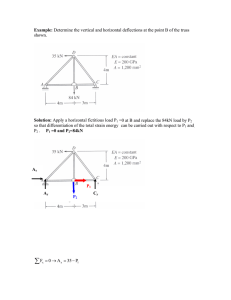

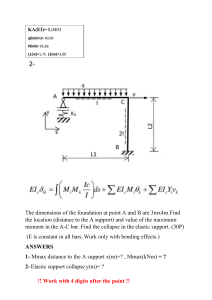

Analysis of portal frame building In accordance to EN 1993-1-1(2005) 1 description A/ The portal frame is the main structural element of the building. The frame is designed for the following loads Roof loads such as workmen, snow or hail Wind loads Wind loads can be positive as on AB or negative (suction)as on BC,CD and DE. Roof loads are positive and up to down direction B/ If The joints at B,C and D are not rigid,they will open up and the frame will be unstable C/ 1) Vertical loading on the frame results in A and E tending to be pushed outwards.if the foundation cannot resist this horizontal push,outward movement will occur,and the frame will l oose structural strength 2) Wind subjects the portal frame to uplift forces(the roof tends to fly-off)like an overturning forces on the sides and ends of the building, plane wing,to These destabilizing forces are resisted essentially by the weight of the building,and in this regard,the foundations contribute significantly to this weight. Generally speaking it is a fact that portal frame buildings of this kind are light weight structures, and as such they tend to collapse “sideward” and “upwards” rather than do wnwards”. The effect of wind on a light building cannot be overemphasized. The destabilization it causes is a major design consideration, and in this context, foundations can be regarded as the building’s “anchors D/ the rafter of the portal frame is a slender structural element,and it is restrained it will buckled when loaded. In a braced roof this restraint is provided by the purlins acting together with a braced bay.The purlins provide the restraining force for the rafters,and the braced bay acts as a “buttress” wich absorbs these purlin restraining forces. While this system is effective in restraining the top flange of the rafter I-beam,the bottom flange remains relatively unrestrained, and to achieve the requisite restraint,short lengths of angle iron are connected at intervals between the bottom flange of the I-beam and the purlins.This simple and necessary anti-buckling feature is sometimes neglected in the design of the portal frames. E/ A building frame subjected to wind forces along its length will tend to collapse as shown above ,while a building with a braced side bay as shown below will be stable,since the braced bay will functions as a “buttress” to resist the wind forces, and transform them to the foundations 2 portal frame design 2.1 Basic data Total length b = 70 m Bay width d= 25 m Spacing s= 7 m E=210000N/mm 2 G=80770N/mm 2 Steel:S235 Height h= 7.5 m Roof slope α= 5° Purlin spacing sp=1.5 m Cladding rail spacing Sp’=2.0m Articulated purlin purlin cladding rail column I nternal portal frame door 4*5m α= 5° 7.5m 6.41m 25.0m Int ernal portal frame 2.2 Loads 2.2.1 Permanent loads Self-weight of the beam Roofing