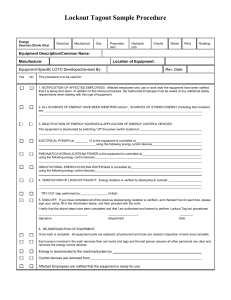

[Date] LOCKOUT PROGRAMME 0.1 AUTHOR NAME [COMPANY NAME] HEALTH SAFETY ENVIRONMENTAL MANAGEMENT SYSTEM Table of Contents 1. DOCUMENT INFORMATION ...................................................................................................................................... 2 2. REVISION HISTORY .................................................................................................................................................... 2 3. INTRODUCTION ......................................................................................................................................................... 2 4. SCOPE ........................................................................................................................................................................ 2 5. LOCKOUT PROGRAMME ........................................................................................................................................... 2 5.1. LEGISLATION ..................................................................................................................................................... 2 5.2. DEFINITIONS ...................................................................................................................................................... 2 5.3. RISK MANAGEMENT.......................................................................................................................................... 4 5.4. TRAINING .......................................................................................................................................................... 4 5.5. NON-CONFORMANCES ..................................................................................................................................... 4 5.6. PROCEDURE ...................................................................................................................................................... 4 5.6.1. SPECIAL LOCKOUT/TAGOUT SITUATIONS ..................................................................................................... 5 5.6.2. INSPECTIONS OF WRITTEN LOCKOUT PROCEDURES .................................................................................... 6 5.6.3. ALTERNATIVE METHODS ............................................................................................................................... 6 5.6.4. TAGOUT DEVICES .......................................................................................................................................... 6 ANNEXURE 1 TAGOUT - TAG EXAMPLE............................................................................................................................. 7 ANNEXURE 2 LOCKOUT POLICY STATEMENT .................................................................................................................... 8 1|Page 1. DOCUMENT INFORMATION PREPARED BY APPROVED BY DOCUMENT NAME DOCUMENT REF CURRENT REV DATE Manus De Waal NAME DOCUMENT NAME DOC-REF DD/MM/YYYY SHE Consultant JOB TITLE NEXT REV DATE DD/MM/YYYY 2. REVISION HISTORY Date DD/MM/YYYY Revision 0.1 Description Initial Release 3. INTRODUCTION The purpose of this policy is to prevent the injury or death of an employee, contactor, or visitors by providing a set of minimum requirements designed to prevent the unexpected release of stored energy during the servicing or maintenance of machines or systems. 4. SCOPE The lockout Programme shall apply to all staff, contractors, visitors and any other person who is required to perform lockout on the company premises. 5. LOCKOUT PROGRAMME 5.1. LEGISLATION General Machinery Regulations Regulation 4: Operation of machinery Regulation 5: Working on moving or electrically alive machinery Regulation 6: Devices to start and stop machinery 5.2. DEFINITIONS Lockout Placing a lockout device on an energy-isolating device, under an established procedure, to ensure the energyisolated device and the equipment it control can’t be operated until the lockout device is removed. Lockout device A device that locks an energy-isolating device in safe position. 2|Page Lockout Procedure A series of steps taken to isolate energy and shut down equipment. Authorized employee A person who locks out or tags out equipment to do service or maintenance work. Affected employee A person who uses equipment that is being serviced under lockout or tagout procedures, or who works in an area where equipment is being serviced. Energized A Connected to an energy source or containing potential energy. Energy source Any source of energy. Examples: electrical, mechanical, hydraulic, pneumatic, chemical, and thermal. Energy-isolating device A mechanical device that physically prevents transmission or release of energy. Hazardous energy Any of the types of energy existing at a level or quantity that could be harmful to workers or cause injury through inadvertent release or start-up of equipment. Tagout device A prominent warning sign, such as a tag, that can be securely fastened to an energy-isolating device to indicate that the energy-isolating device and the equipment it controls can’t be operated until the tagout device is removed. Tagout Placing A tagout device on an energy-isolating device, under an established procedure, to indicate that the energyisolating device and the equipment it controls can’t be operated until the tagout device is removed. 3|Page 5.3. RISK MANAGEMENT In collaboration with the lockout Programme, Safe Working Procedures shall be developed in relation to the specific lockout activities being performed on the company premises. 5.4. TRAINING Employees who may be exposed to hazardous energy will receive training before assignment to ensure that they understand Company Name lockout policy. In providing training the employee will have the skills to apply, use, and to remove energy controls correctly. Affected employees will be trained in the purpose and use of lockout procedures. Authorized employee will be trained to recognize hazardous energy sources, the type and magnitude of energy in the workplace, the methods and means necessary for isolating and controlling energy, and the means to verify that the energy is controlled. Employees who operate in areas where lockout procedures are used will be trained about the procedures and the prohibition against starting machines that are locked or tagged out. Authorized employees and affected employees will be retrained annually to ensure they understand lockout programme and procedures. 5.5. NON-CONFORMANCES Any person who fails to comply with the lockout policy and procedure shall be subjected to disciplinary and affirmative action. 