cost Classification

MA/FMA Study Notes

Production cost = Prime Cost + Production Overheads

Non‐manufacturing overheads = Selling cost + distribution cost + Administration cost + Finance cost + Research cost

Total cost = Production cost + Non‐manufacturing overheads

CONVERSION COST: These are the costs of converting purchased raw materials into finished or semi‐finished

products, i.e. production cost excluding direct material cost.

Conversion cost = Direct Labour + Direct Expenses + Production Overheads

Conversion cost = Total Production Cost – Direct Material Cost

Calculating the cost of a product:

Production cost

Direct material

Direct labour

Direct expense

Indirect material

Indirect labour

Indirect expense

Selling cost

Distribution cost

Administration cost

Finance cost

Research cost

Prime cost

Total manufacturing/

production/factory cost

Manufacturing/

production/factory

overheads

Total cost

of

the

company

Non‐manufacturing/ non‐

production/

non‐factory overheads

✓ By Function: “All activities and operations of the company are called functions”.

Different functions of an organisation: Consider the example of a furniture manufacturing company.

▪ They would have a factory department which is also called as production or manufacturing department.

▪ Also there might be a department helping with all sales (sales and distribution department).

▪ Than businesses also need advertisement and marketing (marketing department).

▪ This business might need a separate function to hire and train employees (Human resource department).

▪ Also to arrange money there might be a separate department (accounts and finance department).

▪ Most businesses also have an administration department to do all the administrative work.

When we classify cost according to the above mentioned functions, this is called as functional classification.

Following is the detail:

1. Production / Manufacturing Costs: Cost incurred in making the goods. There are three main elements of

production costs

● Cost of material: Material costs include the cost of obtaining the materials and receiving them within

the organisation. The cost of having the materials brought to the organisation is known as carriage

inwards.

● Cost of labour: Labour costs are those costs incurred in the form of wages and salaries, together with

related employment costs.

Page 5

Cost Classification

●

MA/FMA Study Notes

Cost of expenses: Expense costs are external costs such as rent, business rates, electricity, gas and

similar items which will be documented by invoices from suppliers.

2.

Selling cost: It is an indirect cost incurred in promoting sales and retaining customers.

● Advertising cost

● Sales promotion

● Printing of catalogues and price list

● Salaries and commissions of salesmen

● Sales department includes costs like staff, rent & rates and insurance of showroom

● Bad debts

● Cost of free samples to customers

3.

Distribution cost: It is an indirect cost incurred in making the packed product ready for dispatch and

delivering it to customers.

● Packing cost

● Wages of packers, drivers, dispatch clerks

● Rent and rates, insurance and depreciation of finished goods warehouse

● Cost of delivery of finished goods

4.

Administration Costs. Normally it includes office related expenses.

● Office Cost

● General manager’s salary

● Accountant’s salary

● Auditor’s fee

● Telephone and Postage costs

● Depreciation of Office Building and Equipment

5.

Financial Costs: Cost incurred when a business has to borrow.

● Interest paid on loans

● Cost for any legal documentation required to acquire loan

6.

Research Costs: Cost incurred before making a product like research work.

● Testing cost in the laboratory in making of medicine.

Important: Functional classification may have more heads, depending on the size and number of activities of an

organisation.

This classification helps in controlling cost, stock valuation and in the preparation of financial statements, etc.

❖ Question‐1: A company manufactures and retails clothing. You are required to group the costs, which are

listed below and numbered 1‐20, into the following classifications (each cost is intended to belong to only

one classification):

a) Direct material

b) Direct labour

c) Direct expenses

d) Production overheads

Page 6

Cost Classification

MA/FMA Study Notes

e)

f)

g)

h)

i)

Research cost

Selling cost

Distribution costs

Administration costs

Finance costs

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

Lubricant for sewing machines

Floppy disks for general office computer

Maintenance contract for general office photocopying machine

Telephone rental plus metered calls

Interest on bank overdraft

Performing rights society charge for music broadcast throughout the factory

Market research undertaken prior to a new product launch

Wages of security guards for factory

Carriage on purchases of basic raw materials

Royalty payable on number of units of product XY produced

Road fund licenses for delivery vehicles

Parcels sent to customers

Cost of advertising products on television

Audit fees

Chief accountant’s salary

Wages of operators in the cutting department

Cost of painting slogans on delivery vans

Wages of storekeepers in raw materials store

Wages of fork lift truck drivers who handle raw materials

Developing a new product in the laboratory

❖ Question‐2: The following data is given of a wooden furniture manufacturer:

$

Wood

5,000

Glue used in manufacturing

250

Leather skin for chairs

6,000

Designing costs of a skin (specific Request of the customer)

350

Machine hire charges

25,000

Other factory overheads

2,200

Selling overheads

1,400

Admin overheads

1,200

Find the prime cost, the production cost and the total cost.

✓ Product & Period Costs:

Product Costs: “Cost incurred on making product is called product cost”. Examples are, Materials, Labour and

expenses for production.

Page 7

Cost Classification

MA/FMA Study Notes

Period Costs: “A cost that does not change, which remains fixed. It relates with the passage of time rather than

the output of individual product or service is called period cost”. Examples are Salaries, Insurance, Rent of

building, etc.

This classification helps in controlling cost, inventory valuation and Absorption and Marginal costing, etc.

✓ Controllable & Uncontrollable Costs: Normally all the cost incurred by an organisation is controllable for

management. But some costs are uncontrollable for a particular manager.

▪

Controllable: A cost which can be influenced by management decisions and actions. Controllable costs can

be controlled by departmental managers for example material costs. Examples are Material used for

production, Labour paid to production workers, etc.

▪

Uncontrollable: A cost which is not influenced by management decisions and actions. These costs are not

under the control of departmental managers like general manager's salary. Examples are, Share of

electricity bills and rent expense of the building between the departments, etc.

✓ By Behaviour: “Cost behaviour is the way the costs change as the level of activity changes.”

The level of activity is the amount of work done or the volume of production (i.e. number of units produced).

Many factors may influence cost. Major influences include volume of output or level of activity. Level of activity

can be referred to in one of the following ways:

Number of shirts produced.

Number of labour hours worked.

Number of machine hours worked, etc.

The common cost behaviour is that level as level of activity rises, cost will usually rise for example it will cost

more to produce 200 units than it will to produce 100 units. However; the problem is to determine which cost

will rise and by how much. Cost behaviour is usually measured according to the number of units produced.

Classification by Behaviour

Variable Costs

Fixed Costs

Stepped Fixed Cost

Semi‐Variable Cost.

