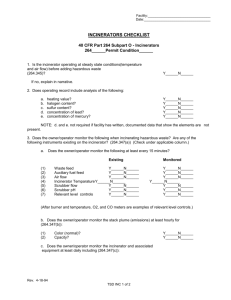

IMPROVED INCINERATOR DESIGN FOR HANDLING MEDICAL WASTE GROUP 7 Chifuniro Matope, Dominic Mapanje, John Kabambe. SUPERVISOR. Dr. Uluko. INTRODUCTION • 10 -25% of hospital waste is toxic and harmful and requires special handling. (International Committee for Red Cross ; Medical Waste Management) • Medical waste incineration (MWI) is the dry oxidation process that reduces organic and combustible waste to inorganic, incombustible matter at temperatures between 600-12000C, resulting in a significant decrease in overall waste volume (Incineration o f Healthcare Waste and the Stockholm Convention Guidelines, p. 9). PROBLEM STATEMENT • Incinerators emit harmful and toxic substances i.e., dioxins and furans, particulate matter, acid gases and heavy metals. They cause birth defects, reproductive effects, serious respiratory problems and they have great impacts on the immune system. • There is high emission levels of black smoke. This creates discomfort for people working around the incinerators. OBJECTIVES Main objective To design an incinerator with an improved air pollution control system suitable for exhaust gas cleaning in medical waste incinerators to improve air quality. Specific objectives To reduce concentrations of harmful flue gas. To minimize black smoke emissions by reducing the number of particles in the smoke emissions. To test the incinerator to ascertain its performance with regard to black smoke emission reduction and air quality improvement. LITERATURE REVIEW Medical waste management Methods • Recycling • Dumping in landfills • Incineration - Incineration converts waste into ash, flue gas and heat. Incineration is preferred since it is able to reduce the solid mass of the original waste material by 80% 85% and the volume by 95% - 96% • Has a significant benefit in treatment of hazardous clinical waste where pathogens and toxins can be destroyed by high temperatures INCINERATORS • Several types and sizes of incinerators used depending on the volume of waste material and the type of waste materials • Moving Grate Incinerators • Fixed Grate Incinerators • Rotatory kiln incinerators • Liquid injection Incinerators • Controlled air incinerators INCINERATOR’S FLUE GAS AND ITS COMPOSITION • Particulate matter • Heavy metals • Acid gases • Carbon monoxide • Organic compounds EFFECTS OF THE ABOVE COMPONENTS OF FLUE GAS • Particulate matter - Long-term exposure = heart disease, decreased lung function, increased respiratory symptoms such as coughing • Polycyclic aromatic hydrocarbons - linked to increased risk of cancer, blood and liver abnormalities (long-term inhalation of PAH vapor) • Acid gases - can damage eyes and mucous membranes along with the respiratory system • Dioxins and furans - most-hazardous organic products of incomplete combustion; skin toxicity causing skin lesions, immunotoxicity and neurotoxicity, teratogenicity, endocrine disruption and predisposition to cancer CURRENT WAYS OF AIR POLLUTION CONTROL IN INCINERATORS • Cyclone Separators • Gas conditioner systems • Baghouses (fabric filters) • Wet scrubbers • Mist eliminators PROBLEMS WITH CURRENT TECHNOLOGY • Wet scrubbers: They are prone to severe corrosion and require frequent maintenance. • Fabric filters: The fabric life is shorted due to high temperatures, and they burn and melt at high temperatures • Cyclone Separators: Low efficiencies for small particles, they are unable to process sticky materials and have high operating costs due to pressure drop. • Mist eliminators: Major problem of this technology is plugging, which is the blockage due to substance build up on the surface of the mist eliminator. WHAT’S LACKING ? • Malawi incinerators hospitals do not have incinerators with air pollution control systems PROPOSED SOLUTION. • • We are going to design an incinerator with an improved APCE. The direction we will take in coming up with a solution is to improve on the already existing technologies by analysing their drawbacks and evaluating which areas we can modify, or combine their operation with other technologies. • To come up with a more effective way of purifying the smoke that it released from the incinerators. PRODUCT DESIGN SPECIFICATION (PDS) DESIGN SPECIFICATION DETAILS Low Cost should not exceed K100,000. Size diameter between 90mm and 140mm to fit the size of the chimney of the incinerator. Reliability Maximum of 3% failure rate over service life. Expected Product Safety Should not have sharp projections. Should not be toxic to the user and the environment. Should not be corrosive or flammable. Efficiency purify exhaust gas at a faster rate, at least matching the rate of gas exhaustion. Disposal disposed after 1 years of operation. Shelf life expected to be two years from date of manufacture. DESIGN SPECIFICATION DETAILS Life in service expected to be run for a year with nominal maintenance before becoming completely inoperable. Materials Light-weight transportable not easily damaged by impact. Maintenance minimal maintenance, easily be performed by the operator Standards comply with the medium US EPA emission limits, especially for the dioxins/furans. Expected product service environment. The operating temperature is 200°C - 1000°C The product will be exposed to dirt or other contaminants. Testing Prototypes to be proven to meet International Organisation for standards. MATERIALS AND METHODS Data collection • The data that will be collected for the implementation of this device will be both qualitative and quantitative • The qualitative data will be collected from surveys that will be generated • Quantitative data will be collected from the different ways of measuring and quantifying smoke. • smoke photometers • gas chromatograph connected to a mass spectrometer or GCMS. Data Analysis • The survey will have a Likert scale that is more effective to use. • The rest of the data, gathered from tests, will be analysed using statistics software, i.e. R Studio, SPSS. • This will also develop relationships that indicate whether its effective and successful. Materials The materials that will be needed in the course of this design include; A smoke photometer Gas chromatograph Mass spectrometer Glass Jars An incinerator. EXPECTED RESULTS • To have an incinerator design with an air pollution control equipment suitable for cleaning of smoke in medical waste incinerators before it is released into the atmosphere to improve air quality. • The concentrations of toxins when measured should fall under the ranges recommended by the WHO. • The color of smoke should be clear by removing smoke particles to have a reduced emission of black smoke. • The APCE should be simple and it should efficiently clean the gas exhaust from the MWI. • The equipment designed should be able to undergo testing to prove that it is successful in reducing the particles in smoke that lead to air pollution DISCUSSION • An incinerator with improved APCE prototype is going to be produced. • It will be able to change the colour of black smoke and improve air quality • The laboratory tests that will be conducted during the prototype design will help ensure that the prototype produces the desired results. CONCLUSION • Handling of medical waste remains a major problem in many hospitals. • Incinerators emit smoke containing flue gases that cause air pollution. • The aim of this project report is to develop an incinerator with a an APCE that is durable, efficient and low cost. • To improve air quality by reducing content of flue gases and also changing the colour of smoke. THANK YOU