a-o)t

rJ-J

I

cf I J

J\

o

Li-r-l I -iS

a(-t-,!

WBE FOR SAFETY CO.

I

a" APpnovED

W

I

EXCIrT

AMEND /.ND fiESU'81'1 7

o, RE;EcTED

L]

Molr€<

t -flnte

L. FM200 SYSTEM

)

?x ltttru i!A,a' :"*1 'rrih

r/b rur'nJ^;

//-,

ooonJ :- -"ri*r/Zfr

aPPata

"*$h;.e- sLto'lttT

aLtFm

yift

&frrt"

*t2

tt"/6 dAZla

7/+ar

ZZt.n o J

'

Lo,u

ltrJsu*-*iUt,

0'

bi%

tharl

t7n,

f

,

(**''a

//1t/4 fn<ru.*

o trlr/ * r' # 9,2 7'r/*<

c-orfiA;* 2./ uL/ F\ /,,- ntt

? n-.*;,2, &e

Sh'*ta-, trr.r/4 4o. i^ "*rt*/fi

Ftr t ^,\a-r^' fu'-1yntl*

Z_- D is.h c/.--?.

,

t2a

o

{li*tu'Ll

ae

J

5

4

ER.

tlrtrZ*c* O

;'4 r;/*

=

[R. 413t282422

n-

TUBE

Ft}R SAFffiI

.ltuJlris +4rl

AolrrlrglrEA.l

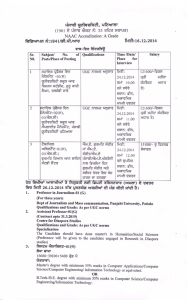

TECHNICAL SUBMITTAL

AL KHALIJ MALL PROJECT

CONTRACTOR:

FAWAZAL HUKAIRCOMPANY

MATERIALS:

SYSTEM-NAFFCO SYSTEM WITH

SHIELD BRAND FIRE ALARM SYSTEM

FM2OO

REF : TS-WBE-SS-I 161-00-FS- 2020

SUBMITTED BY:

WATARAL-BENAA FOR SAFETY CO.

- Kingdom of Saudi Arabia Email: lgte@Ju@re,ts

TELL NO.012-6050622

FAXNO. 012-6588909

rvrvw.WBESAFE.com

Jeddah

Date: Monday, December 2812020

FtlR SAFETY

4tidl-1;g n#Jt

6oldlr:rlasal

INDEX:

1.

FM200 SYSTEM ...................................r.r......................3

2. FIRE ALARM SHIELD ...........................o.o.o............... L5

3. PIPES & FITTINGS........... o.................... o........31

o

4. EMT

PANASONTC PIPES...........r...,........o..... ...66

5. BELDEN CABLES

............t.o....r............o......o...o...........7 4

\

A GENT STORAGE CONTAINER:

FEATURES

,/

tr

. Pressure Vessel to hold agenf until activated.

. Container Super - Pressurization Level

360 psig at 7O'F (24.8 bar dt zt'C)

after filling with dry nitroge4

. Container Storage Temperati.rre Limitation

ff

\ffi

l30"F (54.4"C) Maximum

. Container Rating

DOT 4BWsOO

. Container Actuation

.

v.

,

Metho$-

Electric / Pneumatic / ManUal

. Container Color Options i

White (Default)

Red

lncrements

lbs (O.5 kg)

. Fill Range

. Fill

:l

'l,O

s- 'l

4O to 7O lbs/ft3 (630

i

to 11^kg/m3)

i

*:"#dxceeds'IJO9F ( WeC,

valve will open automatically, this also fulfills the

pressure relief valve requirements in accordance

with DOT regulations.

*

I

f

co n t a i n e r

t e m p e r a t u r es

/.

r"'

PRODUCT APPROVALS

-**--, ,

\

I.ISIEB

Fill range

Valve

Minimurm Maximum

Size

Container

#ffi

P/N

i&ffi#sffi

?S;

NF-7o.263

,ffi

NF-7o'264

?:;,

NF-7o26s

ffi

NF-7o.266

'u?(];o'

ffi

ff:,

ffi

l:t$

NF-7o.267

NF-7o.268

NF-7o.26s

NF-7o.27o

NF-7o.271

(kg)

12

tbs.

(s.s)

22

(1O.O)

39

(18.O)

63

(28.s)

87

(39.s)

124

(s6.s)

217

(98.s)

378

(171.5)

598

(271.s)

lbs. (kg)

in, (mm)

21

1

(9.s)

(2s)

38

1

C7.O)

(2s)

68

1

(30.s)

(2s)

108

1

(4s.O)

(2s)

150

3

(68.0)

(80)

216

3

(98.O)

(80)

378

3

(171.s)

(80)

660

3

(299.0)

(80)

1045

3

(474.0)

(80)

Tare

APPROVM

DimenSiOn (approximate)

weight Diameter Height

lbs. (kg)

in. (mm) in. (mm)

21

7.O

22.375

(9.s)

(178) (568.3)

7.O

32.5

31

o4.s)

(178)

10.75

52

(2s.6> (273)

77

10.75

(34.9) (273)

150

20.O

(68.0) (sO8)

155

20.O

(7O.3) (sO8)

225

20.O

(102.1) (sO8)

385

24.O

(174.6) (610)

550

24.O

(249.s) (610)

Mounting

Position

(984.3)

Upright Horizontal

Upright Horizontal

Upright Horizontal

Upright (Valve Up)

23.63

Upright/

(600.1)

lnverted

Upright (Valve Up)

(82s.s)

28

<711.2)

38.75

28,87

(733.3)

42.5

(1079.5)

50.625

(1286)

70

(1778)

Upright

-

(Valve Up)

Upright (Valve Up)

Upright

-

(Valve Up)

ri

IMPULSE VALVE

FEATURES

. The 1" & 3" lmpulse Valves are a rupture disc (metal

diaphragm), pressure operated device that allows

the agent to be released from the container and

into the protected enclosure via the associated

piping network and discharge nozzle(s).

.

Agent Discharge Port allows agent release from

container and also fulfills the pressure relief valve

requirements in accordance with DOT regulations.

.Agent Fill Port is used to fill (refill) and pressurize

the container and also used for the Low Pressure

Switch.

.

Actuator Port is used to connect an lmpulse Valve

Operator (lVO) with Manual Strike Button for

electric and manual actuation of the container or

an lmpulse Valve Pneumatic Operator (IVPO) for

pneumatic operation.

. Pressure Gauge Port is used to connect a Pressure

Gauge that will monitor internal container pressure,

also equipped with an orifice plug that allows the

pressure gauge to be removed safely when the

container is pressurized.

PRODUCT APPROVALS

I.ISTED

APPBWE)

i

I

MODEL NF.O6.52O

Valve Body

CLEAN AGENT

FIRE SUPPRESSION SYSTEM

CLEAN AGENT: HFC-227ea

CHEMICAL NAME: Heptafluoropropane ASHRAE Designation HFC-227ea

TRADE NAME: HFC,227eB (DuPont'")

/

PHYSICAL PROPERTIES

Chemical Name

Hentafl urilrdnr0sidas,J &Fqsl'l F.,.qF3)

'170.o3

Molecular Weight

Boiling Point @ 76O mm Hg

Freezing Point

3.9"F (-1s.61b)

-2O4"F ({31.1"C)

2't5"F (101.7h)

422 psia (2912 kPa)

Critical Temperature

Critical Pressure (psia)

Critical Volume (ft3llbm) (cclmole)

Critical Density (lbm/tts)

Specific Heat, Liquid (BTU/lb-F') G)

o.o258 (274)

38.8 (621 kg/mz1

0.283 (1.184 kj/kg/"C)

77"F <25"C)

Specific Heat, Vapor (BTU/Ib-"F) @ constant

pressure of 1 ATM @77.F (25.C)

Heat of Vaporization (BTU/lb) at Boiling Point

Thermal Conductivity (BTU/h ft"F) of Liquid @

77"F (25"C)

Viscosity, Liquid (lblft/hr) @ 77"F (24"C)

Vapor Pressure (psia) @77"F (25"C)

Ozone Depletion Potential

Estimated Athmospheric Lifetime (years)

LC5O (Rats;4hrs - ppm)

FEATURES

. Colorless, odorless, liquified compressed gas,

liquid.

. Electrically-nonconductive.

stored

as a

. Discharge as gaseous vapor (due

/

to its relatively

boiling point).

low

O.1932 (O.8o8 ki/kg/ " C)

s7.o (132.6 ki/kg)

O.O4O (O.O69 w,/m"C)

O.443 <O.184 centipoise)

66.4 (457.7 kPa)

o

31-41

>788,OOO

. Zero ozone depleting potential.

. Low global warming potential.

. lncluded on the U.S. EPA Significant New

Alternative Policy (SNAP) rules.

USE and LIMITATIONS

HFC-227ea system shalt be used on the

Class of Hazards

following HFC*227ea system shall "NOT" be used on fire

Class A & C:

Electrical and Electronic Hazards

Telecommunication Facilities

High value assets, where the associated

down-time would be costly.

