Mechanism and Machine Theory Vol. 16, p p . 227-245, 1981

Printed in Great Britain.

0094-114XI81/030227-19502.00/0

Pergamon Press Ltd.

=,

•

Three And Four Precision Point Kinematic Synthesis of Planar

Linkagest

Arthur G. Erdman~:

Received for publication 31 October 1980

Abstract

Dyads modelled by complex numbers are presented in several different equation forms

for three prescribed positions of either motion, path generation with prescribed timing

or function generation. Different strategies are suggested depending on how the free

choices are best utilized. Interactive computer techniques are suggested for both the

three and four prescribed position cases. Several examples are presented to help

illustrate each of the design situations.

1. The Standard Form

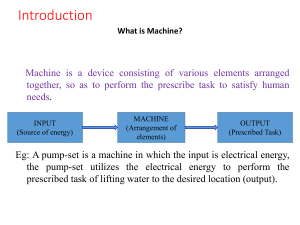

TIlE GREATmajority of planar linkages may be conceived as combinations of vector pairs called

dyads. For example, the 4-bar linkage in Fig. 1 can be perceived as two dyads: the left side of

the linkage represented as a solid vector pair (W and Z), and the right side represented by the

dashed dyad. (Other vectors between the coupler pins AB and the fixed pivot pins AoBo are

easily determined when the dyad pairs are known.) The tracer point of the coupler link moves

along a path from position P~ to Pi defined in a fixed (but arbitrarily located) complex

coordinate system by rj and r/respectively.

All vector rotations are expressed relative to the corresponding vector position when the

dyad is drawn at the first prescribed precision point (Figs. 2 and 3). Rotation fl2 is the angular

change of vector W from the first position to the position associated with the second precision

point, f13 is the rotation from the first to the third position, etc. Angles ai are similarly the

prescribed rotations of the Z vector relative to its first position.

/y

rH ~

X

Figure 1. 4-bar: Two dyads.

tPresentted at Kinematic Geometry of MechanismsWorkshop, Sydney, Australia, 11-15 June, 1979.

SProfessor of Mechanical Engineering,University of Minnesota, Minneapolis,MN 55455, U.S.A.

227

228

0

/

i ~.__ Movingplane /g

~'Y

\

\

8

°,vo,

Figure 2. Three finitely separated positions.

Figure 3. Vector representation of a dyad.

A dyad loop closure equation form is derived by summing the vectors clockwise around the

loop containing We ~aj,Ze~% r s, rt, Z, and W (Fig. 1):

We~t~j+ Ze~j - r s + r] - Z - W = 0

(1)

W ( e i ~ j - 1) + Z ( e i a j - I) = 8 i

(2)

or

where the displacement vector along the prescribed path from P] to Pi is 8i = rj - r]. This makes

the coordinate system of Fig. 2 arbitrary--for simplicity it will be located at the first precision

point (Fig. 2).

Equation (2) is the so called Standard Form (Refs. (9) and (12)). This equation is simply the

vector sum around the loop describing the first and jth position of the left side of the 4-bar

linkage. Equation (2) is in the "standard form" if 8s and either a i or fls are prescribed (the rest

of the variables must be unknown). This requirement is fortunately consistent with the

definitions of the standard kinematic synthesis tasks--Motion Generation, (or Rigid Body

Guidance) Path Generation with Prescribed Timing, and Function Generation. The 4-bar as well

as the large majority of planar linkages may be modeled with groups of standard form equations

for these tasks. For dyad synthesis, the second column of Table 1 summarizes the prescribed

quantities in the standard form equation.

Table 1.

For 3 prescribed positions

Task

Motion Generation

Path generation/

prescribed timing

Function generation*

Alternately prescribed

dyad angles

prescribed

quantities

Arbitrarily

Picked angle

Angle varied

0° -~ 360°

82, 83, a2, ~3

3z

/33

82, 83,/32,//3

82, 83, 02, 33

82, 83 and

either az, f13

or ct3, f12

a2

a2

a3

a3

either as

or ot2

either 32

or/~3

* The delta's are prescribed along a circular arc timed with the prescribed output

link rotations.

Number of Prescribed Positions vs Number of Free Choices

Since there are only a finite number of adjustable parameters which completely describe the

linkage of Fig. 1 (the two components of each independent vector of the moving links) it has

been shown that there are only a finite number of prescribable parameters which can be

imposed in a kinematic synthesis effort. Table 2 reviews how to determine the maximim number

of positions of synthesis for the 4-bar motion generation dyad. Tracer point displacement

229

Table 2.

