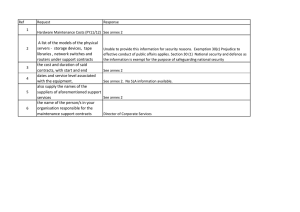

GMP Inspection Preparation Checklist A Tool for Internal Auditing and Training Copyright© 2017 by FDAnews. Digital version ISBN: 978-1-60430-025-3. Price: $230. All rights reserved. Contains material excerpted from GMP Manual, Good Manufacturing Practices and Implementation, Copyright © 2012 by Maas & Peither AG - GMP Publishing, reprinted with permission. Photocopying or reproducing this book in any form, including electronic or facsimile transmission, scanning or electronic storage is a violation of federal copyright law and is strictly prohibited without the publisher’s express written permission. No copyright is claimed in the text of guidances, regulations and excerpts from regulations quoted within this work. This report may not be resold. FDAnews only sells its publications directly or through authorized resellers. Information concerning authorized resellers may be obtained from FDAnews, 300 N. Washington St., Suite 200, Falls Church, VA 22046-3431. Main telephone: (703) 538-7600. Toll free: (888) 838-5578. While every effort has been made by FDAnews to ensure the accuracy of information in this report, this organization accepts no responsibility for errors or omissions. The report is sold as is, without warranty of any kind, either express or implied, respecting its contents, including but not limited to implied warranties for the report’s quality, performance, merchantability, or fitness for any particular purpose. Neither FDAnews nor its dealers or distributors shall be liable to the purchaser or any other person or entity with respect to any liability, loss, or damage caused or alleged to be caused directly or indirectly by this report. GMP Inspection Preparation Checklist A Tool for Internal Auditing and Training Table of Contents Introduction Using the Checklist......................................................................................................................... 5 Part I: General Questions for Manufacturers of Medicinal Products and Active Pharmaceutical Ingredients (API).................................................................................................. 6 1. Opening discussion................................................................................................................. 6 2. Application File for Marketing Authorization or Regulatory approval................................ 7 3. Personnel and QMS............................................................................................................. 7 4. Buildings and Infrastructure.................................................................................................10 5. Sanitation...............................................................................................................................12 6. Apparatus and Equipment....................................................................................................13 7. Control of Raw Materials and Containers............................................................................14 8. Sampling of Materials, Reference and Retention Samples................................................15 9. Storage and Distribution....................................................................................................... 17 10. Manufacture and Process Controls......................................................................................18 11. Packaging and Label Control................................................................................................19 12. Laboratory Controls...............................................................................................................20 13. Product Release.....................................................................................................................21 14. Rejection and Reprocessing.................................................................................................22 15. Documentation......................................................................................................................22 16. Contract Manufacturing/Contract Analysis.........................................................................24 17. Complaints and Recalls........................................................................................................26 18. Self-Inspection.......................................................................................................................28 19. Qualification and Validation..................................................................................................28 20. Change Control......................................................................................................................32 21. Liquids, Creams and Ointments...........................................................................................34 Part II: Manufacturing and Testing of Sterile Products.............................................................. 35 22. Manufacture of Sterile Products...........................................................................................35 23. Aseptic Processing.................................................................................................................36 24. Isolator Technology................................................................................................................36 25. Blow-Fill-Seal Technology......................................................................................................36 26. Terminally Sterilized Products...............................................................................................36 • Rooms and Equipment...................................................................................................... 37 • Processing..........................................................................................................................38 27. Heat Sterilization...................................................................................................................40 28. Sterilization Using Moist Heat...............................................................................................40 29. Sterilization Using Dry Heat..................................................................................................41 30. Sterilization by Radiation......................................................................................................41 31. Sterilization with Ethylene Oxide..........................................................................................41 32. Sterile Filtration without Final Sterilization..........................................................................42 33. Finishing of Sterile Products.................................................................................................42 34. Sterility Testing.......................................................................................................................43 Part III: Trade of Active Pharmaceutical Ingredients (API) and Excipients............................... 44 35. Trade of Active Pharmaceutical Ingredients and Excipients, Including Repackaging/Relabeling.......................................................................................................44 Introduction Regulatory inspections are, in many regards, stressful situations for the people at the receiving end. Because there generally is a great deal hanging on the result of the inspection, all the members of staff involved in the inspection are under intense psychological pressure, which can make it difficult to present normally self-evident processes to the investigator in a comprehensible way and to answer questions fully and correctly. Common concerns include the following: ºº Will we be able to provide the correct answers or explanations to the questions posed in spite of general nervousness? ºº Can we prove everything with documented evidence? ºº Can we explain that (and how) our GMP or QA system works? ºº Is our GMP status adequate? ºº Will the staff make oversights because they feel watched or because they are scared to fail? ºº Will the investigators set “traps?” ºº Will someone be caught out by their own reasoning because they want to make a particularly good impression? ºº How will we stand internally after the inspection, e.g. with regard to other departments? Preparation can help relieve these uncertainties, and internal audits can play an important part. The advantage of internal auditing is that you can play with an open hand, and any deficiencies that are recognized can be corrected before an official inspection begins. The disadvantage is that an internal auditor can be too familiar with the company’s individual processes and may be blind to problems an outsider would see. Another drawback to internal auditing is that company auditors are likely to use terms and concepts unique to the company rather than those a regulator or other independent investigator would recognize, leaving both sides feeling like they are speaking a foreign language. Even the terms used in GMP rules and regulations do not always correspond to the expressions used in the company and can cause uncertainty. For example, if an investigator asks about “test procedures,” does he or she mean the control procedures, the testing instructions, the testing plan, the analysis procedure, the calibration procedure or the stability plan? What does “process instruction” mean in a particular instance? The EU GMP regulations may define it as the manufacturing formula or processing instructions, while FDA regulations may use the term “master production record.” The generality of investigators’ questions also can present a problem. What do they mean by “adequate water systems,” “suitable equipment” or “qualified personnel?” Suppliers, who have generally structured their quality management system according to ISO standards, in particular use very different terms than customers that inspect them for GMP compliance. How do “quality planning,” “quality control,” “quality assurance” and “quality improvement” translate into GMP terms? The best way to avoid such misunderstandings is to train internal auditors to ask – and staff to answer – the same questions they would face in an outside inspection. This checklist includes more than 650 of the most common GMP inspection questions asked by investigators from the FDA and international regulators. Divided into three sections – general questions, questions related to manufacturing and testing of sterile products and questions on trade of active pharmaceutical ingredients and excipients – the checklist provides a framework for conducting internal audits that can serve as preparation for facing regulatory inspections. About the Authors Max Lazar, Chemist, FDA Regulatory Compliance Consulting For more than 35 years, Max Lazar worked with Hoffmann-La Roche. Following his retirement, he established a consulting business specializing in API GMP issues and the training of personnel covering the ICH Q7 guidance. His more than 40-year career in the pharmaceutical industry includes numerous memberships in professional organizations and chairs of committees. Christine Oechslein, Pharmacist, GMP-Praxis As a freelance GMP trainer, Christine Oechslein provides internal GMP training for pharmaceutical companies, manufacturers of active ingredients and suppliers. She has worked in the pharmaceutical industry for many years. As a speaker and an author, she shares her GMP knowledge in the areas of process validation, GMP training and GMP in development. Bernhard Gotter, Pharmacist, F. Hoffman-La Roche, Ltd. Bernhard Gotter took up the position of QA Manager in inspection management at F. Hoffmann-La Roche in 2016. In the previous five years, he had worked at Bayer in quality assurance, auditing, supplier management and project management. During this time, he managed numerous audits, and organized and supported official inspections. GMP Inspection Preparation Checklist: A Tool for Internal Auditing and Training Using the Checklist There are three ways to use the GMP Inspection Preparation Checklist: 1. As a tool for planning and guiding an internal audit; 2. As a training resource for employees that will be involved in future regulatory inspections; and 3. As a guide to prepare for an upcoming inspection, especially to identify documentation that will need to be readily available. However, when using checklists to prepare for an inspection, it must be taken into consideration, that: ºº Simply filling in these lists can at best provide an initial overview; they should not replace the kind of intensive internal review needed to maintain a company’s quality system; ºº Checklists can never be as comprehensive, exhaustive or specific enough to do justice to the situation at every company (pharmaceutical, supplier, packaging, etc.) with all their different product ranges, equipment pools and organizational structures; and ºº Specific national or regional requirements may have to be considered in addition to the checklist. And while a list of questions can help an internal auditor ensure that all relevant areas are reviewed, it can’t tell you what the right or best answers are. It also isn’t the correct tool for documenting audit findings. Simple yes or no answers don’t provide the details necessary to evaluate and deal with problems. A separate table is recommended for documenting findings (see Figure 1). Figure 1. Sample Audit Findings Table Question Fulfilled yes or no Partially fulfilled acceptable Partially fulfilled not acceptable Not fulfilled Comment/Discussion and Documents Examined 1. 