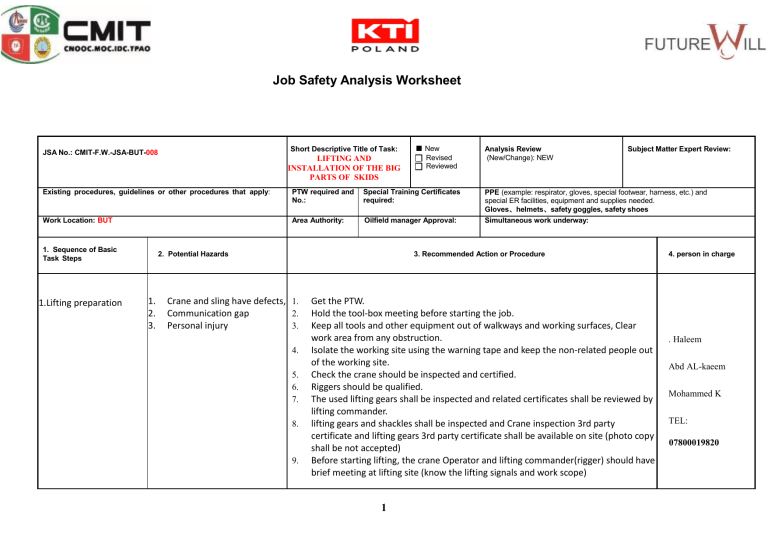

Job Safety Analysis Worksheet Short Descriptive Title of Task: JSA No.: CMIT-F.W.-JSA-BUT-008 LIFTING AND INSTALLATION OF THE BIG PARTS OF SKIDS ■ New Revised Reviewed Existing procedures, guidelines or other procedures that apply: PTW required and No.: Special Training Certificates required: Work Location: BUT Area Authority: Oilfield manager Approval: 1. Sequence of Basic Task Steps 1.Lifting preparation 2. Potential Hazards 1. 2. 3. Analysis Review (New/Change): NEW Subject Matter Expert Review: PPE (example: respirator, gloves, special footwear, harness, etc.) and special ER facilities, equipment and supplies needed. Gloves、helmets、safety goggles, safety shoes Simultaneous work underway: 3. Recommended Action or Procedure Crane and sling have defects, 1. Communication gap 2. Personal injury 3. 4. 5. 6. 7. 8. 9. Get the PTW. Hold the tool-box meeting before starting the job. Keep all tools and other equipment out of walkways and working surfaces, Clear work area from any obstruction. Isolate the working site using the warning tape and keep the non-related people out of the working site. Check the crane should be inspected and certified. Riggers should be qualified. The used lifting gears shall be inspected and related certificates shall be reviewed by lifting commander. lifting gears and shackles shall be inspected and Crane inspection 3rd party certificate and lifting gears 3rd party certificate shall be available on site (photo copy shall be not accepted) Before starting lifting, the crane Operator and lifting commander(rigger) should have brief meeting at lifting site (know the lifting signals and work scope) 1 4. person in charge . Haleem Abd AL-kaeem Mohammed K TEL: 07800019820 1. 2. 2. Lifting 1.Crane damage. 2.Cargo damage. 3.Finger crushed. 4.Load falling. 5.Caught between load and crane/structure. 6. Outrigger losing stability. 7.Structural damage. 8.Buildings, equipment damage by carne boom. 9.Hoisting equipment breakdown. 10. Poor or lack of communication. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 3. Skid Installation Sand Removal / Fiber Ball 1.Hand injury / Finger crushed 2.Falling from heights. 3.Caught between skid and structure/ground. 4.Slip and trip. 5.Falling from same level. 6. Bruising. 7.Equipment damaged by contact with skid. 8.Skid damaged during installation. Prepare PTW for this activities and have them sign by relevant departments. TBT+JAS to all involves workers. Lifting operation to be explained in advance to all workers. Lifting Plan available and approved by all PMC,Contractor and FCD. Training and qualifications of operator valid/update and appropriate for this job. Check by PMC, contractor and WTP HSE crane technical conditions, outriggers extensions and hoisting equipment – before actual lifting start. Check slings, taglines and shackles for internal and/or external damages. Should be under validation time. Perform lift test for heavy equipment, in a safe area. Barricade lifting area and check wind speed (10.8 m/s), before lifting. Create exclusion zone for pedestrians. Post warning signs. Prohibit lifting during foggy and/or rainy weather. Designate lifting coordinator and rigger in charge of this lifting. Have them dress in distinctive colors. Only one person is communicating with crane operator. Apply communication methods. Prohibit to stand and/or walk under the load during lifting. Provide tag lines for direction of the load. Ground area used by the crane should be level, compacted and no underground pipes/cables located under the crane surface. During lifting is prohibit that load and/or boom pass over live CPD facilities (pipes, vessels, reactors etc.). Avoid SIMOPS activities at all time. Emergency Units (fire truck, ambulance) stand by for intervention in case that lifting is failing. Supervision at site all time from HSE and Civil Department. 1. 2. 3. 4. 5. 6. 7. Prepare PTW for this activity and have them sign by relevant departments. TBT+JAS to all involves workers. Provide full PPE for all workers involved in this operation. Barricade work area and place warning signs during this installation. Supervision at site all time from HSE and relevant department. Skid should be proper secured on his position before installation work start. Follow design from drawing in order to prevent any malfunctions, that could jeopardize worker’s life. 8. Provide safety harness is necessary to perform working at height. 9. Avoid SIMOPS activities, during skid installations. 10. First Aid Kit on site – and Emergency units (ambulance, fire truck) if is necessary. 2 . Haleem Abd AL-kaeem Mohammed K TEL: 07800019820 . Haleem Abd AL-kaeem Mohammed K TEL: 07800019820 4. Housekeeping 1.Back pain. 2.Slip and Trip. 3.Falling from same level. 4.Hand injury. 5. Bitten by venomous animal/insects. 1. 2. 3. 4. Move all materials, tools, equipment and waste out of CPD area, when work is completed. Make sure that no materials, tools and/or equipment was left behind. Maintain fix barricade in area, if situation is required. Post warning signs. Garbage bags resulting from housekeeping to be loaded in trucks and removed from CPD area. All the staffs working on the site ensure to be familiar with the details above, and follow the instruction. SIGNATURE: 3 . Haleem Abd AL-kaeem Mohammed K TEL: 07800019820 4