W(e ~ej- I)+ Z(e ~=j- 1)= 8j

Number of

Number of

Number of

positions (/) real equations real unknowns

2

3

4

5

2

4

6

8

5(W, Z,/]2)

6(above +/]3)

7(above +/]4)

8(above +/]5)

Number of

free choices

Number of

3

2

1

0

0(~)

0(#)

O(mt)

Finite

solutions

vectors 8j and coupler rotations a t are prescribed for this task. Although Table 2 is based on

the left side of the linkage of Fig. 1 (eqn 2), the right side of the linkage will yield the same

results. The table shows that for two positions there are two independent scalar equations

contained in eqn (2) (the real and imaginary parts of the equation). This system of two real

equations contains five unknowns: the vectors W and Z (which represent the left side of the

4-bar) and the input rotation f12. If three of the five unknowns are chosen freely, then the

system is easily solved for the remaining two unknowns. Since in general there are an infinite

number of choices of each of the three free variables, the number of possible solutions for the

two position problem is on the order of infinitely cubed, symbolized by 0(~) 3.

In the case of three prescribed motion positions there are two more scalar equations but

only one more scalar unknown (/33). Thus two free choices must be made and ideally 0(~) 2

solutions available. Each additional prescribed position in Table 2 adds two more scalar

equations and one more scalar unknown so that for four positions there is one free choice and a

single infinity of solutions and for five prescribed positions there are no free choices allowed

and at best a finite number of solutions. Five prescribed positions is the maximum number of

precision points possible for a dyad solution.

The system of dyad equations for three positions is

W(e e2 - 1)+ Z(e i~2- 1)= 82

W(e ia3- 1) + Z(e i l 3 - 1) -~83.

(3)

If the two remaining unknown angles are picked arbitrarily, then/32,/33, a2, a3, 82 and 83 are

known and system (3) is a set of linear complex equations that can be solved for W and Z (the

vectors representing the dyad in its first position) by Cramer's Rule. By varying the free choices,

up to two oo's of solutions for W and Z may be derived.

The results of Table 2 coincide with a geometric description of the motion synthesis for a

dyad. Figure 4(a) shows a moving plane in two positions. An arbitrary point "A" is picked in

the moving plane as a moving pivot or circle point. The perpendicular bisector of Al, A2 locates

a line of possible ground pivots or center points. With point Ao chosen, vectors Z and W

p,

W

Figure 4.

m

230

represent one of three infinites of dyads for two prescribed positions (the x and y coordinates

of A and the location of Ao along the perpendicular bisector).

For three prescribed positions (Fig. 4b), point "A" is again arbitrarily picked. Two

perpendicular bisectors are generated, one between A1, A2 and the other between A2, A3. The

intersection of these midnormals locates the center point Ao that will allow A to rotate through

its three positions. Thus there are two infinities of solutions for Z and W for three prescribed

positions of the moving plane. Therefore there is a correlation between the two methods of

modeling the two and three position motion generator dyads.

If an arbitrarily chosen fourth position were added to Fig. 4b, one would discover it hard to

find point A such that it's four positions would lie on a circle. Burmester and others who

followed[2, 4, 5, 7-9, 13-15] showed us that there in fact are points A whose four positions lie

on a circle, an infinite number. These points lie on the circle point curve and their corresponding centers lie on the center point curve.

Three Precision Point Standard Form Example

Completion of an assembly line requires the synthesis of a motion generator linkage to

transfer boxes from one conveyor belt to another as depicted in Fig. 5. A pickup and release

position plus an intermediate location are specified. A 4-bar is picked for this task (two

solutions of eqn 3). The prescribed quantities which are fed into the solution of eqn (3) are:

~ 2 = - 6 + Ili

a2=220

/~3= - 17 + 13i

a3 = 68°.

The free choices for each side of the 4-bar are

left side

right side

f12 = 90°

f12 = 40°

f13 = 198°

f13 = 73°.

The left side W rotations are chosen as large to try to obtain a crank rocker solution. Figure 6

shows the resulting 4-bar synthesized this task.

4

Conveyor#

I

Figure 5.

Ground Pivot Specification for Three Prescribed Precision Points[11]

In some cases it is advantageous to make different use of the two free choices of Table 2 for

the three finitely separated precision point dyad equations. Although the standard form allows

us to prescribe continuous crank rotations, with two free choices available, one of the vectors

231

- .