with purlins For an internal frame G= 0.35 KN/m 2 G=0.35*7=2.45 KN/m G=-2.45 KN/m α=5° 6.406 m 7.5 m 25.0 m 2.2.2 Construction loads Q=0.5 KN/m 2 EN 1991-1-6 clause 4.11(2005) For an internal portal frame Q=0.5*7=3.5 KN/m 2.2.3 Wind loads Take from the document treated “ wind actions to EN 1991-1-4(2005) as a values described below -3.74 (J) -6.55 (G) -3.74 (H) -3.74 (I) -8.88(F) 92.0 (F1 etF2 ) w1 -2.34 (E) +2.34(D) 1.5 11 1.5 11 2.2.4 Approximation calculations 1/ wind forces applied to duopitch roofs and partial variables live loads These actions are very small in ccomparison with the wind actions on vertical walls(0.5% to 1.3%). In this case they will be neglected for calculations. 2/ wind forces (up-to fly) The actions applied to duopitch roofs are oriented as described above (perpendicular to rafters).For simplifications we admit that these forces will be oriented vertically as gravity forces. 3/ Forces transmitted by purlins The forces transmitted to rafters by purlins, (are ponctual forces and must be applied in calculations of rafters),will be converted to linear forces.The error caused by this simplification is ≈0.5%,and conduct to increase the moments at B and D 4/ Stiffness at B and D To conduct manually calculations we consider that the inertia of the column and the rafter are equals Ic =IR The coefficient of stiffness k IR h will be S IC k h s This simplification ,justified by the presence of the haunchs ,conduct to increase the moment at C and decrease moments at B and D.It will be compensated by the simplification applied to purlin calculations,wich act in opposite sens. 2.3 Simple cases 1/Case 1 Vertical actions dead (G) variable (Q) loads Y C s IR - + f=1.09 + - B D - h=6.41 HA A - E VA VE Rigidity coefficient at B and D K I h stiffness.of .rafter R stiffness.of .comumn S IC In application of Castigliano théorem and with the structure symetry M dM ds 0 ABCDE EI dH where H is the horizontal force Displacement 1 in AB column. In any ordinate point ,y, of the column AB , the moment is M H . y ,then dM y and dH h 1 0 Hy 1 . y.dy EI R EI R h 2 Hy dy 0 Displasment 2 in BC rafter The moment expression at abscissa ,x,is: x 2 cos2 M H h x sin q Vx cos 2 dM h x sin dH and x 2 cos2 2 H h x sin q Vx cos h x sin dx 2 0 s HE 1 Hh3 EI R 3 x cos We have 1 EI R 2 l and 2s f then s sin f 2s 1 5 2 . H . h 2 .s h. f .s q l . f .s hl 2 s 3 12 96 Then the equation 1 2 0 give the result ql 2 s 32 I R H 3 h IC 5 f 8h h s f 2 f 3 3 2 IR h h 2 and may be reduced if we use the rigidity k h s k IR h s IC in place of the real expression We obtain the simplified expression H ql 2 5 f 8h 2 32 h k 3 f 3h f Conclusion M B M D Hh ql 2 MC H h f 8 H A HE H VA VE ql 2 5 f 8h 2 32 h k 3 f 3h f ql 2 2/Case 2 Vertical actions( wind up to fly) M B M D Hh MC ql 2 H h f 8 H A HE H ql 2 5 f 8h 2 32 h k 3 f 3h f VA VE ql 2 Y q C - - + B HA + D A E VA VE 3/Case 3 Horizontal actions( wind 