➢ Variable Cost: “A cost that varies in total with the change in activity level but remains constant in per unit

is called variable costs”. Examples are;

● Direct costs are mostly variable costs.

● Sales commission is also variable in relation to volume of sales.

● If cost per labour hour worked is constant labour productivity is also constant. This means that

efficiency levels can be determined by analysing variable costs per unit.

Page 8

Cost Classification

MA/FMA Study Notes

Charts:

$ Total cost

$ per unit

0

Activity Level.

0

Activity Level.

Another example for Variable Cost is bonus payment for example when the activity reaches a certain level,

labour might get a bonus. Graph of this is shown below

Cost

$

Bonus

A

Up to Output A, No Bonus Is Awarded

In case of bulk purchase discount the purchase price/unit of raw material is constant and after achieving a

certain level of quantity a bulk purchase discount is given. After this point the price/unit will fall and will be

charged to further purchases and will also be applied retrospectively to all units already purchased. Graph

illustrating bulk purchase is shown below:

Cost

$

Level of activity

Page 9

Cost Classification

MA/FMA Study Notes

If bulk purchase discount is only available on additional units then the graph will change as follows:

Cost

$

Level of activity

If the relationship between total variable cost and volume of output can be shown as a curved line on graph,

the relationship is said to be Curvilinear.

➢ Fixed Costs: “A cost that remains fixed in total with the change in activity level (with a specific range) but

changes in per unit is called fixed cost”. Fixed cost does not depend on the activity level, it relates with the

passage of time. This means that fixed cost per unit decreases with an increase in the level of production.

Examples include the salary of the managing director, the rent of the factory building, straight‐line

depreciation etc.

Charts:

$ Total

costs

$ Per unit

0

Activity Level.

0

Activity Level.

➢ Stepped Fixed Cost: “The cost which remains fixed for a certain level of production, then increases by a

constant amount , and will then remain fixed again until another level of production has been achieved is

called stepped fixed cost.” Examples are,

1. A factory supervisor’s bonus could depend on output. At between 0 and 100 units of production, he

would be paid $200, for 101‐200 units he would be paid $300 and so on.

2. Rent of one factory building would be fixed but if more space needed due to higher output levels,

another building would have to be rented so total rent expense will increase.

3. Basic wages or minimum wage of employees may be fixed (by law) but as output rises more employees

are required.

Page 10

Cost Classification

MA/FMA Study Notes

Charts:

$ Total:

$ In per unit:

1

Activity level

0

Activity level

➢ MIXED COST (SEMI VARIABLE AND SEMI FIXED): “A cost which has both elements fixed and variable is

called semi‐variable cost”. These are costs, which are partly variable and partly fixed. Examples include the

phone bill. It has a fixed element, which is the line rent, and a variable element, which is the cost of a call.

Other examples include:

● Salesman's salary and commission

● Cost of running a car

GRAPH FOR TOTAL MIXED COST

Total Cost

Cost $

Variable cost portion (call charges)

10,000

Fixed Cost (line rent)

Fixed cost portion (line rent)

0

10

100

Activity Level (Units of output)

Here the slope of the line represents variable part of the cost.

Page 11

Cost Classification

MA/FMA Study Notes

GRAPH FOR MIXED COST PER UNIT

$ Cost/unit

1,000

100

0

10

100

Activity Level (Units of output)

❖ Question‐3: Identify the cost behaviour of the costs shown above in the table.

Cost item

X‐ray film used in radiology lab of a hospital

The costs of advertising a music concert

Rental cost of the space occupied by a McDonald restaurant

Property insurance on a coca cola bottling plant

The cost of synthetic material used to make Nike running shoes

Cost behaviour

Variable

Fixed

❖ Question‐4: A company has established the following information for the costs and revenues at an activity

level of 500 units:

Sales revenue

Direct materials

Direct labour costs

Production overheads

Selling costs

Profit

$

40,000

(15,250)

(10,000)

(6,000)

(5,000)

3,750

40% of the selling costs and 60% of the production overheads are fixed over all levels of activity.

What will be the total profit at an activity level of 700 units?

ANALYSING COST INTO FIXED AND VARIABLE ELEMENT

HIGH‐LOW METHOD: This a method used to determine fixed and variable elements of mixed cost. It relies on the

assumption that mixed costs are linear.

APPLYING HIGH‐LOW METHOD: This method consists of selecting the periods of highest and lowest activity levels

and comparing the changes in costs that result from two levels. Application of the method requires the following

steps:

Page 12

Cost Classification

MA/FMA Study Notes

1.

Identify two different levels of activities: the highest and the lowest level of activities and the corresponding

costs.

2.

Find the variable cost per unit by

Total costs at highest activity level – Total costs at lowest activity level

Total units at highest activity level – Total units at lowest activity level

3.

Compare the variable cost with the total costs at either the lowest activity level or highest activity level to

compute the total fixed cost.

Total costs at highest activity level – (Total units at highest level x Variable cost per unit)

OR

Total costs at lowest activity level – (Total units at lowest level x Variable cost per unit)

4.

Form the equation

Total Cost = Total Fixed Cost + Total Variable cost

Total Cost = Total Fixed Cost + (Variable cost per unit x Number of Units)

Y = a + bx

Where,

Y is the dependent variable i.e. the total cost for the period at activity level of X

x is the independent variable, i.e. the activity level

a is the constant, i.e. the total fixed cost for the period

b is also a constant, i.e. the variable cost per unit of activity

ADVANTAGES AND DISADVANTAGES OF HIGH LOW METHOD

Advantages:

● It is easy to use

● Easy to understand

Disadvantages:

● It relies on historical data assuming that level of activity is the only factor affecting cost and historical cost

can reliably predict future cost.

● It uses only two level of activity highest and lowest, which means that the result may be distorted because

of random variation of these values.

❖ Question‐5: The following data was collected for the period of January to March last year:

Months

January

February

March

Sales Units

8,500

9,100

10,200

Total Cost($)

46,000

50,000

54,925

Estimate the total costs when output is 9,500 units using high – low method.

Page 13

Cost Classification

❖ Question‐6: The

total costs

measured as follows:

Output Units

10,000

13,000

11,000

11,500

14,000

12,500

MA/FMA Study Notes

incurred at various output levels for a process operation in a factory were

Total Costs ($)

154,000

190,200

165,325

169,566

181,600

170,000

Using high‐low method, divide the costs of the process operation into fixed and variable cost. Then form the

equation and determine total cost at 16,000 units.

HIGH‐LOW METHOD WITH STEPPED FIXED COST

Sometimes fixed costs are only fixed within certain level of activity and increase in steps as activity increases.

The High‐Low method can still be used to estimate fixed and variable costs.

