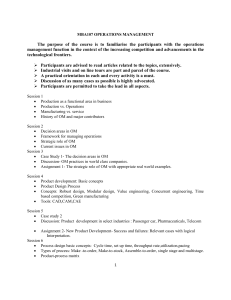

Dalubhasaan ng Lungsod ng Lucena SBA – STRATEGIC BUSINESS ANALYSIS S.Y. 2020-2021 MODULE 5: QUANTITATIVE MANAGEMENT AND TECHNIQUES Learning Objectives: a. Understand the nature and concepts of quantitative management and techniques. b. Apply quantitative techniques in solving business problems Metalanguage Quantitative techniques – refer to the application of mathematics in actual business operations. It is also known as quantitative methods. Operations research - refers to the discipline of applying quantitative methods in organizational planning and control. Introduction Managerial activities have become complex and it is necessary to make right decisions to avoid heavy losses. Whether it is a manufacturing unit, or a service organization, the resources have to be utilized to its maximum in an efficient manner. The future is clouded with uncertainty and fast changing, and decision-making – a crucial activity – cannot be made on a trial-and-error basis or by using a thumb rule approach. In such situations, there is a greater need for applying scientific methods to decision-making to increase the probability of coming up with good decisions. Quantitative Technique is a scientific approach to managerial decision-making. The successful use of Quantitative Technique for management would help the organization in solving complex problems on time, with greater accuracy and in the most economical way. Today, several scientific management techniques are available to solve managerial problems and use of these techniques helps managers become explicit about their objectives and provides additional information to select an optimal decision. The Quantitative Analysis Approach The methodology adopted in solving problems is as follows: Network Models Network models involve project scheduling techniques that are designed to aid the planning and control of large-scale projects having many interrelated activities. These models aid management in predicting and controlling costs that pertain to certain projects or business activities. Common project scheduling techniques (Network Models) 1. 2. 3. 4. 5. 6. 7. Gantt or bar chart Program Evaluation and Review Technique (PERT) Critical Path Method (CPM) Probability Analysis Learning Curves Inventory Models Linear Programming 1. GANTT OR BAR CHARTS The project is divided into different sub-projects called activities or tasks. The starting and completion time of activity is estimated and a bar chart is prepared showing each activity as a horizontal bar along a time scale. a. Which task is the longest in completion time? Answer: Task B. b. All tasks are being perform in what month? Answer: May 2&3. PROGRAM EVALUATION AND REVIEW TECHNIQUE (PERT) – CRITICAL PATH METHOD (CPM) PERT is developed to aid managers in controlling large-scale, complex problems. PERT diagram is a probabilistic diagram of the interrelationship of a complex series of activities; it is a free-form network showing each activity as line between events. EVENTS – discrete moment in time representing the start or finish of an activity; they consume no resources. ACTIVITES – tasks to be accomplished; they consume resources (including time) The following are the common type of activities: o Series – an activity cannot be performed unless another activity is undertaken o Parallel – can be performed simultaneously CPM, like PERT, is a network technique, but unlike PERT, it uses deterministic time and cost estimates; its advantages include cost estimates plus the concept of crash efforts and costs. CRITICAL PATH – is longest path through the PERT network. EXPECTED TIME – is the average time an activity would require if it were repeated several times. te = (to + 4 tm + tp) / 6 Where to –optimistic time; tm – most likely time; tp – pessimistic SLACK TIME – the amount of time that can be added to an activity without increasing the total time required on the critical path; the length of time an activity can be delayed without forcing a delay for the entire project. CRASH TIME – the amount of time to complete an activity assuming that, under rush or urgent condition, all available resources were devoted to the task (e.g., overtime, extra labor, etc.); any crash time spent in an activity normally would incur crash cost. PERT VS. CPM Key Differences PERT CPM 4. PROBABILITY ANALYSIS Probability Analysis is important to decision-making because of the unpredictability of future events. Decision-making involves: RISK – this occurs when the probability distribution of the possible future state of nature is known. UNCERTAINTY – this occurs when the probability distribution of possible future state of nature is not known and must be subjectively determined. The probability of an event varies from 0 to 1 (0% to 100%). 100% or probability of 1.0 means that event is certain to occur while zero probability means the event cannot occur under any circumstances. THE CONCEPT OF EXPECTED VALUE The expected value of an action is found by multiplying the probability of each outcome by its payoff and summing up the products. A decision tree diagram is normally devised to show the several decisions or acts and the possible consequences (outcome or events) of each act. Objective probabilities – calculated from either logic or actual experience. Subjective probabilities – estimates, based on judgment, of the likelihood of future events. Two events are said to be mutually exclusive if they cannot occur simultaneously. Two events are said to be independent if occurrence of one has no effect on probability of another. The joint probability of two events is the probability that both will occur. The conditional probability of two events is the probability that one will occur given that the other has already occurred. 