1 pressure) qh2 MB H E .h 2 M D H E .h HE 5kh 6 2h f qh2 HE 16 h2 k 3 f 3h f H A q.h H E x qh2 MC HE h f 4 qh2 VE VA 2l Y C - + + B + D q - HA A E VA HE x VE 4/ Case 4 Horizontal actions( wind 1 succions) MD qh2 H A .h 2 HA M B H A .h 5kh 6 2h f qh2 2 16 h k 3 f 3h f H E q.h H A qh2 MC H A h f 4 qh2 VE VA 2l Y C + + B + D q - HA A VA E HE VE x Calculation of the rafter in bending Dead loads G=2.45KN/m W1 wind in long span (internal surpressure) Wc,3 Wc,1 Wc,2 wc ,1 2.34 KN / m see fig above wc ,2 2.34KN / m wc,3 3.74KN / m W2 wind in long span (internal depressure) Wc,3 Wc,1 Take c p ,i 0.3 Wc,2 EN 1991-1-4(2005) (7.2.9 (6)note 2) wc ,1 c p ,e c p ,i q p s 0.7 0.3 0.668*7 4.68 KN / m wc,2 0KN / m We have choose the max value of G zone for wind calculation but not the better wc ,3 c p ,e c p ,i q p s 1.2 0.3 0.668*7 4.21KN / m And For the zones H;I,and J this value is wc ,3 c p ,e c p ,i q p s 0.6 0.3 0.668*7 1.4 KN / m W3 wind gear ( with internal surpressure) Wc,3 Wc,1 W3 Wc,2 We take a middle value of the zones G,H and I as described in wind actions to EN 1991-1-4(2005) We take also a middle value of the zones A,B and C then we will have wc,1 wc,2 0.668*7 4.676 4.68KN / m wc,3 1.0*7 7 KN / m Calculus actions It is to determinate: --the support reactions HA ; H E ;VA and VE -- the max bending moments M B ;M C and M D These forces are obtained from the actions mentioned in tables above Values for calculations: S=12.55; f=1.09 ; h=6.41; k=0.511 2.45*252 5*1.09 8*6.41 H A HE 16.494KN 32 6.412 0.511 3 1.09 3*6.41 1.09 VA VE 2.45* 25 30.625KN 2 2.45*252 MC 16.494 6.41 1.09 67.7 KNm 8 M B M D 16.494*6.41 105.73KNm actions case q(KN/m) H A(KN) HE(KN) VA(KN) VE(KN) M B(KNm) M C(KNm) M D(KNm) G 1 2.45 16.494 16.494 30.625 30.625 105.73 67.7 105.73 Q 1 3.5 23.31 23.31 43.75 43.75 149.42 98.62 149.42 W 1 ;W c,1 3 2.34 11.39 3.61 1.92 1.92 24.933 3.04 23.14 W 1; W c,2 4 2.34 3.61 11.39 1.92 1.92 23.14 3.04 24.933 W 1 W c,3 2 3.74 24.9 24.9 46.75 46.75 159.61 105.44 159.61 39.90 17.12 50.59 42.91 207.68 105.44 111.54 Total W 2 ;W c,1 3 4.68 22.69 7.21 3.85 3.85 49.93 6.0 46.22 W 2 ;W c,2 4 0 0 0 0 0 0 0 0 W 2 ;W c,3 2 4.21 28.03 28.03 52.63 52.63 179.67 118.68 179.67 50.72 35.24 56.48 48.78 229.6 124.68 133.45 Total W 3 ;W c,1 4 4.68 22.79 7.21 3.85 3.85 49.93 6.0 46.22 W 3 ;W c,2 4 4.68 7.21 22.79 3.85 3.85 46.22 6.0 49.93 W 3 ;W c,3 2 7 46.61 46.61 87.5 87.5 298.77 197.3 298.77 31.03 31.03 87.5 87.5 295.06 185.3 295.06 Total 3 Load combinations Partial factor G max 1.35 permanent loads G min 1.0 permanent loads Q 1.50 variable loads When there is more then one variable action acting,requiring the actions to be combined, the expression is ULS : j g, j GK , j 0.9 Q ,i QK ,i i 1 SLS G K, j j 0.9 QK ,i i 1 These combinations are obtained from the NADF2 (French,national annex ) the coefficient 1.2 applied for wind will be omitted if we use combinations above ULS