Involving the following materials

Chemicals or mixtures of chemicals that are capable of

rapid oxidation in the absence of air.

(Examples include: Cellulo Nitrate and Gunpowder)

Reactive metals such as Lithium, Sodium, Potassium,

Magnesium, Titanium, Zirconium, Uranium,

and Plutonium

Metal hydrides such as Sodium Hydride and Lithium

Aluminum Hydride.

Class B:

Flammable liquids and gases,

Chemicals capable of undergoing auto-thermal

decomposition.

(Examples: Organic Peroxides and Hydrazine)

EXPOSURE LIMITATIONS

HAZARD TYPE

DESIGN CONCENTRATION

MAXIMUM HUMAN EXPOSE TIME

Normally Occupied Space

6.25%to1O.5%

5 minutes

Not Normally Occupied Space

11.O%to12.O%

30 seconds

IMPULSE VALVE OPERATOR (IVO) KIT

MODEL: NF-7O-279

,*"\"\"

FEATURES

. Provides the means to electrically or manuall*1"...r

activate the lmpulse Valve clean agent container

by providing the force required to extend a piston

that will open the rupture disc, allowing the agent

to be released from the container.

. The IVO can be activated electrically via a signal

from NAFFCO control panel or manually by

depressing red strike buttom.

. NAFFCO Clean Agent Containers with lmpulse

Valve must use an lmpulse Releasing Module

(lRM) to supervise the agent release circuit wiring

(for open and ground fault conditions) from the

container to the control panel.

PRODUCT APPROVALS

LISTEII

APPNWE

lrl@

NF-O2r12728

0.2-1275,5

',

r,'

ttnpirls-6.V-afue Operator (lVO)

Wire Lead (5i long) w/ Connector

Normal Supply Voltage

24VDC

Electrical Consumption

DIN Connector w,/ Cable & %" NPT for conduit connection

Temperature Range

32oF to 13O'F (O'C to 54.4"C)

I

IMPULSE RELEASE MODULE

FEATURES

. The lmpulse Releasing Module provides the

primary interface between the supervised releasing

circuit(s) of a NAFFCO fire suppression system and

the lmpulse Valve Operator (lVO); which is used to

release the fire suppressant agent from an impulse

valve container.

. The IRM is equipped with three capacitors

that

receive a constant charging current from the

releasing circuit of the control panel. When fully

charged, the module is capable of firing a single

tvo.

. Upon circuit activation, the output circuit reverses

its output voltage polarity, causing the energy in

the capacitors to be released to the lmpulse Valve

Operator.

. Each IRM is equipped with a red LED to provide

positive indication that the module is in the active

(release) state.

/

+24V Supervisory:

2O,O ma (during capacitor charging), 3.O ma (after capacitor is charged)

CURRENT

CONSUMPTION

MODULE WIRING

-24V Activated:

-37.O ma (LED active)

Control panel to IRM connections are supervised and power-limited

lmpulse Valve Operator connection is non-supervised and power-limited

COMPATIBLE RELEASING

PANELS

*Note: A maximum

of

six IRM's, wired in parallel,can

NAFFCO Single Hazard Panel*

be connected to each panel's releasing circuit.

@ououals'

Clean Agent Fire Extinguishing Systems

These systems contain electrically nonconducting, volatile, or gaseous fire extinguishing agents that don't leave a residue upon

evaporation (per NFPA 2001 paragraph 1-3.1). They are effective for total flooding protection against hazards involving liquid

flammable materials, electrical equipment, and ordinary solid combustibles in occupancy arrangements which produce only surface

burning. ln general, these agents are not effective or appropriate for hazards which produce deep-seated burning or for those which

involve chemicals containing their own oxygen (such as cellulose nitrate), metal hydrides, or reactive metals (such as sodium,

magnesium or uranium).

Clean Agent systems are similar in many respects to Halon 1301 and carbon dioxide systems. Discharge of the agent by total flooding

or local application may create atmospheric hazards to personnel. Toxic thermal decomposition products can be minimized by fast fire

detection coupled with rapid agent discharge. Personnel should not remain in the area following system discharge. Table A-1 -5.1 .1 of

NFPA 2001 provides information on toxicological and physiological effects covered in this equipment classification. The No Observed

Adverse Effect Level (NOAEL) is the highest concentration at which no adverse physiological or toxicological effect has been

observed. The Lowest Observed Adverse Effect Level (LOAEL) is the lowest concentration at which an adverse physiological or

toxicological effect has been observed.

Systems can only be FM Approved under this classification if they use agents having a component Approval. The system Approvals

specifically reference the relevant agent Approval. lndividual agent listings appear under the category Clean Extinguishing Agents.

Compatible FM Approvals controls must be used. (See AUTOMATIC RELEASES FOR EXTINGUISHING SYSTEMS AND OTHER

FIRE PROTECTION EQUIPMENT under ELECTRICAL SIGNALING.)

Application of this equipment should be subject to the limitations specified and subject to FM Global's acceptance of plans prior to

installation. Required design concentrations vary from agent to agent and depending upon maximum design parameters, the

concentration may vary among system manufacturers. The design concentrations listed by the system manufacturers are generally

accepted in electrical/electronic hazards, i.e. computer, telecommunication areas, provided that Class A ordinary combustibles are

kept to a minimum, thereby minimizing the potential for a deep seated Class A fire.

System charging and recharging shall be done only by the manufacturer or a FM Approved representative.

The Clean Agent systems FM Approved under this classification have been addressed by NFPA 2001, Standard on Clean Agent

Extinguishing Systems, 1994 Edition and must be listed in the United States Environmental Protection Agency (EPA) Significant New

Alternatives Policy (SNAP) as an acceptable substitute to Halon 1301.

Jurisdictions oubide the United States may nof recognize NFPA and EPA sanction of certain clean agents. Local and national

governmental regulations should be consulted priorlo agent selection.

*Alternative to Halon 1211 and Halon 1301.

t

System Designation:

System Type:

Engineered Systems, Pre-Engineered Systems

Agent ldentification:

HFC-227ea

Minimum and Maximum Agent Storage Temperatures:

Minimum and Maximum Nozzle Heights:

16 ft (4.9 m) Maximum Height

1

ft (0.3 m) Minimum Height

Types of Nozzles Available:

180',360'

Maximum Area of Coverage for Nozzle Type:

180": Radius 45ft-8in (13.92 m)

360': Radius 29ft-8in (9.04 m)

Minimum Design Concentrations for Hazard Class:

Class A

-

6.25

Class B

-

8.71

Flow Calculation Software:

NAFFCO HFC227ea Flow Calculation NF4.00

Design, lnstallation, Operation, and Maintenance Manual:

NAFFCO HFC-227ea Clean Agent Fire

and Service Manual,

NAFFCO HFC-227ea Clean Agent Fire Suppression System

Equipment LLI lnstruction Manual, NF-06-549, Revision 4,

March 2018

@ 2OO7-2O19 FM

Approvals. All rights reserved.

1ot2

YE

@

o

TL

z

f

c

=co

€6

.E6El

o

=

.g

-CL

E

o

(J

l{r

o

(l,

*,

(tr

()

rr

rF

'E

l(l,

o

E

.s

f

F

u

z

ul

E

(,

IJJ

o

g

=

E

f

o

o

U)

o

z

U)

.9

IJJ

o)

.g

E

..2

It-

f

o)

E

x

o

tu

F

o

ll

o,

c)

o

cP

(E -L.

o

=

Og

(!9

-o6

LL

(E

(E

(E

tr

c{

(\

t6t

o

t*

o

=o

.=

f

tr

o,

o)

o

o)

c

z

o.

o.

=o

-g

E

'=

U)

o,

.9

c(E

o)

o

o

+

t!

E

cn

3

I

o

o

lU

o

to.

rrt

tg

c

o

o

(\I

ox

N>

N-

o:

Eo

o

o

LL

o

Lr

I

o

o

Lr

IL

trtr

LLi

z

z

>3

o

lL

I

lL

L6

.)'=

;-\o

€

o

d

oo

iE o

E

o)

ah

..2

..2

I(!

o

E

o,

(,

.9,

F

tr

o

(!

tr

.9

tr

.9

o s

,

o..

oo EE

E

o

o

o

oE

rg

lio

tLl,

6b=

EE6

E*e

o -r!