❖ Question‐7: A company incurs the following costs at various activity levels:

Activity level (units) Total Cost ($)

10,000

$180,000

20,000

$ 310,000

Variable cost is constant within this range but there is a step‐up of $35,000 in total fixed cost for output over

15,000 units. What is total cost for an activity level of 18,000 units?

Months

1

2

3

4

5

Units

1,000

2,000

900

1,200

2,200

Total cost ($)

4,400

7,200

3,000

5,900

7,100

❖ Question‐8: Information;

Fixed cost will increase by $200 when activity level is more than 1,000 units. Variable cost per units will remain

constant. Calculate total cost at 800 units and 1,500 units

HIGH‐LOW METHOD WITH CHANGES IN THE VARIABLE COST PER UNIT

Sometimes there may be changes in the variable cost per unit, and the High‐Low method can still be used to

determine the fixed and variable elements of semi‐variable cost. The variable cost per unit may change because:

● Availability of discounts

● Inflation

Page 14

Cost Classification

MA/FMA Study Notes

❖ Question‐9: The following information relates to the manufacture of Product JK in 20X8:

Output (Units)

200

300

400

Total Cost ($)

7,000

8,000

8,600

For output volumes above 350 units the variable cost per unit falls by 10%. (This applies to all units). Estimate

the cost of producing 450 units of Product JK in 20X9.

OTHER COST CLASSIFICATIONS

Avoidable Costs: Costs which would not be incurred if the activity to which they relate did not exist. For example

variable costs and specifically incurred fixed cost.

Unavoidable Costs: Costs which would incurred whether or not the product is discontinued for example factory rent.

Discretionary Costs: Costs which are incurred as a result of top management decision but cannot be raised or lowered

at fairly short notice like advertisement costs, sales promotion, research cost and training costs.

Page 15

Materials

MA/FMA Study Notes

MATERIALS

❖ This Chapter covers:

✓ MATERIALS

✓ STOCK CONTROL SYSTEM

✓ DOCUMENTS FOR BUYING MATERIAL

✓ STOCKTAKING

✓ STOCK VALUATION METHODS

✓ FREE STOCK

✓ ORDERING STOCK

✓ STOCK CONTROL LEVELS

✓ ECONOMIC ORDER QUANTITY

✓ BULK PURCHASE/ LARGE ORDER DISCOUNTS

✓ ECONOMIC BATCH QUANTITY

✓ ACCOUNTING FOR MATERIAL COSTS

Page 16

Materials

MA/FMA Study Notes

MATERIALS

Material is something with which product is manufactured. For example, wood is to manufacture chair so wood is

material, fabric used in making of shirt so fabric is material, etc. Material can be divided into the following categories:

Direct Material: The material, which can be directly or easily associated / related with a particular unit of product /

service. It becomes a major part of finished good. Examples: wood for a table, papers for a book, etc.

Indirect Material: Materials that are cannot be directly traceable or identifiable. It will not become a major part of

product. Examples: cleaning materials, lubricants, nails, glue, buttons, etc.

Inventory has three types:

Raw material: The goods purchased, which are to be used in the manufacturing of products. For example, plastic is

used for the manufacturing of toys.

Work in progress: When the product is in manufacturing phase that is known as work in progress. It represents the

intermediate stage of converting the raw material to finished goods.

Finished goods: When the manufacturing phase has ended, than we have products which are ready for dispatch are

called finished goods. For example, bike, marker, robot etc.

STOCK CONTROL SYSTEM

Stock control is the regulation of stock levels, which includes putting a value to the amounts of stock issued and

remaining. A business may wish to control stock because:

● Holding cost of stock may be expensive

● Production will be disrupted if there is stock‐out

● Unused stock with short shelf life may incur unnecessary expenses.

A stock control system for materials consist of

● Ordering of stock

● Purchase of stock

● Receipt of stock

● Storage

● Issue of stock

The Storage of Raw Materials: The objective of storekeeping:

● Speedy issue and receipt of materials

● Full identification of all materials at all times

● Correct location of all materials at all times

● Protection of materials from damage and deterioration

● Provision of secure stores to avoid pilferage, theft and fire

● Efficient use of storage space

● Maintenance of correct stock levels

● Keeping correct and up to date records of receipts, issues and stock levels

Page 17

Materials

MA/FMA Study Notes

The store department is responsible for:

● Receipt of goods;

● Storage of materials;

● Issue of materials;

● Recording receipts and issues.

The Purchase of Raw Materials: The purchase of material may be controlled by

● Purchasing only necessary items

● Orders to supplier after considering price & delivery issues;

● Goods received agreed with goods ordered in quantity and quality;

● Price paid is the price agreed when order was placed.

DOCUMENTS FOR BUYING MATERIALS

The company buys materials from the market for making products. The procedures and documents involved in

buying and selling are prime source of cost and revenue information. Their complexity will depend on the type and

size of both the organisation and the purchase. There are some descriptions of these documents:

Purchase requisition: It is a written request sent by the storekeeper to purchase department for buying the goods

when inventory level falls down to the Re‐order level. It is authorised by the supervisor of the stores or the

departmental head who is responsible for department’s budget.

Letter of Enquiry: It is used to determine an appropriate supplier. The purchase department sends out a letter of

enquiry (in case of new supplier) to various suppliers to find out about the price, delivery time, delivery charges,

discounts, terms of payment etc. The suppliers will respond to the letter of enquiry with:

● A catalogue and price list (for standard goods)

● A quotation (for non‐standard goods)

● An Estimate of cost (for services such as building work and repair)

Purchase Order: A purchase order is prepared by purchase department and sends to the selected or existing

supplier. It specifies the quantity, quality and the price of the goods that are to be bought. It is authorised by head

of purchase department. The original purchase order is sent to the supplier. Four copies of the purchase order are

sent to the following:

1. The Purchase department (To keep records)

2. The accounts department (so that when the goods are arrived and invoice is received, the invoice can be matched

with the purchase order for price confirmation)

3. The stores section (for updating the stock records and making arrangements for new stock)

4. The goods received section (so that they can expect to get the goods by the date mentioned on the purchase

order)

Advice Note: Advice note is an agreement which takes place as a result of trade with new supplier or change in terms

and conditions of the trade with the supplier to avoid future disruptions. Confirmation of purchase order is also done

with the sign of this agreement for the supplier.

Delivery Note: Supplier sends delivery note to the customer with the goods. It contains the details of the quantity

of goods send by the supplier. The delivery note has two copies, both are signed by buyer.

1. One copy is retained by buyer for documentation

Page 18

Materials

2.