'%,

/_

z

Figure 6.

can be picked freely instead. In fact, by forming the dyad equations differently, a ground or

moving pivot location may be specified. Referring to Fig. 3, the loop closure equations can be

rewritten in the form:

W(l)+ Z(1) = - R

We'O2 + Ze~2 = - R + 82

(4)

We~O3+ Ze~"3 = - R + 83.

If

R I ~ -R

R2- - R + 8 2

R3 -= - R + 83

then

W(1) + Z(1) = R~

We~O2+ Zei'~2 = R2

(5)

We~a3 + Zei~3 = R3.

Table 2 still applies to eqn (5) so that two free choices are still available. Besides specifying 82,

83, a2, and a3, Ri will be arbitrarily picked. Thus R2 and R3 are now known.

Viewing eqn (5) temporarily as three complex equations with two complex unknowns (W

and Z), then this dependent set only has a solution for W and Z if the determinate of the

augmented matrix is identically zero:

1

eia2

eia3

1

R1

ei,~2 Rz = 0.

ei,~3 R3

(6)

Equation (6) represents a complex equation with two unknowns,/~2 and/~3. Since the unknowns

are in the first column, the determinant is expanded about this column:

(R3e~'~2- R2e ''3) + ei'2( - R3 + Rle ;'~3)+ ei~3(R2- Rle i~2)--- 0

232

or

1)1 + 1)2 ei02 + O3 eio3 = 0

(7)

where

D1 = R3e i~2 R:e i~3

-

D2 --- R l e i'3 - R3

D3 = R2 - R1e ic~2.

A simple graphical construction aids in solving eqn (7). Figure 7 shows an arbitrary solution

where the knowns 1)b !)2, and D3 are represented as vectors. Notice that 1)3, 1)~, and D: are

connected together but vector D~ is fixed. Note in eqn (7) that vectors 1)2 and !)3 are multiplied

by e i~2 and e i~ respectively. Recognize these quantities as rotation operators. If the vectors

formed a closed loop then eqn (7) will be satisfied. Thus 1)2 and Da are rotated (about their

connection with 1)]) until they meet. The rotations required to close the loop. are then/32 and/33.

Notice that there are two solutions for the triangle;/32,/33 and/32,/33. On set of solutions will be

trival however (/32= a2 and/33 = aa). Once the non-trivial set of/~'s is found (either graphically

or analytically based on Fig. 7), W and Z can be found from any two of eqns (5).

D2

Da

Figure 7.

Ground Pivot Specification (GPS) Example

An engineering student who had recently purchased a tape recorder unit for his sports car

was concerned with possible theft of his investment. Therefore, the student envisioned

synthesis of a 4-bar linkage to hide the tapeplayer behind the glove compartment when not in

use. Figure 8 shows a cross section of the area of interest including the glove compartment and

heating duct as well as the three prescribed positions for the tape unit. Since there is a small

acceptable area for possible ground pivots, the development above is used as a synthesis tool.

Two ground pivot locations are chosen (Ao and Bo) as shown in Fig. 8. The three position

vectors for the first dyad of the 4-bar are:

Rj = 2.14- 3.68i

R2 = 4.46 - 0.63i

R3 = 4.10 - 3.22i

while the rotations of the coupler (the tapeplayer) are

a2 = 50,7°

a3 = 91.9°.

233

\

\

Glove

Compartment

\

Line

X

of visibilit,y~ ~

Tope Player

Figure 8.

From eqn (7)

D1 = - 0.377 + 0.734i

D2 = - 0.493 - 0.959i

D3 = + 0.257 + 0.045i.

From the graphical solution of eqn (7)

/32 = 58.05o

/]3 = 122.650.

The first dyad can now be determined by inserting /32 and /33 into eqn (4) and solving

simultaneously. Thus:

W

= - 1.42-

1.45i

Z = 3.56 - 2.23i.

The second side of the linkage may be obtained by picking another ground pivot Bo, and

following the same procedure. Figure 9 shows one possible solution including the dyad

synthesized above.

Interactive Graphics and GPS

Even though the GPS method allows specification of the ground pivot location, most

applications require regions of acceptability. Thus the GPS technique was programmed [19] on a

Tektronix 4013 terminal so that the user could specify a range of possible ground pivots and ask

the computer to display the corresponding moving pivots. Then the user could interactively

synthesize dyads to form his/her linkage.