ESoa

gE

6EOE tr

.6

8oo8E

E&3

E

E

o

o

J

J

c(l,

o

o

Io

a*

G

IE

(l,

(J

o

1;$

6(\t

o.:

or

Eo6;

qii

o.(D

o(E

o

5

-9.

d-ai

o

$

b

o-Ndt

g

,E

DEI

E er

.-

E

=

E>I

E &E

H

t

{g gE'EE I

E

"E

H

;

*tr

E flIIE E

o

,HPEs

?

i*9a 3

;-Enslo

a=O=EC.)O-

3

OE

qE

P:e!=

-=o86

E8o)-a

g

=

{

Ig

Sl

E

e,

E

t

d

E

=$

6l

Etl

E=I

fr

E

1;o-e

{ o

E

fi-(, 8

Bg

t -.E &

gr€fi

HI

fl5l

o

E"

s

o

(\l

o

AI

b

o

f

-o

tro

\t

E

E

A

HE

.tP

o

.3

$H =€

$F.E

-Li q

EO

H

EE

x

se

figsf;3E

Fq {A E ET

o

E

(,

9

&gfiP

tE

q

E&

g#{

gs-E

EEEr

E=#I

EE E:

o

a

E

f

L

'91

(E

Ee

o

'=

o

iEE

IU

o,

CJ

#

€u

>o

o6t

^Eo

*E<

er=

E3H

= {- }

o

(,)

o

c

EEE

F E+

#€ $sa #

0)

v'6.

(E

o.

H#

>9

lL?Z

b

(,

ET

IJI

e

trE

trL

trL

%

gEr

-

e

- ,

L-i

EL

-

o

L

f\

tt

o

U

.a

s'

F

GAQF.EXI58,14 - Clean-agent Extinguishing System Units

1219t2018

GAQF.EXts844

CIean-agent Extinguishing System Units

Ege Bottom

See General Information for Clea n-aoent Extin gu

ish in

g;!yg!4@i!g

Hf#it#*

NATIONAL FIRE FIGHTING MFG FZ CO

PO BOX 17014

JEBEL

ALI FREE ZONE

DUBAI, UNITED ARAB EMIRATES

ENGINEERED UNIT, NAFFCOInert, Models NFIGo1-200-067A, NFIGo1-200-0678, NFIGo1-300-067A, NFIGo1-300-067B, NFIG01-200-080A,

NFIG01-200-080B, NFIGO1-300-080A, NFIGO1-300-0808, NFIG01-200-140, NFIGO1-300-140, and NFIGO1-300-140A Clean Agent Extinguishing

System Units, stored pressure type, having nominal charging capacities of 67, 67, 67, 67, 80,80, 80, 80, l4O, t4O and 140 L of IG-01 (Argon)

Clean Agent, respectively, The units are pressurized to 200, 200, 300, 300, 200,200,300, 300, 200, 300 and 300 bar, respectively, with

operating temperatures of -4oF (-20oC) to 149oF (65oC). The units are designed for total flooding protection against Class A surface burning,

Class B flammable liquid and C fires occurring within an enclosure.

NAFFCOInert, Models NFIG100-200-067A, NFIG100-200-067B, NFIG100-300-067A, NFIG100-300-067B, NFIG100-200-080A, NFIG100-200-080B,

NFIG100-300-080A, NFIG100-300-080B, NFIG100-200-140, NFIG100-300-140, and NFIG100-300-140A Clean Agent Extinguishing System Units,

stored pressure type, having nominal charging capacities of 67, 67, 67, 67, 80, 80, 80, 80, t4O, t4O and 140 L of IG-100 (Nitrogen) Clean Agent,

respectively. The units are pressurized to 200,200, 300,300, 2OO,200,300, 300,200,300 and 300 bar, respectively, with operating

temperatures of -4oF (-20oC) to 149oF (65"C). The units are designed for total flooding protection against Class A surface burning, Class B

flammable liquid and C fires occurring within an enclosure.

NAFFCOInert, Models NFIG55-200-067A, NFIG55-200-067B, NFIG55-300-067A, NFIG55-300-067B, NFIG55-200-080A, NFIG55-200-080B,

NFIG55-300-080A, NFIG55-300-080B, NFIG55-200-140, NFIG55-300-140, and NFIG100-300-140A Clean Agent Extinguishing System Units,

stored pressure type, having nominal charging capacities of 67, 67, 67, 67, 80,80, 80, 80, t4O, 140 and 140 L of IG-55 Clean Agent,

respectively. The units are pressurized to 200,200,300, 300, 20O,2OO,300,300,200, 300 and 300 ba[ respectively, with operating

temperatures of -4oF (-20oC) to 149oF (65oC). The units are designed for total flooding protection against Class A surface burning, Class B

flammable liquid and C fires occurring within an enclosure.

NAFFCOInert, Models NFIG541-200-067A, NFIG541-200-067B, NFIG541-300-067A, NFIG541-300-0678, NFIG541-200-080A, NFIG541-200-0808,

NFIG541-300-080A, NFIG541-300-0808, NFIG541-200-140, NFIG541-300-140, and NFIG55-300-1404 Clean Agent Extinguishing System Units,

stored pressure type, having nominal charging capacities of 67, 67, 67, 67, 80,80, 80, 80, L4O, L4O and 140 L of IG-541 Clean Agent,

respectively. The units are pressurized to 200, 200, 300,300,2OO,2OO,300, 300,200,300 and 300 bar, respectively, with operating

temperatures of -4oF (-20oC) to 149oF (65'C). The units are designed for total flooding protection against Class A surface burning, Class B

flammable liquid and C fires occurring within an enclosure.

These system units are intended to be designed and installed in accordance with the Listee's Engineered System Installation, Design and

Maintenance Manual, P/N 027650015-NF Rev. 07 dated September 2017, and the VDS SCHADENVERHUTUNG Engineered System Flow Calculation

Software Version 2.2.01.

AGENT STORAGE CONTAINER ASSEMBLY

Weight of Agent (lbs)

Palt No.

67L,200 Bar, IG-01 Unit

NFIG01-200-067A, NFIG01-200-067B

671, 300 Bar, IG-01 Unit

NFrG01-300-067A, NFrG01-300-067B

801, 200 Ba[ IG-01 Unit

NFIG01-200-080A, NFIG01-200-080B

http://database.ul.com/cgi-bin/)(Wtemplate/LISEXT/1FRAME/showpage.html?name=GAQF.EX15844&ccnshorttitle=Clean-agent+Extinguishing+Syst...

112

GAQF.EX15844 - Clean-agent Extinguishing System Units

12t9t2018

FIG01-300-080A, NFIG01-300-0808

BoL, 300 Bar, IG-01 Unit

N

1401, 200 Ba[ IG-01 Unit

NFrG01-200-140

1401, 300 Bar, IG-01 Unit

NFIG01-300-140, NFIG01-300-140A

67L,200 Bar, IG-100 Unit

NFrc100-200-067A, NFrG100-200-0678

671, 300 Bar, IG-100 Unit

NFIG

BoL, 200 Bar, IG-100 Unit

NFIG100-200-080A, NFIG100-200-0808

801, 300 Bar, IG-100 Unit

NFIG100-300-080A, NFIG100-300-080B

140L, 200 Bar, IG-100 Unit

NFIG100-200-140

1401, 300 Bar, IG-100 Unit

NFrG100-300-140, NFIG100-300-140A

67L,200 Bar, IG-55 Unit

NFIG55-200-067A, NFrG55-200-0678

671, 300 Bar, IG-55 Unit

N

80L, 200 Bar, IG-55 Unit

NFIG55-200-080A, NFIG55-200-080B

80L, 300 Bar, IG-55 Unit

NFIG55-300-080A, NFIG55-300-0808

140L, 200 Bar, IG-55 Unit

NFIG55-200-140

140L, 300 Bar, IG-55 Unit

NFIG55-300-140, NFIG55-300-140A

67L,2O0 Bar, IG-541 Unit

NFIG541-200-067A, NFIG541-200-0678

671, 300 Ba[ IG-541 Unit

NFIG541-300-067A, NFIG541-300-0678

801, 200 Bar, IG-541 Unit

NFIG541-200-080A, NFIG541-200-0808

BoL, 300 Bar, IG-541 Unit

NFIG541-300-080A, NFrG541-300-0808

140L, 200 Bar, IG-541 Unit

NFIG541-200-140

1401, 300 Bar, IG-541 Unit

NFIG541-300-140, NFIG541-300-140A

100-300-067A, NFIG100-300-067B

FIG55-300-067A, NFIG55-300-067B

Last UpjglCd on 2018-11-21

Questions?

Print this

Egg

Terms of Use

Ege

Top

O 2018 UL

LLC

The appearance of a company's name or product in this database does not in itself assure that products so identified have been manufactured

under UL's Follow-Up Service. Only those products bearing the UL Mark should be considered to be Certified and covered under UL's Follow-Up

Service. Always look for the Mark on the product.

UL permits the reproduction of the material contained in the Online Certification Directory subject to the following conditions: 1. The Guide

Information, Assemblies, Constructions, Designs, Systems, and/or Certifications (files) must be presented in their entirety and in a non-misleading

manner, without any manipulation of the data (or drawings). 2. The statement "Reprinted from the Online Certifications Directory with permission

from UL" must appear adjacent to the extracted material. In addition, the reprinted material must include a copyright notice in the following

format: "O 2018 UL LLC".

http://database.ul.com/cgi-bin/XWtemplate/LISEXT/l

FRAME/showpage.html?name=GAQF.EX15844&ccnshorttitle=Clean-agent+Extinguishing+Syst...