MA/FMA Study Notes

Other copy is taken back to the supplier by the driver to confirm the supplier that the goods have been delivered

to the right buyer.

Important: If the supplier does not use his own transport, the consignment note will provide the same evidence as

the delivery note.

Goods Received Note (GRN) (internal document): When the goods have been received at the goods received

section, a goods received note is prepared and sent to the other departments so that they know that the goods have

arrived. It is also used to update stock records. Four copies of the goods received note are sent to the following

departments:

1. The accounts department (to check against the invoice and purchase order for quantity confirmation)

2. The stores section (for updating stock records)

3. The purchase department (to confirm that the goods have arrived)

4. The goods received section (will keep a copy in its records)

Invoice: The supplier’s sales department will send the invoice to the buyer’s accounts department detailing the

amount that the company has to pay to the supplier. The buying company should check the invoice carefully to check

the following:

● That the supplier has only charged for the goods which have been received (check Good received note for

quantity).

● That the price and terms are as agreed (look at the purchase order to check price).

● That the calculations on the invoice are correct (including VAT)

If the invoice is correct, an entry is passed in the purchase ledger. The purchase is then recorded in the accounts and

the invoice is paid.

Credit Note: If the invoice sent by the supplier has any error, a Debit Note is send to supplier by the accounts

department and then the supplier will send a credit note (which in effect reverses the invoice).

A credit note may be issued for the whole of the invoice instead of for the incorrect amount only so this way both

the supplier and the company can remove the incorrect invoice from their books and replace it with the correct

invoice. Accounts department of buyer authorises it to make payment against it.

Important: Two types of discounts may be offered by the suppliers:

Trade discount: usually given for larger orders. It is shown as a deduction in the invoice.

Cash discount/Settlement discount: usually given for prompt/immediate payment within a specified period of time.

It is NOT shown as a deduction on the invoice.

If VAT is payable, discounts are deducted from the cost of the goods and THEN VAT is calculated and added to the

invoice. (I.e. the amount net of VAT is coded)

OTHER DOCUMENTS USED IN AN ORGANISATION

There are more documents which are used in the organisation:

Store or material requisition: A material requisition will be completed when materials are needed from stores by

the production department. An officer from production will sign to authorise it, and stores will issue the materials

when the requisition is given to them. It is then used as a source document for:

Page 19

Materials

●

●

●

MA/FMA Study Notes

Updating the bin card in stores;

Updating the stores ledger account in the costing department; and

Charging the job, overhead or department that is using the materials.

Goods or material return note: A materials return note will accompany any unused material back to stores. In effect

this document is reverse of a material requisition and therefore it must contain all the information that is present

on material requisition and will be used as the source document to update the same records. This time, though, the

material will be a receipt into stock and a deduction from the job originally charged with the material issued.

Materials transfers and returns: A material transfer note is usually raised when material issued to one department

is transferred to another department directly. This note shows the name of both, transferor and transferee

departments. This process enables stock ledger accountant to appropriately allocate the cost between two

departments.

Page 20

Materials

MA/FMA Study Notes

Purchase Cycle:

PProduction

Department

Issue Material

Order to regular supplier

Available

(Material Requisition)

Stores

Department

If routine purchase

(Purchase order)

Not Available (Purchase Requisition)

Purchase

Departme

(Quotations)

If first purchase

(Letter of enquiry)

Multiple

suppliers in the

(Advice Note)

Copies:

1 Purchase Dept

1 Stores Dept

1 Goods Receipt

Dept. 1 Accounts

Sending goods

to stores

(Purchase Order)

Selected

Supplier

Goods Received Department

(Delivery Note)

Two copies:

(Goods Received Note)

1 for supplier

1 for goods receipts Dept

(Invoice)

(Credit note)

(Debit note)

Copies:

1 for Goods Receipt Dept

1 for Purchase Dept

1 for Accounts Dept

1 for Stores Dept. (with goods)

Invoice inaccurate

Invoice accurate

Pay the supplier

Accounts Department

DOCUMENTS FOR RECORDING MATERIAL

Purchased inventory is usually kept in warehouses or in stores. There are two types of stock records that are

maintained in the stores; Bin cards and Stock ledger accounts.

Bin Card: It contains the description of material held in stock. It is maintained and kept by the storekeeper for every

material in the stores. It can be manual or computerised inventory records. The information on the bin card would

be as follows:

● Description of the material (type of material)

● Stock code

Page 21

Materials

●

●

●

●

●

MA/FMA Study Notes

Stock unit (meters, kgs, boxes etc.)

Bin number (the location of the items in the store)

Issues to production records: date, quantity, material requisition number against which the material was issued

as a reference number.

Receipts records: date, quantity, good received note, Materials Returned Note (MRN) for goods that were

returned from the production department because they were not used in production (obviously the material will

also be sent back to the store with the materials returned note.)

Balance of the quantity of stock on hand after each stock movement (after each time stock is received or issued)

Note: Bin cards do not have the amounts or cost of stock.

Stock Ledger Account: It is maintained by the accounts department. It records quantities and values (amounts) of

all stock movements made from store department. It can be manual or computerised and this would enable the

amount of free stock to be monitored.

● Stock ledger accounts carry all the information that is in bin cards such as goods received note, material

requisition, material return note details etc, but they also have the value/cost of stock units.

● This means that total cost of each issue, receipt and that of the balance amount is shown in the store ledger

accounts.

Bin cards are kept in the store but the store ledger accounts are kept in the costing department or a separate stores

office where a cost bookkeeping clerk maintains them.

Important: Bin cards and store ledger accounts are kept by separate departments so comparing them to check if the

quantity of stock shown by each match can be a good control to ensure that the records are correct.

Computerised inventory control system: Now‐a‐days many inventory control systems are computerised. Features

of computerised inventory control systems:

a. Data must be inputted into the system: For example details relating to receiving goods may be entered directly

to the computer and after that goods received note will be printed & signed as evidence of the transaction.

Some systems may be devices such as bar code reader.

b. Inventory master file is maintained: This file contains details of every type of inventory and frequently updated

as defined by the company. It also contains details of inventory movement (receipt, issue or return) over a

period but this will depend on the type of system used.

c.

Two types of systems are generally used for recording inventory movement:

● Batch systems: Transactions relating to a certain defined period are grouped separately and then it is

updated to master file only.

● On line systems: Each transaction may be input to the master file directly. In this system, inventory records

are continuously updated that will help in monitoring & controlling inventory.

(The system may generate purchase orders automatically once the quantity in stock has fallen to reorder

level)

System will generate outputs: Outputs can be generated in any form depending upon users.

● Hard copy: Sometimes output may be required in form of paper for evidence purpose like goods received

note.