2. etc. In the following checklist, most questions cite the particular regulatory reference that applies from either the U.S. Code of Federal Regulations and/or the EU GMP Guideline. 5 GMP Inspection Preparation Checklist: A Tool for Internal Auditing and Training Part I: General Questions for Manufacturers of Medicinal Products and Active Pharmaceutical Ingredients (API) Typical audit questions 1. Opening discussion 1.1 Name and function of all persons present at the meeting EU GMP Guideline CFR reference no partly met/ not accepted partly met/ accepted yes/met Assessment 1.2 Which operations are performed at the inspected company? 1.2.1 Manufacturing of • • • • Drug substances (API) Excipients Packaging material Drug product? o o o o Packaging, Repackaging or labeling? o o 1.2.3 Contract Manufacturing? o o 1.2.4 Quality Control? o o 1.2.5 Contract Analysis? o o 1.2.6 Batch Release? o o 1.2.7 Storage? o o 1.2.8 Distribution? o o 1.2.9 Import, Export, Trade? o o o o o o Chapter 1: Principle o o Annex 16: General principles, 1.1, 1.3 1.2.2 1.2.10 Other 1.3 Do the completed operations require a permit (authorization) from the relevant authorities? • 1.4 o o o o Is the permit (authorization) present and is it up to date? Does an SMF exist? o o 1.4.1 Is it up to date? o o Chapter 4: Required GMP documentation 1.4.2 Does it refer to the guidance of the EU GMP Guideline Part III? o o Part III, SMF 1.5 Have there been any changes with regard to the company‘s ownership or corporate identity? o o 601.12 1.6 Have any additions or changes been made to the buildings or facilities which could affect the manufacture of the inspected product? o o 601.12 Annex 15: 11.2 o 601.12 Part III: 4.1 1.7 6 Is a current building floor plan available? o o o GMP Inspection Preparation Checklist: A Tool for Internal Auditing and Training Typical audit questions 2. o o o o o o o o 3.2 Are there up-to-date detailed job descriptions for personnel who carry out GMP tasks? o o o o 3.3 Have there been changes of personnel which could have an effect on the product concerned? o o o o Were the authorities informed when required? o o o o Who is responsible for manufacturing? 3. Personnel and QMS 3.1 Is a current organization chart available? 3.5 o o o o 3.5.1 Does he/she have the necessary qualifications, knowledge and practical experience? o o o o 3.5.2 Does he/she have sufficient skills/competences? o o o o o o o o Who is responsible for Quality Control? o o o o 3.7 Are raw materials, intermediates and/or final products approved by authorized persons as defined by regulatory authorities? o o o o 3.7.1 Is a “Qualified Person” designated? o o o o 3.7.2 Do they have the necessary qualifications, knowledge and practical experience? o o o o 3.7.3 Do they have sufficient skills/competences? 3.6 EU GMP Guideline Application file for marketing authorization or regulatory approval 2.1 Do the actual manufacturing and testing procedures agree with the Marketing Authorization/Regulatory Filing? 3.4 CFR reference no partly met/ not accepted partly met/ accepted yes/met Assessment Is there a quality control unit in place? • 1.4xv, 1.8, 1.9 v + vii 4.2 + 6.15 Annex 16: 1.3, 1.7.5 601.12 2.2 2.3 Part II: 3.11 601.12 1.4xii 2.7 211.25 2.1 2.2, 2.3 211.22 6.1 2.8, 6.1–6.2 Part II: 2.13, 2.19 211.22d Part II: 2.14, 2.32 Annex 16 2.5 211.25 2.3, 2.6, 6.1 Annex 16: 1.2 2.2, 2.3, 6.1 o o o o 3.8 Are the responsibilities and procedures of the Quality Control Unit established in written documentation? o o o o 3.9 Are the heads of Production and Quality Control independent from each other? o o o o 3.10 Are there enough appropriately qualified personnel for each department? o o o o 211.25c 1.8 iii+v 2.1, 2.102.14, 6.6 Part II: 3.10 3.11 Is there a written training plan for employees? o o o o 211.25a 2.11, 4.29 Part II: 3.12 3.11.1 Does it include basic GMP principles as well as applicable regulations? o o o o 211.25a 2.11 3.11.2 Does training include initial (new to the job) as well as ongoing (long-term) training? o o o o 211.25a 2.7 vi, 2.8 vii, 2.11 211.22 1.5, 2.8, 2.9 Part II: 2.13, 2.32 2.5, 6.1 7 GMP Inspection Preparation Checklist: A Tool for Internal Auditing and Training Typical audit questions yes/met partly met/ accepted partly met/ not accepted no CFR reference EU GMP Guideline Assessment 3.11.3 Does it include information on technical, maintenance and cleaning personnel, as well as sales, production planning, QS and temporary staff? o o o o 3.11.4 Does it address the specific requirements of each working field? o o o o 211.25a 2.12, 2.22 Annex 1 A. 3: 1, A. 5: 1, A. 6: 2, A. 8: 1, A. 11: 2, A. 13: 3 3.12 Are there written records maintained of employee training? o o o o 211.25 2.11 Part II: 3.12 3.13 Is the effectiveness of training measures verified? How? o o o o 3.14 Are the qualifications of consultants checked? o o o o 211.34 2.23 Part II: 3.30 3.15 Is there a list of all consultants, their addresses, qualifications and the tasks they perform? o o o o 211.34 2.24 Part II: 3.31 3.16 Is a documented quality assurance system in place? o o o o 1.7 Part II: 2.11 3.16.1 Does the QMS refer to the size and complexity of the corporate activities? o o o o 1.3 3.16.2 Is it documented in a quality manual or other appropriate document? o o o o 1.7 2.10 2.13 2.11 Part II: 3.12 3.16.3 Is its suitability regularly checked? o o o o 1.4 xvii, 1.6 3.16.4 Is it supported by the management and personnel on all levels at all sites? o o o o 1.5 3.16.5 Has a quality risk assessment been implemented as an essential part of the QM System? o o o o 1.3, 1.4 xv, 1.12 Part III: Q9 3.17 Does the QMS cover all existing areas: o o o o 1.1, 1.2 3.17.1 Product development? o o o o 1.2, 1.4 iii 3.17.2 Production of investigational products? o o o o 1.2 3.17.3 Outsourced operations (including transfer of technology)? o o o o 1.2 + 1.4 vii 3.17.4 Commercial manufacture up to the suspension of production? o o o o 1.2 o o o o 1.4 xv 3.18.1 GMP is considered at development and manufacturing stages? o o o o 1.2, 1.4 iii + iv 3.18.2 Product and process knowledge are maintained across the entire product life cycle? o o o o 1.4 ii 3.18.3 Process performance and quality of the product are being kept under control with efficient surveillance and control systems? o o o o 1.4 viii 3.17.5 Batch release? 3.18 Does the QMS ensure that: 8 GMP Inspection Preparation Checklist: A Tool for Internal Auditing and Training Typical audit questions yes/met partly met/ accepted partly met/ not accepted no CFR reference EU GMP Guideline Assessment 3.18.4 The outcome of product and process surveillance at batch release, variance analysis and CAPA is being considered? o o o o 1.4 ix 3.18.5 Continuous quality improvement is conducted, including the current status of the product and process knowledge? o o o o 1.4 xii 3.18.6 Planned changes are evaluated and authorized in advance? o o o o 1.4 xiii 3.18.7 The completion of changes and their impact on the quality of the product are checked? o o o o 1.4 xiv 3.18.8 Deviations, suspected product defects and problems are systematically checked (root cause analysis) and CAPA measures are adopted? o o o o 1.4 xv, 1.8 vii, 1.9 vi 3.18.9 The efficiency of CAPAs is monitored on a risk based approach? o o o o 1.4 xv o o o o 1.4 v 3.19 Is the leadership responsibility of the management concerning GMP clearly specified? 3.20 Does the senior management carry the responsibility that: 3.20.1 A valid QMS exists and is being used? o o o o 1.5 3.20.2 Appropriate resources are available? o o o o 1.5 3.20.3 The scope of duties and all responsibilities are defined and communicated? o o o o 1.5 3.21 Are there regular management reviews in order to continuously improve product, process and QMS? o o o o 1.6 3.22 Are there procedures in place for notifying responsible senior management in case of regulatory inspections, severe GMP deficiencies, product faults or subsequent related actions (complaints, recalls)? o o o o 211.180f Part II: 2.18 3.23 Are there regular product reviews conducted for all permitted products or products manufactured in the EU? o o o o 211.180e 1.10, Part II: 2.60 3.23.1 Is the PQR conducted and documented at least yearly? o o o o 1.10, Part II: 2.60 3.23.2 Is it used in order to identify trends and improvement possibilities (CAPAs)? o o o o 1.10, 1.11 Part II: 2.61 3.23.3 Are the results evaluated? o o o o 1.11 Part II: 2.61 3.23.4 Is the quality and traceability of all starting and packaging materials as well as the qualification status of the supplier checked? o o o o 1.10i 3.23.5 Are the results of critical IPCs, final product checks and stability programs evaluated? o o o o 1.10i + vii 3.23.6 Are all deviations, OOS-batches, complaints and recalls checked, as well as associated inspections, including CAPAs? o o o o 1.10iii + iv + viii 3.23.7 Is the efficiency of previous CAPAs checked? o o o o 1.10 ix 9 GMP Inspection Preparation Checklist: A Tool for Internal Auditing and Training Typical audit questions partly met/ not accepted no EU GMP Guideline partly met/ accepted 3.23.8 Are all changes to process, analysis methods and marketing authorization dossier checked? o o o o 1.10 v + vi 3.23.9 Are potential post marketing obligations checked? o o o o 1.10 x 3.23.10 Is the qualifying status of relevant equipment and rooms checked? o o o o 1.10 xi 3.23.11 Are all contractual agreements that affect the product checked? o o o o 1.10 xii, Chapter 7 o o o o o o o o o o o o Buildings and infrastructure 4.1 Are all buildings and rooms of an appropriate size, build and location in order to facilitate cleaning, maintenance and operations? • Are they qualified? 4.2 Are buildings/rooms kept in an adequately clean, hygienic and tidy condition? 4.3 CFR reference yes/met 4. Assessment 211.42 211.58 600.11 1.8 iii Chapter 3, Part II: 4.10 Annex 15 211.56a 3.2, 5.11, 5.19, 5.21 Part II: 4.7 Are separate or defined areas of sufficient size available for: 4.3.1 Incoming goods? o o o o 4.3.2 Storage of raw materials? o o o o 211.42c1 4.3.3 Storage of packaging materials? o o o o 211.42c1 4.3.4 Weight of the contents? o o o o 4.3.5 Manufacture? o o o o 211.42c5 3.1–3.8 Part II: 4.14 4.3.6 Packaging? o o o o 211.42c6 3.15 4.3.7 Quality control? o o o o 211.42c9 3.26–3.29 Part II: 4.14, 4.16 4.3.8 Storage of semi-finished or in-process materials? o o o o 211.42c4 1.8 iii, 3.8, 5.41 4.3.9 Storage of finished products? o o o o 211.42c8 1.8 iii 5.63-5.65 o o o o 3.24 4.4 Are the rooms used exclusively for their intended purpose? o o o o 3.5 Part II: 4.43 4.5 Is the material flow and the production process logical so as to minimize the risk of mix-ups or omission of manufacturing or testing steps? o o o o o o o o o o o o 3.7, (Annex 1-3) o o o o 2.7 iv, 2.8 v 4.3.10 Storage of highly toxic medicinal products and narcotic substances? 4.6 Are the rooms labeled? 4.7 Are the rooms classified according to their cleanliness? 4.8 10 Are the rooms regularly maintained? 3.20, Part II: 4.14 3.18, 5.7 Part II: 4.14 1.8 iii, 3.25 3.13 211.42b +c 3.7, 3.8, 3.38 Part II: 4.13, 5.26 GMP Inspection Preparation Checklist: A Tool for Internal Auditing and Training Typical audit questions yes/met partly met/ accepted partly met/ not accepted no CFR reference EU GMP Guideline Assessment 4.9 Are different tasks carried out in areas set up especially for that purpose and which are of an appropriate size and which have suitable equipment so as to prevent contamination and mix-up? o o o o 211.42 3.1, 3.7–3.8 3.14, 5.175.20 Part II: 4.13 4.10 Are measures taken to avoid cross-contamination? o o o o 211.42 3, 3.6, 3.8, 3.14, 3.15, 3.22, 5.9, 5.17–5.21 Part II: 4.13, 4.42 o o o o 211.46 3.3, 3.12 Part II: 4.21 o o o o 211.46 3.6 4.11.2 Are filters regularly changed and checked? o o o o 4.11.3 Is a cross contamination in the ventilation and air conditioning system ruled out (circulating air, waste air, air flow)? o o o o 4.12.1 Do constant conditions exist concerning temperature, moisture and, if applicable, particle and bacterial count? o o o o 4.12.2 Are temperature and humidity constantly checked? o o o o 4.11 Ventilation 4.11.1 Are the ventilation and air conditioning systems qualified, are they regularly maintained and checked? • Are there separated ventilation systems for highly active agents? Part II: 4.21 4.12 Control of temperature and moisture 4.12.2.1 Storage rooms? o o o o 4.12.2.2 Production rooms? 