combination combination Reactions (KN) HA 101 1.35G 1.5Q HE 57.23 102 1.35G 1.5W1 VA Bending moments (KNm) VE MB MC MD 57.23 106.97 106.97 366.87 239.33 366.87 useless 103 1.35G 1.5W2 53.81 30.59 43.38 31.83 201.66 95.63 57.44 104 1.35G 1.5W3 24.28 24.28 89.91 89.91 299.85 186.56 299.85 105 G 1.5W1 43.36 9.19 45.26 33.74 205.79 90.46 61.58 106 G 1.5W2 59.59 36.37 54.09 42.55 238.67 119.32 94.45 107 G 1.5W3 30.05 30.05 100.63 100.63 336.86 210.25 336.86 108 1.35G 1.8W1 49.55 8.55 49.72 35.89 231.09 98.4 109 1.35G 1.8W2 69.03 41.17 60.32 46.46 270.54 133.03 97.47 110 1.35G 1.8W3 33.59 33.59 116.17 116.17 388.37 242.15 388.37 The maximum values are collected in the table Reactions (KN) HA Bending moments (KNm) HE VA VE MB MC MD 57.23 57.23 106.97 106.97 388.37 239.33 388.37 69.03 41.17 116.17 116.17 366.87 242.15 366.87 4/ Rafter 4.1/Resistance The maximum moment in: - Apex connection : M B= M D=-366.87 KNm - Eave connection : M C=+239.33 KNm The expression With M Rd M M Rd M W pl . f y M0 must be verified for bending .We have W pl . f y M0 then W pl M . M 0 fy 58.04 For 366.87 apex connection Wpl 235000 239.33 eave connection Wpl 235000 - In apex connection Wpl 1561.1cm3 - In eave connection Wpl 1018.4cm3 IPE 360+(1/2) IPE 360 IPE 360 The 1.5 IPE360 section is considered as welded beam . the table below show it’s characteristics Caractéristiques du profil P.R.S. Caractéristiques géométriques Caractéristiques mécaniques Axe neutre élastique Axe neutre plastique h = 540 mm hw = 514,6 mm tw = 8 mm bf = 170 mm tf = 12,7 mm g = 66,21 kg/m A = 84,35 cm2 Iy = 39105,7 cm4 Wel.y = 1448,4 cm3 Wpl.y = 1668,1 cm3 iy = 21,53 cm Iz = 1042,1 cm4 Wel.z = 122,6 cm3 Wpl.z = 191,7 cm3 iz = 3,52 cm It = 32 cm4 Iw = 722861 cm6 Zane = 270 mm Zanp = 270 mm Yane = 85 mm Yanp = 85 mm This choice is preliminary and will be completed by others 4.2/ Vertical deflection Vertical deflection of the rafter The vertical deflection will be calculated under G Q The moment in a section is q ql M x M B x x2 2 2 By integration of the equation d2y M dx 2 EI We have l 2 dy M 1 dx dx 0 EI EI For x 1 y EI l 2 l 2 ql q 2 M x 0 B 2 2 x dx dy 0 we have dx then l 2 ql 2 q 3 l ql 3 0 M B .x 4 x 6 x M B . 2 24 dx For x=0 we have y=0 then ymax 1 384 EI 5ql 4 48M B .l 2 E=210000 MPa=210000N/mm 2=2.1x108 KN/m 2 I=16270 cm 4 q= G Q =2.45+3.5=5.95KN/m L=25.1m M B=105.73+149.42=255.15 KNm For IPE 360 the vertical deflection is 5*5.95* 25.1 4 ymax 48* 255.15* 25.12 384 * 2.1*108 *16270 *10 8 0.3119m 31.2cm In this case we must upgrade to IPE 500 and we obtain a limit value but less because we haven’t consider the presence of apex 5*5.95* 25.1 4 ymax f adm 48* 255.15* 25.12 384* 2.1*108 * 48200*10 8 0.1052m 10.52cm l 2510 12.55cm 200 200 CARACTERISTIQUES GEOMETRIQUES h = 500 mm b = 200 mm tw = 10,2 mm tf = 16 mm r = 21 mm d = 426 mm IPE 500 CARACTERISTIQUES MECANIQUES g = 90,70 kg/m A = 116,00 cm 2 Iy = 48 200,00 