212

GAQF.EX15844 - Clean-agent Extinguishing System Units

12t9t20',!8

GAQF.EXts844

Clean-agent Extinguishing System Units

Ege

Bottom

See General Information for Clean-agent ExtinguishingSystem Units

,ffi1-{q$#

NATIONAL FIRE FIGHTING MFG FZ CO

PO BOX 17014

]EBEL ALI FREE ZONE

DUBAI, UNITED ARAB EMIMTES

ENGINEERED UNIT, NAFFCOInert, Models NFIGOl-200-067A, NFIG01-200-0678, NFIGO1-300-067A, NFIGO1-300-067B, NFIGO1-200-080A,

NFIGo1-200-0808, NFIGo1-300-080A, NFIGo1-300-080B, NFIGo1-200-140, NFIGo1-300-140, and NFIG01-300-140A Clean Agent Extinguishing

System Units, stored pressure type, having nominal charging capacities of 67, 67, 67, 67, 80,80, 80, 80, 140, t4O and 140 L of IG-01 (Argon)

Clean Agent, respectively. The units are pressurized to 200,200,300,300, 200,20O,300, 300,200, 300 and 300 bar, respectively, with

operating temperatures of -4oF (-20oC) to 149oF (65"C). The units are designed for total flooding protection against Class A surface burning,

Class B flammable liquid and C fires occurring within an enclosure.

NAFFCOInert, Models NFIG100-200-067A, NFIG100-200-0678, NFIG100-300-067A, NFIG100-300-0678, NFIG100-200-080A, NFIG100-200-0808,

NFIG100-300-080A, NFIG100-300-0808, NFIG100-200-140, NFIG100-300-140, and NFIG100-300-140A Clean Agent Extinguishing System Units,

stored pressure type, having nominal charging capacities of 67, 67, 67, 67, 80,80, 80, 80, t40, 140 and 140 L of IG-100 (Nitrogen) Clean Agent,

respectively. The units are pressurized to 200, 200,300,300, 200,200,300, 300,200, 300 and 300 bar, respectively, with operating

temperatures of -4oF (-20oC) to 149oF (65'C). The units are designed for total flooding protection against Class A surface burning, Class B

flammable liquid and C fires occurring within an enclosure.

NAFFCOInert, Models NFIG55-200-067A, NFIG55-200-0678, NFIG55-300-067A, NFIG55-300-0678, NFIG55-200-080A, NFIG55-200-0808,

NFIG55-300-080A, NFIG55-300-080B, NFIG55-200-140, NFIG55-300-140, and NFIG100-300-140A Clean Agent Extinguishing System Units,

stored pressure type, having nominal charging capacities of 67, 67, 67, 67, 80, 80, 80, 80, 140, I4O and 140 L of IG-55 Clean Agent,

respectively. The units are pressurized to 200, 200, 300, 300, 200,200,300, 300, 200, 300 and 300 bat respectively, with operating

temperatures of -4oF (-20oC) to 149oF (65'C). The units are designed for total flooding protection against Class A surface burning, Class B

flammable liquid and C fires occurring within an enclosure.

NAFFCOInert, Models NFIG54t-200-067A, NFIG541-200-0678, NFIG541-300-067A, NFIG541-300-067B, NFIG541-200-080A, NFIG541-200-080B,

NFIG541-300-080A, NFIG541-300-0808, NFIG541-200-140, NFIG541-300-140, and NFIGs5-300-140A Clean Agent Extinguishing System Units,

stored pressure type, having nominal charging capacities of 67, 67, 67, 67, 80, 80, 80, 80, t4O, l4O and 140 L of IG-541 Clean Agent,

respectively. The units are pressurized to 200, 200, 300, 300, 2OO,2OO,300, 300, 200, 300 and 300 bar, respectively, with operating

temperatures of -4oF (-20oC) to 149oF (65oC). The units are designed for total flooding protection against Class A surface burning, Class B

flammable liquid and C fires occurring within an enclosure.

These system units are intended to be designed and installed in accordance with the Listee's Engineered System Installation, Design and

Maintenance Manual, P/N 027650015-NF Rev. 07 dated September 20L7, and the VDS SCHADENVERHUTUNG Engineered System Flow Calculation

Software Version 2.2.01.

AGENT STORAGE CONTAINER ASSEMBLY

Weight of Agent (lbs)

Part No.

67L,20O Bar, IG-01 Unit

NFIG01-200-0674, NFIG01-200-0678

67L, 300 Bar, IG-01 Unit

NFrG01-300-067A, NFrG01-300-0678

801, 200 Bar, IG-o1 Unit

NFrG01-200-080A, NFrG01-200-0808

http://database.ul.com/cgi-bin/XWtemplate/LISEXT/l

FRAMUshowpage.html?name=GAQF.EX15844&ccnshorttitle=Clean-agent+Extinguishing+Syst...

112

12/9t2014

Last

GAQF.EXI5E44 - Clean-agent Extinguishing System Units

801, 300 Bar, IG-01 Unit

NFIGo1-300-080A, NFIGo1-300-0808

140L, 2OO Bar, IG-o1 Unit

NFIGOl-200-140

1401, 300 Bac IG-01 Unit

NFrG01-300-140, NFrGo1-300-140A

67L,2OO Bar, IG-100 Unit

N

FrG

100-200-067A, NFrG100 -200-067 B

671, 300 Bar, IG-100 Unit

N

FIG

100-300-067A, NFIG100-300-0678

80L, 200 Bar, IG-100 Unit

N

FIG

100-200-080A, NFIG100-200-0808

801, 300 Bar, IG-100 Unit

N

FrG

100-300-080A, NFrG100-300-0808

1401, 200 Bar, IG-100 Unit

NFrG100-200-140

1401, 300 Bar IG-100 Unit

NFrG100-300-140, NFIG100-300-140A

67L,200 Bar, IG-55 Unit

N

FIG55-200-067A,

N

FrG55-200-067B

67L, 3OO Bar IG-55 Unit

N

FIGSs-300-067A,

N

FrG55-300-067B

801, 200 Bar, IG-55 Unit

N

FIG55-200-080A,

N

FIG55-200-0808

801, 300 Bar, IG-55 Unit

NFrG55-300-080A, NFrG55-300-0808

1401, 200 Bar, IG-55 Unit

NFIG55-200-140

140L, 300 Bar, IG-55 Unit

N

FrG55-300-140, NFrG55-300- 140A

67L,200 Bar, IG-541 Unit

N

FIG541-200-067A, NFIG541-200-0678

671, 300 Bar, IG-541 Unit

N

FIG541-300-067A, NFIG541-300-0678

801, 200 BaL IG-541 Unit

N

FrG541-200-080A, NFrG541-200-0808

801, 300 Bar, IG-541 Unit

N

FIG541-300-080A, NFrG541-300-0808

1401, 200 Bar IG-541 Unit

NFIG541-200-140

1401, 300 Bar, IG-541 Unit

NFIG541-300-140, NFIG541-300-140A

UpjEtgl on 2018-11-21

Questions?

Print this p3gg

Terms of Use

Ege

Top

O 2018 UL

LLC

The appearance of a company's name or product in this database does not in itself assure that products so identified have been manufactured

under UL's Follow-Up Service, Only those products bearing the UL Mark should be considered to be Certified and covered under UL's Follow-Up

Service. Always look for the Mark on the product.

UL permits the reproduction of

the material contained in the Online Certification Directory subject to the following conditions: 1. The Guide

Information, Assemblies, Constructions, Designs, Systems, and/or Certifications (files) must be presented in their entirety and in a non-misleading

manner, without any manipulation of the data (or drawings). 2. The statement "Reprinted from the Online Certifications Directory with permission

from UL" must appear adjacent to the extracted material. In addition, the reprinted material must include a copyright notice in the following

format: "@ 2018 UL LLC'.

http://database.ul.com/cgi-bin/XWtemplate/LISEXT/l

FRAME/showpage.html?name=GAQF.EX15844&ccnshorttitle=Clean-agent+Extinguishing+Syst...

212

o[j-5Jl -iS aSJpi

e-o),,r-Jl dltj.:\

WBE FOR SAFEry CO.

l

2.

FIRE ALARM SHIELD

ER. ER.

t+138282422

Extinguishant

Control Panel

Shield A-XT is a new

generation extinguishant

releasing panel which is

UL,FM listed

The simple, programmable

configuration options and

easy to install construction

make Shield A-XT panels the

ideal choice for small to

medium sized systems

using all extinguishant

agents.