3.19 o o o o 4.12.2.3 Rooms with sensitive appliances? o o o o 4.12.2.4 Are all measures taken in case of overrun or lower deviation? o o o o 4.13 Is the lighting adequate? o o o o 211.44 3.3, 3.16 Part II: 4.5 4.14 Are the installed finishes for the walls, ceilings and floors capable of not emitting particles into the room? o o o o 211. 42c10i 3.9 4.15 Are the rooms easy to clean and, if necessary, to disinfect? o o o o 211.42 211.56 3.9, 3.14 Part II: 4.10 4.16 Is the access to GMP-areas restricted to authorized personnel? o o o o 211.28c 3.5, 5.16 4.17 Is it ensured that production areas are not used as a passage by staff members who do not work in these areas? o o o o 4.18 Do the personnel enter production areas solely via the changing rooms, or via the double door system (if applicable)? o o o o 4.19 Is it ensured that street clothes are not taken into rooms with specific requirements? o o o o 1.4 ix 3.5 Annex 1: 20, 42 11 GMP Inspection Preparation Checklist: A Tool for Internal Auditing and Training Typical audit questions partly met/ accepted partly met/ not accepted no EU GMP Guideline yes/met CFR reference Assessment 4.20 Are Quality Control laboratories separated from production areas? o o o o 4.21 Are the water systems adequate? o o o o 211.48 3.43 Part II: 4.30, 4.34 4.22 Are waste and sewage disposed of safely and hygienically? o o o o 211.50 3.11 Part II: 4.24, 4.6 5. Sanitation 5.1 Is there a written sanitation program? 3.26–3.29 6.5 Part II: 4.16 211.56a o o o o 211.56 2.15, 3.2 4.29, Part II: 4.71 o o o o 211.56 3.2 Part II: 4.71 o o o o 211.56 2.9, 3.2 5.3 Do the personnel practice good sanitation and health habits? o o o o 211.28b 2.15, 2.17, 2.22 Is direct contact with products avoided? o o o o 5.4 Is eating and smoking prohibited in the manufacturing areas? o o o o 211.28b 2.19, Part II: 3.23 5.5 Is clean hygienic and protective clothing worn that is suitable for the activities performed? o o o o 211.28a 2.15, 2.18 Part II: 3.21 5.6 Are staff members who are suffering from an infectious illness, or who have open wounds, excluded from direct contact with products? o o o o 211.28d 2.16 Part II: 3.24 5.7 Where applicable, are there written procedures on how to prevent microbiological contamination of medicinal or API products? Are they complied with? o o o o 211.113 5.10 o o o o 211.56 3.2 Part II: 4.70 5.9 Are the rooms free from rodents, birds, insects and other vermin? o o o o 211.56c 3.4 Part II: 4.72 5.10 Are there adequate clean toilet and washing facilities easily accessible from working areas? o o o o 211.52 2.21, 3.31 Part II: 4.15 5.11 Are there sufficient changing rooms? o o o o 5.12 Is there a written environmental monitoring plan? o o o o 5.1.1 Does it contain responsibilities as well as cleaning intervals, techniques, equipment and materials? 5.2 Is the sanitation program followed? • 5.8 12 Are the rooms clean? Part II: 3.2 2.20, Part II: 3.22 3.31 211. 42c10iv 2.9 ii, 4.29 5.12.1 Are there records available? o o o o 4.29 5.12.2 Are the measures carried out documented? o o o o 4.29 GMP Inspection Preparation Checklist: A Tool for Internal Auditing and Training Typical audit questions partly met/ accepted partly met/ not accepted no EU GMP Guideline yes/met CFR reference Assessment o o o o 211.63 211.65 3.34–3.39 Part II: 5.10 Annex 9: 2 o o o o 211.67a 3.36 Part II: 5.10 Annex 9: 1 6.3 Are tanks, containers, pipes and pumps designed and installed in such a way that they can be easily cleaned and disinfected? There should be no dead-legs or poorly accessible points. o o o o 6.4 Are sufficient measures carried out during the manufacturing and packaging operations to prevent contamination of the medicinal or API products and their containers? o o o o 211.42b 211.65b 3.38 6.5 Is the equipment constructed in a way that surfaces which come into contact with products do not alter the quality of the products? o o o o 211.65 3.39 Part II: 5.11, 5.14 Annex 9: 3 6.6 Is defective equipment removed from the production or control area or clearly labeled as defective? o o o o 211. 160b4 3.44 6.7 Are there up-to-date drawings available of the equipment and installations? o o o o 6.8 Are there written plans available for DQ, IQ, OQ, PQ and requalification? o o o o Are the qualification plans based on documented quality risk assessments? o o o o 6.9 Are there specifications available and written protocols of regular calibration of measuring, weighing, recording and control equipment? o o o o 211.68 211.160b4 211.194d 3.41 Part II: 5.30 6.10 Are there written procedures on how to clean and maintain the equipment? o o o o 211.67 2.7iv + 2.8v, 3.36, 3.43, Part II: 5.2 o o o o 6. Apparatus and equipment 6.1 Is the design, installation and location of all apparatus suitable for the intended purpose? 6.2 Is thorough cleaning facilitated? • 6.10.1 Are they sufficiently detailed? 3.10 Part II: 4.23 Annex 9: 2 Part II: 5.16 211.68 4.29 Annex 15 1.13 Part II: Q9, Annex 15: 1.7 Do they contain information on cleaning intervals? o o o o 6.10.3 Do they specify when cleaning has to be repeated, in case equipment has not been used for some time? o o o o 6.11 Are they complied with (e.g. cleaning intervals, maintenance intervals)? o o o o 211.67 3.36 6.12 Are cleaning, maintenance and use of equipment documented, e.g. in equipment logs? o o o o 211.182 4.29, Part II: 6.2 6.13 Have the cleaning processes been validated? o o o o Annex 15: 10.1 6.14 Who performs equipment cleaning? o o o o 2.10, 2.11, 2.12 6.10.2 13 GMP Inspection Preparation Checklist: A Tool for Internal Auditing and Training Typical audit questions partly met/ accepted partly met/ not accepted no EU GMP Guideline yes/met CFR reference Assessment o o o o 2.10, 2.11, 2.12, 2.13 o o o o 2.10, 2.11, 2.12 o o o o 2.10, 2.11, 2.12, 2.13 6.16 Are there written operating instructions for manufacturing and testing equipment? o o o o 4.30 6.17 Are logbooks kept (for major equipment)? o o o o 211.67c 211.182 4.31 6.18 Are all the major equipment and facilities identified and is this information included in batch records? o o o o 211.105b 4.20e 4.21e 6.19 Are there records available on the cleaning and usage of the equipment? o o o o 211.67c 211.182 4.29, 4.31 Part II: 6.2 6.20 After maintenance or repairs, are appliances/equipment approved to be GMP-compliant for use? o o o o 6.21 Are there adequate controls for the computers and associated systems to ensure that changes to the (master) specifications can only be made by authorized personnel? o o o o 211.68 4.1, 4.2, 4.3 Part II: 5.4 6.22 Is the data input and output checked for accuracy? o o o o 211.68 Annex 11: 6 Part II: 5.45 6.23 Are files backed up? o o o o 211.68 Annex 11: 7.2 6.24 Are fiber-releasing filters used for liquid filtration? If so, are additional non-fiber-releasing filters used as required? o o o o 211.72 • Is this staff specially trained to perform cleaning correctly? 6.15 Who performs maintenance of equipment? • Is this staff specially trained in GMP issues? 7. Control of raw materials and containers 7.1 Is there a list available of all raw material suppliers? o o o o 680.1 7.2 How often is this list updated? o o o o 680.1 7.3 Have the suppliers been suitably qualified? o o o o • 1.4vi, 1.10 i 5.27-5.29 + 7.4, 7.5 Part II: 7.11, 7.31 o o o o 5.29 Were all required steps to qualify a supplier conducted? o o o o 1.4 vi 7.5 Are there written contracts, and where appropriate, Quality Agreements with suppliers that address GMP expectations/requirements? o o o o 1.4vi, 1.10xii, 5.28, Chapter 7 7.6 Are there supplier lists for all incoming raw materials, including those that are rejected? o o o o Part II: 7.1 o o o o 7.4 7.7 14 Are the suppliers continuously monitored? 5.27, Part II: 7.1 Are there records for all raw materials? 211.180b 4.22 GMP Inspection Preparation Checklist: A Tool for Internal Auditing and Training Typical audit questions partly met/ accepted partly met/ not accepted no EU GMP Guideline yes/met CFR reference Assessment 7.7.1 Do they contain details of their origin? o o o o 1.4 vi, 4.23d, 5.27 Part II: 7.13 Annex 2: 26 7.7.2 Do they contain the date of receipt? o o o o 4.23c 7.7.3 Is every single delivery of starting materials and packaging materials checked as to whether they originated through an approved supply chain? o o o o 1.4vi, 1.10i 7.8 Are there written instructions that describe the following procedures for raw materials and product containers: 211.80 211.82 5.2 Part II: 7.10, 7.33 + 7.4 7.8.1 Receipt o o o o 4.22, 4.23 7.8.2 Identification o o o o 4.23, 4.24 7.8.3 Storage o o o o 4.24 7.8.4 Handling o o o o 7.8.5 Sampling o o o o 4.25 7.8.6 Analysis o o o o 4.26 7.8.7 Release or rejection? 4.27 o o o o o o o o 211.80 Chapter 4, Principles 7.10 Is each container identified with a unique code when it is received? (Not required in the U.S.) o o o o 211.80d 4.24, 5.3 Part II: 7.24 7.11 Is there a status identification for each batch? o o o o 211.80d 5.32 7.12 Are there adequate quarantine procedures in place? o o o o 211.82b 211.110d2 11.142 4.24, 5.2, 5.5, 5.63 Part II: 4.14, 7.10, 7.44, 10.11 o o o o 211.82 Chapter 4, Principles 7.13 Are all materials fully and satisfactorily assessed before they are approved or used? o o o o 211.84a 1.9 Part II: 2.17, 7.20 7.14 Does the manufacturer rely on the suppliers‘ certificates? o o o o 211.84d2 + d3 If yes, how does the manufacturer “validate” the suppliers‘ test results? o o o o 5.27, 5.28, Part II: 7.30 Annex 8: 3 o o o o o o o o o o o 7.9 Are these instructions/procedures followed? • • Are they complied with? 7.15 Are there written specifications that ensure that product containers and closures are suitable for their intended use? 8. • Are they complied with? 211.94 211.130d Sampling of materials, reference and retention samples 8.1 Are the personnel who carry out the sampling sufficiently trained to do this correctly? o 1.9i, 4.25 Annex 8: 1 15 GMP Inspection Preparation Checklist: A Tool for Internal Auditing and Training Typical audit questions partly met/ accepted partly met/ not accepted no EU GMP Guideline yes/met CFR reference Assessment 8.2 Are samples from each shipment of each batch taken, tested or examined correctly and approved for use by quality control? o o o o 211.84a 211.84e 1.9ii 4.25 8.3 Is at least one identity test carried out for each raw material? Are specific identity tests used? o o o o 211.84d1 5.33 Part II: 7.30 Annex 8: 3 8.4 Is each individual container sampled and identity tested or is there a validated process to ensure that not one single container can be incorrectly labeled? o o o o 8.5 Are there measures in place to prevent contamination/cross-contamination of the sampled material during sampling? o o o o 211.84c2 211.80b 4.25 Part II: 7.34 Annex 8: 1 8.6 Is the number of samples taken determined statistically and established in a sampling plan? o o o o 211.84b 211.165c 1.9ii Part II: 7.33 Annex 8: 4 8.7 Are there written instructions to ensure that the samples are representative and adequately labeled? o o o o 211.84 211.160 211.110 211.186 b(9) 1.9ii, 4.25, 6.11–6.13 Part II: 7.33, 11.12 Annex 8: 4 211.188 b(10) 211.194 a(1) Annex 8: 1 8.7.1 Are there records of every sampling? Annex 8: 2 Annex 8: 3 o o o o o o o o 8.7.2 Are sampled containers marked to indicate that a sample has been taken from it? o o o o Part II: 7.35 8.8 Is the number of individual samples to be blended to form a composite sample defined? o o o o Annex 8: 4 Are the packaging material manufacturers audited? o o o o Annex 8: 5 8.10 Are the sampling plans for packaging materials sufficiently detailed? o o o o 4.25 Annex 8: 5 8.11 Does the manufacturer, importer or site of batch release keep reference and/or retention samples from each batch of finished product (active pharmaceutical ingredient/ medicinal product)? o o o o 211.170 1.9viii, 6.2, 6.14 Part II: 11.7, 19.81 Annex 19: 2.2, 4.3 8.12 Are the reference samples stored in identical or comparable packaging to the commercial product? o o o o 211.170b 1.9viii, 6.14 Part II: 11.72 Annex 4: 8 +9 • 8.9 Do they also include (unusual) observations of the sampler? Annex 19: 3.1 8.13 Does the manufacturer keep a reference sample from each batch of starting material (including packaging material) or intermediate product? 