cm 4 Wel.y = 1 928,00 cm 3 Wpl.y = 2 194,00 cm 3 iy = 20,43 cm Avz = 59,87 cm 2 Iz = 2 142,00 cm 4 Wel.z = 214,20 cm 3 Wpl.z = 335,90 cm 3 iz = 4,31 cm It = 89,29 cm 4 We remark that IPE 500 is very suffisant to resist under positif and negative bending moment 4.3/Classification The section is class 1 as a similar (but not the same) verification for the column (see§5) 4.4/Buckling resistance This figure shows different Sections categories and buckling modes Lateral torsional buckling check using the simplified assessment methods for beams with restraints in buildings: 8*1.5m Lateral restraints (purlins) IPE 500 ● 4.19m Lateral restraints (bracing system) 3*4.18m ● Bracing system In buildings , members with discrete lateral restraint to the compression flange are not susceptible to lateral-torsional buckling if the length L c between restraints or the resulting equivalent compression flange slenderness f k L i c c f ,z 1 f satisfies: c ,0 M M c , Rd [6.3.2.4] y , Ed Where M y,Ed is the maximum design value of the bending moment within the restraint spacing k is a slenderness correction factor for moment distribution between restraints, see EN 1993-1-1 c Table 6.6; i , is the radius of gyration of the compression flange including 1/3 of the compressed part of the web fz area, about the minor axis of the section; c ,0 is the slenderness parameter of the above compression element: c ,0 LT ,0 0.10 LT ,0 0.4 1 c ,0 0.4 0.10 0.5 E 93.9 and fy fy I f ,z then 235 N mm 2 3 d tw I z 2* * 3 12 2 [6.3.2.3] then I f ,z 3 42.6 1.02 2142 2* * 3 12 1069.74cm4 2 1 d Af , z A 2* * tw 2 3 then 1 42.6 2 I f , z 116 2* *1.02 43.52cm 2 3 I f ,z i f ,z Af , z 1069.74 4.96cm 43.52 Wy Wpl , y 2194cm3 E 93.9 93.9 fy 1 M c , Rd Wy f y M1 2194* 235*103 515.59 KNm 1.0 Combination 1.35G 1.5Q MB=MEd=366.87 KNm We consider that the coefficient is the same if the rafter is unrestraint then M C 239.33 0.65235 M B 366.87 Then KC 1 1 0.647 1.33 0.33 1.33 0.33*0.65235 table 6.6 But between restraints in the centre of the rafter where the moment are maximum, the moment distribution may be considered as constant :K C=1.0 f table 6.6 KC LC 1.0*150 0.322 i f , z 1 4.96*93.9 The maximum bending moment is at the origin B of the rafter then the lateral torsional buckling may be also in the origin M y , Ed 366.87 KNm M M c ,0 c , Rd 0.5* y , Ed 515.59 0.703 366.59 KC LC 1.0*150 0.322 i f , z 1 4.96*93.9 f 0.322 0.703 Combination MB= M c ,0 M M f y , Ed c , Rd 1.35G 1.8W3 388.37 KNm 0.5* y , Ed 515.59 0.6637 388.37 KC LC 1.0* 418 0.8975 Not verified i f , z 1 4.96*93.9 It’s necessary to add other bracing systems each 3m spacing then LC=3m M y , Ed c ,0 M M f 388.37 KNm c , Rd y , Ed 0.5* 515.59 0.6637 388.37 KC LC 1.0*300 0.6441 i f , z 1 4.96*93.9 0.644 0.663 Then the lateral torsional buckling is satisfactory A detailed procedure to do verification for the rafter is sho wn below as for column When the