Proorammable

,-Features

B

fr

u1864 and FM listed

r- Product Overuiew

B

Three initiation circuits as standard

s

r

r

E

r

Any single zone or any

combinations of zones can

be configured to

Access Level 2

Test Zones I to 3

release

Disable Zones 1 to 3

Disable

lst

Stage Alarms

Disable Pre-actilEted

lst

Stage Relay

Disable Pre-acti\Eted 2nd Stage Relay

r

r

E

r

r

F

r

r

Disable Extract Fan Output

Disable Manual Release Input

Disable Extinguishant Sub System

Activate Extract Fan Output

E

Zone Alarm Delay (Call Poinb)

s

Configure Zone for LS Barrier Use

r

r

F

t

F

t

manual release option

B Non-latching zone input

option to receive signals

from other systems such

as aspirating equipment

Disable Panel Features

Zone Short Circuit Alarm

B The extensive configuration options of the Shield

A-XT allow the functionality of the system to be

extensively modified

tr The panel contains a large

LED display to enable

easy configuration and control which also displays

the time remaining until extinguishant release for

added user safety.

Configurable extinguishant

delays up to 60

in 5 second steps

6,

Configurable extinguishant

duration up to 5

in 5 second steps

E With all

seconds

Zone Non Latching

Zone Inputs Delay

Extinguishant Release Time Delay

Extinguishant Release Duration Timer

refighting installations

extinguishant release can be configured to

activate from any combination of detection zone

inputs to allow (among other combinations) any

two from three type activations such as would be

required for detection in ceiling void, room and

floor void applications.

tr Zero time delay upon

Access Leve! 3

Zone Alarm Delays (Detectors)

t he highest

E With three detection zones as standard,

Configurable detection delays

tr Compatible with LS. barriers

Coincidence Detection

fl

Configurable first stage

NAC delays

Activate Alarm Delays

Sounder Delay

Designed and manufactured to

standards in a quality controlled environment and

with uL & FM approvals, the Shield A-XT

releasing panel offers outstanding value

and performance for all small to medium fixed

minutes

of the electronics mounted on a single,

easily removable, steel plate Shield A-Xlpanels are

both robust and easy to install.

Extinguishant Reset Delay Timer

B Countdown timer shows

time remaining until release

Suppofts up to seven,

four wire status indicators

The countdown timer is duplicated on up to seven

remote status units to provide local indication of

the system status.

4

Shield A-XT is supplied in an enclosure that matches

the design and colour of the elite RS range and is

available in standard red or optional grey.

Built in Extract Fan control

Thp menrfa.'hrFr rc@rup< the ridhi tn ampn l qHifi.aH^n<

withdlt nd6r nntic

lat Staoc

ftraihn

Appfdr

Specifications

P8

;;;llftlgl

Er

a

,t

u

ffFI

Rdtlob

$

conbsl

Ir$uts

TofrE

AEifEy shrCtllc RdqE

Ljnlt

Technical

Construction

1.2mm mild sheet steel

lP30

lP Ratlng

Finish

Colour-lid&box

Malns supply

Mains supplyfuse

Power supply

ntlng

Maximum ripple current

Batterytype (Yuasa NP)

Battery charge voltage

Battery charge curent

Battery fuse

Maxlmum current draw from batterles

Qulescent curent of panel ln malns fail

output

RoV

Sounder outputs

Fault relay contact rating

Flre relay contact ratlng

Local fire relay Gontact rating

Flrst stage contact rating

Second stage contact rating

Extract contact rating

Zone quiescent current

Termina! capaclty

Number of det€ctors per zone

ratlng

-letectlon circuit end of line

lonltored Input end of line

Sounder circuit end of llne

Extinguishant output EOL

No. of initlating circuits

NAC

No. of NAC <ircuits

Extinguishant release output

Extlnguishant release delay

Extinguishant release duration

Sll- A!- FTL RST inputs

Zone norma! threshold

Detector alarm threshold

Call polnt alarm threshold

Short clrcult threshold

Monltored lnputs normal threshold

Monitored inputs alarm threshold

Monitored Inputs Short clrcuit threshold

Status uniUAncillary board connection

Statu3 unlt power output

Epory powdercoated

Red RAL 3002 (optional qrey BS 00 A 05 semFmatt)

230V AC or I 1 5V AC

1.6 Amp (Fl.6A L2s0V)

3 Amps total including battery charge 28V +/-2V

200 millivolts

Two 12 Volt 7Ah sealed lead acid in series

27.6VDC nominal (temperature compensated)

O.7A maximum

20mm, 3.15A glass

3 Amps

0.0954

Fused at 500mA with electronic fuse

24V Fused at 500mA with electronic fuse

30VDC lAAmpmaximum

30VDC lAAmpmaximum

30VDC 1A Amp maximum

30VDC 1A Amp maximum

30VDC 1A Amp maximum

30VDC 1A Amp maximum

2mA maximum

l2AWG

Dependent on type (maximum 32)

0.5A per circuit

6K8 5% /2 Watt resistor

6K8 5% Y2 Watt resistor

10K 5% % Watt resistor

,a\

g

1N4004 Diode

.L-

3

x lst Stage, I x 2nd Stage

I Amp

Adjustable 0 to 60 seconds (in 5 second steps)

Adjustable 60 to 300 seconds (in 5 second steps)

2

Fused at

Switched -ve, max resistance 100 Ohms

8K ohms to 1 K ohm

999 ohms to 400 ohms

399 ohms to 100 ohms

99 ohms to 0 ohms

8K ohms to I K ohm

999 ohms to 100 ohms

99 ohms to 0 ohms

Two wire R985 connection

Fused at 500mA with electronic fuse

'.5

ar$

Y

fr

Yet

r'

Panels

Product Code

SHIELD FIRE,SAFETY

AND SECURITY LTD

28th Floor Regus Suite

One Canada Square

Canary Wharf

London, E14 sDY

United Kingdom

511sR-EXT

S23OR-EXT

51 1SG-EXT

S23OG-EXT

Size (mm)

Description

Surface mounting panel - Red

1l5V

368x310x90

Surface mounting panel - Red

230V

368 x 310 x 90

368x310x90

Surfacemountingpanel-Grey239y 368x310x90

Surfacemountingpanel-Grey115V

The manufacturer reserves the right to amend specifications without prior notice

Fire Alarm Devices

Features

r

Twin LED for 360oview.

6€

Remote indicator output available.

Complies with EN 54-7 standard.

F-

..c

/4

-tl \

r;rtJ

Description

D-C401 Conventional Photoelectric Smoke Detector is

non-addressable. Used together with end of line unit, it can

process

connect with compatible control panels

detection signals. lt shows fire alarm by LED indicators and

transmits the fire signal to the control panel. Using infrared

scattering technology, the smoke density can be detected.

The detector receives very weak infrared light under

to

normal smokeless condition. lf smoke particles enter the

chamber,

the received light signal will increase

by

scattering. When smoke density reaches a pre-set level,

the detector will alarm out. ln order to reduce interference

and power consumption, the emitting circuit works in pulse

mode to prolong the life of lR LED.

Note: The detector shall be horizontally installed. ll it

has to be installed on an inclined plane, the inclinatlon

angle shall not be over 45o.

Fig. 3 shows the installation of the detector.

Connection and Cabling

Fig.1 shows the detector bottom and Fig. 2 the base.

Fio' 3

Application,

Fig.'l

There are four

'l: Detection

2: Detection

3: Detection

Warning: The detector should be connected with a fire

alarm control panel or other devices with current llmit

functlon. Othenrise the detector may be damaged by

heavy alarm current.

Fig.2

terminals with numbers on the base.

zone positive lN

zone positive OUT

zone negative lN and OUT

I

When the detector is connected with a compatible fire

alarm control panel in series, with a DB-CA active end of line

unit connected to the end of loop, a 1N5819 Diode should be

connected on the detector base.

Used as the detector base, the AEOL is to install

conventional detector

The system

connection is shown in Fig. 4.

2: Positive terminal of remote indicator

on it.

a

4: Negative terminal of remote indicator

Recommended Cabling

1.0mm2 or above fire cable is recommended but subject to

local codes.

lnstallation

A fixed installation direction is ensured by the

location

elements on the detector and the base. Fix the base with

two tapping screws, and then align mark C on the detector

with A on the base, rotate the detector to align mark C with

Bemoto

mark B (Refer to Fig. 1 and 2 for the position of the marks),

the detector will be fitted to the base.

t

lndicabr

Remote lndicator

ConventionalDeleclor

ConvfftionalDetector ConventionalMCP

Fig. 4

When the AEOL is not used as the detector

base, a cover should be put. The system connection

is shown in Fig. 5.

Specifications

Ooeratino Voltaoe

Standby Current

Alarm Currenl

lndicators

Remote

lndicator

Output

Fig. 5

base. The system connection is shown in Fig. 6.

Red. Quiet

in

normal condition.

llluminates steadilv in alarm.

Directly connecting

LED

(built-in 2kO resistor in series). Quiet

normal condition. llluminates

steadily in alarm.

4V (peak-to-peak)

with

in

I

When the detector is connected with a compatible fire

alarm control panel, with an end of line resistor connected to

the end of loop, there should be no diode connected on the

24YDC (12VDC-28VDC)

s608A

1OmAsls30mA

Maximum

Ripple

Voltaoe

Alarm Clear

lnstantaneous Power-off (5s Max.,

Power-up Time

Max. Wind Soeed

Wiring

2.SVDC Max.)