16 o o o o Annex 19: 2.2 GMP Inspection Preparation Checklist: A Tool for Internal Auditing and Training Typical audit questions yes/met partly met/ accepted partly met/ not accepted no CFR reference EU GMP Guideline Assessment 8.14 Are the reference and retention samples from finished products retained for at least one year after the expiry date? o o o o 211.170b Annex 19: 3.1 8.15 Are the reference samples from starting materials (other than solvents, gases or water) retained for at least two years after the release of the product? o o o o 211.170a Annex 19: 3.2 8.16 Are the reference samples from packaging materials retained for the duration of the shelf life of the finished product? o o o o Annex 19: 3.2 9.1 Is it ensured that medicinal products are appropriately stored and dispensed to ensure that their quality during shelf-life is preserved? o o o o 1.4xvi, 1.8 iii 9.2 Are there written instructions for storage and quarantine procedures? o o o o 211.82b 211.142 211.110d 5.2, 5.63 Part II: 7.10, 7.4, 10.1 9. Storage and distribution o o o o 211.142 5.2, 5.63 9.3 Are the containers stored correctly in the warehouse (e.g. under controlled conditions)? o o o o 211.82 211.142b 3.18–3.25, 5.7 Part II: 7.4 9.4 Are the containers in the warehouse correctly labeled? o o o o 211.80d 211.82 5.32 Part II: 8.11 Are the containers free from any damage? o o o o 211.82a 5.30 9.6 Are rejected materials clearly labeled and controlled using a suitable quarantine system? o o o o 211.89 211.42c2 211.110d 3.23, 5.66 Part II: 4.14 + 7.44 + 10.1 9.7 Does the “FIFO” (first-in first-out) or “FEFO” (firstexpired first-out) principle apply in the warehouse? o o o o 211.86 211.150a 5.7 Part II: 7.42 9.8 Are there written instructions and records regarding distribution? o o o o 211.150 5.2 Part II: 10.2 o o o o 5.2 9.9 Are products transported in such a way that their quality is not affected? o o o o • Are special transport or storage conditions indicated on the label? o o o o 1.4xvi, 1.8iii + ix Part II: 10.21, 10.22 9.10 Does the manufacturer make sure that the transport company knows and complies with the transport and storage conditions? o o o o 9.11 Do the warehousing and distribution specifications/ documentation make provision for a recall if necessary? o o o o 211.150 4.28, 4.29 Part II: 10.24 9.12 Are returns labelled as such and placed in quarantine until a decision is made regarding their further use/destruction? o o o o 211.204 5.70 Part II: 14.5 + 17.8 • 9.5 • Are they complied with? Are they complied with? Part II: 10.23 17 GMP Inspection Preparation Checklist: A Tool for Internal Auditing and Training Typical audit questions partly met/ accepted partly met/ not accepted no EU GMP Guideline yes/met CFR reference Assessment 9.13 Are records kept on returns and their further disposition? o o o o 211.204 5.70, 1.10viii Part II: 14.52,17.8 9.14 Are there written instructions on how to deal with returns? o o o o 211.204 4.29 5.70 o o o o 211.204 Chapter 4: Principles 10.1 Are there written instructions for production and process controls that ensure that an acceptable product is manufactured? o o o o 211.100 211.110 211.186 211.188 5.2 Part II: 8.30 1.8i 10.2 Are manufacturing operations and controls carried out under the management and supervision of responsible specialists? o o o o 211.25 2.7 Part II: 2.2 + 2.3 10.3 Are weighing, measuring and sub-dividing operations adequately supervised? Is the addition of raw materials to the product verified by a second person? o o o o 211.101 Part II: 8.12 10.4 Is all equipment inspected for cleanliness immediately before use? o o o o 211.67b6 5.40 Part II: 5.21 10.5 Are all the vessels, containers, machines, major equipment and pipes clearly and visibly identified? o o o o 211.101b 211.105 3.42, 5.12, 5.13 Part II: 5.26, 5.13, 4.23, 8.11, 8.16 10.6 Is the content and the manufacturing step always indicated on the equipment/containers? o o o o 211.105a 5.12 Part II: 8.16 10.7 Are actual yields and the percentages of theoretical yield determined at the end of each appropriate manufacturing step? o o o o 211.103 211.188b7 211.192 4.17d, 4.20g 5.44, 5.8, 5.61 Part II: 8.14 10.8 Are these calculations verified by a second person? o o o o 211.103 6.17vii 4.20 c + i Part II: 6.52, 6.60 10.9 Are there written instructions for in-process controls (IPC)? Are they complied with? o o o o 211.110 4.18e Part II: 8.3 10.10 Are IPC techniques authorized by quality control/ quality assurance? o o o o 10.11 Are there time limits established for completion of each manufacturing step? o o o o 211.111 Part II: 8.2 10.12 Are deviations from specifications documented, justified and authorized? o o o o 211.110b 211.111 4.20h, 1.8vii, 5.15, 5.44, 5.61, Part II: 2.16 • 10. 18 Are they complied with? Manufacture and process controls 6.18 Part II: 8.32 GMP Inspection Preparation Checklist: A Tool for Internal Auditing and Training Typical audit questions partly met/ accepted partly met/ not accepted no EU GMP Guideline yes/met CFR reference Assessment 10.13 Are intermediate products and bulk stored under suitable conditions? o o o o 10.14 Are there written procedures for reprocessing and/or reworking products that do not comply with specifications? o o o o 10.15 Are only sub-batches or intermediate products that correspond to the specification blended to give a homogeneous batch? o o o o 10.16 Is there a “manufacturing history” (list of all the manufactured batches of the product concerned, including defective batches)? o o o o 211. 180e1 1.10ii-iv 11.1 Are there written instructions that describe receipt, identification, storage and handling of labels and packaging materials in detail? o o o o 211.122a 4.22, 5.45, 5.62 Part II: 9.10 11.2 Are records kept for each shipment of labelling or packaging material indicating the results of inspection? o o o o 211.122c 4.22 Part II: 9.12 11.3 Are the labels for each different product stored separately and suitably identified? o o o o 211.122d 3.25, 5.46, 5.47 11.4 Is access to the label storage locations controlled? o o o o 211.122d 3.25, 5.46 Part II: 9.30 11.5 Are out of date or obsolete labels and packaging materials destroyed? o o o o 211.122e 5.48 Part II: 9.33 11.6 Are excess labels/packaging materials bearing batch/ control numbers destroyed? o o o o 211.125d 4.21h, 5.62 Part II: 9.32 11.7 Are there written instructions that describe labeling issuance in detail? Are they complied with? o o o o 211.125f 5.46 Part II: 9.31 11.8 Is the amount of bulk product and printed packaging material reconciled against the number of units actually produced? o o o o 11.9 Are discrepancies investigated, documented and reported? o o o o 211.125c 211.192 5.61, 1.4ix Part II: 9.31 11.10 Has it been shown that containers are suitable and that they provide sufficient protection against deterioration or contamination during storage and transport? o o o o 211.94b Part II: 9.2 11.11 Are containers and closures stored in such a way that contamination, damage and mix up/misidentification can be prevented? o o o o 211.80b-d 211.122d 11.12 Are there written instructions to ensure that the correct labels and packaging materials are used? o o o o 211.130 4.19d Part II: 9.35, 9.40 11.13 Are packaging and labeling results documented in batch processing records or batch packaging records? o o o o 211.130d 4.21 d + f Part II: 9.35 11.14 Are packaging and labeling activities carried out in such a way that mix-ups are prevented, i.e. physically or spatially separated from other products? o o o o 211.130a 5.49 Part II: 9.41 11. 5.7, 5.41 Part II: 17.4 211.115 211.165f 5.67 Part II: 14.2, 14.3 Part II: 8.4 Packaging and label control 4.21h, 5.61 Part II: 9.31 19 GMP Inspection Preparation Checklist: A Tool for Internal Auditing and Training Typical audit questions partly met/ accepted partly met/ not accepted no EU GMP Guideline yes/met CFR reference Assessment 11.15 Are there written procedures for the complete removal of previously used materials and the cleaning and inspection of packaging areas before the start of the next packaging operation? o o o o 211.130e, 211.188b6 11.16 Are tamper-evident closures or seals (seals for tank wagons or HGVs) used? o o o o 211.132 11.17 Are packed and labeled products tested adequately? Are a representative number of packages sampled after completion of packaging operations and visually examined for correct labelling? o o o o 211.134 4.19i, 5.59 Part II: 9.45 11.18 Are the results of these investigations entered in the batch records? o o o o 211.134c 5.60 Part II: 9.45 11.19 Do the products bear an expiration date that has been determined in stability studies? o o o o 211.137 211.166 4.19e Part II: 11.6 12.1 Are there adequate written instructions that ensure that raw materials, containers, in-process materials, labels and products correspond with the actual standards (specifications) with regard to identity, strength, quality and purity? o o o o 211.22d 211.160 211.165 4.13–4.16, 4.26 6.2 Part II: 11.11 12.2 Are these instructions authorized by quality assurance/quality control? o o o o 211.160a 1.9i + ii Part II: 11.12 12.3 Do the testing methods comply with those described in the Marketing Authorization or Regulatory Filings? If there is a Contact in place for the product, are the contract requirements being satisfied? o o o o 12.4 Do all the specifications, sampling plans and analytical procedures have a scientific basis? o o o o 211.160b 1.4ii + iv Part II: 11.12 12.5 Are there written instructions for calibrating instruments, measuring and recording devices with exact specifications, schedules, limits for accuracy and precision and procedures in the event of deviations? o o o o 211. 160b4 3.41, 4.29 6.7 + 6.19 Part II: 12.82 12.6 Are there complete calibration records? o o o o 211.194d 4.29, 6.7 12.7 Do premises and equipment of control laboratories meet the specific tasks performed in the particular lab? o o o o 12.8 Have the precision, sensitivity, selectivity and reproducibility of the test methods been validated? o o o o 211.165e 211.194a2 1.9iii, 6.15 Annex 15: 5.9, 9.1-9.3 Annex 16: 1.7.12 Part II: 12.8 12.9 Is there a written test program designed to assess the stability characteristics of products? o o o o 211.166 6.2, 6.266.36 Part II: 11.5 12.10 Is a sufficient number of batches of each product tested to determine the stability? o o o o 211.137 211.166 6.30 Part II: 11.5 12. 20 4.19 f + g 5.50 Laboratory controls 6.15 Part II: 13.17 Annex 16: 1.7.13 6.5, 6.6 GMP Inspection Preparation Checklist: A Tool for Internal Auditing and Training Typical audit questions partly met/ accepted partly met/ not accepted no EU GMP Guideline yes/met CFR reference Assessment 12.11 Are the stability tests that are carried out fully documented and archived? o o o o 211.194e Part II: 11.5 12.12 Is there a written procedure for handling OOSresults? o o o o 211.160a 6.7iv, 6.35 Part II: 11.15 12.13 Are all deviations from instructions documented and investigated? o o o o 211.100b 1.9vi, 5.15 Part II: 2.16 Annex 16: 3.1 211.160a 12.14 Are trend evaluations performed on analytical test results, yields and environmental controls? o o o o 12.15 Are changes in methods documented and compared to the established methods? o o o o 12.16 Are reagents and standards manufactured and labeled in accordance with written procedures? o o o o 12.17 Is the handling of reference standards (source and manufacture, storage, analysis, use) documented? o o o o 211.194c Part II: 11.17–11.19 13.1 Are there written procedures for the approval and rejection of materials and products? o o o o 211.84a +e 211.122b 211.165 1.4xv, 1.9vii 2.8i, 4.27, 6.3 Part II: 2.13, 2.14 13.2 Are approved starting materials/containers re-inspected if they are expired or following exposure to harmful conditions, such as heat, moisture, etc.? o o o o 211.87 211.160b1 13.3 Is the batch release of products performed in accordance with their specific Marketing Authorizations or Regulatory Filings? o o o o Annex 16: 1.7.5 13.4 Is each batch of a finished drug product certified by a QP within the EC/EEA before being released for sale or supply in the EC/EEA or for export? o o o o Annex 16: 1.1, 4.1 13.5 Does the QP ensure that reliance on earlier quality relevant steps is well founded? o o o o Annex 16: 1.3-1.4.3, 1.5.6, 1.5.7, 1.7.1-1.7.3 13.5.1 Manufacture and packaging in accordance with GMP? o o o o Annex 16: 1.7.7 13.5.2 Each site involved holds a Manufacturing Authorization? o o o o Annex 16: 1.3, 1.7.4 13.5.3 The batch and its manufacture do comply with Marketing Authorization or Regulatory Filing? o o o o Annex 16: 1.7.5 13.5.4 Manufacturing and testing processes have been validated? o o o o Annex 16: 1.7.12 1.4x 13. 