Mkff Vol. 16, No. 3--E

234

%

Figure 9.

interactive GPS Example

Dyads are to be synthesized for the following motion generation positions

R~ = 2.5 + 3.75i

R2 = 1.1 + 4.4i

R3 =

0.8 + 4.4i

-

a 2 = 20 °

a3 = 58 °.

The ground pivots were picked to be along the line x = - 1.17 between -5-< y < 5. Figure 10

shows the ground pivot curve, the corresponding moving pivot curve and the prescribed

precision points. Notice that the curves have letters A, B, etc. which correlate with the

Plot of M - / ( curves (set I)

M

K. . . .

6.00

OA

5B

IOC

15D

20 E

25F

30 G

35H

40 I

45J

0

4.00

0

~

/.~-5

14

21

19

24

27

31

:35

42

48

F //

2.00

0.00

-2.00

B

A

C

O

E

F

G

H

I

J

-4,00

"6.00

i

-6.00

Figure 10.

I

-4D0

,

I

-2C0

,

I

OO0

,

I

2.00

i

I

4.00

i

6.00

235

corresponding fixed and moving pivots. Notice also the lines drawn between the curves. These

were located using the cross-hairs on the Tektronix screen. They also identify corresponding

fixed and moving pivots. Any one of these lines extended from its moving pivot to the first

precision point (the square) will display a possible dyad solution. Of course the computer can

be programmed to display ground pivots in any fashion desired.

The GPS procedure allows the specification of ground pivots--an improvement over the

standard form approach for problems with tightly constrained ground pivot locations. Further

improvement is possible, however. Readjustment again of the dyad equations will yield a

solution procedure which allows unique display of numerous circle and center points at a time.

Circle and Center Point Circles for Three Prescribed Positions

Equations (4) are vector loop equations for three finitely separated positions shown in Fig. 3.

It is of interest to examine the array of ground and moving pivots described by vectors R and

- Z with respect to the first precision point.

In order to eliminate W from eqn (4), W is expressed in terms of Z and R in the first

position.

W=-R-Z.

(8)

Equation (8) is substituted into the 2nd and 3rd position eqations of (4) to yield

Z(e i°'2-

R(e ig2- 1) =

e ith) -

82

R(e ia3- 1) = 83.

Z ( e i~3 - e ~#3) -

(9)

Using Cramer's Rule the vector between the coupler tracer point

is

R=

Pl

- 63(e/"2 - ere2)- 8 2 ( e i ° 3 - e~3)

+ (e;'~2_ e~#2)+ (et#~ _ e~3) + e~S2e~3_ e~#~e~2•

and the fixed plane pivot m

(1o)

The vector between Pl and the circle point kl may be determined.

-- Z =

-

~ 2 ( e i'83 -

1) +

~ 3 ( e i'62 -

1)

e i~2 - e i~s3 -b e ia3 - e ia2 - eiO2e ia3 -b e i a 2 e i~3"

(ll)

There are two free choices to be made in eqns (10) and (11) (Table 2). Table 1 (last two

columns) suggests a strategy for choosing the remaining angles. One angle will be picked while

the other is varied between 0* and 360°. With this method in mind, eqns (10) and (11) may be

rewritten in the form

R-

aO+b

cO+d

(12)

eO+t

Z = gO +-~

(13)

where a-~ h are known and

0 = e i°

where 0 = the "angle varied" from Table 1.

It has been found[l, 16] when 0 varies from 0 to 2~r, # describes the unit circle. Equations

(12) and (13) are tantamount to the following sequence of transformations:

p(O) = aO,

a stretch rotation,

q(O) = aO + b,

a change of origin,

236

r(O) = cO,

another stretch rotation,

s(O) = cO + d,

another change of origin, and

_

q(O)

t(0)- s(0)

(15)

a "bilinear mapping".

Since both q(0) and s(0) are circles, it can be shown that t(0) is also a circle[3]. Thus, it is

seen that the loci of R(0) and -Z(0) are circles which, in the limit can become straight lines.

The complex constants a through h are found by appropriately rearranging eqns (10) and (11) in

the form of eqns (12) and (13). The centers of the circular loci Cu and Cr can be found directly

from the constants a through h[1], or by evaluating R and - Z at three 0 values, yielding three

points each which define the circles.

The circles of circle and center points were discovered during the displaying of ground and

moving pivots on the Tektronix 4013 graphics terminal, Loerch[1].

Many new observations have been made concerning the three precision point dyad synthesis

case[l, 16]. Some of these are:

1. For motion generation, all the ground pivot circles M intersect the poles P13 and P23

while all the moving pivot circles kl intersect pole P13 and image pole P~3 (Figs. 13-15,

discussed below).

