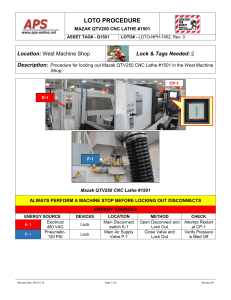

F.B. ENGINEERING (PTY) LTD Plot 68285 Phakalane PO Bag Br. 47 Gaborone Tel: (267) 395 9038 Fax :( 267) 395 7083 Procedure Name: Log out Tag Out (LOTO) Procedure Procedure NO: PR-FB-PNT-12 Originator: Technical Issue No: 01 Distribution: All employees Effective Date: 20/01/2021 Next Review Date: 20/01/2023 1. INTRODUCTION. The LOTO procedure is a pretty straight forward safety policy that has saved thousands of lives and prevented many more injuries. The basic requirements are as follows: 2. PREPARE FOR THE SHUTDOWN. Shutdown is planned. The expected duration of shutdown id estimated. All activities for shut down are listed and analyzed. A shut down program is then created. 3. NOTIFY AFFECTED EMPLOYEES. Prior to shutting off the mains or power supply all affected areas and employees are notified in writing through a signed memo. The memo should state the following? i. Date and time for shut down. ii. Duration of the shutdown. iii. Responsible person for logging off tag off. iv. The contact details for the responsible person. ORIGINATOR APPROVAL TITLE Technical NAME SIGNATURE DATE General Manager Doc no. SWP- FB-PNT12 Name: LOTO procedure Issue no: 01 1 Page 1 of 3 4. SHUT DOWN THE EQUIPMENT. Power is disconnected – The first step is to physically remove all power sources from a piece of machinery. This includes the primary pour source and all backup sources as well. 5. LOCK OUT THE POWER – Next, the person who will be working on the machinery will physically lock the power out. This typically means putting an actual lock around the plug so that it can’t be inserted into the machine. If there is more than one plug, then multiple locks will be needed. The equipment should be logged off and tagged off. A pad lock is lock off the switches or energized parts a machine. 6. FILLING OUT THE TAG . The lock will have a tag on it that provides information about who removed the power, and why. This will further help to inform those in the area that they should not attempt to energize the machine at this point. The tag will be clearly inscribed with the contact details of the responsible person. 7. HOLDING THE KEY. The person who is actually entering the machine or other hazardous area will hold on to the key to the lock. This will ensure that nobody can remove the lock and restore power while the worker is still in a hazardous area. A tag with the name of the responsible is place on the lock. Only the responsible person is ORIGINATOR APPROVAL TITLE Technical NAME SIGNATURE DATE General Manager Doc no. SWP- FB-PNT12 Name: LOTO procedure Issue no: 01 2 Page 2 of 3 allowed to remove the lock. Contact details for the responsible person must be clearly visible. 8. NOTIFY OTHERS THAT THE TASK HAS BEEN DONE AND WE REMOVING THE LOGOUT. After work prior to removing the lock notify ll concerned parties the you have completed the task. It is now time to remove the log out. This is done to concertize others who might have taken advantage of the log out period to carry their works on the same equipment or line during your log out period. 9. RESTORING POWER. Only after the work has been completed and the worker has existed the area where danger exists can they remove the lock and restore power. ORIGINATOR APPROVAL TITLE Technical NAME SIGNATURE DATE General Manager Doc no. SWP- FB-PNT12 Name: LOTO procedure Issue no: 01 3 Page 3 of 3