6.9, 6.32 211.194b 6.19–21 Part II: 11.16 Product release 21 GMP Inspection Preparation Checklist: A Tool for Internal Auditing and Training Typical audit questions partly met/ accepted partly met/ not accepted no EU GMP Guideline yes/met CFR reference Assessment 13.5.5 Any deviations and changes in production and control have been authorized according to a procedure and, if appropriate by regulation, authorities are notified? o o o o Annex 16: 3.1, 1.7.15, 1.7.16 1.4xiii 13.5.6 All checks and tests have been performed? o o o o Annex 16: 1.7.15 1.4x 13.5.7 Production and QC documents are completed and authorized? o o o o Annex 16: 1.7.11 13.5.8 All audits were carried out according to QA System? o o o o Annex 16: 1.7.3 1.4xvii 13.5.9 Any other quality-relevant factors are taken into account? o o o o Annex 16: 1.7.1 13.6 Does the QP rely on the confirmation of one or more other QPs? Is there a written agreement on the specific responsibilities of each QP involved? o o o o Annex 16: 1.4.1, 1.4.3 14.1 Are materials that do not correspond to the specifications placed in quarantine? Is the further disposition (e.g. reprocessing, disposal) of such materials documented? o o o o 211.42c2 211.89 211.110d 211.122b 211.165f 211.184e 6.66 Part II: 7.44, 14.1 14.2 Is a careful investigation of the cause of failure carried out before reprocessing or reworking? o o o o 211.115 Part II: 14.30 14.3 Before reprocessing or reworking, is there an investigation into whether the quality of the materials would be negatively affected by the reprocessing/reworking (e.g. creation of by-products, stability)? o o o o 211.165f 5.67, 5.69 6.33 14.4 Are there written procedures describing the cleaning of reusable containers (for active pharmaceutical ingredients or excipients)? o o o o Part II: 9.22 o o o o 1.8iv 4.18 4.19 14. 15. Rejection and reprocessing Part II: 14.22 Documentation (instructions, records and reports) 15.1 Are there current operating procedures that are accessible to all staff? 15.2 Do the processing instructions address: 15.2.1 Equipment o o o o 15.2.2 Methods o o o o 15.2.3 IPCs o o o o 15.2.4 Storage of bulk or intermediates o o o o 15.2.5 Any special precautions o o o o o o o o 15.3 Are the operating procedures regularly reviewed, updated, and authorized by responsible persons? Is staff properly trained? 22 4.3, 4.5 GMP Inspection Preparation Checklist: A Tool for Internal Auditing and Training Typical audit questions partly met/ accepted partly met/ not accepted no EU GMP Guideline yes/met CFR reference Assessment 15.4 Do the operating instructions and specifications comply with the Marketing Authorization or Regulatory Filings? o o o o 15.5 Are there effective measures in place to prevent inadvertent use of outdated and deleted or replaced documents? o o o o 15.6 Are all quality-relevant activities documented at the time they are carried out? o o o o 211.100b 211.160a 211.182 15.7 Is handling of raw data described in a written procedure? o o o o 211.194(4) 4.8, 6.10 Part II: 6.6 15.7.1 Can raw data be changed or destroyed? o o o o 15.7.2 Can raw data get lost? o o o o 15.7.3 Are printouts from equipment fully traceable? o o o o 15.8 Are handwritten entries in documents made in a clear, legible and indelible manner? Are any alterations to entries signed and dated, and made in a way that the original information is still visible? o o o o 15.9 Are cleaning, maintenance and usage records available for all major equipment (e.g. in logbooks, see question 6.17)? o o o o 211.182 4.31 Part II: 6.2 15.10 Are there complete records of suppliers, test results, and usage of starting materials, product container, closures and labels? o o o o 211.184 4.14, 4.22–4.24 5.2 Part II: 6.3 Do records also include receipt of each delivery, test or examination records, and inventory records of each material as well as label checks? o o o o 211. 184 a–d 4.22, 5.2 Part II: 6.3 15.11 Are the master manufacturing instructions and control procedures available and complete? o o o o 211.186 4.17, 4.18, 4.26 Part II: 6.4 15.12 Are these checked, dated and signed by a second independent person? o o o o 211.186 Part II: 6.40 15.13 Are the manufacturing instructions and control procedures (batch documentation) available and complete? o o o o 211.188 211.68(b) 4.20, 6.7 Part II: 6.5 o o o o o o o o 211.186 4.3 Part II: 2.21 Annex 16: 1.7.11 • • Is the corresponding master record reproduced accurately? 15.14 Are all the manufacturing and control documents authorized by persons entitled to do so? 1.10vi + x 4.1 + 4.2 Annex 16: 1.7.5 1.8vi, 4.8 Part II: 2.15, 6.14 4.7, 4.9 Part II: 6.14 23 GMP Inspection Preparation Checklist: A Tool for Internal Auditing and Training Typical audit questions partly met/ accepted partly met/ not accepted no EU GMP Guideline yes/met CFR reference Assessment 15.15 Are all production and control records reviewed by a Quality Unit function before the product is released (batch record review)? o o o o 211.192 6.3, 1.4vx Part II: 2.13, 2.14, 6.71 Annex 16 15.16 Is the collection of critical data checked by a second person? o o o o 211.192 211.194a8 211.103 4.20c, 4.21c 6.16 + 6.17vii Part II: 6.52, 6.60 15.17 Is there a written procedure for investigating and documenting deviations? o o o o 211.100b 211.192 211.160a 1.8vii, 1.9iv Part II: 2.16, 6.53 Annex 16: 3 15.18 Are stability studies conducted after any significant change or deviation to the process or package? o o o o 15.19 Are the test documents (sampling records, laboratory records, physical and chemical determinations, all raw data, calculations and results) available and complete? o o o o 211.194 211.160 4.26, 6.7, 6.17 Part II: 6.60 15.20 Are the distribution records available and complete? o o o o 211.196 1.8viii + x 4.28 15.21 Are the production, control and distribution records that are specifically related to a product batch kept for at least one year after the expiration date so that they are readily available to an authorized inspector? o o o o 211.180 4.10–4.12 6.8, 6.10, 6.34 Part II: 6.13 15.22 Is there sufficient security with regard to computer system access, data modifications and record manipulation? o o o o 11.10(d) Chapter 4, Principles, 4.1–4.3 Part II: 5.43 Annex 11: 1, 12 15.23 Are adequate back-up measures in place to ensure that the data is available? o o o o 4.1, Part II: 5.48 Annex 11: 7.2, 16 15.24 Are all QM Documents listed in an inventory that is kept up to date? o o o o 4.32 16. Contract manufacturing/Contract analysis 16.1 Which of the following activities are completed by contractors? 24 16.1.1 Production, filling or single production steps? o o 16.1.2 Packaging or single packaging steps? o o 16.1.3 Packaging/labeling of clinical test samples? o o 16.1.4 Chemical, physical or microbiological analytics? o o 16.1.5 Stability testing? o o 16.1.6 Microbiological monitoring? o o 16.1.7 Storage of stability or retention samples? o o 6.33 GMP Inspection Preparation Checklist: A Tool for Internal Auditing and Training Typical audit questions 16.1.8 Storage of input materials, intermediates or finished products? EU GMP Guideline CFR reference no partly met/ not accepted partly met/ accepted yes/met Assessment o o o o 16.1.10 Calibration? o o 16.1.11 Maintenance of appliances, systems and installations, e.g. ventilation? o o 16.1.12 Cleaning/disinfection of systems and appliances? o o 16.1.13 Cleaning/disinfection of rooms? o o 16.1.14 Cleaning/disinfection of hygiene clothing or cleaning appliances? o o 16.1.15 Pest control? o o 16.1.16 Filing? o o 16.1.17 Auditing of suppliers and contractors? o o 16.1.18 Personnel training? o o 16.1.19 Occupational health examinations? o o 16.1.20 Others? Which ones? o 16.1.21 Are the aforementioned outsourced activities described in detail in the SMF? o o o o Part III, SMF 2.3 16.1.22 Are manufacturing, packaging and testing performed in accordance with the Marketing Authorization or Regulatory Filing? o o o o 1.4xv, 1.8, 1.9v + vii, 4.2, 6.6, 6.15, 7.2, 7.3, 7.14 Annex 16: 1.7.5, 1.7.15 16.1.23 Does the client check the legitimacy, eligibility and competency of the contractor prior to contract award? o o o o 7.5, 7.9 16.1.24 Does the client supply all necessary information, including information on possible problems and risks for rooms, equipment, personnel or follow-up products? o o o o 7.6, 7.10 16.2 Are there written contracts or formal agreements that set out the GMP responsibilities of both parties and the quality measures in detail? o o o o 1.4vii, 1.10xii, 6.34 7.1, 7.2, 7.14–7.17 Part II: 16.12 Annex 11: 3 Annex 16: General Principles, 1.4.3 16.2.1 Does the contract contain a commitment to GMP? o o o o 7.5 16.1.9 Qualification/validation? o 25 GMP Inspection Preparation Checklist: A Tool for Internal Auditing and Training Typical audit questions yes/met partly met/ accepted partly met/ not accepted no CFR reference EU GMP Guideline Assessment 16.2.2 Does the contract contain an exact distinction of the responsibilities of both contracting parties for each step of the outsourced activities? o o o o 16.2.3 Does it include clear rules concerning the responsibility of the Qualified Person at the market release? o o o o 16.2.4 Does the contract describe the communication process, for example, concerning deviations, changes or OOS? o o o o 7.14 16.2.5 Does the contract ensure an audit by the client and relevant authorities takes place? o o o o 7.13, 7.17 16.2.6 Are the technical aspects of the contract drawn up by appropriately competent people? o o o o 7.14 o o o o 7.4 16.3.1 Are principles of Quality Risk Management applied? o o o o 7.4 16.3.2 Are audits carried out at contract acceptor’s premises? o o o o 7.13, 7.17 Part II: 16.11, 16.13 16.4 Are necessary improvements identified and implemented at these checks? o o o o 7.7 16.5 Does the client check and evaluate records and results? o o o o 7.8 16.6 Does the contract giver keep manufacturing, testing and distribution reports, as well as retention samples, or are they available? o o o o 6.34, 7.16 16.7 Is traceability guaranteed at the contract acceptor? o o o o 7.16 Part II: 16.10 16.8 Are changes in the process, equipment, test methods, specifications or other contractual requirements only made after approval by the contract giver? o o o o 7.12 Part II: 16.16, 13.17 16.9 Is it guaranteed that the contract giver will be informed if the contract acceptor subcontracts parts of the work? o o o o 7.11 Part II: 16.14 17.1 Is the check, the decisionmaking, as well as the definitions of quality defect procedures in agreement with the principles of Quality Risk Management? o o o o Chapter 8 Principle, 8.9iv + v, 8.10 17.2 Are there written procedures in place for recalls? o o o o 1.8x, 4.28, 4.29 8.20–8.31 Part II: 2.18, 15.13 +17.7 16.3 Has the client put procedures into place in order to check and monitor the sub-contracted activities? 17. 26 Chapter 7 Principle, 7.15 211.22 7.8 Complaints and recalls GMP Inspection Preparation Checklist: A Tool for Internal Auditing and Training Typical audit questions partly met/ accepted partly met/ not accepted no EU GMP Guideline yes/met CFR reference Assessment 17.3 How often are the recall procedures updated and checked for their effectiveness? o o o o 8.20 17.4 Is a responsible person designated for execution and coordination of recalls who is independent of sales/marketing? o o o o 8.1-8.4 17.5 Is the responsible person supported by sufficient staff to handle recalls rapidly? o o o o 8.1-8.4 17.6 May recall procedures be initiated promptly and at any time? o o o o 8.22 17.7 Is all information needed for a recall readily available? o o o o 8.23 17.8 Is the progress of recalls recorded and final reports issued? o o o o 8.29 o o o o 17.9 Are recalled batches noted in the approval register or other documents? o o o o 17.10 Is there a complaints list available? o o o o 211.198 8.7, 8.10 Part II: 15.10, 17.7 17.11 Is there a written procedure for handling complaints? o o o o 211.198 1.8xi 4.29, 6.2, 8.5 Part II: 2.18, 15.10, 17.7 17.12 Is a responsible person designated for handling of complaints and deciding the measures to be taken? o o o o o o o o 17.13 Are complaints recorded with all details and thoroughly investigated? o o o o 8.5, 8.9, 8.10 17.14 Are other associated batches or products checked to determine if they could be affected if a product defect is discovered or suspected in another lot or product? o o o o 8.11 17.15 Are recalled products identified and stored separately in a secure area? o o o o 8.28 17.16 Are there measures in place to prevent errors from occurring again? o o o o 1.4ix + xv, 1.5vii, 1.10iv + ix 8.18– 8.19 Part II: 2.32, 15.12, 17.7 17.17 Is the Qualified Person made aware of any complaint, product failure investigation and recall? o o o o 8.1-8.4 Annex 16: 3.1 • • Do they include reconciliation of delivered and recovered quantities of the products? Is this responsible person supported by sufficient staff? 