● Visual display unit (VDU screen): In response to an enquiry like current inventory level or details about a

particular transaction can be just viewed on screens.

Page 22

Materials

●

MA/FMA Study Notes

Printed reports: These reports are devised to fit in with the need of the organisation like inventory

movement reports, GRNs, different notes etc. Computerised inventory control systems are more up to date

and flexible in reporting as compared to manual systems but both systems require same type of data to

function properly.

Other systems of store control & recording:

1. Order cycling method: Under this method, stocks in hand of each material are reviewed periodically (every 1, 2

or 3 months). For low cost materials, a technique called the 90‐60‐30 days technique can be used, so that when

stock falls to 60 days’ supply, a fresh order is placed for 30 days’ supply so as to boost stocks to 90 days’ supply.

For high cost materials a more stringent stores control procedure is advised so as to keep down the holding cost

of stock.

2. Two bin system: In this method, each item of stock stores in two storage bins. When the first bin is empty, an

order must be placed for new suppliers, the second bin will contain enough quantity to be used until the first

order is received. It is a simple method not based on any formal analysis of usage so it may result in holding too

much quantity or too little.

3. Classification of material methods: In this method materials are classified in three categories:

● Expensive material

● Middle cost range material

● Inexpensive material

Expensive and medium cost materials require careful store control procedures to minimize cost.

On the other hand inexpensive material can be stored in large quantities because fewer controls are required.

This method is also called ABC method under which materials are classified in A, B or C groups (A is more

expensive material, B is medium cost material & C is inexpensive materials)

STOCKTAKING

A stock taking is the counting and recording of the physical quantities of each item of stock at regular interval

(monthly or annually) and the checking the balance against the stock record. If all receipts and issues of stocks are

correctly recorded, then total quantity counted should agree with the balance in the bin card and stock ledger

account. There are two methods of stocktaking:

● Periodic Stocktaking: All stocks are counted and updated on specific date periodically, usually at the end of the

accounting period.

● Perpetual and Continuous Stocktaking: All stocks are counted and updated after each transaction. Valuable

items are checked more frequently.

Advantages of continuous stocktaking compared to periodic stocktaking: Though the greatest disadvantage is

the time and manpower factor as it involves more frequent stocktaking, there are many advantages of

continuous over periodic stocktaking:

▪ It improves the quality of the physical stocktaking as there are more frequent physical counting;

▪ It allows stock discrepancies to be more fully investigated as more time is available;

▪ Maintain a higher working standards as the warehouse personnel know that they need to count the stock

more frequently;

▪ Production hold‐ups, a common issue in periodic stocktaking are eliminated.

▪ Deficiencies and discrepancies are detected sooner than they would be if there was an annual stocktaking

system in place.

▪ Control over inventory levels are improved as there is less likelihood of overstocking or running out of stock.

Page 23

Materials

MA/FMA Study Notes

STOCK DISCREPANCY

It is the difference between the physical and reorder quantity of inventory. The reasons for stock discrepancy

should be investigated and adjustments should be made accordingly if needed. There are some possible

adjustments:

Reasons for differences

Action taken

1. error in recording or calculating

correct the bin card

2. omission of goods received or issues

correct the bin card

3. stock store in wrong position

move back to correct place

4. goods may be stolen

review security system and goods written off as an

expense

STOCK VALUATION METHODS

Pricing of Materials Issued: Materials are purchased in large quantities at different prices and issued to production

in smaller lots. It is necessary to price the material requisitions so that the cost centres (and cost units) can be

charged in a fair and consistent manner.

Methods of pricing of raw materials:

1. FIFO (First in first out)

2. LIFO (Last in first out)

3. Weighted average (AVCO)

4. Periodic weighted average pricing method

1.

2.

First in First out (FIFO) Method: In this method, the inventory is used from the earliest purchases.

● The earliest price of materials is used for each issue.

● If prices are rising, issued price will be lower, vice versa.

● Closing stock is valued at most recent prices.

Advantages

● This method is adopted by most of the organisations as this method assumes the oldest receipts are issued

first.

● Issued prices are based on the prices actually paid for the stock.

● Closing stock values are based on the latest prices.

● It is an acceptable method for company act 1985, IAS 2, and for taxation purposes.

Disadvantages

● It uses the older prices and this can affect the costing of worked done.

● In time of rising prices FIFO value stock at out of date prices which lower the cost of sales figure thus

increases the profit figure which is not prudent.

Last in First out (LIFO) Method: In this method, the inventory is used from the latest purchases.

● The most recent price of materials is used for each issue.

● If prices are rising, issued price will be higher, vice versa.

● Closing stock is valued at the earliest prices.

Page 24

Materials

MA/FMA Study Notes

Advantages

● The value of closing stock is based on prices actually paid for the stock.

● Issues are valued at the most recent prices so it incorporates the prudence concept.

Disadvantages

● It is less realistic than FIFO since it assumes that the most recent purchases will be issued before the older

stock.

● LIFO is unacceptable for the purpose of taxation and IAS 2.

3.

Weighted Average Price Method: In this method, a weighted average rate is calculated before each stock issue,

whenever, two or more quantities at different rates is found in the balance. All issues are made at the weighted

average rate.

● Weighted average rate is calculated by dividing total cost of different quantities with the quantities sum.

● Weighted average rate is calculated before every issue.

● Issue price will be between FIFO & LIFO methods for example average price.

● Closing stock valued at weighted average rate.

Advantages

● Since prices are averages, it recognises that issues from stock have equal value to the business and variation

in these values is minimized.

● The value of closing stock will be fairly close to latest price paid for purchases.

● AVCO is an acceptable method for purpose IAS 2 and company act 1985.

Disadvantages

● Time consuming.

● It involves complex calculations

● The prices charged to the issues of stock will not agree to the price paid to purchase the stock

4.

Periodic Weighted Average Pricing Method: In this method, a weighted average rate is calculated for the whole

period on the basis of the period receipts. It is calculated at the end of the period, as it has to incorporate all

receipts (and their values) of the period. All issues are made in the period but are valued at the end of the period

at the periodic weighted average rate. Periodic weighted average rate is calculated as:

Periodic Average price per unit =

Cost of opening stock + Cost of all receipts in the period

Opening stock units + no of units received in the period

❖ Question 1: Receipts during the month are given below

January 8

800 tonnes @ $50 per tonne

January 16

500 tonnes @ $60 per tonne

January 26

700 tonnes @ $70 per tonne

During the same period four materials requisition were completed for 300 tonnes each on January 10,

19, 25 and 29.