2. For path generation with prescribed timing, all the M circles intersect the so called

pseudo-polest 813 and 823. The kl circles do not intersect at a single point but are all tangent to

two non-existence circles (one of which surrounds the first precision point). For example in Fig.

11, with 8j = 2 + 2i, 83 = 4 + 4i,/32 -- 0.5 rad and/33 = 1 rad, the M and K circles are displayed

for several values of a 2. The K circles (dashed) are tangent to two "forbidden regions" labeled

as "F". Notice also several possible W links are sketched in the diagram.

3. The dyad synthesis with opposite angles prescribed exhibit somewhat similar characteristics as path generation with timing. Figure 12 shows the K circles for the example

8 2 : 2 + 4i, 83 = 1 + 2i, a2 = - 1 rad and/33 = - I rad. The forbidden regions are signified by the

letter "F".

4. Superposition of two three position, motion generator subproblems with two precision

350" 17.35

3" 51,68

Figure 11.

tPoles with rotations/3 rather than a.

237

Figure 12.

20"

-20"

.70 °

+1

M Circles

{ ÷ - A Precision Point)

Figure 13.

-40"

238

K Circles

Figure 14.

K'(24)

~

'

K(23)

Rgure 15.

points common will generate exactly the classical construction for the four precision point

Burmester Curves based on the opposite pole quadrilateral[2].

5. Superposition of either two or three of the three position, path generation with prescribed

timing subproblems will yield non-existence areas for the four or five precision points problems

respectively.

The example below will illustrate a dyad motion generation example.

Motion Generation Example

In Figs 13-15 the intersections of the " + " of + :, + 2 and + 3 mark the prescribed positions

of the tracer point P, with 82 = 2 + 2i, 83 -- 5 + 2i, a2 = 60° and a3 = 120°. The M and Km circles

are generated for several values of the varied angle/~2 with/33 ranging from 0 to 2~r. These

circle-point circles and center-point circles are sufficient to display the properties of the

diagram. Figure 15 shows two dyad solutions which will form a 4-bar solution (f12= 24° and

/~2-- -23°). The simple steps required to construct a set of circular M and K loci for motion

generation are:

1. Find the circle-intersection poles: Pt3 and P23 for the M circles; P~3 and P~3 for the K,

circles.

239

2. Bisect the lines between the intersection pole pairs to find the lines of centers for the M

and K~ circles.

3. For each value of the varied angle//2, lay off the circle centers so that ,t;.P~3CMP23 = ~2

and ' ~ P I 3 C r P ~ 3 = a s - ~2.

4. Draw the circle pairs through the intersection poles with centers CM and CK. It can be

shown that the complex number expressions for the pole are:

82

P12 = ~1 - , a 2

83

e l 3 = -1 -- a 3

and

(15)

P23 = 8 3 a 2 -- 82at3,

~lf2 -- 0'3

where Pii is the vector from the origin of R,. to the pole Pij and where aj = e ia~.

Slider and Rotating Slider Block Solution

A search of the kinematics literature only yielded a couple special cases of these circles

considered by Beyer[4]. He noticed that the image pole triangle P~2P~3P~3has a circumscribing

circle that represents the locus of moving pivots with links of infinite length, or sliders. The

moving pivot can be replaced by a slide, moving along a line from its location on this circle

through the altitude intersection H of the pole triangle (See Fig. 16). The fixed pivot can be

considered at ooperpendicular to this line. A second case involves the circumscribing circle C of

the pole triangle itself, which is the locus of fixed pivots with moving pivots at oo. The infinite

links may be replaced by rotating slides at the fixed pivots; the initial sliding axis of the moving

pivots being a line from the circle, through the image H' of the altitude intersection H. The first

circle is the K circle for 4)2 = 0; the second is the M circle when a2 =//2. Figures 17(a) and (b)

show examples for these special cases.

~

2

Nt--e~

23

/

/

/

/

/

/

/

I

I

I

Figure 16.

Four Proscribed Posltion~The Standard Form

Table 2 shows that for four prescribed dyad motion positions that there is an infinite number

of solutions based on changing one free choice. Returning to the standard form, an additional

complex equation must be added to eqns (3) for the fourth position:

W(e i~'- 1) + Z(e i~'- I)= 84.