8.1-8.4 27 GMP Inspection Preparation Checklist: A Tool for Internal Auditing and Training Typical audit questions yes/met partly met/ accepted partly met/ not accepted no CFR reference EU GMP Guideline Assessment o o o o 8.26 18.1 Is the QA system regularly evaluated with regard to effectiveness and suitability? o o o o 1.4xvii Annex 16: 1.7.19 18.2 Are there written plans for carrying out self-inspections? o o o o 9.1 Part II: 2.50 18.2.1 Are they complied with? o o o o 9.1 Annex 16: 1.7.19 18.2.2 Are the audit findings and proposed corrective actions documented and brought to the attention of responsible management?. o o o o 9.3 o o o o 9.3 Part II: 2.51 19.1 Are major changes to facilities, equipment and processes validated? o o o o 1.4x, 1.8ii, 5.25 Annex 1: 82-84 Annex 15: 1, 5.1, 11.4 19.2 Do procedures exist for validation of product processes? o o o o o o o o Annex 15: 1.2, 5.3, 5.24 19.3 Are risk assessments carried out to determine the scope and extent of validation? o o o o 1.13 Annex 15: General Principle, 1.7, 11.4 Annex 20 Annex 11: 1 19.4 Is there a validation master plan (VMP) or comparable document? o o o o Annex 15: 1.4 Part II: 12.10 19.5 Does the VMP contain information concerning qualification and validation policy, organisational structure of the qualification and validation activities, and relevant tasks and responsibilities? o o o o Annex 15: 1.5 17.18 Are all Competent Authorities of all countries involved informed promptly if products are intended to be recalled? 18. Self-inspection 18.3 Are corrective actions completed in a timely and effective manner? 19. Qualification and validation • 28 Do these procedures describe whether the method of the validation (traditional, continuous or hybrid) is permitted and under which conditions they must be applied? 211.113b 4.29 5.23-5.26, 5.42 Annex 15: 1.2 GMP Inspection Preparation Checklist: A Tool for Internal Auditing and Training Typical audit questions partly met/ accepted partly met/ not accepted no EU GMP Guideline yes/met CFR reference Assessment 19.6 Does the VMP contain a summarized report of the facilities, equipment, systems and processes at the location, as well as their qualification and validation status, and guidelines on the development of acceptance criteria? o o o o Annex 15: 1.5 19.7 Are there written instructions for qualification or validation specifying critical steps and acceptance criteria? o o o o Annex 15: 2.4, 5.21 Part II: 12.21 19.8.1 Cross-reference the qualification and/ or validation protocol o o o o Part II: 12.22 19.8.2 Summarize the results o o o o Annex 15: 2.9 19.8.3 Comment on deviations o o o o Annex 15: 2.8 Annex 11: 4.2 19.8.4 Draw conclusions o o o o Annex 15: 2.9 19.8.5 Make recommendations for follow-up actions if necessary? o o o o Part II: 12.22 19.9 Are changes to the protocol documented and justified? o o o o Part II: 12.23 Annex 15: 2.7, 2.9 19.10 Is a successful qualification followed by a formal written approval? o o o o Annex 15: 2.10 19.8 Are there qualification or validation reports that: 19.11 Was the User Required Specification (URS) defined? Annex 15: 3.2 19.12 Is there a documented design qualification? o o o o Part II: 12.30 Annex 15: 3.3 19.13 Did an evaluation of the equipment take place as part of a Factory Acceptance Test (FAT)/Site Acceptance Test (SAT)? o o o o Annex 15: 3.4 19.14 Is an IQ implemented for new and modified facilities/ equipment? o o o o Part II: 12.30 Annex 15: 3.8 19.15.1 Installation of equipment, pipes, supply lines and instruments? o o o o Part II: 12.30 19.15.2 Verification of current drawings and specifications? o o o o Annex 15: 3.9 19.15 Does the IQ include at least the following: 29 GMP Inspection Preparation Checklist: A Tool for Internal Auditing and Training Typical audit questions partly met/ accepted partly met/ not accepted no EU GMP Guideline yes/met CFR reference Assessment 19.15.3 Compilation of operation, work, maintenance and calibration instructions? o o o o Part II: 12.30 Annex 15: 3.9 19.15.4 Verification of the construction materials? o o o o Part II: 12.30 Annex 15: 3.9 19.16 Is an operational qualification (OQ) carried out after the IQ? o o o o Part II: 12.30 Annex 15: 3.10 19.17 Do the OQ tests include the upper and lower operating limits? o o o o Part II: 12.30 Annex 15: 3.11ii 19.18.1 Are calibration, operation and cleaning processes and preventative maintenance requirements established? o o o o Annex 15: 3.12 19.18.2 Are operating personnel trained? o o o o o o o o Part II: 12.30 Annex 15: 3.13 19.20.1 Tests with production materials or qualified substitutes/simulated products? o o o o Annex 15: 3.14 19.20.2 Tests that include the upper and lower operating limits? o o o o 19.21.1 Are data available that verify operational parameters and limits for critical variables? o o o o 19.21.2 Are there written instructions for calibration, cleaning, maintenance and operation in place? o o o o 1.8iv o o o o 1.8iii + v o o o o 1.4x, 1.8ii Part II: 12.4 Annex 1: 83 Annex 15: 5.16 Annex 16: 3.5.13 19.18 Following a successful OQ: 19.19 Is a performance qualification (PQ) carried out following a successful IQ and OQ or is the PQ carried out together with the OQ? 19.20 Does the PQ include at least: 19.21 For facilities that are already in use: 19.21.3 Are the operators adequately trained? 19.22 Are all processes validated prospectively or concurrently in exceptional cases and are long-established processes validated retrospectively? 30 GMP Inspection Preparation Checklist: A Tool for Internal Auditing and Training Typical audit questions partly met/ accepted partly met/ not accepted no EU GMP Guideline yes/met CFR reference Assessment 19.23 Have critical process steps/process parameters been identified and validated? o o o o 1.8ii Part II: 12.44 (1) + 12.51 Annex 15: 5.7, 5.21, 5.22, 5.24 19.24 Are all the facilities/equipment qualified, the test methods validated and the staff trained before the process validation is performed? o o o o Part II: 12.3 Annex 15: 5.9, 5.11 19.25.1 A short process description? o o o o 19.25.2 The critical process parameters? o o o o Annex 15: 5.22 19.25.3 All equipment to be used, including calibration status? o o o o 19.25.4 Approval specifications for the finished product? o o o o 19.25.5 Methods of testing? o o o o 19.25.6 IPCs including methods of testing? o o o o 19.25.7 Sampling plan? o o o o 19.25.8 Recording and evaluation techniques? o o o o 19.25.9 Responsibilities? o o o o 19.26 Are at least three successive batches manufactured within the final established parameters for the process validation? o o o o Part II: 12.50 Annex 15: 5.19 19.27 Are the validation batches the same size as the batches intended for the market? o o o o Annex 15: 5.8 19.28 Are validation batches intended to be sold or supplied manufactured according to GMP and in conformity with the Marketing Authorization or Regulatory Filing? o o o o 1.4xv Annex 15: 5.14 19.29 In case of a concurrent validation, has the rationale been adequately justified, documented and authorized by a person who is entitled to do so? o o o o Part II: 12.43 Annex 15: 5.16 19.30 In the case of a retrospective validation, which is only accepted in the API production, is it checked whether there were recent changes to the structure, operating procedures or equipment? o o o o Part II: 12.44 19.31 Are the batches selected for the retrospective validation representative of all the batches manufactured during the period considered (including OOS)? o o o o Part II: 12.45 19.25 Does the validation protocol include at least: Annex 15: 5.22 31 GMP Inspection Preparation Checklist: A Tool for Internal Auditing and Training Typical audit questions 19.32 Provided the continuous process verification is applied: • • EU GMP Guideline CFR reference no partly met/ not accepted partly met/ accepted yes/met Assessment Annex 15: 5.23, 5.24 Is the method used defined in writing? o o o o Does the strategy contain source material, critical quality attributes and critical process parameters? o o o o 19.33 Is it ensured that product control is monitored in the form of continued process verification during the whole life cycle, in order to maintain a controlled status? o o o o Annex 15: 5.28, 5.29 19.34 Is the continuous verification process conducted with an approved record and the results outlined in a report? o o o o Annex 15: 5.31 19.35 Is the rationale for the establishment of cleaning validation limits logically understandable, accessible, verifiable and documented in the form of a risk assessment? (toxicological evaluation, product residues, residues of cleaning detergent, microbial contamination) o o o o Part II: 5.26, 12.72 + 12.74 Annex 15: 10.6, 10.7 19.36 Are the test methods for cleaning validation validated and proven to be sufficiently sensitive? o o o o Part II: 12.74 Annex 15: 9.1 19.37 Have the maximum intervals between use and cleaning and between cleaning and use been specified? o o o o Part II: 5.21 Annex 15: 10.8 19.38 Have the cleaning intervals and cleaning methods been specified? o o o o Annex 15: 10.5 19.39 Have the cleaning processes for similar products and processes been considered according to the “worstcase” principle? o o o o Part II: 12.71 Annex 15: 10.10 19.40 Was the validation process for cleaning procedures based on a risk assessment and conducted sufficiently frequently and successfully? o o o o Annex 15: 10.13 19.41 For toxic or hazardous substances, are simulations carried out with substances with similar physicochemical properties? o o o o Annex 15: 10.1 20. Change control 20.1 Is there a written procedure that specifies the procedure in the event of intended changes to: 32 1.4xiii Part II: 7.14, 13.10 Annex 15: 11 Annex 11: 10 GMP Inspection Preparation Checklist: A Tool for Internal Auditing and Training Typical audit questions partly met/ accepted partly met/ not accepted no EU GMP Guideline yes/met CFR reference Assessment 20.1.1 Starting materials? o o o o 20.1.2 Components? o o o o 20.1.3 Equipment? o o o o 20.1.4 Process environment? o o o o 20.1.5 Facilities? o o o o 20.1.6 Production methods? o o o o o o o o 20.2 Do the change control procedures ensure that the desired product quality is achieved? Is sufficient data generated to prove this? o o o o 20.3 Are all changes formally requested, documented and authorized? o o o o 211.100a 1.4xii Part II: 13.13 Annex 15: 11.5 20.4 Are the affects assessed (risk analysis) and the need for re-qualification and/or re-validation evaluated? o o o o 211.100a 1.4xiii Part II: 13.13 Annex 15: 11.4 Annex 16: 1.7.15 20.5 Are stability studies conducted after any significant change or deviation to the process or package? o o o o 6.33 20.6 Are stability tests conducted after significant changes or deviations to process or packaging? o o o o 1.4xiii Annex 16: 1.7.15 20.7 Are all facilities, equipment, processes and cleaning processes assessed regularly, in writing, to evaluate the need for re-qualification and/or re-validation? o o o o 5.26 Part II: 2.60 + 12.6 Annex 15: 4.1 20.8 Are customers informed in case of changes? o o o o 7.12, Part II: 13.17 20.9 Are there Standard Operating Procedures (SOPs) concerning contact with local authorities for reporting or authorization obligations in relation to planned changes? o o o o 1.4xii 20.1.7 Test methods? Part II: 7.14, 13.10 Annex 15: 11 1.4xii + xiii Part II: 13.13 Annex 15: 11.4, 11.6, 11.7 33 GMP Inspection Preparation Checklist: A Tool for Internal Auditing and Training Typical audit questions partly met/ accepted partly met/ not accepted no EU GMP Guideline yes/met CFR reference Assessment 21.1 Does the processing and transport take place in closed systems? o o o o Annex 9: 1 21.2 Are open products and open cleaned vessels ventilated with filtered air? o o o o Annex 9: 1 21. Liquids, creams and ointments 21.3 Is glassware avoided? o o o o Annex 9: 3 21.4 Is the chemical and microbiological quality of the water specified and is it monitored? o o o o Annex 9: 4 21.5 Is there careful maintenance of the water systems? o o o o Annex 9: 4 21.6 Is there a validated flushing procedure of the water system after every chemical disinfection? o o o o Annex 9: 4 21.7 Is the quality of substances that are received in tank wagons checked before they are transferred to bulk storage tanks? o o o o Annex 9: 5 21.8 When materials are transferred via pipelines, can it be guaranteed that they are delivered to their correct destination? o o o o Annex 9: 6 21.9 Are materials likely to shed fibers (wood, cardboard, etc), kept away from products and clean containers? o o o o Annex 9: 7 21.10 Is it guaranteed that homogeneity of mixtures, suspensions, etc. is maintained during filling operations? Are mixing and filling procedures validated? o o o o Annex 9: 8 21.11 Is the maximum storage duration/storage conditions specified if filling is not to take place immediately? o o o o Annex 9: 9 34 GMP Inspection Preparation Checklist: A Tool for Internal Auditing and Training Part II: Manufacturing and Testing of Sterile Products Manufacture of sterile products 22. 