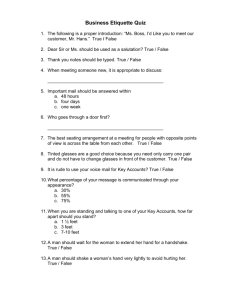

Biomaterials 23 (2002) 4263–4275 Microstructural dependence on relevant physical–mechanical properties on SiO2–Na2O–CaO–P2O5 biological glasses V. Rajendrana,*, A. Nishara Beguma, M.A. Azoozb, F.H. El Batalb a Department of Physics, Mepco Schlenk Engineering College, Mepco Engineering College (PO), Virudhunagar (DT), Tamilnadu 626 005, India b Glass Research Department, National Glass Research Centre, Dokki, Cairo, Egypt Received 14 June 2001; accepted 16 May 2002 Abstract Bioactive glasses of the system SiO2–Na2O–CaO–P2O5 have been prepared by the normal melting and annealing technique. The elastic moduli, attenuation, Vickers hardness, fracture toughness and fracture surface energy have been obtained using the known method at room temperature. The temperature dependence of elastic moduli and attenuation measurements have been extended over a wide range of temperature from 150 to 500 K. The SiO2 content dependence of velocities, attenuation, elastic moduli, and other parameters show an interesting observation at 45 wt% of SiO2 by exhibiting an anomalous behaviour. A linear relation is developed for Tg ; which explores the influence of Na2O on SiO2–Na2O–CaO–P2O5 bioactive glasses. The measured hardness, fracture toughness and fracture surface energy show a linear relation with Young’s modulus. It is also interesting to note that the observed results are functions of polymerisation and the number of non-bridging oxygens (NBO) prevailing in the network with change in SiO2 content. The temperature dependence of velocities, attenuation and elastic moduli show the existence of softening in the glass network structure as temperature increases. r 2002 Elsevier Science Ltd. All rights reserved. Keywords: Ultrasonic velocity measurements; Bioactive glasses; Elastic properties; Fracture toughness and fracture surface energy; Structural softening 1. Introduction In recent years biomaterials, namely traditional ceramics, metals, bioactive glass and bioglass ceramics or a combination of these materials have gained more interest in the field of medicine in view of their variety of potential applications such as replacement of damaged/ diseased body parts [1–3]. The most important biomaterial in this series, which finds immense application in the field of medicine, is bioactive glasses. Some of the bioactive glasses and bioglass ceramics with a specific composition will form bond with natural bone and hence, it is known as bioactive glass ceramics [4]. For the effective bonding of the bioactive glass to bone, a selection of proper composition is more essential. The suitable composition of the bioactive glasses has been selected through an optimisation procedure [5]. Thus, several compositions of the *Corresponding author. Tel.: +91-4562-351720; fax: +91-4562351520. E-mail address: vee rajendraan@yahoo.com (V. Rajendran). bioactive glasses have been developed with an aim to improve the bioactivity and mechanical properties. The optimisation of bioactive glasses also require the proper understanding of their physical, chemical, biological and mechanical properties. Hench [6] reported first, the formation of an apatite layer on bioactive glasses in Na2O–CaO–SiO2–P2O5 system, in vitro as well as vivo. Recently, attempts have been made by many researchers [7–14] on the successful implementations of bioactive glasses for a variety of biomedical applications employing different preparation methods, changing their composition, subjecting them to different thermal treatment conditions, etc. Some of the bioactive glasses such as Al2O3–K2O–Na2O–CaO–P2O5 glass ceramics [15] with different heat treatment conditions lead to an important application in dental restoration due to the change in microstructure, mechanical and chemical properties. The structural strength and reactions occurring inside the rigid porous bioactive glass bodies immersed in a simulated body fluid (SBF) have been studied by Heimo et al. [16]. Thus, the biocompatible and bioactive glass–ceramics have been treated by many 0142-9612/02/$ - see front matter r 2002 Elsevier Science Ltd. All rights reserved. PII: S 0 1 4 2 - 9 6 1 2 ( 0 2 ) 0 0 1 8 9 - 8 4264 V. Rajendran et al. / Biomaterials 23 (2002) 4263–4275 researchers for replacing bone structure in human medicine and restorative dentistry [17–20]. In order to develop new bioactive glasses, which are closely related to bone stiffness, the determination of elastic properties is more essential as it involves the mechanical interaction between implant and surrounding tissues. However, the elastic properties of bioactive glasses have not been studied systematically in most of the bioactive glasses. This is possibly due to the fact that most of the available techniques such as static bending, resonance, etc., are destructive and semi-destructive testing methods [21] and also the materials will be subjected to harm during the above testing. Nevertheless, a review of literature indicates that only very few attempts [22–24] have been made on the measurement of elastic moduli, hardness, thermal expansion and fracture toughness on binary and multi-compositional bioactive glasses, to explore the