5.6. PROCEDURE Authorized employees or effected employees who lockout or tagout equipment or do service and maintenance must follow specific lockout procedures. The procedure must include the following: • • • • • The intended use of procedure Steps for shutting down, isolating, blocking, and securing equipment Steps for placing, removing, and transferring lockout devices Equipment-testing requirements to verify the effectiveness of the energy-control procedures Tagout tags must consist of name, telephone number and work department When re-energizing equipment is necessary when power is needed to test or position the equipment, for example temporary removal of lockout or tagout devices is allowed. This applies only for the time required to perform the task and the procedure must be documented. Authorized employees must do the following before they begin service or maintenance work: 1) 2) 3) 4) 4|Page Inform all affected employees of equipment shutdown. Shut down equipment. Isolate or block hazardous energy. Remove any potential (stored) energy. 5) Lockout or tagout the energy sources. 6) Verify the equipment is isolated from hazardous energy and de-energized. Authorized employees must do the following before they remove lockout or tagout devices and re-energize equipment: 1) 2) 3) 4) 5) 6) 5.6.1. Remove tools and replace machine or equipment components. Inform co-workers about energy-control device removal. Ensure all workers are clear of the work area. Verify machine or equipment power controls are off or in a neutral position. Remove the lockout or tagout device. Re-energize equipment. SPECIAL LOCKOUT/TAGOUT SITUATIONS Energized testing When an energy-isolating device is locked or tagged and it is necessary to test or position equipment, do the following: 1) 2) 3) 4) 5) 6) Remove unnecessary tools and materials. Ensure that all other employees are out of the area. Remove locks or tags from energy isolating devices. Proceed with test. Deenergize equipment and lockout or tagout energy-isolating devices. Operate equipment controls to verify that the equipment is de-energized. Group lockout When authorized employees service equipment that has several energy sources and several energy-isolating devices, the employees must follow group lockout procedures. 5|Page Shift changes and long-term shutdowns Company Name must make sure that there is a continuity of lockout or tagout protection. This includes the orderly transfer of lockout or tagout device protection between outgoing and incoming shifts to control hazardous energy. When lockout or tagout devices remain on energy-isolation devices from a previous shift, the incoming shift members must verify for themselves that the machinery is effectively isolated and deenergized. 5.6.2. INSPECTIONS OF WRITTEN LOCKOUT PROCEDURES Company Name will perform and document annual inspections of lockout and tagout procedures to ensure that authorized employees and affected employees understand them effectively. 5.6.3. ALTERNATIVE METHODS When lockout or tagout is not used for tasks that are routine, repetitive, and integral to the production process, or prohibits the completion of those tasks, then an alternative method must be used to control hazardous energy. Selection of an alternative control method must be based on a risk assessment of the machine, equipment, or process. The risk assessment must consider existing safeguards provided with the machine, equipment or process that may need to be removed or modified to perform a given task. Under all circumstances, the affected employee must have exclusive personal control over the means to maintain the state of the control circuit in a protective mode. 5.6.4. TAGOUT DEVICES When tagout devices be used instead of lockout devices When an energy-isolating device cannot be locked out, the employer must modify or replace the energyisolating device to make it capable of being locked out or use a tagout system. Whenever Company Name significantly repair, renovate, or modify machinery or install new or replacement machinery, however, they must ensure that the energy-isolating devices for the machinery are capable of being locked out. Tagout devices may be used on energy-isolating devices that are capable of being locked out if the employer develops and implements the tagout in a way that provides employees with a level of protection equal to that achieved through a lockout system. When using a tagout system, the employer must comply with all tagout-related provisions of the standard and train employees in the limitations of tags, in addition to providing normal hazardous energy control training for all employees. The limitations of Tagout devices A tagout device is a prominent warning that clearly states that the machinery being controlled must not be operated until the tag is removed in accordance with an established procedure. Tags are essentially warning devices and do not provide the physical restraint of a lock. 6|Page ANNEXURE 1 TAGOUT - TAG EXAMPLE 7|Page ANNEXURE 2 LOCKOUT POLICY STATEMENT LOCKOUT POLICY The purpose of this policy is to prevent the injury or death of an employee, contactor, or visitors by providing a set of minimum requirements designed to prevent the unexpected release of stored energy during the servicing or maintenance of machines or systems. Only authorized individuals are permitted to isolate hazardous energy in machines or systems. Lockout of energy isolation devices must be done using individually assigned locks. If tags alone are used, a specific procedure must be in place that includes taking an additional energy disabling step to de-energize the machine or system. Lockout Programme In relation to this policy, the company shall develop, implement and maintain a “Lockout Programme” that shall outline the rules, training, terms and conditions for lockout activities performed on the company premises. Department Managers/Supervisors and authorised personnel shall familiarize themselves with the requirements of the Lockout Programme and ensure continuous compliance thereof. Lockout Permit/Register Any person who requires to perform work that requires lockout shall obtain authorisation from the department manager/supervisor by completing a lockout register. Only after the department manager/supervisor provided signature approval on the lockout register may lockout commence. Lockout Procedure Disconnecting or making safe the equipment involves the removal of all energy sources and is known as isolation. The isolation procedure includes the following tasks: 1. 2. 3. 4. 5. Announce shut off Identify the energy source(s) Isolate the energy source(s) Lock and tag the energy source(s) Prove that the equipment isolation is effective _______________ _______________ NAME DATE Chief Executive Officer 8|Page