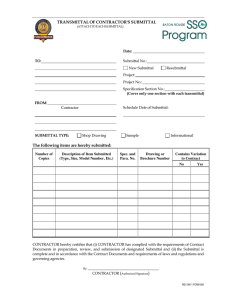

Date: Approval needed by: SUBMITTAL TRANSMISSION OF MATERIAL/SAMPLE DOCUMENTS CONTRACTOR: SUBMITTED FOR PACKAGE NO. PS-08/B Fire Fighting CODE APPROVAL INFORMATION RECORD REFERENCE 1 2 3 ACTION TO: Cc. Cc. Cc. Cc. WE ARE SENDING HERE WITH THE DOCUMENT LISTED BELOW. S/N 1 No. Copies Dwgs., Specs. or BOQ Ref. No 3 Specification No. FF section 2-2.3 section 3-3.2 DOCUMENT NO. FF-MS0001 DESCRIPTION CODE A APPROVED APPROVED AS NOTED APPROVED SUBJECTED TO ADDITIONAL INFO REVISE AND RESUBMIT D FOR INFORMATION R Soft Copy B C TYPE REV. 06 CODE SUBMITTED BY (1) Tower-B Method Statement for Fire Hydrant, Sprinkler pipes & fittings installation & Hydro test √ MS ACTION (2) 1 HIGHLIGHT DEVIATIONS: I certify that above submitted items have been reviewed in detail and correct and in strict conformance with specification except as otherwise stated COPIES: 3 HARD COPIES Design Consultant to enter Action Codes and Remarks, and return to Contractor REMARKS: COPIES: DATE: (1) Code to be entered by contractor • TYPE: SD· Shop Drawings GT- Guarantee / Warrantee MD - Manufacturer's Data SM-Sample TI- Test/Inspection CD- Coordination Dwg (2) Code to be entered by Designer / Consultant CA- Calculation CT- Certificates MS- Method Statement SC- Schedule RP- Report OT- Others WORLI MIXED USE DEVELOPMENT PROJECT – PHE/FF Response to Samsung comments Comments received for: 1 2 Submittal No: Contractor Submittal No: Revision: Submitted Date: BSL Reply Date: Comments received Date: Action Code: Sr No. A Method Statement for Fire Hydrant, Sprinkler pipes & fittings installation & Hydro test Comments from Samsung SMT-BS-0034 BSL Reply to Samsung General Comments: Flushing of FF system shall be in accordance with NFPA guidelines Confirm compliance Submit separately hold tite joint compound material with technical details for Engineers The same submitted through submittal no – SMT-BS-0166, dated 8th March 2014 & same approved as noted Handling/shifting of pipe inside shaft riser to be briefed Logistic plan for vertical material movement shall be submitted separately for approval Attached risk assessment not specify to the activity involved Revised RA attached 3 4 5 Mention the testing pressure for hydro-testing separately for risers as well as branch pipes Testing pressure shall be 2 times the working pressure or 1.5 times the working pressure plus 3.5 bar whichever is the lowest but in any case not less than 7 bars as per specification is referred for construction. This will retain @ lowest point of the riser of that particular zone. (Page Attached) The same is mentioned in MOS under the head of “material standard” 6.1. G.I. Pipe 25mm dia to 150mm dia shall be as per IS: 1239 – “C” Class. G.I. Pipe of size 200mm and above shall be as per IS: IS: 3589 min wall thickness 6.35 mm. 6 Type of material & jointing procedure to be mentioned Fittings – 25mm dia to 50mm dia shall be “G.I. Threaded forged” fitting. Jointing procedure for these fitting with piping shall be “thread” joint. Fittings – 65mm dia & above shall be “D.I. grooved type” fitting. Jointing procedure for these fitting with piping shall be “grooved” joint Date: Approval needed by: SUBMITTAL TRANSMISSION OF MATERIAL/SAMPLE DOCUMENTS CONTRACTOR: SUBMITTED FOR PACKAGE NO. PS-08/B Fire Fighting CODE APPROVAL INFORMATION RECORD REFERENCE 1 2 3 ACTION TO: Cc. Cc. Cc. Cc. WE ARE SENDING HERE WITH THE DOCUMENT LISTED BELOW. S/N 1 No. Copies Dwgs., Specs. or BOQ Ref. No 3 Specification No. FF section 2-2.3 section 3-3.2 DOCUMENT NO. FF-MS0001 DESCRIPTION CODE A APPROVED APPROVED AS NOTED APPROVED SUBJECTED TO ADDITIONAL INFO REVISE AND