5. LEARNING CURVES Learning curves describes the efficiencies arising from experience, because with experience comes increased productivity. This productivity increases with production size, but at decreasing rate as diagrammed below: The time required to perform a given task becomes progressively shorter, but this is applicable only to the early stages of production or any new stages The curve is expressed as a percentage of reduced time (usually between 60% and 80%) to complete a task of each doubling of cumulative production. Hence, the time required is reduced by 20% to 40% each time cumulative production is doubled. The cumulative average time per unit is reduced by a certain percentage each time production doubles Incremental unit time (time to produced the last unit) is reduced when production 6. INVENTORY MODELS Inventory models are usually devised to minimize the cost associated with inventory while maintaining certain level of inventories needed to sustain smooth operations. The total inventory costs are comprised of: CARRYING COSTS: This cost increases with order size or quantity of inventory on hand Example: Storage cost, insurance on inventory, normal spoilage, record keeping cost, etc. ORDERING COSTS: This cost decreases with order size or quantity of inventory on hand Example: Delivery costs, administrative costs – inspection, purchasing and receiving THE CONCEPT OF ECONOMIC ORDER QUANTITY (EOQ) EOQ is the quantity to be ordered that minimizes the sum of ordering cost and carrying cost. EOQ tries to answer the question “How many units should be ordered (and when to order) to minimize inventory costs?” Where: o = Cost of placing one order (ordering cost) D = Annual demand in units K = Annual cost of carrying one unit for one year EOQ = 2 Do k At EOQ, a firm incurs the minimum total inventory costs computed as follows: TC EOQ D (k ) (o) 2 EOQ Average inventory is computed as follows: No safety stock: EOQ/2 With safety stock: EOQ/2 + safety stock If EOQ is not available: (beginning inventory + Ending Inventory)/2 Assumptions of EOQ models: Annul determinable demand for inventory is spread evenly throughout the year. Lead time does not vary and each order is delivered in a single delivery. The unit costs of the time ordered are constant; thus, there can be no quantity discounts. When applied to production operations, the EOQ formula is used to compute the Economic Lot Size (ELS) ELS = 2 Do k Where: o = Set-up cost D = Annual production requirement K = Annual cost of carrying one unit for one year EOQ-RELATED TERMINOLOGIES Lead time is period between the time the order is placed and received Normal time usage is derived by multiplying normal lead time with average usage Safety stock = (maximum lead time – normal lead time) x average usage or demand Order (Reorder) point is the inventory level that automatically calls for a new order When to order is a stock-out problem; the objective is to order at a point in time so as not to run out of stock before receiving the inventory ordered but not so early that an unnecessary quantity of safety stock is maintained. When order point is computed, there may be stock-out situation if: Demand is greater than expected during the lead time, or The order time exceeds the lead time Re-order point (without safety stock) Re-order point (with safety stock) = Normal lead time usage = Normal lead time usage + safety stock = Maximum lead time x average usage 7. LINEAR PROGRAMMING Linear programming is a mathematical technique that helps managers to determine the volume of various products to produce when resources are limited or scarce in order to maximize net income. It is a technique used to optimize an objective function (maximize revenue of profit function, or minimize a cost of function), subject to constraints (such as scarce resources, minimum/maximum levels of production, performance, etc.) Maximize revenue OBJECTIVE Maximize net profit Minimize costs and expenses Limited resources must be allocated to the company’s most profitable products so that net income is maximized. Linear programming models are extremely helpful in the analysis and solution of resource allocation problems. Simplex method is a more complex linear programming technique especially useful if there are more than two variables in a linear programming problem. Exercises Problem 1 Network Analysis Palafox Construciton Firm, Inc. will soon begin to work on a building for US Tea that was initially started by another firm that has gone out of business. The construction firm’s schedule of activities and related expected completions times for US Tea project are presented in the following time table: Activity Code Activity Description Estimated Time (in weeks) A-B Obtain on-site work permits 1 B-E Repair damages done by vandals 6 B-C Inspect construction materials left on 1 site C-E Order and receive additional 2 construction materials C-D Apply for waiver to add new materials 2 D-E Obtain waiver to add new materials 2 E-F Perform electric work 12 F-G Complete interior partitions 4 Required: a. Prepare the PERT network. b. Identify critical path and determine the path’s expected time in weeks for the project. c. Which path requires the shortest time to complete? What is the path’s slack time? Problem 2. Probability Analysis Tamansky Sports Club sells cold sodas at Far East College’s home basketball games. In the year 2021, the frequency of distribution of the demand for cups of sodas per day is presented below: (2021 had 360 operating days) Sales Volume in Cups Frequency 2,000 48 days 5,000 80 days 6,000 144 days 8,000 32 days 10,000 16 days Required: Determine next years’ estimated daily demand for cups of sodas at Far East College’s home games using: a. Deterministic approach (based on most likely event) b. Expected value approach Problem 3. Learning Curves A particular manufacturing job is subject to an estimated 80% learning curve. The first unit required 20 direct labor hours to complete. Required: a. What is the cumulative average time per unit after four units are completed? b. What is the total time required to produce 2 units? c. How many hours are required to produce the second unit Problem 4. Inventory Models Shirley Company requires 40,000 shells for its P500-signature product, “pearly Shirl”. The shells, which are purchased from outside suppliers, will be used evenly throughout the year. The cost to place one order is P20, while the cost to carry the shells in inventory for one year is P0.40 Required: a. The optimal order (economic order quantity) b. The number of times the company should place orders within a year. c. The average inventory. Problem 5. Economic Order Quantity Based on EOQ analysis, the optimal order quantity is 3,000 units. Annual inventory carrying cost equal 30% of the average inventory level. The company pays P 5 per unit to buy the product, selling for P 12. The company pays P112.50 to place an order. The monthly demand for the product is 5,000 units. Required: a. Annual inventory carrying cost b. Annual inventory ordering cost c. Total inventory costs Problem 6. Linear Programming Following are the data about Maximin Company’s two products that it produces through its production facilities: Product A Product B Contribution Margin Per Unit P3 P4 Materials Used: Material X 2 units 5 units Material Y 4 meters 2 meters Available Quantity of Materials: Material X 120 pieces Material Y 80 meters Required: a. Objective function – involving maximization of the company’s contribution margin. b. Constraint function for Material X c. Constraint function for Material Y d. The optimal mix of products that must be produces by Maximin Company. ---------------------END