above procedure is not satisfactory. NOTA The real comportement of the rafter is shown in the figure 1 tension flange 7 restraints 2 elastic section 8 bending moment diagram 3 plastic stable length 9 Compression flange 4 plastic stable length 10 plastic stable length 5 elastic section 11 plastic stable length 6 plastic hinge 12 elastic section Annex A y 4.5/ the haunch verification C + - D O F S x the equation of the bending moment curve is a parabolic form Y aX 2 the point F is considered the limit of elastic moment M el Wel f y M0 1928*103 * 235 453.8KNm 1.0 X 0m S=12.55 Y M C=242.15 M D+MC=388.37+242.15=630.52 a Then Y 630.52 4 2 X 157.5 The bending moment curve equation will be For X 12.55 F then Y M el Wel f y Then 454 4 12.55 F then 2 Conclusion M0 Y 4X 2 1928*103 * 235 453.8 KNm 1.0 F 2 100.4 F 176 0 F 1.78m Length of the rafter F=2m The same verification for buckling 1/about yy 2/about zz 3/lateral torsional buckling as for column in section 5 may be used 5/COLUMN The verification of the column is carried out for the combination 101 1.35G 1.5Q N Ed 106.97KN V Ed 57.23KN (assumed to be constant along the column) (assumed to be constant along the column) M Ed 366.87 KNm (at the top of the column) 5.1/Classification of the section Web: the web slenderness is dN c 437.6 42.9 tw 10.2 N Ed 106970 44.63 tw f y 10.2* 235 d w d N 426 44.63 0.552 0.50 2d w 2* 426 Then the limit for the class is §5.5 (tab5.2) 396 396*1 64.119 13 1 13*0.552 1 42.9 ≤ 64.119 Until the web is class 1 Flange: the flange slenderness is c tf b t w 2r tf 2 73.9 4.618 16 §5.5 (tab5.2) The limit of the class is 9 9*1.0 9 Until 4.618 ≤ 9.0 the flange is class 1 So the section is Class 1. The verification of the member will be based on the plastic resistance of the cross-section. 5.2 /Resistance Verification for shear force Shear area AV max A 2bt f t w 2r t f ; hwt w §.6.2.6 AV max 11600 2*200*16 10.2 2*21 *16;1.0*426*10.2 AV max 6035.2; 4345.2 AV 6035.2mm2 V pl , Rd f AV y 6035.2 235 3 3 *103 818.84 KN M0 1.0 VEd 57.23 0.07 0.5 V pl , Rd 818.84 § 6.2.8(2) The effect of the shear force on the moment resistance may be neglected Verification to axial force N Pl , Rd N Ed Af y M0 11600* 235 *103 2726 KN 1.0 §6.2.4 106.97KN 0.25N Pl , Rd 0.25*2726 681.5KN 6.2.9.1(4)equ 6.33 0.5hwtw f y M0 Since 0.5* 426 *10.2 * 235 510.56 KN 1.0 *1000 106.97 ≤ 681.5 and 6.2.9.1(4)equ 6.34 106.97 ≤ 510.56 The effect of the axial force on the moment resistance may be neglected Verification to bending moment M pl , Rd WPl , Rd f y M0 2194* 235 515.59 KNm 1.0*1000 M Ed 366.87 0.711 1.0 Ok! M pl , Rd 515.59 §6.2.5 5.3 serviability limit state Horizontal Deflection Horizontal Deflection at the top of the column must be verified for two combinations and Combination 201: G+Q combination 202:G+W1 Combination 201 G+Q The moment at a point x in the column is G+Q M x HA M x H A.x By introducing a virtual force P at the