(16)

Consider eqns (3) and (16) as a set of three complex equations in two complete unknowns, Z

and W. In order for this set of equations to be valid, one of the complex equations must be

linearly dependent on the other two, that is, the coefficients of the equations must satisfy

certain "compatibility" relations. These relations will lead to the solution of the above

240

Fixed Sliding Axis

~'~,,..Gz~---- SIidirlg Pivot

Ist C~se

P23

2nd Cose

Io)

Figure 17.

equations. This system can only have a solution if the rank is 2. Thus the determinant of the

augmented matrix M of this system must be equal to zero.

(ei"2-1)(eia2-1)82I

M= (ei~3-1)(eia3-1)83 =0.

(ei~,-1)(ela4-1)84

(17)

If /32 is arbitrarily picked, then /33 and /3,, remain as unknowns. But eqn (17) is a complex

equation (containing two independent scalar equations) and may be solved for/33 and/34. Notice

the similarity between eqn (17) and eqn (6). Equation (17) may be rewritten as:

eilhA2 + e~3A3+

ei~4A4 + A I = 0

A2 = cofactor of (e i~2- 1)

A3 = cofactor of (e ia3- 1)

A4 = cofactor of (e ~a' - 1)

(18)

A 1 =-A

(19)

2 - A 3-~1t4"

Equation (18) is almost the same as eqn (7), especially once a /32 is chosen. Therefore the

graphical solution of eqn (18) with eqn (19) in mind is similar to Fig. 7 except that a

"compatility 4-bar" geometric solution exists [9, 17, 18]. The solutions for/33,/34, Z and W come

in pairs for all values of/32 that the compatibility linkage closes.

LINCAGES (Linkage INteractive Computer Analysis and Graphically Enhanced Synthesis Package)[17]

briefly

The following

describes an interactive computer package which uses graphics output

to help synthesize and analyze planar linkages. This program is available by contacting the

author at the Department of Mechanical Engineering, University of Minnesota.

The LINCAGES Package is the first such program to be generally available over telephone

lines in a time sharing mode and to be designed to make optimal use of graphical output from

either a teletype, graphics CRT or a micro computer. The computer, the designer and graphics

output are used strategically to maximize the utility of each. Synthesis programs (based on the

theory described above may be applied for either 3, 4, or 5 finitely spaced precision points for

combinations of motion, function, and path generation with prescribed timing.

In the four precision point option, LINCAGES uses 132 as an independent parameter to

generate solutions to the synthesis equations. The two solutions for each value of /32 are

assigned so that each solution dyad may be designated by a 1/2 value (0° - 360°) and a set number

(1 or 2).

241

LINCAGES Example: Motion Generation for Four Precision Points

The assembly of a filter product begins by forming the filtration material into what is known

as a filter blank. Next the filter blank is placed by hand onto a mandrel. This mandrel is part of a

machine that completes the assembly of the filter. The objective of this problem is to design a 4-bar

linkage for removing the filter blanks from the hopper and transferring them to the mandrel.

Figure 18 diagrams the kinematic synthesis objective. A gravity feed hopper holds the

semi-cylindrical filter blanks with the diametral plane surface initially at a 270 angle from

vertical. The blank rotated around until this plane surface is horizontal on the mandrel. The

position of the hopper can be moved about within the area indicated, although the angle must

remain at 27°.

At the beginning of the "pick and place" cycle, it is desirable to pull the blank in a direction

approximately perpendicular to the face of the hopper. To prevent folding the filter blank on the

mandrel, it is necessary to have the rotation of the blank completed at a position of 5 cm

approx, above the mandrel and then translate without rotation onto the mandrel. The motion of

the linkage should then reverse to remove the completed filter from the mandrel and eject it

onto a conveyor belt. After this, the linkage should return to the hopper and pick another blank.

Due to the requirement of reversibility, a double-crank or crank-rocker would have no real

advantage over a double rocker.

An acceptable linkage solution must have ground pivots and linkage motions within areas

that do not interfere with the hopper or assembler. Also, since the resulting linkage may be

driven by a dyad (to provide a crank-rocker input) the total angular travel of the input link of

the 4-bar synthesized here should be minimized so as to obtain acceptable transmission angles

for the entire mechanism, including its driving crank and connecting link which actuates the

input of the motion-generator 4-bar linkage.

This example is a typical challenging problem that faces linkage designers many times. Some

of the constraints are firm while others can vary within some specified range. This means

mathematically a number of infinities of solution possibilities. The computer graphics screen is

an ideal tool to help survey a large number of solutions.