<10s

7.6m/s (1500fpm)

Polarized 2-nre tor detection zone

cable.

Polarized Z-core

R€motE

lndi€tor

Fig.6

Maximum 15 detectors can be connected in one zone.

Cooperating with end of line device, the compatible panel

can monitor the cable for open circuit and short circuit.

Panel will report if any detector is removed. With Active

End of Line unit (AEOL), the functioning of other device will

not be affected by the detector removal.

Maintenance

1. The detector should be

2.

3.

4.

just

installed

before

commissioning and kept well before installation, taken

corresponding measures for dust-proof, damp-proof

and corrosion-proof.

The dust-proof cover should not be removed until the

project plunged into usage. Otherwise it may not

report alarm properly.

Clean the detectors regularly, at least once a year to

ensure normal operation of the system.

Maintenance should be carried out for false alarm

detectors, either clean or replace the chamber if

necessary. Before cleaning, notify the proper

authorities that the system is under maintenance and

will temporarily be out of service. Disable the

automatic controls relating to the zone or system

under maintenance to avoid unwanted actions.

Steps for chamber cleaning:

a)

b)

c)

d)

Open the top cover of detector.

Draw out the chamber slightly shaking by hand.

Clean the internal of the chamber by alcohol

cotton or other clean liquid swab with tweezers.

Make sure not to leave any fiber in the chamber.

Put back the chamber and the top cover.

5.

The detector should be tested after re-instdled to

6.

ensure normal operation.

Fire simulation test should be done to the detector at

least every 6 months.

for

remote

indicator.

Ambient

temDerature

Relative Humidity

lngress Protection

Rate

Material and Color

of Enclosure

Dimensions

-108-+ 5ffi

Mounting

45mm-75mm

s957o, non condensinq

lP23

ABS, white (RAL9016)

Diameter:100mm

Heioht: 56mm (with base)

Hole

Distance

Weight

About 1209

Accessories and Tools

Model

Name

Remarks

DB-CA

Active End of Line Unii

Order seoaratelv

DZ-03

Base

Order seoaratelv

Limited Warranty

SHIELD warrants that the product will be free of charge for

repairing or replacing from defects in design, materials and

workmanship during the warranty period. This warranty does

not cover any product that is found to have been improperly

installed or used in any way not in accordance with the

instructions supplied with the product. Anybody, including

the agents, distributors or employees, is not in the position to

amend the contents of this warranty. Please contact your

local distributor for products not covered by this warranty.

Fire Alarm Devices

,{

Features

,\

Twin LED for 360"view.

J

Built-in microprocessor samples and collects

data in real time.

Rate of rise and fixed temperature alarm modes.

Remote indicator output avallable.

Complies with EN 54-5 standard.

)

)

)

Description

D-C4O2 Conventional Rate

of

Rise and

Fixed

Temperature Heat Detector is non-addressable. With

built-in microprocessor, it works stably with reliable

lixed fire judging program. Used together with an

active end of line unit (AEOL), it can connect with

Note: The detector sha!! be horizontally installed. lf

compatible control panels to process fire alarm signals.

It transmits fire signal to lire alarm control panel or

it

interface module by changing its own current and

shows the fire alarm by LED indicator until it's reset.

Fig. 3 shows the installation of the detector.

has to be installed on an lncllned plane, the

incllnation angle shall not be over tL5o.

Connection and Cabling

Fig.1 shows the detector bottom and Fig. 2 the base.

Fig. 3

Applications

Warning: The detector should be connected with

Fig.

Fig.2

1

There are four

1: Detection

2: Detection

3: Detection

terminals with numbers on the base.

zone positive lN

zone positive OUT

zone negative lN and OUT

2: Positive terminal of remote indicator

4: Negative terminal of remote indicator

Recommended Cabllng

1.0mm2

or above fire cable is

recommended but

subject to local codes.

lnstallation

A fixed installation direction is ensured by

current limit function. Otherwlse the detector may

be damaged by too heavy alarm current.

The detector is especially applicable to places where

fire occurs with sharp rise of temperature. Used

together with smoke detectors, it can detect fire with

more reliability to reduce losses.

I When the detector is connected with compatible

lire alarm control panel in series, it a DB-CA AEOL is

connected to the end of loop, a 1N5819 Diode should

be connected to the detector base.

I Used as the detector base, the AEOL is to

install a conventional detector on it. The system

connection is shown in Fig. 4.

the location

elements on the detector and the base. Fix the base

with two tapping screws, and then align mark C on the

detector with A on the base, rotate the detector to align

mark C with mark B (Refer to Fig. 1 and 2 for the

position of the marks), the detector will be fitted to the

base.

fire alarm control panel or other devlces with

Rffiolndk$r

Fig.4

Specifications

r

When the AEOL is not used as the

detector base, a cover should be put. The

system connection is shown in Fig. 5.

Operatinq Voltage

Standby Gurrent

Alarm Current

24VDC(12VDC-28VDC)

s60uA

lndicators

in normal condition.

llluminates steadilv in alarm.

Directly connecting with remote

indicator (built-in 2kQ resistor in

series,). Quiet in normal condition.

llluminates steadilv in alarm4V (peak-to. peak value)

1OmA<l<30mA

Red. Quiet

Hemole rnorcalon

output

Maximum

Ripple

Voltaoe

Fig. 5

I

When the detector is connected with compatible

fire alarm control panel, with an end of line resistor

to the end of loop, then no diode is

connected to the detector base. The system

connected

Alarm Clear

lnstantaneous Power-off (5s Max.,

2.5VDC Max.)

Power up Time

Action Temperature

<1Os

Class

A1B

Polarized z-core

Wiring

Polarized 2-core

Operating

Material and Color

lndi€tor

for

remote

<9570, nOn COnOenslnq

IP33

ABS, white (RAL9016)

of Enclosure

Diameter:100mm

Heioht: 58mm (with base)

Dimensions

Mounting

Fig.6

detection

indicator.

-1G- +508

Temperature

Belative Humidity

lngress Protection

Flatinn

lndietor

for

zone cable.

composition is shown in Fig. 6.

Bemote

588

Hole

45mm-75mm

Distance

Maintenance

Weiqht

Maximum 15 detectors can be connected in one zone.

Cooperating with end of line device, the compatible

panel can monitor the cable for open circuit and short

circuit. Panel will report if any detector is removed.

With Active End of Line unit (AEOL), the functioning of

other device will not be affected by the detector

About 120q

Accessories and Tools

Model

Name

DB.CA

Active End of Line Unil

DZ-O3

Base

Remarks

Order seoaratelv

Order seoaratelv

removal.

1

The detector should be installed just before

commission and kept well before installation,

taken corresponding measures for dust-proof,

damp-proof and corrosion-proof

2

.

The dust cover should not be removed until the

project has been plunged into usage. Otherwise it

may not report alarm normally.

3

Fire simulation test should be done to the detector

at least every 6 months.

Limited Warranty

SHIELD warrants that the product will be free of

charge for repairing or replacing from defects in design,

materials and workmanship during the warranty period.

This warranty does not cover any product that is found

to have been improperly installed or used in any way

not in accordance with the instructions supplied with

the product. Anybody,

including

the

agents,

distributors or employees, is not in the position to

amend the contents of this warranty. Please contact

your local distributor for products not covered by this

warranty.

WIRING DIAGRAM:

Smoke

Detector

Part Number S-C2011----------------

CONVENTIONAL

SMOKE DETECTOR

Standard Features

I

!

t

I

Responds

wellto slow-burning, smouldering

*

t\

o

Operati

fires

The S-A201 1 Photoelectric Smoke Detector

Well suited for bedrooms and escape routes

polycarbonate case with wind resistant smoke

inlets. Nickel plated stainless steel wiper

The alarm current also illuminates the detector

integral LED.

A

contacts connect the detector to the base.

between the

l

Unaffected by wind or atmospheric pressure

Wide operating voltage

Flashing LED option

I

@

'J:t

section - Smoke Detector

Flashing LED and magnet operated test switch

option

has

a

lnside the case a printed circuit board has the

optical system mounted on one side and the

signal processing electronics on the other.

The sensing chamber is a black moulding

configured as a labyrinth which prevents

penetration of ambient light.

Options

1. Flashing LED:The integral LED flashes when

the detector is in a quiescent state.

2. Magnetic test switch and Flashing LED:

A magnetic test switch in the circuit of the

detector can be magnetically activated from

outside the case to initiate an alarm condition

for test and commissioning purposes. A flashing

LED, as

outlined above, is also included.

obtuse angle to the diode.

moulded self-extinguishing white

The Shield Photoelectric Smoke Detector has

insect-resistant cover. The chamber houses

an infrared light emitting diode (LED) and a

photo-diode which has an integral visible-light

filter as extra protection against ambient light.