Page 25

Materials

MA/FMA Study Notes

Required: Calculate the cost of issues and value of closing stock using each of the following valuation methods:

a. FIFO

b. LIFO

c. Weighted average

d. Periodic average

Comparison of FIFO, LIFO and AVCO

● The values for AVCO lie between those for LIFO and FIFO. This should always occur because AVCO is an averaging

method.

● Both LIFO and FIFO require records to be kept of each batch of purchases so that the appropriate price may be

attached to each issue.

● Price fluctuations are smoothed out with the AVCO method which makes the data easier to use for decision‐

making, although the rounding of the unit value might cause some difficulties.

● Many management accountants would argue that LIFO provides more relevant information for decision‐making

because it uses the most up‐to‐date price.

● However LIFO may sometimes confuse managers, since the pricing method represents the opposite to what is

happening in reality, that is, the items in store will probably be physically issued on a FIFO basis.

● The prices of receipts are rising during the month. Therefore the FIFO method, which prices issues at the older,

lower prices, results in the highest value of closing inventory and the highest profit figure. The AVCO method

produces results that lie between those for FIFO and LIFO.

FREE STOCK

Free stock means the stock available for use without any restrictions. When a material requisition from the

production department is received at the store, it is important to ensure that only that stock is issued which is ‘free’

(that has not been already scheduled to be used in production or allocated to a job). When an order is received from

a customer, the required quantity of material is reserved, to ensure the order is complete in the given deadline. Free

stock is calculated as:

Free stock = Stock in hand + Stock on order (with supplier) – Reserved/scheduled stock.

❖ Question 2: A business has 8,400 units outstanding for Material X on existing customer's orders. There are 4,000

units in stock and calculated free stock is 5,650 units. How many units does the wholesaler have on order with

his supplier?

ORDERING STOCKS

Some organisations place orders according to their plans of future production or sales. They planned on the basis of

the purchase and sales requirements for the upcoming period.

For Retail Business: One which purchases and sales goods. It considers sales demand, because purchases are made

in accordance with sales requirements. Order quantity is calculated as;

Order quantity = Sales requirements + Closing stock– Opening stock

For Manufacturing Business: One which buys raw materials from the market, convert it to products and sells them.

It buys raw materials as per the production requirements. Order quantity is calculated as;

Order quantity = Production requirements + Closing stock– Opening stock

Page 26

Materials

MA/FMA Study Notes

Production units can be calculated using the following equation.

Production units = Sales units + Closing stock – Opening stock

❖ Question 3: A company buys and sells Deltas. At the beginning of June the store’s manager realizes that there

are only 35 Deltas in stock and decides to order more. He determines from the sales department that the

planned sales for the next 3 months are as follows;

June

July

August

Planned sales

120

150

130

The store’s manager feels that there will be 50 Deltas in stock at the end of August. How many Deltas must be

ordered?

❖ Question 4: A business makes a product, the Eel, each unit of which requires 4kgs of material X. At the end of

July, the store’s manager decides to place more order for material X as there are only 220 kgs in stock at that

date. The production plans for the next 2 months are 400 Eels in August and 500 Eels in September. At the end

of September it is planned to have 300 kgs of material X in stock. How much of material X should be ordered?

STOCK CONTROL LEVELS

Stock control levels are maintained to avoid stock out situation. Stock out situation is when too little stock is left that

regular orders cannot be made. All expenses and losses suffered by the business as a result of stock out situation

are called stock out cost. There are three stock control levels maintained to minimise the chances of stock out. The

purpose is to ensure only the right quantity of stock is held, not over or under stocking.

Reorder Level: It is also called replenishment order level. When stock reaches this level, it indicates that ordering of

stock is necessary. At this level, even if usage is at maximum level and the lead‐time is the longest, there will still be

no stock‐out situation. It can be calculated as;

Reorder level = Maximum Usage x Maximum lead time

Lead time: Lead time is the time between placing the order and receiving the goods.

Maximum Level: This identifies the maximum quantity of stock to keep. It avoids cost of over‐stocking. The stock

level should not exceed from this level. It can be calculated as;

Maximum level = Reorder level + Reorder quantity – (Minimum usage x Minimum lead time)

Reorder quantity: Reorder quantity is the number of units of stock ordered each time when re‐order level is reached.

If it is set so as to minimise the total costs associated with holding and ordering stock, then it is known as EOQ.

Minimum Level: This is the lowest quantity of stock that should be kept. This level warns the danger of stock‐out.

When stock reaches this level, emergency action will have to be taken to avoid stock‐out.

Minimum level = Reorder level – (Average usage x Average lead time)

Note: Safety stocks (or buffer stocks) are level of units maintained in case there is unexpected demand. Buffer

Stock/Safety Stock can also be calculated using Minimum Level formula.

Page 27

Materials

MA/FMA Study Notes

❖ Question 5: Mike Ltd has the following information:

Reorder quantity

2,500

units

Usage per month:

Estimated delivery period:

Max

Min

Max

Min

1,000 units

700 units

8 weeks

4 weeks

Required: Calculate

● The reorder level

● The maximum level

● The minimum level

It is also important to understand the concept of average stock for stock control purpose:

Average Stock: Average stock is the average between the minimum stock level and the highest possible stock level.

It is calculated as;

Average stock = Safety stock + ½ reorder quantity

❖ Question 6: A component has a safety stock of 600 units and the reorder quantity is 4,000 units and at a rate of

demand which varies between 200 and 650 units per week. What is the average stock?

STOCK COSTS

Stock costs include purchase costs, holding costs, ordering costs and stock out costs.

Stock‐out cost: If stock is kept too low, there is a risk of stock‐out, for example production stoppage, loss of customer

goodwill, loss of sales, labour idle time and extra cost for urgent re‐orders.

Purchase cost: The cost of buying the material. This is the largest cost faced by an organisation and once purchased,

stock has to be carefully controlled and checked. It can be reduced through availability of bulk purchase discounts.

Page 28

Materials

MA/FMA Study Notes

Holding cost: The costs incurred in keeping and storing stock, for example interest charges, insurances, electricity

and water, storekeeper's wages and risk of obsolescence, pilferage and deterioration. A company has to make a

balance between keeping the stock for production and having an amount of working capital tied up in stock. It can

be reduced through ordering less quantity in an order. Reasons of holding stock are:

● To ensure sufficient quantity is available to meet future demand.

● To meet future shortage of required material.

● To avail bulk purchase discounts.

● To avoid blockage in production process.

● To avoid stock‐out costs.

Ordering cost: The costs involved in ordering, receiving and paying for stock for example administrative costs for

contacting supplier to place an order, transport costs, filing paper works, receiving goods, checking quantities and

paying invoices. It can be reduced through ordering more quantity per order.