22.1 Is entry of personnel to clean areas only possible via air locks? o o o o Annex 1: 1 22.2 Is entry of materials or apparatus to clean areas only possible via air locks? o o o o Annex 1: 1 22.3 Are the clean areas ventilated through adequately effective filters? o o o o Annex 1: 1 22.4 Do operations with exposed product or open primary packaging material take place in separate rooms from operations with closed final containers or unexposed products? o o o o Annex 1: 2 o o o o Annex 1: 3 22.6 Are the specified clean area classifications complied with? At rest/in operation state? o o o o Annex 1: 3 22.7 Is the “at rest” state achieved approximately 20 minutes after work has ended? o o o o Annex 1: 14 22.8 Is the particulate cleanliness in the room monitored during operation? o o o o Annex 1: 4 22.9 Is work in clean areas carried out by a minimum number of people? o o o o Annex 1: 36 22.10 Do all those who work in clean areas receive regular training in hygiene, microbiology and appropriate handling of sterile products, including: o o o o 22.5 How are the clean areas classified? 211.25 Annex 1: 37 22.10.1 Cleaning staff? o o o o 22.10.2 Maintenance staff? o o o o 22.11 Are external parties carefully instructed and supervised? o o o o Annex 1: 37 22.12 Can it be guaranteed that persons who work with animal tissues or microbiological cultures only have access to clean areas in accordance with rigorous and clearly defined entry procedures? o o o o Annex 1: 38 22.13 Are periodic health checks of personnel carried out? Are there procedures established if individual persons present an unacceptable microbiological risk to products? o o o o 22.14 Are there written procedures for washing and changing clothes to keep contamination of clean clothes to a minimum? o o o o Annex 1: 41 22.15 Are wristwatches, make-up or jewellery worn in clean areas? o o o o Annex 1: 40 22.16 Is the quality of the working clothing suitable for the cleanliness class? o o o o Annex 1: 42 22.17 Is the clothing worn in such a way that the product is protected from contamination? o o o o Annex 1: 42 211.28d Annex 1: 39 22.18 Are hair and beards covered? o o o o Annex 1: 43 22.19 Is outdoor clothing brought into air locks that lead to class B or C? o o o o Annex 1: 44 22.20 Are face masks and gloves changed at least at the beginning of each working session? o o o o Annex 1: 44 22.21 Is cleanroom clothing washed, cleaned and handled according to written instructions so that no additional contamination occurs and fibers are not damaged (which may increase the risk of shedding particles)? o o o o Annex 1: 45 35 GMP Inspection Preparation Checklist: A Tool for Internal Auditing and Training Aseptic processes 23. 23.1 Has aseptic filling been correctly validated (at least 3 separate media fills, at least twice a year for each shift and each fill line, at least 14 days incubation period)? o o o o 23.2 Are the results of the microbiological monitoring also taken into account at the batch documentation check of aseptic products? o o o o 211.42c(10) Annex 1: 18 23.3 Is there additional microbiological monitoring following critical operations or following validation, cleaning or disinfection work? o o o o Annex 1: 18 23.4 Are there appropriate alert and action limits defined for particle and microbiological monitoring? o o o o Annex 1: 20 23.5 Are there written procedures for how to proceed if limits are exceeded and for corrective actions? o o o o Annex 1: 20 • Are they complied with? Annex 1: 66–71 o o o o 23.6 Are sterile starting materials handled in class A with grade B background? o o o o Annex 1: 31 23.7 Is the preparation of solutions that are to be sterile filtered during the process done in at least a grade C environment? o o o o Annex 1: 32 23.8 Are partially closed containers handled either in grade A environment with grade B background or in sealed transfer trays in grade B environment? o o o o Annex 1: 34 23.9 Are ointments, creams, suspensions and emulsions prepared and filled in grade A environment with a grade B background? o o o o Annex 1: 35 24.1 How is the air quality in the isolator and in the environment specified? o o o o Annex 1: 21 24.2 Is the air quality being monitored and the specifications being met? o o o o Annex 1: 23 24.3 Has the isolator (air quality, integrity of the isolator) and all the critical operations (disinfection, transfer operations) been qualified and/or validated before use? o o o o Annex 1: 24 24.4 Are leak tests carried out on the isolator and the glove/ sleeve system? Are they carried out frequently enough? o o o o Annex 1: 25 25.1 How is the air quality at the facility and in the environment specified? o o o o Annex 1: 26 25.2 Is the air quality being monitored and the specifications being met? o o o o Annex 1: 26 o o o o Annex 1: 27 o o o o Annex 1: 27 o o Annex 1: 28 26.1.1 Is microbial growth actively supported by the product? o o 26.1.2 Is there a long holding time before sterilization? o 26.1.3 Is preparation in closed vessels possible? o Isolator technology 24. Blow-fill-seal technology 25. 25.3 What protective clothing is worn? 25.4 Was the facility sufficiently qualified before use and were critical operations such as cleaning, sterilization and aseptic assembly adequately validated before filling was started? 26. Terminally sterilized products 26.1 Is there an increased contamination risk during preparation? 36 o o o o GMP Inspection Preparation Checklist: A Tool for Internal Auditing and Training 26.2 In this case, is preparation done in at least a grade C environment? o o o o Annex 1: 28 26.3 Does filling take place in at least a grade C environment? o o o o Annex 1: 29 o Annex 1: 30 26.4 Is there an increased contamination risk during filling due to: 26.4.1 A slow filling process? o 26.4.2 Wide-necked containers? o o 26.5 In this case, does filling take place in zone A with an environment of at least grade C? o o o o Annex 1: 30 26.6 Are ointments, creams, suspensions and emulsions prepared and filled in at least grade C environment before sterilization? o o o o Annex 1: 28 26.7 Are the surfaces in the clean rooms smooth, impervious and free from cracks? o o o o Annex 1: 46 26.8 Are inaccessible niches, corners, ledges and sliding doors on which particles could collect avoided? o o o o Annex 1: 47 • Are shelves, cabinets and equipment kept to a minimum and designed in such a way that they can be easily cleaned? o o o o Rooms and Equipment o o o o Annex 1: 48 26.10 Are doors, pipes and lines arranged so that there are no hard to clean niches, unsealed openings or surfaces? o o o o Annex 1: 47, 49 26.11 Are there drains or sinks in grade A/B areas that are used for aseptic processing? o o o o Annex 1: 50 26.12 Are drains/sinks in other cleanliness classes fitted with air breaks and are floor drains fitted with traps or water seals to prevent backflow? o o o o Annex 1: 50 26.13 Are the changing rooms designed as air locks? Are the individual changing procedures physically separated from each other so that particulate contamination of the protective clothing is minimized? o o o o Annex 1: 51 26.14 Are the changing rooms effectively ventilated with filtered air? o o o o Annex 1: 51 26.15 Does the last zone in the changing room have the same grade (in the at-rest state) as the area into which it leads? o o o o Annex 1: 51 26.16 Are hand wash basins avoided in the last part of the changing rooms? o o o o Annex 1: 51 26.17 Are locks or audible or visual warning systems employed to prevent simultaneous opening of more than one air lock door? o o o o Annex 1: 52 26.18 Is there a positive pressure of approximately 10-15 Pascal between a neighboring area with a lower cleanliness grade and is it maintained (opening a door)? o o o o Annex 1: 53 26.19 How is the airflow pattern resolved when pathogenic, highly toxic, radioactive or live viral or bacterial materials are being processed? o o o o Annex 1: 53 o o o o 26.9 Are there false ceilings? Are they sealed? • How are the facilities decontaminated and the exhaust treated in these cases? 37 GMP Inspection Preparation Checklist: A Tool for Internal Auditing and Training 26.20 Has it been proven that the selected air flow pattern does not present any contamination risk, e.g. that no particles emitted from persons or machines are brought into higher risk zones? o o o o Annex 1: 54 26.21 Is there a warning system in place indicating malfunctions in the air supply? o o o o Annex 1: 55 26.22 Are differences in air pressure between areas in which this is important, regularly recorded, documented, and evaluated? o o o o Annex 1: 55 26.23 Are there conveyor belts between a grade A and operating areas with lower cleanliness classes? Are these conveyor belts continually sterilized? o o o o Annex 1: 56 26.24 Are equipment, fittings and operating elements arranged so that operation, maintenance and repair work can be conducted from the outside of the clean areas if necessary? o o o o Annex 1: 57 26.25 Are clean rooms cleaned, disinfected and, if necessary, sterilized following maintenance work before processing recommences? o o o o Annex 1: 58 26.26 Are water purification and distribution facilities arranged so that a reliable water quality can be produced? o o o o Annex 1: 59 o o o o 26.27 Is water for injection treated, stored and distributed in such a way that microbial growth is prevented? o o o o Annex 1: 59 26.28 Is all equipment maintained and qualified according to plan and is their return to use authorized, including: o o o o Annex 1: 60 • Is the facility operated only up to its intended capacity? 26.28.1 Sterilizers? o o o o Annex 1: 60 26.28.2 Air treatment systems? o o o o Annex 1: 60 26.28.3 Air vent and gas filters? o o o o Annex 1: 60 26.28.4 Water treatment systems? o o o o Annex 1: 60 26.28.5 Water storage and distribution systems? o o o o Annex 1: 60 26.29 Is there a written sanitation program for plant hygiene? o o o o Annex 1: 61 26.30 Are different types of disinfectants used in an alternating manner? o o o o Annex 1: 61 26.31 Are microbiological controls carried out? o o o o Annex 1: 61 26.32 Are disinfectants and detergents monitored for microbiological contamination? o o o o Annex 1: 62 26.33 Are unsterilized dilutions of disinfectants kept only in previously cleaned containers and for a specified time period? o o o o Annex 1: 62 26.34 Are disinfectants and detergents sterilized for use in zones A and B? o o o o Annex 1: 62 26.35 Is fumigation performed to reduce microbial contamination of inaccessible places? o o o o Annex 1: 63 26.36 Are precautions taken at all processing steps to keep contamination to a minimum? o o o o Annex 1: 64 26.37 Are preparations with microbiological origins (apart from vaccines of dead organisms or inactivated bacterial extracts) handled separately from other products? o o o o Annex 1: 65 26.38 Are aseptic procedures validated? Does this validation include a media fill? o o o o Annex 1: 66 Processing 38 GMP Inspection Preparation Checklist: A Tool for Internal Auditing and Training 26.39 Does this process simulation include the routine manufacturing procedure as well as all the critical manufacturing steps? o o o o Annex 1: 67 26.40 Does the process simulation take worst case situations into consideration? o o o o Annex 1: 67 26.41 Are three successive successful simulations carried out per shift for the initial validation? o o o o Annex 1: 68 26.41.1 Are process simulation tests repeated twice a year per shift and process? o o o o Annex 1: 68 26.41.2 Is the number of containers used for media fill sufficient for valid evaluation (i.e. for small batches at least equal to the product batch size)? o o o o Annex 1: 69 26.42 Are the process simulations repeated at defined intervals and after every significant change to ventilation systems, equipment, process or number of shifts? o o o o Annex 1: 68 26.43 What is the contamination rate? Has the manufacturer specified alert and action limits? o o o o Annex 1: 69 26.44 Is every contamination investigated? o o o o Annex 1: 70 o o o o 26.45 Is it ensured that the validations do not compromise the manufacturing procedures? o o o o Annex 1: 71 26.46 Are