The problem clearly requires motion generation synthesis (or rigid body guidance), in which

the position and angle of the filter blank is specified at different points. Four precision points

along a specified path and four corresponding coupler angles were chosen.

The first set of precision points chosen are shown in Table 3. The mandrel was designated

position one and the second position was picked above the mandrel with no rotation (to prevent

folding the filter blank). The third position was chosen to be halfway between the second and

fourth positions with about half the required rotation. The fourth position corresponded to the

angle and position of the hopper.

The M - K curves (center and circle point curves) for this set of precision points is shown in

Fig. 19. The solid and short dashed lines represent the portions of the center point curve from

Hopper

Mandrel

(not shown)

Figure 18.

Conveyor Belt

242

Table 3.

Position

X Coordinate

Y Coordinate

Rotations (degrees)

I

2

3

4

0

1

17

38

0

7

18

21

0

0

60

117

Plot of M - K

M I ~ K I ~

400

Curves (Both sets)

M2 ....

K2-----

3,00

20.0

\

,

I00

\

\

x

"%.~"-..

O0

-I0.0

-200

-I00

0.0

I00

.0

'300

Figure 19.

sets 1 and 2 respectively, while the long dash and dash-dot lines are the circle point curves from

sets 1 and 2. Figure 20 shows an M-K curve option where the/~2 values are correlated to their

m-kl positions on the curves by letters corresponding to the table along the left hand side of

the figure. The results of interactively locating ground pivots and moving pivots (by using the

cross-hairs on the graphics screen) corresponding to f12 = 340° and f12 = 20°, both from set 2, are

also shown in Fig. 20. As the designer locates a ground pivot with the cross-hairs, the computer

finds the moving pivot of the dyad and draws lines to represent the dyad. These two dyads

formed what looked to be an acceptable 4-bar solution to be further analyzed. The coupler

Plot of M - K

M

/(~

30.0

Curves (set 2)

20

340

OA

0

30B

60C

90D

120E

150F

180G

210H

240 I

27OJ

300K

330 L

36OM

20.0

I0.0

O0

\ "~.....~..

-I0.0

-I0.0

Figure 20.

0.0

////

I0.0

L:~).O

30.0

40.0

243

Coupler Curve

30.00

25.00

/

\

/

200O

I

~x3

/

1500

/

/

I0.00

/

5.00

I

/

!

~1111

\

000

/

/

-5.00

, I L L

. . . .

I

,

-I000

5.00

-500

0.00

,

,

i

I

i

,

i

i

I

,

,

,

•

I

. . . .

15DO

I0.00

I , I

,I

I l l

' '

25.0O

20.00

i

. . . .

35D0

30.00

40.00

Figure 21.

40¸00

s't.,

3500

3000

,,

25.00

...~,.-...',,

~

e'.. - "

~ -. . . . . .

s

N.

" "~

,~---'.~--'® I " "

20100

i

15,00

,, ///

i /"

I0.00

5.00

0.00

- 5.00

5.00

0 lO0

15,00

I0,00

25.00

20.00

This is The Linkage in the Precision Point

~0

"3000

Positions

Figure 22.

curve of this linkage is generated by another subroutine. Figure 21 shows that the coupler curve

shifts to the left between points one and two, and also approaches point 4 vertically. Both of

these are unacceptable characteristics. Although this linkage is not acceptable, there are others

which also satisfy the prescribed precision points in Table 3 as well as new choices for the

middle two precision points.

Making a long story short[18], the precision points in Table 3were changed and a number of

the options on the LINCAGES Package were used to optimize for the final solution. The final

linkage is shown in several positions in Fig. 22 while it's coupler curve is shown in Fig. 23.

Conclusions

This paper attempted to present several strategies for solving the three precision point dyad

synthesis problem. Each technique seems to have advantages and disadvantages which should

be weighed when choosing a specific technique for a problem. Also presented was an

introduction to the LINCAGES Computer Graphics Synthesis Package. Many illustrative

examples were also given.

244

Coupler

Curve

2500

A

0

B

C

D

E

F

G

H

i

J

K

L

30.0

600

900

120.0

1500

180.0

2100

240.0

270,0

300.0

3300

2000

/

/c"

~5.00

/

/

~000

/

/

/

5O0

oo(1

-5

oo

\

\

-Iooo

~

-1500 . . . .

000

~L....._

, ....

5 O0

, ....

1000

~...+

; ....

1500

! .........

2000

2500

i ....

30.00

I ....

4000

3500

Figure 23.