Every three seconds the LED emits a burst of

collimated light, modulated at 4kHz. ln clear

air, light from the LED does not fall directly on

the diode because the LED is positioned at an

L

remote indicator connected

lN terminal and the -R terminal

will have a voltage equal to the supply voltage

less 1 volt across it and so will illuminate.

To ensure correct operation of the detector

the control panel must be arranged to supply

a maximum of 33 volts DC and a minimum of

9 volts DC in normal operation. The supply

may fall to 6 volts DC in alarm conditions if a

supply current of at least 1OmA is available at

this voltage. To ensure effective illumination of

the integral LED and any remote indicator, the

supply to the detector should exceed 1 2 volts.

To restore the detector to quiescent condition,

it is necessary to expel any smoke and interrupt

the electrical supply to the detector for

a

minimum of one second.

Notc: Specifications are subicct to change without notice

Tech n ica I Specifi cations

Specifications are typical and given at 73'F and

50olo

relative humidity unless otherwise stated.

Detection Principle: Photoelectric detection of light scattered in a forward direction by

smoke particles

Chamber Configuration: Horizontal photoelectric bench housing an infra-red emitter and

sensor arranged radially to detect forward scattered light

Sensor: Silicon PIN photo-diode

Emitter: GaAs infra-red light emitting diode

Sampling Frequency: Once every 3 seconds

Supply Wiring: Two wire monitored supply, polarity insensitive

Terminal Functions:

Ll lN and

supply in connections (polarity insensitive)

Ll OUT and

supply out connections (polarity insensitive)

remote indicator negative connection

-R

L2

L2

SupplyVoltage:9 to 33 V DC

Ripple Voltage: 2V peak to peak maximum at

0.1 Hz

to 1 00kHz

Quiescent Current:3G50pA at 24V

Switch on Surge Current: I 1 5UA at 24V

Alarm voltage:6 to 28V

Normal Alarm Current:

61

mA at 28V 52mA at 24V 18mA at 1 0V

Design Alarm load:420pA in series with 2V drop

Alarm Reset Voltage: 1 2V

Alarm ResetTime:

I

second

Temperature range: -4"F to +140'F (No condensation or icing)

Humidity: (No condensation or icing)

0%o

to

9590 relative

humidity

Wind Speed: lnsensitive to wind

Atmospheric Pressure: lnsensitive to atmospheric pressure

lP Rating:23D

Detector weighL3.49 oz

Detector with base weight: 5.29 oz

Dimensions: Diameter:

Materials:

3.93'1

Height:

1.65",

Height in base: 1.96"

Detector Housing: White polycarbonate V-0 rated to

Terminals:

UL 94

Nickel plated stainless steel

Note: Specifications are sublect to change without notice

Address

Buttons

Thermistor Bead

lid Moulding

HeatDetector

@

When the sum of the resistance of the insulated

Heat Detector

Part Number

thermistor and the fixed resistor compared

to the

of the exposed thermistor

a preset value, an alarm is initiated.

The value of the fixed resistor is selected to

CONVENTIONAL

HEAT DETECTOR

t,

Standard Features

l)

!

I

I

Can be used for applications where smoke

detectors are unsuitable

ldeal environments that are dirty or smoky

under normal conditions

Wide operating voltage

f

I

$t'

{

*

{

Flashing LED option

!

resistance

reaches

Operation

set the detector into alarm state at a specified

fixed temperature.

The detector has a moulded self-extinguishing

white polycarbonate case. Nickel

plated

stainless steel wiper contacts connect the

detector to the base. lnside the case a printed

circuit board holds the signal

electronics.

A pair of

processing

matched negative

temperature co-efficient thermistors

The detector signals an alarm state by switching

an alarm latch on, increasing the current drawn

from the supplyfrom about 50prA to a maximum

of about 75mA.This fall in the impedance of the

detector is recognised by the control panel

as

an alarm signal.

are

The alarm current also illuminates the detector

Flashing LED and magnet operated test switch

mounted on the PCB in such a way that one

thermistor is exposed to give good thermal

option

contact with the surrounding air while the

between the LI IN terminal and the -R terminal

will have a voltage equal to the supply voltage

less 1 volt across it and so will illuminate.

other thermistor

Options

1. Flashing LED: The integral LED flashes when

the detector is in a quiescent state.

is

thermally insulated.

Under stable conditions both thermistors

are in thermal equilibrium and have the

same value

of

resistance.

lf air

temperature

increases rapidly the resistance ofthe exposed

thermistor becomes less than that of the

2. Magnetic test switch and Flashing LED:

A magnetic test switch in the circuit of the

integral LED. A remote indicator connected

insulated thermistor.The ratio of the resistance

detector can be magnetically activated from

outside the case to initiate an alarm condition

of the thermistors is monitored electronically

and an alarm is initiated if the ratio exceeds a

factory preset level. This feature determines

for test and commissioning purposes. A flashing

the'rate of rise'response of the detector.

LED as outlined above, is also included.

To ensure correct operation of the detector

the control panel must be arranged to supply

a maximum of 33 volts DC and a minimum of

9 volts DC in normal operation. The supply may

fall to 6 volts DC in alarm conditions if a supply

current of at least 10mA is available at this

voltage.

To ensure effective illumination of the integral

LED and any remote indicator, the supply to the

detector should exceed 1 2 volts. To restore the

detector to quiescent condition, it is necessary

Air temperature increase slowly, no significant

resistance difference develops between the

thermistors, but at high temperatures a fixed

value resistance connected in series with the

to

insulated thermistor becomes signifi cant.

for a minimum of one second.

restore a normal temperature level and

interrupt the electrical supply to the detector

Note: Speciflcations are subiect to change wlthout notlce

Tech n ical Specifi

cations

Specifications are typical and given at 73"F and 5070 relative humidity unless

otherwise stated.

5upply Wiring: Two wire supply, polarity insensitive

Terminal Functions:

Ll lN and

supply in connections (polarity insensitive)

supply out connections (polarity insensitive)

Ll OUT and

remote indicator negative connection

L2

L2

-R

Supply voltage:9-33V

Ripple voltage: 2V peak to peak maximum at

Quiescent current:

see

0.1 Hz

to 100kHz

table

Switch on surge current: As per quiescent current

Alarm voltage:

6

to 28V

Alarm indicator: Red light emmiting diode

Design Alarm load:420O in series with a 2V drop

Holding voltage: 6V

Holding current: 100mA

Storage temperature: -22'F to 248'F

Operating temperature: -4'F to 194'F (no condensation/icing)

Humidity:0 to 9570 relative humidity

lP

rating:23D

Detector weightz 2.82 oz

Detector with base weight 4.62 oz

Dimensions: Diameter: 3.93'i Height:

Supply

Voltage (v)

A1 R

Standard

Al

1.65'1

R

Height in base: L96"

Flashing LED

AI R Flashing LED/

Magnetic test switch

Quiescent

Quiescent

Alarm

Quiescent

Alarm

24

45pA

52mA

55pA

52mA

55pA

52mA

9

40pA

17mA

50pA

17mA

50pA

17mA

Alarm

Typical current against voltoge choracteristics for quiescent and alarm states

Note: specifications are sublect to change without notice

'rilt

t

lFdalW

Features

+

+

LED indication.

Built-incurrent-limitingresistor.

{

/

Description

R-C480S Passive Remote lndicator (the indicator) is

directly controlled by

a

detector

like

1/D-C401|D-A41AD-C402, transmitting the fire

alarm signal to the conspicuous place so that people in

D-A41

J

field can evacuate or dispose it urgently.

Connection and Cabling

Terminals are shown in Fig. 1.

m

+

Fig.

Application

+ The indicator can

connect with conventional

detectors like D-C401

graphic is shown in Fig.S.

1

" + ": To the anode of input line.

" - ": To the cathode oI input line.

or

D-C402, schematic

Recommended Cabling

'I .0mm2

or above fire cable for all the terminals, subject to

local codes.

lnstallation

The base of B-C480S is shown in Fig. 2. There are six

mounting holes, four oval at corners and two round near

the middle.

Fig. 5

The indicator can connect with intelligent detectors

such as D-A41'l or D-4412, as shown in Fig. 6.

E

s

42.5mmt 0.2mm

@

J.7fln

.).,/

UMtrU

,.1

\y

i

-'

L

Fig. 6

Specification

----i

Fig. 2

lf the cable conduit is on the surface, the indicator

is

installed directly on the wall, as shown in Fig. 3. And if the

cable conduit is inside the wall, a variety of back boxes are

available. Mounting method is shown in Fig. 4.

ODeratino Voltaoe

2.OVLr(;

Operating Current

Standby current : OmA

Action current <30mA

-:l-(IVLt(

Bed. lt turns off

lndicator

ODeratino TemDerature

Relative Humiditv

Material and Color of

Enclosure

Dimension (LxWxH)

when

but

constantly illuminates in action.