The cost should be considered when determining optimum stock level consists of holding costs and ordering costs.

To maintain stock at optimum level and to minimise cost, the total costs of holding and ordering stock a company

can

● Order in large quantity by placing a few orders

● Order in small quantity and placing many orders

● The aim of stock control is to minimize stock costs.

ECONOMIC ORDER QUANTITY (EOQ)

The Economic Order Quantity (EOQ) is the optimized order size/ quantity that will result in minimum total annual

cost. In other words, it is the economic stock replenishment order size which minimizes stock costs. At EOQ, ‘Total

annual holding cost’ is equal to the ‘Total annual ordering cost’.

Assumptions / Limitations of EOQ model

● Demand is constant throughout the year.

● Lead time is constant or zero (for example suppliers are reliable)

● Purchase price per unit is constant (for example no bulk discounts)

● Holding cost per unit will be constant per annum.

● Ordering cost per order will be constant

● No safety stock

● Average stock concept

● Ignore any uncertainty.

EOQ formula is

Where, D: expected annual sale (demand)

Ch: cost of holding one item of stock for one year

Co: cost of placing one order

Page 29

Materials

MA/FMA Study Notes

Total annual costs = Total annual purchase cost + Total annual ordering cost +Total annual holding cost

No. of orders

= D/EOQ

Frequency of orders

= EOQ/D x 365 (if required in days)

Annual ordering cost

= No. of orders x Co

Annual holding cost

= (EOQ/2 + Safety stock) x Ch

Annual Purchase cost

= D x Purchase Price

EOQ GRAPH

The total costs are at a minimum for an order quantity at point Q, which is EOQ. It is also a point where the holding

cost curve intersects with the ordering cost curve. Which means annual ordering costs and annual holding costs are

equal at the point of intersection.

❖ Question 7: The demand of a company’s particular stock item is 25,000 units per year. The cost of ordering that

stock item is $32 per order and it costs $6.40 per item to store for a year. The purchase price is $16 per stock

item.

Required:

a. What is EOQ?

b. Calculate the number of orders will be placed?

c. What is frequency of orders?

d. What is the annual ordering cost?

e. What is the annual holding cost?

f. What are the total costs?

BULK PURCHASE / LARGE ORDER DISCOUNTS

Frequently, discount will be offered for ordering in large quantities. When bulk discounts are available we have two

options; take advantage of discount by ordering a larger quantity or ignore the discount offer and go for economic

order quantity. We take the decision based on mathematical calculation.

We choose the option under which the sum of three costs; total purchase cost, total inventory holding cost and total

inventory ordering cost, is minimised. The total cost under two options is compared at following level:

● Pre‐discount EOQ level.

● Minimum order size to earn discount.

If total cost is minimised at pre‐EOQ level then discount offer should be ignored outright and vice versa.

Page 30

Materials

MA/FMA Study Notes

It may be solved by the following procedures:

● Calculate EOQ as usual, ignoring discounts.

● If this is below the quantity which must be ordered to obtain discounts, calculate total annual stock costs at EOQ.

● Recalculate the total annual stock costs using the order size required to just obtain the discount.

● Compare the cost of steps 2 and 3 with the saving from the discount and select the minimum cost alternative.

● Repeat for all discount levels to determine the best ordering quantity.

The ways in which discounts might affect the order size and the total costs:

● Discounts are likely to lower the total purchase cost and it will likely to increase order size in order to obtain

discount in bulk purchases

● The total ordering cost will be reduced as the increase in order size will lower the number of orders.

● The total holding cost will be increased or decreased. The increase is due to the increase of the number of average

stocks held annually but if the holding cost is a percentage of purchase price, then the holding cost will per unit

per annum decrease when the purchase price decreases.

❖ Question 8: Ralph purchases raw material at a cost of $96 per unit. The annual demand for the raw material is

4,000 units. The holding cost per unit is 10% and the cost of placing an order is $300.

Required:

a. Calculate EOQ?

b. How many orders will be placed?

c. What will be the frequency of order?

d. Calculate the annual ordering cost?

e. Calculate the annual holding/stock holding cost?

f. Calculate total annual inventory cost at EOQ?

The supplier offers an 8% discount for orders of 1,000 units or more at a time.

g. Ascertain whether the company should secure the discount?

ECONOMIC BATCH QUANTITY (EBQ)

Economic Batch Quantity (EBQ), also called Optimal Batch Quantity or Economic Production Quantity, is a measure

used to determine the quantity of units that can be produced at minimum average costs in a given batch or

production run.

Where: Co = cost of setting up a batch

D = Demand per period

Ch= holding cost per unit per period

R = production replacement rate/production rate per period.

❖ Question 9: Which of the following statement is true about economic batch quantity (EBQ)?

a. EBQ gives even better result for reorder quantity compared to EOQ

b. EBQ means ordering quantities in large batches for each inventory component

c. EBQ means that once our stock level reaches to half of optimal level, new order should be placed

d. EBQ concept is used to determine optimal quantity that should be produced

Page 31

Materials

MA/FMA Study Notes

❖ Question 10: Gera is a manufacturing company. It produces goods and sent them to stores. Demand is met

throughout the year from this finished goods stock. The company can manufacture 40,000 units a month.

Machine set up costs are $2,500 per machine set up. Holding cost is $12 per month. Monthly demand for the

product is 30,000 units. What is economic batch quantity (EBQ)?

a. 7,071 units

b. 3,535 units

c. 6,124 units

d. 1,2640 units

ACCOUNTING FOR MATERIAL COSTS

The opening balance of materials is a debit balance because it is a current asset (i.e. it will come on the debit side of

the materials control account.)

Entries

1. Purchase of material (in an integrated system of accounts)

Debit Material control account

Credit Creditors account

Purchase of materials (in an interlocking system of accounts)

Debit Material control account

Credit Cost ledger control account

2. Direct material issued to production

Debit Work in progress control account

Credit Material control account

3. Indirect material issued to production

Debit Production overhead control account

Credit Material control account

4. Direct material returned to stores.

Debit Material control account

Credit Work in progress control account

5. Indirect material returned to stores.

Debit Material Control account

Credit Production overhead control account

Material account and its contents are given below:

Materials Control Account

Opening balance

Purchases

$

X

X

Returned to stores:

Direct Material (WIP)

Indirect Material (Production OHs)

X

X

$

Issued to production

Direct materials (WIP)

Indirect materials (Production OHs)

Written off

Return to supplier

Theft / Loss

Closing Balance

Page 32

X

X

X

X

X

X

Labour

MA/FMA Study Notes

LABOUR

❖ This Chapter Covers:

✓

LABOUR

✓

RECORDING OF LABOUR COST

✓

LABOUR REMUNERATION METHODS

✓

OVERTIME AND OVERTIME PREMIUM

✓

RECORDING OF LABOUR COST (DOCUMENTATION AND PROCEDURE)

✓

PERFORMANCE MEASUREMENT OF USING STANDARD HOURS

✓

BONUS SCHEME

✓

LABOUR TURNOVER

✓

ACCOUNTING FOR LABOUR COST

Page 33

Labour

MA/FMA Study Notes

LABOUR

Labour cost represents the human contribution to production. It is the cost paid to workers in exchange of the work

they have performed. It is an important cost factor requiring constant measurement, control and analysis. It is

classified as;

Direct Labour Cost: It can be specifically traced to or identified with a particular product/service. They are directly

involved in making a product. For example, wages of stitching worker in a garments company, doctor in a hospital,

accountant in a firm, etc.