RESUBMIT D FOR INFORMATION R Soft Copy B C TYPE REV. 06 CODE SUBMITTED BY (1) Tower-B Method Statement for Fire Hydrant, Sprinkler pipes & fittings installation & Hydro test √ MS ACTION (2) 1 HIGHLIGHT DEVIATIONS: I certify that above submitted items have been reviewed in detail and correct and in strict conformance with specification except as otherwise stated COPIES: 3 HARD COPIES Design Consultant to enter Action Codes and Remarks, and return to Contractor REMARKS: COPIES: DATE: (1) Code to be entered by contractor • TYPE: SD· Shop Drawings GT- Guarantee / Warrantee MD - Manufacturer's Data SM-Sample TI- Test/Inspection CD- Coordination Dwg (2) Code to be entered by Designer / Consultant CA- Calculation CT- Certificates MS- Method Statement SC- Schedule RP- Report OT- Others CONTRACTOR’S SUBMITTAL PROJECT TITLE: CONTRACTOR: PROJECT DIRECTOR: DISCIPLINE: SCHEDULE ACTIVITY No.: DATE REQUESTED BY CONTRACTOR: DATE SENT: DRAWING REFERENCE TYPE: SUBMITTED FOR: TO: CC: CONTRACTOR’S SUBMITTAL NO: REFERENCE NO: CHECK ONE: ORIGINAL SUBMITTAL 2nd SUBMITTAL OF SUBMITTAL OF O and M SUBMITTAL Initiator: LEGEND Submitted for: Action: Approved A APPROVAL: Approved as Noted B Type: Shop drawing SD Calculation CA Certificate CT No Copies Doc No. INFORMATION: Approved subjected to Additional info C Revise & Resubmit:-D Guarantee/Warrantee GT Manufacturer’s Data MD Sample SM Verified Statement VS Schedule SC Report RP Rev Description Type Tower-B Method Statement for Fire Hydrant, Sprinkler pipes & fittings installation & Hydro test RECORD: For information R Test/Inspection TI Others OT Soft copy SmtP (a) WE HAVE VERIFIED THAT THE MATERIAL, EQUIPMENT OR OTHER INFORMATION CONTAINED IN THIS SUBMITTAL MEETS ALL THE REQUIREMENTS SPECIFIED OR SHOWN (NO EXCEPTIONS) (b) WE HAVE VERIFIED THAT THE MATERIAL EQUIPMENT OR OTHER INFORMATION CONTAINED IN THIS SUBMITTAL MEETS ALL THE REQUIREMENTS SPECIFIED OR SHOWN EXCEPT FOR THE FOLLOWING DEVIATIONS Project Director Date: ORL COMMENT: Refer comments on attached sheets. SECTION 17 FIRE PROTECTION INSTALLATION GENERAL SPECIFICATION TESTING COMMISSIONING AND HAND OVER same throughout the jacking pressure range varied by applying the hand pump iii) Flow switches The testing equipment for the flow switches shall be as shown on the drawings or of an equivalent approved by the Employer The calibration test equipment shall provide a flow of 60 dm3/min over the vane of the flow switch in the direction shown, to be confirmed by the direct reading flow meter. The flow switch contacts shall make with energisation of the lamp and the buzzer, upon a flow not greater than 60 dm3/min flowing over the vane in the correct direction. iv) Hydrostatic Tests All parts of the water circuit shall be filled with water before hydrostatic pressure testing, and pump running tests for verification of pressure and flow rate, are conducted. The hand jacking pump shall be applied to increase the system pressure to 2 times the working pressure or 1.5 times the working pressure plus 3.5 bar whichever is the lower but in any case not less than 7 bars. The pressure shall be maintained for a period not less than 24 hours. Where any section of pipework or equipment unable to withstand the maximum pipework test pressure, it shall be isolated during the pipework test then that section of pipework or equipment shall be re-tested at the appropriate test pressure. The working pressure for various systems shall be as NFPA rules or NBC/BIS guidelines. Before performing the hydrostatic test, the following system component shall be fulfilled: For WR/HR System All first aid hose reel isolating gate valves shall be closed.