Acknowledgements--The author would like to acknowledgethe contribution of Richard Loerch, George Sandor and others

whose work is reported here. The support of the University of Minnesota's Educational Development Fund Program,

Department of Mechanical Engineering and the Computer Center is most appreciated. The author also thanks Lana

Schermerhorn for typing this manuscript.

References

1. R. J. Loerch, Extensions of revolute dyad synthesis for three finitely displaced positions. M.S. Thseis, University of

Minnesota, July (1977).

2. T. S. Hartenburg and J. Denavit, Kinematic Synthesis of Linkages. McGraw-Hill,New York (1964).

3. R. L. Goodstein, Complex Functions. Mcgraw-Hill,Maidenhead, England (1965).

4. R. Beyer, Kinematic Synthesis of Mechanisms, translated by Kunzel, Chapman and Hall Ltd., London.

5. K. Hain, Applied Kinematics, 2rid Edn. McGraw-Hill,New York (1967).

6. D. C. Tao, Applied Linkage Synthesis. Addison-Wesley,Reading, Mass. (1964).

7. A. S. Hall, Jr., Kinematics and Linkage Design. Prentice-Hall, Englewood Cliffs, New Jersey (1961).

8. F. Freudenstein and G. N. Sandor, Synthesis of path generating mechanisms by means of a programmed digital

computer. ASME J. Engng Ind. 81(2), May (1959).

9. A. G. Erdman and G. N. Sandor, Mechanism Design: Analysis and Synthesis. To be published by Prentice-Hall, 1982.

10. Tektronix Plot 10 Terminal Control System User Manual. Tektronic, Inc., Beaverton, Oregon (1977).

11. R. J. Loerch, A. G. Erdman, G. N. Sandor and A. Midha, Synthesis of four-bar linkages with specified ground pivots.

Proc. 4th OSUAppL Mech. Conf. Chicago, pp. 10(1)to 10-8,2-5 November (1975).

12. A. Rao, A. G. Erdman, G. N. Sandor et aL, Synthesis of multi-loop dual-purpose planar mechanisms utilizing

burmeister Theory. Proc. 2nd OSUAppL Mech. Conf. pp. 7-1 to 7-25, Stillwater, Oklahoma, 7-9 October (1971).

13. R. E. Keller, Sketching rules for the curves of burmester mechanisms synthesis. Trans. ASME, Paper No. 64-MECH5, Lafayette, IN, 19-21 Oct. (1964).

14. G. N. Sandor, A general complex-number method for plane kinematic synthesis with applications. Doctoral dissertation, Columbia University, University Microfilms,Ann Arbor, MI, 305 pp., Library of Congress Card No. 59-2596

(1959).

15. F. Freudenstein and G. N. Sandor, On the burmester points of a plane. ASME J. AppL Mech., Trans. ASME 25(3),

473-475 Sept. (1961).

16. R. J. Loerch, A. G. Erdman and G. N. Sandor, On the existence of circle point and center point circles for three point

dyad synthesis. ASME Paper No. 78-DET-44.To be published in the ]. Mech. Design. 101(4),October 1979,pp. 554-556.

17. A. G. Erdman and J. E. Gustafson, LINCAGES: Linkage INteraction Computer Analysis and Graphically Enhanced

Synthesis Package. ASME Paper No. 77-DET-5.

18. K. R. Struble, J. E. Gustafson and A. G. Erdman, Case study: synthesis of a four bar linkage to pick and place filters

using the LINCAGES computer package. Proc. 5th OgU Appl. Mech. Conf., Nov. (1979).

19. G. Rowley, Unpublished design report, University of Minnesota.

SYNTHESE CINEMATIQUE A TROIS ET QUATRE POINTS DE PRECISION DES MECANISMES ARTIOULES PLANS

Arthur 0, Erdman

R4sum4

--

Les dyades m4oaniques model4es par des nombres complexes sonZ pr4sent4es sous

plusieurs formes d'4quations diff4rentes pour trois positions prescrit4~, soit du mouvement,

245

soit de la g@n@ration de traJectoire avec synchronisation prescrite, soit de la g@n~ration

de fonction. Diff@rentes strategies sont sugg@r@es selon la fa~on dont les choix libres

sont le mieux utilis@s. Des techniques interaetives d'ordinateur sont sugg~r~es pour les

cas ~ trois et ~ quatre positions prescrites. Plusieurs exemples sont pr~sent~s pour

illustrer chacune de ces situations de conception.