Indirect Labour Cost: It cannot be specifically traced to or identified with a particular product/service. They are not

directly involved in making a product. For example, Admin manager’s salary and supervisor’s salary, maintenance

worker’s salary, etc.

Measuring Labour Activity: Production and productivity are common methods of measuring labour activity.

Production: It is the quantity or volume of output produced by worker.

Productivity: It is the measure of the efficiency with which output has been produced. It is the comparison of

input with the output.

PLANNING AND CONTROLLING PRODUCTIVITY

Production levels can be raised by

● Working overtime

● Hiring extra staff

● Subcontracting some work to an outside firm

● Managing the work force so as to achieve more output

Productivity if improved, the company will enable to produce its products in fewer hours therefore it will reduce

labour cost per unit.

Automation: When the automation (machinery) is introduced, it often increases productivity but then the

productivity will be correctly measured as output per machine hour, instead of per man hour.

Production levels can be reduced by

● Cancelling overtime

● Laying off staff

RECORDING LABOUR COST

Several departments are involved in the collection, recording and costing of labour. These include:

● Personnel;

● Production planning;

● Timekeeping: responsible for recording the attendance time and the time spent in the factory and spent on

particular job by each employee;

● Payroll: Labour costs paid to employees according to records;

● Cost accounting.

Page 34

Labour

MA/FMA Study Notes

Pay‐slips: Records showing how each employee's pay has been calculated are known pay‐slips. These are produced

payroll section in calculation of wages and salaries. It contains the details of hours (basic and overtime) worked,

incentives paid and the deductions made from salaries and wages.

Personnel Department: The personnel department is headed by a professional personnel officer trained in managing

people, labour laws, company personnel policy and industry conditions. The professional personnel should have an

understanding of the needs and problems of employees. He/she is responsible for:

● Engagement, transfer and discharge of employees

● Classification and method of remuneration

Production Planning Department: The production planning department is headed by a professional person, who

has good understanding of production techniques, product quality standards and industry conditions regarding

machinery and workers skills and expertise. The production planning department is responsible for:

● Scheduling work

● Issuing job orders to production department

● Chasing up jobs when they run late

Remuneration Payment Methods

Time related

Fixed Salary

Hourly Base

Rate payment

Output related

Straight Piece

rate payment

Differential Piece

rate payment

Guaranteed Piece

rate system

✓ Time Related

This is the most commonly used remuneration method. Under this system, employees are paid on the basis of

hours, days, week or month they work. It contains two systems, fixed salaries hourly base rate payments.

1. Fixed Salary: A fixed salary, which employee receives after particular time intervals (usually weekly,

monthly). It does not depend on output produced. Employees paid on fixed salary basis are required to work

specific hours. Either the employees would be paid extra or not when they work more than the required hours

depends on the business’s policy.

2. Hourly Based Rate Payments / Day Rate System: In this system, employees are paid on hourly basis of

number of hours worked they have worked. The company has decided a rate per hour with the worker, which

is fixed for each hour worked. It can be calculated as:

Hourly pay = Number of actual hours worked x standard rate per hour

Advantages and Disadvantages of time related pay:

Advantages: This system has some advantages including

● Simple pay system, both for employee and employer.

● Employees are only paid for the time they work.

● It focuses on quality of product rather than quantity.

Page 35

Labour

MA/FMA Study Notes

Disadvantages: This system has some serious drawbacks including

● Pay system is time based rather than output or performance based.

● There is no motivational impact on this pay system

● Employees may try to remain present in order to become entitled to the wages rather than focusing on

performance/output

In order to improve performance, employees need to be kept motivated. A time based system is not so

designed.

✓ Output Related (Piecework)

Under this system employees are paid based on output they have produced. Employees are paid for the good

units produced. This system is normally used for the production workers. It is further split into straight piece

rate system, differential piece rate system and guaranteed piece rate system.

1. Straight Piecework: Employees are paid according to the number of units that they produce in a period

at a flat rate per unit. Employees earn more as they produce more. There is no motivation for the employees

in this system as the rate remain unchanged.

Basic pay=Number of good units produced x standard rate per unit

2. Differential Piecework: Differential piecework system is where a higher amount per unit is paid the more

the employee produces. In this system, different band rates are offered which are applied on different range of

outputs. Only the additional units qualify for the higher rate. Such a differential system is too common

nowadays. This system is designed to improve productivity and employee morale but may have adverse effects

on employee health and social life.

❖ Example 1:Payments by differential piece rates for an organisation are as follows:

Up to 99 units per week

$1.75 per unit

100 to 119 units per week

$2.00 per unit

120 or more units per week $2.25 per unit

If an employee produces 103 units in a week how much will he be paid?

3. Guaranteed Piecework: Guaranteed piecework system is where the employee is paid a guaranteed amount

of minimum pay in case there is not enough work available for each employee.

❖ Example 2:A piecework system works as follows:

$3.2 per unit for up to

40 units per week

$3.5 per unit for 41 units to

50 units per week

$3.8 per unit for each unit over

50 units per week

There is a guaranteed weekly wage of $120 per week. One employee has produced the following

amounts for the last 2 weeks

Week 1 35 units

Week 2 44 units

Required: What is the employee’s gross wage for week 1 and 2?

Page 36

Labour

MA/FMA Study Notes

IDLE TIME / DOWN TIME

It is the time which is paid for at normal basic rate but in which no work is done. It is also known as non‐productive

time. It is always treated as an indirect labour cost for both direct and indirect workers. It cannot be in overtime but

overtime may arise due to idle time. Idle time hours are deducted from the normal basic hours.

Reasons for idle time: There are some possible reasons for idle time.

● Production disruption

● Machine breakdown

● Shortage of material