microstructural, physico-chemical and mechanical properties, which widen the range of options for clinical application of this material. The ultrasonic technique is a non-destructive testing (NDT) and it has been found to be one of the best techniques for complete characterisation of bioactive glasses [25,26]. The various advantages of ultrasonic technique over mechanical and other methods include, the determination of the material properties without harming, comparative analysis to physical testing as a function of materials loading and also, it provides the information about grain size, orientation and materials anisotropy. This is possibly due to interaction of ultrasonic waves with macro, micro and sub-microscopic particles during wave propagation into the bioactive glasses and also the availability of multi-mode and wide range of frequency selection. Therefore, in the present investigation, it is aimed: (i) to prepare bioactive glasses of the SiO2–Na2O–CaO– P2O5 system for different SiO2 contents, (ii) to study the change in structure of bioactive glasses with change in SiO2 content in light of the measured ultrasonic velocities, attenuation and elastic properties, (iii) to measure the fracture toughness and hence, to correlate the observed results with the ultrasonic NDT studies, (iv) to study the effect of the change in frequency of ultrasonic waves on bioactive glasses and finally, (v) to evaluate the structure and stability of the bioactive glasses as a function of temperature from 150 to 500 K. 2. Experimental procedure 2.1. Preparation of bioactive glasses The bioactive glasses of the system 25.5Na2O–25.5CaO–6P2O5 (named as B43), 24.5Na2O–24.5CaO–6P2O5 (named as B45), 22Na2O–22CaO–6P2O5 (named as B50) and 43SiO2– 45SiO2– 50SiO2– 55SiO2– 19.5Na2O–19.5CaO–6P2O5 (named as B55) have been prepared using the normal melting and annealing technique. The chemicals used in the present investigation were AR grade with purity 99.99% of SiO2, 99.99% of Na2O, 99.99% of CaO and 99.99% of P2O5 used without further purification. The materials used include fine-grained quartz for silica. Lime and soda were introduced in the form of their respective anhydrous carbonates. P2O5 was added in the form of ammonium hydrogen phosphate. The mixture was melted in a platinum 2% Rh crucible for 2 h in an electric furnace. The melting was carried out at 1400751C. The melt was stirred before casting two or three times in order to achieve a homogenous melt. Then, the homogenised melt was cast into a preheated stainless steel mould of 1 1 4 cm3 dimension. The same procedure was employed to prepare the remaining bioactive glasses. The bioactive glasses have been removed from the block and then cooled to room temperature at a rate of 201C h1 after annealing at 4301C in a muffle furnace well below Tg values. The required size of the bioactive glasses for ultrasonic velocities and attenuation measurements was cut from the above-prepared bioactive glasses. The two opposite faces of the bioactive glasses were highly polished. Further, all bioactive glasses were cleaned with acetone to remove the foreign particles. 2.2. Density measurements Density of all bioactive glasses was measured using Archimedes principle employing CCl4 as a buoyant. The density was obtained employing the relation Wa r¼ r ; ð1Þ W a Wb b where Wa is the weight in air, Wb the weight in buoyant and rb the density of buoyant. All the weight measurements have been made using a digital balance (M/s. Sartorius, Model: BP221S, USA). The accuracy in the measurement of weight is 70.1 mg. The experiment was repeated five times to get an accurate value in density. The overall accuracy in the density measurement is 70.5 kg m3 and hence, the percentage error in the measurement of density is 70.05%. 2.3. Ultrasonic velocity measurements The ultrasonic velocities (both longitudinal and shear) and attenuation measurements were carried out using a high-power ultrasonic pulser receiver system (M/s. Fallon Ultrasonics Inc. Ltd., Model–FUI1050, Canada) employing the cross-correlation technique [27]. A specially designed and fabricated separate experimental set-up in the author’s laboratory [28] was used for the measurement of velocities and attenuation in the low (liquid nitrogen to room temperature) and high V. Rajendran et al. / Biomaterials 23 (2002) 4263–4275 (300–500 K) temperature studies. The block diagram of the experimental set-up used for the ultrasonic velocities and attenuation measurements is shown in Fig. 1. The frequency of ultrasonic (longitudinal and shear) waves used for the measurement of velocities and attenuation from 150 to 500 K is 5 MHz. On the other hand, a wide spectrum (5, 10, 15 and 20 MHz) of high-frequency ultrasonic (longitudinal waves only) waves was used to measure the effect of frequency on attenuation at room temperature in all bioactive glasses. A high-power ultrasonic pulser/receiver along with a digital storage oscilloscope (M/s. Hewlett-Packard, Model: 54600B, US) and a computer were used for recording the ultrasonic (r.f.) signals. The different steps involved in the precise ultrasonic transit time for low temperature measurements are: (i) acquisition, digitisation and storage