summit of the column AB This effort generate the following forces k IR h h s IC s k 3 3 3 2 f h 1 3 2 1 2 RA 1 3 2 1 2 RE P RA 1 2 1 3 2 2 P 3 2 1 2 2 VA VE M B Ph M C Ph M D Ph Ph l For an IPE 500 column we obtain : k 0.511 0.17004 4.10786 Then we have the results RA 0.534P RE 0.466P The moment in the point M is M X 0.534Px The resultant moment under the two actions is M X H A x 0.534Px the internal potential energy of the column is: 1 W 2EI h H A x 0.534Px dx 2 0 0.56913 0.43087 0.04458 h 1 W 2EI H A 0.534P 1 W 2 EI 2 1 3 x H 0.534 P A 3 0 2 x 2 dx 0 h h3 2 W H A 0.534P 6 EI dW 1.07 3 h HA P 0 dP 6 EI C 1.07*6.413 *3980.4 1.847cm 6 6*2.1*10 *48200 l 641 2.137cm 300 300 Since 1.847 ≤ 2.137 OK! Combination 202 G+W H A 16.494 39.9 23.406KN By application a similar resolution as the above x2 M X H A x q 0.534 Px 2 the internal potential energy of the column is: 2 h 1 x2 W H x q 0.534 Px dx A 2 EI 0 2 Using a similar calculation we have 1 W 2 EI 2 x2 0 H A x q 2 0.534Px dx h W 1 3 1 2 1 x qx H A 0.134 P H A 0.534P 0.05q 2 x 2 2 EI 4 3 W 1 3 1 2 1 h qh H A 0.134 P H A 0.534 P 0.05q 2 h 2 2 EI 4 3 1 4 3 dW P 0 0.067qh 0.178H A h EI dP 0.067*234*6414 *102 0.178*2340.6*6413 1.345cm 6 2.1*10 *48200 P B M qx2 /2 x q HA A RA 5.4 Buckling Resistance The buckling resistance of the column is sufficient if the following conditions are fulfilled (no bending about the weak axis, M Z,Ed=0): N Ed M Ed k yy 1 y N RK LT M y , RK M1 §6.3.3 equation 6.61 M1 N Ed M Ed k zy 1 y N RK LT M y , RK M1 equation 6.62 M1 Buckling about yy L CR , y 6.41m h 500 2.5 1.2 b 200 Ncr , y y 2 EI y L2cr , y Af y N cr , y t f 16mm 40mm buckling curve :a(αy=0.21) table 6.2 210000*48200*104 24313.64 KN 64102 *103 2 11600 * 235 0.335 24313.64 *103 §6.3.1.2 y 0.5 1 y 0.2 y 0.5 1 0.21 0.335 0.2 0.3352 0.5703 y 1 y 2 y 2 y 2 1 0.5703 0.5703 0.335 2 2 0.9691 Buckling about zz Buckling curve :b (αz=0.34) Ncr , z z 2 EI z 2 cr , z L Af y N cr , z 2 *210000*2142*104 6410 2 1080.5KN 11600* 235 1.5883 1080.5*103 z 0.5 1 z z 0.2 z 2 z 0.5 1 0.34 1.5883 0.2 1.58832 1.9973 z 1 z 2 z 2 z 1 1.9973 1.9973 1.5883 2 2 0.3117 1 tension flange 2 plastic stable length 3 elastic section 4 plastic hinge 5 restraints 6 bending moment diagram 7 compression flange 8 plastic with tension flange restraint, 9 elastic with tension flange Column with restraints by cladding rail along long span Annex A Lateral torsional Buckling h 500 2.5 2 b 200 Annex A then buckling curve c(αLT=0.49) Moment diagram with linear variation : 0 then C1 1.77 The simplification of critical moment may be used: M cr C1 2 EI z L2cr , LT 2 I w Lcr , LT GI t Iz 2 EI z 2 210000*2142*10 4 1249000*10 6 6410 2*80770*89.29 *104 M cr 1.77 64102 *106 2142*104 2 210000* 2142*104 M cr 1.77 2 2.1* 21420 1249*105 6412 2142 6412 *8077 *89.29 676.32 KNm 2 21* 21420 LT Wpl , y f y M cr 2194*10 3 * 235 0.8731 676.32*10 6 2 LT 0.5 1 LT LT LT ,0 y LT 0.5 1 0.49 0.8731 