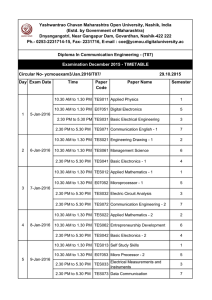

3M Food Safety Technical Bulletin Title: Comparison of Improved 3M™ Clean-Trace™ Water Plus – Total ATP (AQT200) Performance to Current Product (AQT100) Number: TB.185828 Effective Date: August, 2012 Supersedes: New Technology Platform: Hygiene Monitoring Originating Location: St. Paul, Minnesota A study done by 3M Food Safety on 3M™ Clean-Trace™ Water Plus – Total ATP (AQT200) for verification testing shows the AQT200 product’s performance is better than or equivalent to the performance of the 3M™ Clean-Trace™ Water – Total ATP (AQT100). The study compares these characteristics of the two products: Shelf-life, optimal test temperature, RLU background levels, ATP limit of detection, detection of various micro-organisms, repeatability and reproducibility, and the effect of sanitisers and biocides. Shelf-life The study shows that for maximum shelf-life, you can store AQT200 at 2oC-8oC (36°F - 46°F) for 12 months, which is equivalent to AQT100. You can also store AQT200 at 21°C - 25°C (70°F 77°F) for 2 months shelf life. Shelf-life for ATQ100 in these conditions is 2 weeks. Shelf-life for AQT200 is better than shelf-life for AQT100. Optimal Test Temperature The optimal test temperature for AQT200 is 15 oC– 30 oC (59° – 86° F), which is better than the optimal test temperature for AQT100, 15 oC-25 oC (59° – 77° F). RLU Background levels AQT200 test devices and AQT100 test devices (n=2 batches of 200 test devices per batch) were activated without collecting water samples to measure RLU background levels. 3M Food Safety 3M Center Bldg 275-5W-05 St. Paul, MN 55144-1000 USA 1-800-328-6553 TB.185828 Page 1 of 5 © 3M 2012. All rights reserved. 3M Food Safety Technical Bulletin Boxplot of AQT100 (#1208), AQT200 (#555) Boxplot of AQT100 (#1169), AQT200 (#444) 100 50 80 60 30 RLU RLU 40 40 20 20 10 0 0 AQT100 #1169/NX1 AQT100 #1208 AQT200 #444 AQT200 #555 The test results showed the background levels for AQT200 are lower and more repeatable with less variation than the background levels for AQT100. Although the background RLU levels for ATQ200 are lower, the change does not require a re-evaluation of your current pass/fail limits set in your 3M™ Clean-Trace™ NG Luminometer since most customers set their pass/fail limits at much higher levels. However, customers who have set their pass/fail limits low to improve their cleaning efficiency may wish to review their pass/fail limits. Background levels for AQT200 are better than background levels for AQT100. Repeatability and Reproducibility A repeatability and reproducibility study was done on AQT200 using 5 operators. All of the operators obtained results which met the CV% specification with an overall average of 9.2%. ATP Limit of Detection Serial dilutions of ATP positive control were made and measured using AQT200 test devices (n=5 for each dilution). AQT200 test devices (n=10) were activated without collecting water samples to measure RLU background levels. The limit of detection was defined as the mean plus 2 standard deviations of the RLU background levels. The test results show the limit of detection is 5 RLU for batch#111 of the new AQT200 product, easily detecting 1 femtomole (10-15 mole) of ATP, which is the limit of detection for AQT100. Refer to the standard curve below. 3M Food Safety 3M Center Bldg 275-5W-05 St. Paul, MN 55144-1000 USA 1-800-328-6553 TB.185828 Page 2 of 5 © 3M 2012. All rights reserved. 3M Food Safety Technical Bulletin A second batch of AQT200 was tested (#333), and the test results show the limit of detection is 6 RLU. The limit of detection for AQT200 is equivalent to or better than the limit of detection for AQT100, which is 1 femtomole. Detection of Micro-organisms The test does not make any claims for the detection of specific micro-organisms, rather the level of ATP present in water samples is a direct indication of levels of contamination present in the water samples from product residues as well as microbial cells. However, the study included a comparison of the performance of AQT200 and AQT100 in detecting of a selection of gram positives, gram negatives, yeasts, lactobacillus and industryrelevant micro-organisms such as Acetobacter sp. The test results show detection of these various micro-organisms by AQT200 is equivalent to detection by AQT100. Statistical T-test at 250 RLU level Acetobacter (P-Value= 0.915). Detection of micro-organisms for AQT200 is equivalent to detection of micro-organisms for AQT100. Effect of sanitisers and biocides Sanitisers and biocides are widely used in the field in the applications tested by AQT100 (cooling towers, paper/pulp process waters). A wide range of biocides were tested at working strength to compare the performance of AQT200 to AQT100. Both products were tested with and without biocide. The “% Activity” in the presence of biocide for AQT100 and AQT200 was determined Refer to the table below. 3M Food Safety 3M Center Bldg 275-5W-05 St. Paul, MN 55144-1000 USA 1-800-328-6553 TB.185828 Page 3 of 5 © 3M 2012. All rights reserved. 3M Food Safety Technical Bulletin Biocide / Sanitiser DBNPA –based compound (DiBromoNitroPropionAmide THPS –based compound (Tetrakis Hydroxy Phosphonium Sulphate, Pyrophosphate-based corrosion/scale inhibitor Scale inhibitor Chlorine Bronopol-based compound (2-bromo-2nitropropane-1,3-diol) BAC (Quaternary Ammonium compound) CTAB (Quaternary Ammonium compound) Glutaraldehyde –based compound Isothiazolinone –based compound Pyrophosphate- based corrosion/scale inhibitor Pyrophosphate –based corrosion/scale inhibitor) Working Strength 100ppm % Activity (Average of 2 batches) AQT100 AQT200 97 103 100ppm 105 98 150ppm 100 92 150ppm 1ppm 70ppm 100 107 91 103 99 103 10ppm 99 100 50ppm 100 101 50ppm 10ppm 15ppm 95 87 104 104 103 98 150ppm 100 94 Some sanitisers and biocides, particularly anti-corrosion chemicals, contain pyrophosphate. It is known that the new AQT200 formulation can be affected by pyrophosphate. At the working strength for these chemicals, the performance of AQT200 was shown to be acceptable. Effect of CIP Product Residues A wide range of product residues spanning dairy, brewing and juice production were tested to compare the performance of AQT200 to AQT100. Serial dilutions of typical products in water were tested. The test results showed detection levels of typical products for AQT200 were equivalent to AQT100. Performance data for lager beer showed equivalent detection at a typical pass/fail level of 150 RLU. Statistical T-test (P-Value = 0.946) Performance data for whole milk shows equivalent detection. Note that RLU values were slightly lower for AQT200 compared to AQT100 at the 0.1 dilution level of whole milk, but are still well above fail levels at >10,000RLU. This effect is due to phosphate in milk affecting the new AQT200 formulation. This dilution level of milk is not practically significant as levels of milk in CIP rinse waters would never be as high as this, and the maximum practical range for detection is the 0.01 dilution level. Results at the 0.01 dilution level and lower are equivalent. 3M Food Safety 3M Center Bldg 275-5W-05 St. Paul, MN 55144-1000 USA 1-800-328-6553 TB.185828 Page 4 of 5 © 3M 2012. All rights reserved. 3M Food Safety Technical Bulletin 3M Food Safety 3M Center Bldg 275-5W-05 St. Paul, MN 55144-1000 USA 1-800-328-6553 TB.185828 Page 5 of 5 © 3M 2012. All rights reserved.