-10'C - +50'C

<95%. non condensino

monitoring normally,

ABS, White (RAL 9016)

64.SmmxM.Smmx31 .4mm

Limited Warranty

SHIELD warrants that the product will be free of charge for

repairing or replacing from defects in design, materials

and workmanship during the warranty period. This

warranty does not cover any product that is found to have

been improperly installed or used in any way not in

accordance with the instructions supplied with the product.

Anybody, including the agents, distributors or employees,

is not in the position to amend the contents of this

warranty. Please contact your local distributor for products

not covered by this warranty.

www.shieldglobal,com

DATA SHEET

Note: Specifications are subject to change without notice

W

SHIELD conventional standard base has been designed to enable detectors

to be fitted without the need of force - particularly useful when fitting to

suspended ceilings. All bases have one way only fit.

r

r

r

r

r

2 wire base.

One way fit.

Easy to wire.

Detector locking mechanism.

Contains no electrical parts.

Hg

"U

.d

v tr"

i -f

a_

J

Note: Specifications are subiect to change without notice

'Ir)l

f

I

Ez-*,cAW

Features

+

+

High sound level, over 75dB at 3m ahead

+

+

Circuitry and base are twisted together.

Standard: EN 54-3.

High bright red LEDs are used as light source.

horizontally (A weighted).

D,escription

S-C,181 Gonventional Sounder Strobe is a kind of

audible and visual alarm device used to warn people

in field when fire occurs. lt can give audible and visual

alarm when applied to 24VDC power (Dl connected

with anode and D2 with cathode). To connect it with

fire alarm control panel, an addressable control

module should be added

Al-510

to the system, such

as

Addressable Single l/O Module.

Both shallow base with 25.5mm high and deep base

with 40mm high are available, deep base is used if

there is no special statement in this manual.

Connection & Wiring

Terminals on the base are shown in Fig. 2.

\

J

+

{

!nstallation

+.

When the sounder strobe is surface mounted, it

should be placed 0.2m from the ceiling for

normal space height. When the conduit is

embedded, the base can be mounted on the

electrical box. When the conduit is surface

mounted, the deep base should be adopted.

Knock the knock-off hole, then connect the

conduit with it. The mounting hole spacing and

mounting direction are shown in Fig. 2. Mounting

method is shown in Fig. 3a and Fig. 4. When the

shallow base is required, the sounder strobe only

adopts conduit embedded. lts mounting method

is shown in Fig. 3b.

Knod({ff Hol6

Fig.

1

Fig.2

D1 (9), D2 (7): To 24VDC power, polarity-sensitive; D1

to anode and D2 to cathode.

Recommended Wiring

'l.5mm2 or above fire cable for 24VDC power line,

subject to local codes.

www.shieldglobal.com

DATA SHEET

Note: Specifications are subject to change without notice

Specification

Ooeratino Voltaoe

24VDC

Ooeratino Current

s65mA

Wiring

24VDC power

line,

rr)laritu-sensitive

Minimum Sound Level

75dB

Flashino Frequency

1.4x(1t200/olHz

Sound Pattern

2.8kHz (400ms on/340ms

off)

lngress

Protection

tP33

Ratino

+

Fig.4

The base and the sounder strobe are twisted

together. When mounting, remove the sounder

strobe, thread cables through the cable entry in

the base and connect with

corresponding

terminals, then twist the sounder strobe onto the

+

-

-10"C

Operating

Temoerature

+50'C

Relative Humiditv

s957o, non condensino

Material and Color of

ABS, red

Enclosure

1795C)

Dimension (LxWxH)

Q110mmx97.5mm (deep

base.

(PANTONE

base)

lf the sounder strobe is required

anti-removal,

knock down the arch knock-off hole as shown in

Fig. 1 and fix it with ST2.9x6.5 tapping screws (in

this case, it must be removed by a special tool).

O110mmx83mm(shallow

base)

Mounting

Hole

55mm

-

80mm

Soacino

Application

Apply 24vDC power

to D1(9) and

(polarity-sensitive, D1 (9) connects with anode and D2

monitoring state, there should be no voltage input.

Sound Level Data

Horizonlal

Vertical

18V

28V

18V

28V

150

74.47

78.16

71.95

75.55

450

81.85

86.44

82.03

85.36

75"

88.06

92.47

87.88

91.66

105.

88.15

91.93

89.14

92.92

135.

80.50

85.54

82.48

87.07

0

62.32

66.37

73.93

78.07

www.shieldglobal.com

31

7o(shallow base)

Accessories and Tools

Model

Name

Remark

S.49DB

Base

Suoolied seoaratelv

Limited Warranty

Fixed tone. Maximum Volume

165

About

D2(7)

(7) connects with cathode), and the sounder strobe

should generate audible and visual alarm. ln normal

Anqle

About 3459 (deep base),

Weight

SHIELD warrants that the product will be free from

delects in design, materials and workmanship during

the warranty period. This warranty shall not apply to

any product that is found to have been improperly

installed or used in any way not in accordance with the

instructions supplied with the product. Anybody,

including the agents, distributors or employees, is nol

in the position to amend the contents of this warranty.

Please conlact your local distributor for products not

covered by this warranty.

DATA SHEET

Note: Specifications are subject to change without notice

Fire Alarm Devices

c\

Features

+

Low current consumption - only 20mA

+

+

+

+

+

Quickly and easily installed

,I

J

Excellent sound, up to 100dBA @ 1 mt

I

Suitable for indoor and outdoor use

Easy installation and connection

Operating Voltage:

- 6VDC, 12VDC, 24V DC

- 120VAC,220VAC

Description

The FB-1000 series Bells are of aluminum

construction and have a very high sound output

matched with extremely low power consumption with

Alarm Bel! lnstallation

20mA for 6 alarm bell.

The Alarm Bell base should be installed to comply with

The FB-1000 series can be used for internal and

all local codes having a jurisdiction in your area or

eternal installation using the specially designed

NFPA 72 National Fire Alarm Code, NFPA 70 National

weatherproof bells having an back box giving either

Electrical Code. lt is installed onto a standard one

single or double threaded entry for maximum flexibility

square standard outlet gang electrical box.

in installation. Weatherproof bells are supplied as a full

fixing kit with gasket and screws.

Wiring and Gonnection

Connect the wires to the required terminal according

to the wire color. The red cable and the black cabled.

The cable must be fire rated type and the size

depends on the distance and application. Minimum

size gauge 1.0mm2(18 AWG)

.-sdt

gOI

sY ormEnal

FE OrrILEr

6ur*udi

-r'*'*..-

tl

4'

f

Technical Specifications

.q'

T

FFilrnffi/ttlI F&1m([

FFImE/WP

Description

i'{l50mm}

6'{l50mm)wp B'{tffimm}

l'{2il1mm}wp

Protection Rating

tP33

rp65

tP65

Part Number

tP 33

UL4S[

Approval

EvacuateSound :9F$7dB {at mFf}

$ound Level 0utput

Porrrer $upply 24Vdc to I20 VAC

0peratingVoltage

trmAto lfrlmA

Rated Cunent

-10f to50{

OperatingTemperature

Applimtion

lndoor

@9596 Relative Humidity

Indoor

Cutdoor

Aluminium/Rd

Materialand Color

tlliring

2

Wire for Power fable { Polarized}

Ordering lnformation

Part Number

Description

FB-lMOC6AR/P

6" Alarm Bell Weather proof

FB-1m0C8

FB.lOOOCBAIVP

B" Alarm Bell

E" Alarm Bell Weather proof

Selection of compatible Contro! Panels

Compatible with all Shield Conventional panel and

Shield !ntelligent panel using sounder output and

-

lntelligent Sounder Driver Module (Al-514)

Limited Warranty

SHIELD warrants that the product will be free of

charge for repairing or replacing from defects in

design, materials and workmanship during the

wananty period. This warranty does not cover any

product that is found to have been improperly installed

or used in any way not in accordance with the

instructions supplied with the product. Anybody,

including the agents, distributors or employees, is not

in the position to amend the contents of this warranty.

Please contact your local distributor for products not

covered by this wananty.

0utdoor

it-

I

?,t

.

y-I

ftf

<t

A

I

.I

SHIELD

{

J

l

rcltogc

Supdy rcltog.

Ehckirl mmibring

: 2,lV DC

: ,U0R rsics r..irtor

Cdour

:ld

Supgly

Opsaine tmemtur!:.2dCto + 8dC

Elcclricol

moniuring

:

Colow

470Rshr rrri:for

: Rcd

Wihtrs3porud@s

tlomiml rclbgo

Cumnt

Colour

Sound olput

Wcight

: ZilV DC

; 16

ml

: Rcd

: l00dBA@

I

mlr.

:300grom:

rcllogr

Cural

Colosr

;Z4VDC

: Rcd

floshfrcqumcy

Voltogc

Cmloch

Cdou

r lHz

OperaingT.mpcroturo: -ZdCo + 8dC

Eorh cnrgy

Wb'lhl

:0.7i

Nmiml

Supph