0.4 0.75*0.8731 2 0.9663 With a values of LT LT ,0 0.4 1 LT For 0 2 LT then 2 LT Kc 0.75 and 1 0.9663 0.96632 0.75*0.87312 0.6377 1 0.7519 1.33 0.33 Bending moment diagram and the 6.3.2.3 table 6.6 coefficient 2 f 1 0.5 1 K c 1 2 LT 0.8 2 f 1 0.5 1 0.7519 1 2 0.8731 0.8 0.8773 1 0.6377 LT ,mod LT 0.7269 1 f 0.8773 Calculation of the factor K yy K yy Cmy CmLT y 1 N Ed N cr , y Cmy Cmy ,0 1 Cmy ,0 2 Cm , LT Cmy 1 C yy annex A y aLT 1 y aLT aLT N Ed 1 N cr , z N Ed 1 N cr ,T annex A 1 annex A N Ed N cr , y N Ed 1 y N cr , y 1 y annex A Wel , y 1.6 2 1.6 2 2 C yy 1 wy 1 2 Cmy max Cmy max n pl bLT w w Wpl , y y y Calculation of y 106.97 24313.64 y 0.9998 106.97 1 0.9691 24313.64 1 wy Wpl , y Wel , y 2194 1.138 1.5 1928 Critical axial force in the torsional buckling mode N cr ,T 2 EI w A GI t 2 I 0 Lcr ,T For a doubly symmetrical section I 0 I y I z y02 z02 48200 2142 50342cm 4 Ncr ,T 11600 2 *2.1*105 *124.9*104 *106 4 80770*89.29*10 50342*104 *103 64102 Ncr ,T 3113.56KN M cr ,0 C1 2 EI z L2cr , LT L2cr , LT GI t Iw Iz 2 EI z M cr ,0 is the critical moment foe the calculation of 0 annex A . Then we have M cr ,0 1* C1=1 2 210000*2142*104 1249000*106 64102 *106 for uniform bending moment as specified in 2142*104 64102 *80770*89.29 *104 382.1KNm 2 210000*2142*104 0 W pl , y f y M cr ,0 2194*103 * 235 1.162 382.1*106 0,lim 0.2 C1 4 1 N Ed N cr , z For doubly symmetrical section 106.97 N Ed 1 N cr ,TF Ncr ,TF Ncr ,T 106.97 0,lim 0.2 1.77 4 1 1 0.2569 1080.5 3113.56 Then 0 0,lim Calculation of Cmy Cmy Cmy ,0 1 Cmy ,0 y M y , Ed N Ed aLT 1 y aLT 1 y aLT A 366.87*103 11600 20.635 Wel , y 106.97 1928*103 It 89.29 1 0.928 Iw 1249 Calculation of C my,0 Cmy ,0 0.79 0.21 y 0.36 y 0.33 With a value y 0 table A2 then Cmy ,0 0.79 01188 106.97 0.7895 24313.64 Cmy 0.7895 1 0.7895 2 Cm , LT Cmy N Ed N cr , y 20.635 *0.928 0.9596 1 20.635 *0.928 aLT N Ed 1 N cr , z N Ed 1 N cr ,T 1 Cm, LT 0.95962 Then 0.928 106.97 106.97 1 1 1080.5 3113.56 0.9457 1 Cm, LT 1 Calculation of C yy 1.6 2 Wel , y 1.6 2 2 C yy 1 wy 1 2 Cmy max Cmy max n pl bLT wy wy Wpl , y max max y ; z z M z , Ed 0 bLT 0 n pl N Ed 106970 0.03924 N Rk 11600* 235 1.0 M1 1.6 1.6 C yy 1 1.138 1 2 *0.95962 *1.5883 *0.95962 *1.58832 *0.03924 0.978 1.138 1.138 Wel , y Wpl , y Since 1928 0.8787 2194 0.978 ≥ 0.8787 Ok! Calculation of K yy K yy Cmy CmLT K yy 0.9596*1* y 1 N Ed N cr , y 1 C yy 0.9998 1 0.9853 106.97 0.978 1 24313.64 Verification with interaction formula N Ed M Ed k yy 1 y N RK LT M y , RK M1 M1 106970 366.87 *106 0.9853* 0.766 1 0.9691*11600* 235 2194*103 * 235 0.9663* 1.0 1.0 OK! The buckling resistance of the section is satisfactory This figure illustrate different categories of buckling modes A similar method of calculation of the factor K yz in the equation 6.62 mentioned above May be used for the verification of the second formula(not treated for this sheet) http://www.arab-eng.org/vb/u355867.html ibnmessaoud10