the water sources, water treatment systems and treated water regularly monitored for impurities and endotoxins and are these results archived? o o o o Annex 1: 72 26.47 Do personnel carrying out aseptic work move in a controlled and methodical manner to avoid excessive shedding of particles and organisms? o o o o Annex 1: 73 26.48 Are starting materials tested for their microbiological quality? o o o o Annex 1: 74 26.49 Is the use of materials and containers liable to generate fibers avoided in clean areas? o o o o Annex 1: 75 26.50 Are there measures in place to keep particle contamination of the final product to a minimum? o o o o Annex 1: 76 26.51 Are containers and equipment handled in such a way that they are not re-contaminated after final cleaning? o o o o Annex 1: 77 26.52 Is the period between washing, drying, sterilizing and use of material restricted depending on the storage conditions? o o o o Annex 1: 78 26.53 Is the period between manufacturing solutions and sterilization/sterile filtration kept short or restricted depending on the storage conditions? o o o o Annex 1: 79 26.54 Is the bioburden monitored before sterilization? Is the absence of pyrogens tested? o o o o Annex 1: 80 26.55 Are all solutions sterile-filtered? o o o o Annex 1: 80 26.56 Are containers and accessories brought in only via sterilizers in aseptic work areas? o o o o Annex 1: 81 26.57 Are non-combustible gases filtered? o o o o Annex 1: 81 26.58 Is the efficacy of every new procedure validated and the validation verified at scheduled intervals based on performance history or, in case significant changes are made, to the process or equipment? o o o o Annex 1: 82 • Does investigation include potential impact on batches manufactured since the last successful media fill? 39 GMP Inspection Preparation Checklist: A Tool for Internal Auditing and Training 26.59 Are all sterilization procedures validated? o o o o Annex 1: 83 26.60 Does the selected sterilization procedure correspond with the marketing and manufacturing authorizations or Regulatory Filing? o o o o Annex 1: 83 26.61 Before new sterilization procedures are introduced, was it demonstrated that the desired sterilization conditions are achieved in all parts of each type of load? o o o o Annex 1: 84 26.62 Have physical measurements and biological indicators been used for qualification? o o o o Annex 1: 84 26.63 Are sterilizers re-qualified at least once a year and following changes to the equipment? o o o o Annex 1: 84 26.64 Is the sterilization process designed to guarantee that all of the material is effectively sterilized? o o o o Annex 1: 85 26.65 Are loading patterns established and validated for all the different sterilization procedures? o o o o Annex 1: 86 26.66 Is the quality of bioindicators checked using positive controls? o o o o Annex 1: 87 26.67 Are there strict precautions in place to prevent any contamination when using bioindicators? o o o o Annex 1: 87 26.68 Are sterilized and unsterilized products clearly distinguished from each other? o o o o Annex 1: 88 26.69 Is every basket/tray containing products or components clearly labeled with the product name, batch number and a note of any sterilization that has taken place? o o o o Annex 1: 88 26.70 Are there records for every sterilization run that are approved as part of the batch release procedure? o o o o Annex 1: 89 27. Heat sterilization 27.1 Are the sterilization processes validated? o o o o 27.2 Is every heat sterilization cycle recorded with sufficient accuracy and precision? o o o o Annex 1: 90 27.3 Is the position of the temperature probes determined during the validation? o o o o Annex 1: 90 o o o o Annex 1: 91 o o o o Annex 1: 92 o o o o o o o o Annex 1: 93 27.4 tion? Are chemical or biological indicators used in addi- 27.5 Is the heat-up time sufficient for the necessary temperature to be achieved throughout the entire load? • Has this time been determined for every type of sterilization load? 27.6 Are there precautionary measures in place to prevent contamination during the cooling phase, e.g. by cooling fluid or gas? 211.113 Annex 1: 83 28. Sterilization using moist heat 28.1 Are pressure and temperature monitored? o o o o Annex 1: 94 28.2 Are the control instruments independent of the monitoring apparatus and recording charts? Are automatic control and monitoring systems validated? o o o o Annex 1: 94 28.3 Are leak tests performed frequently on chamber if the cycle also includes a vacuum phase? o o o o Annex 1: 94 40 GMP Inspection Preparation Checklist: A Tool for Internal Auditing and Training 28.4 Are the items to be sterilized (other than products in sealed containers) wrapped in a material that allows removal of air and penetration of steam but that prevents recontamination after sterilization? o o o o Annex 1: 95 o o o o Annex 1: 96 o o o o Annex 1: 97 o o o o Annex 1: 97 o o o o Annex 1: 97 30.1 Has it been confirmed experimentally that the product (including the packaging material) is not adversely affected by the irradiation? o o o o Annex 1: 98 30.2 Is the radiation dose recorded during the sterilization procedure by independent dosimeters that are in sufficient number and close enough together in the load? o o o o Annex 1: 99 30.3 Are plastic dosimeters used within the time limit of their calibration? o o o o Annex 1: 99 30.4 Are the dosimeters read a short time after the radiation exposure? o o o o Annex 1: 99 30.5 Is the effect of variations in the density of the packages considered during validation? o o o o Annex 1: 101 30.6 Is irradiated and non-irradiated material handled in such a way as to prevent mix-up? o o o o Annex 1: 102 30.7 Are additional radiation-sensitive color discs used for identification? o o o o Annex 1: 102 30.8 Is the total radiation dose administered within a predetermined time span? o o o o Annex 1: 103 31.1 Was it confirmed during the process validation that the product was not adversely affected by exposure to the gas and that the degassing conditions and time have been selected such that residues of gas and reaction products are reduced to a specified level? o o o o Annex 1: 104 31.2 Are precautions in place that prevent germs from escaping which are either crystallised, contained in dried proteins or packaging material and which thus escape from the sterilisation process? o o o o Annex 1: 105 31.3 Are the materials brought up to the necessary temperature and humidity before exposure to gas? o o o o Annex 1: 106 31.4 Is every sterilization cycle monitored with suitable biological indicators distributed throughout the load and are the results recorded in the batch documentation? o o o o Annex 1: 107 31.5 Is data on duration, pressure, temperature, humidity, gas concentration and total amount of gas used documented for every sterilization cycle and is this included in the batch documentation? o o o o Annex 1: 108 28.5 Is the steam used for sterilization of a suitable quality? 29. Sterilization using dry heat 29.1 Does air circulation and maintenance of a positive pressure within the chamber prevent the entry of non-sterile air? 29.2 Is any air admitted passed through HEPA filters? 29.3 Are challenge tests with endotoxins carried out as part of the validation if the procedure is also used for pyrogen removal? 30. 31. Sterilization by radiation Sterilization with ethylene oxide 41 GMP Inspection Preparation Checklist: A Tool for Internal Auditing and Training 31.6 Is the load stored in a controlled manner under ventilated conditions for a validated time following exposure to gas? o o o o Annex 1: 109 32.1 Has it been demonstrated that the product cannot be sterilized in the final container or subjected to heat treatment? o o o o Annex 1: 110 32.2 Is the last sterile filtration carried out as close as possible to filling? o o o o Annex 1: 111 32.3 Is the fiber shedding from the filters shown to be minimal? o o o o Annex 1: 112 Sterile filtration without final sterilization 32. 32.4 Is the integrity of the filter verified immediately before and after each use using: 32.4.1 A bubble point test? o o o o 32.4.2 A diffusive flow test? o o o o 32.4.3 A pressure hold test? o o o o 32.5 Is the required filtration time per volume and the necessary pressure differential determined in the validation? o o o o Annex 1: 113 32.6 Are all significant deviations from this in routine manufacture documented, investigated and recorded in the batch record? o o o o Annex 1: 113 32.7 Is the integrity of critical gas and air filters confirmed after use? o o o o Annex 1: 113 32.8 Is the same filter used for a maximum of one working day or has longer use been validated? o o o o Annex 1: 114 32.9 Has it been shown that the filter does not adversely affect the product either through absorption of ingredients or through the release of substances? o o o o Annex 1: 115 33.1 Are partially stoppered freeze drying vials maintained under grade A conditions at all times until the stopper is fully inserted? o o o o Annex 1: 116 33.2 Are the containers closed in accordance with validated methods? o o o o Annex 1: 117 33.3 Is crimping of caps to aseptically filled vials performed as soon as possible after stopper insertion? o o o o Annex 1: 118 33.4 Is the crimping of caps done in a separate location with adequate air extraction to avoid the distribution of particles? o o o o Annex 1: 119 33.5 If vial capping is done outside the aseptic core, are vials kept under grade A conditions until the caps have been crimped? o o o o Annex 1: 120 33.6 In case human intervention is required at the capping station (e.g. to remove vials with displaced stoppers), is direct contact with the vials prevented? o o o o Annex 1: 121 + 122 33.7 Are glass or plastic ampules subjected to 100% integrity testing? o o o o Annex 1: 117 33.8 Are containers that are vacuum sealed tested for maintenance of that vacuum after a predetermined time? o o o o Annex 1: 123 33.9 Are the filled containers individually tested for extraneous contamination and defects? o o o o Annex 1: 124 33.10 Are the visual control conditions adequate (lighting, background, pauses, eye-sight tests) and is the test method validated? o o o o Annex 1: 124 33. 42 Annex 1: 113 Finishing of sterile products GMP Inspection Preparation Checklist: A Tool for Internal Auditing and Training 33.11 Are the results for the visual control recorded? o o o o Annex 1: 124 o o o o Annex 1: 125 34.2 In the case of parametric release, is special attention paid to the validation and monitoring of the entire manufacturing process? o o o o Annex 1: 126 34.3 Are the samples for sterility testing representative, in particular for those parts of the batch with increased contamination risk (start/end, interruption, coolest part of the load)? o o o o Annex 1: 127 34. Sterility testing 34.1 Is the sterility test validated for the product concerned? 43 GMP Inspection Preparation Checklist: A Tool for Internal Auditing and Training Part III: Trade of Active Pharmaceutical Ingredients (API) and Excipients Trade of active pharmaceutical ingredients and excipients, including repackaging/relabeling 35. 35.1 Is there a procedure in place that ensures that traders and customers have agreed upon specifications and other requirements? o o o o 1.4vi 35.2 Is traceability of each active pharmaceutical ingredient/intermediate back to the original manufacturer guaranteed? o o o o 5.26-5.29, 35.3 4.23d Part II: 17.2 Are the following documents available at all times: 35.3.1 Identity and address of the original manufacturer? o o o o 35.3.2 Purchase orders? o o o o 35.3.3 Transport documentation? o o o o 35.3.4 Receipt documents? o o o o 35.3.5 Name/designation of the product? o o o o 35.3.6 Batch numbers of the original manufacturer? o o o o 35.3.7 All authentic certificates of analysis? o o o o 35.3.8 Re-test or expiration date? Part II: 17.2 o o o o 35.4 Is all quality and/or regulatory information (e.g. name of the original manufacturer and original batch number) forwarded to the customers? o o o o Part II: 17.6 35.5 Is there a documented and fully functional quality management system implemented? o o o o Part II: 17.3 35.6 Is repackaging, relabeling and storage conducted under thorough GMP controls to prevent mix-ups and contamination? o o o o Part II: 17: 4 35.7 Are stability tests carried out if the product is repacked into a different container type? o o o o Part II: 17.5 35.8 Are all complaints and recalls documented and reviewed in cooperation with the original manufacturer and the customer? o o o o Part II: 17.7 35.9 Does the dispatch documentation allow full traceability to each customer and vice-versa, e.g. in the event of a recall? o o o o Part II: 7.13 35.10 Are returns and their further use documented? o o o o Part II: 17.8 44