of the r.f. signal from the transducer, (ii) crosscorrelation of two desired echoes for finding the approximate time delay, (iii) adopting cubic spline interpretation method to the peak portion of the crosscorrelated function to arrive at the exact time delay and calculating the ultrasonic velocity from the sample thickness and measured time delay. Thus, using the above technique [27,29], one can measure the transit time with an accuracy of 70.2 ns. The precise ultrasonic velocities (UL and US ) in each of the bioactive glasses were obtained by measuring the precise transit time in micron resolution and the sample thickness in micrometer resolution using the relation [29] U¼ 2d ; t ð2Þ where d is the thickness of the sample and t the precise transit time. For high temperature ultrasonic measurements, a heating rate of 0.8 K min1 was employed with the help Sample inside the furnace / low temperature experimental setup PID temperature controller High power ultrasonic pulser / receiver IEEE interface 4265 of a PID controller by monitoring both heater and bioactive glass temperature separately. The error in the measurement of temperature is 70.1 K. Knowing the bioactive glass thickness (d) in micron resolution, and transit time (Dt) in nanosecond resolution, which is the transit time difference before and after introducing the bioactive glass between the two buffer rods [28], ultrasonic velocity is measured employing the relation U¼ d : Dt ð3Þ The other phenomena to be considered in the determination of accurate velocities in bioactive glass are the variation in the thickness and plane parallelism between the two opposite faces. These are eliminated by surface grinding of bioactive glasses and obtaining the plane parallelism between the two opposite surfaces of bioactive glasses with an accuracy of 75 mm. Thus, the overall accuracy in the velocity measurement is 75 m s1. The percentage error in velocity measurement is 70.1%. 2.4. Attenuation measurements Attenuation of the ultrasonic waves (longitudinal waves only) at 5, 10, 15 and 20 MHz was measured using contact type transducer. A uniform pressure was maintained between the transducer and bioactive glass during the contact measurements by taking the necessary care to avoid the near field effects. A suitable couplant has been selected to get a steady back wall echo train on the oscilloscope screen. The peak amplitude of the first and successive back wall echoes from the bioactive glasses was used to determine the attenuation coefficient. The attenuation coefficient of all bioactive glasses was measured using the relation 20 Im a¼ log ; ð4Þ 2ðm nÞd In where Im and In are, respectively, the maximum amplitude (voltage) of the mth and nth pulse echoes (longitudinal waves only). The percentage error in the attenuation measurement is 72%. DSO 2.5. Vicker’s hardness and toughness measurements Personal computer IEEE interfacing cable via measurement / storage module Results Fig. 1. Block diagram of the experimental set-up used for velocity and attenuation measurements. Vicker’s hardness measurements have been carried out in all bioactive glasses at room temperature. A sharp diamond indentor, a three-sided pyramid with the same area-to-depth ratio was used as a Vicker’s indentor. A small indentation at a precise position on the polished surface of the bioactive glass was made by the system using a load of 1 kg for a period of 20 s. For each bioactive glass, at least 10 indentations were made with similar conditions and the average value of the diagonal V. Rajendran et al. / Biomaterials 23 (2002) 4263–4275 4266 length of the indentation was used for the hardness measurement. The energy absorbed by the material, i.e., toughness during plastic deformation is the work required to fracture the material. The toughness of the bioactive glasses was measured using indentation fracture method [22]. The fracture toughness KIC was determined using relation [30] 0:5 Y F KIC ¼ 0:016 ; ð5Þ H C 1:5 where Y ; H and F are Young’s modulus, hardness and applied load, respectively. C is the radius of the welldeveloped median crack. defined by the relation 1=3 1 2 1 þ : Um ¼ 3 US3 UL3 ð12Þ The relative percentage change in velocity was determined by the relation DU U Umin ; ð13Þ ¼ U Umin where Umin is the minimum sound velocity in the experimental temperature range from 150 to 300 K and U the sound velocity (longitudinal/shear) at temperature T K. 2.6. XRD and thermogravimetry studies 4. Results The X-ray diffraction (XRD) pattern (M/s. JEOL, Model: JDX 8027) of B43, B45, B50 and B55 bioactive glasses was made to study the glassy nature. The glass transition temperature (Tg ) (Polymer laboratories, Model: STA 1500, UK) of all bioactive glasses were measured from differential thermal analysis (DTA) curve with a heating rate of 10 K min1. The X-ray diffraction pattern of B43, B45, B50 and B55 bioactive glasses confirms the amorphous nature before heat treatment. All the bioactive glasses showing the amorphous nature are shown in Fig. 2. The velocities and attenuation data are given in Table 1 along with glass transition temperature (Tg ) and nominal composition of bioactive glasses. For a constant temperature, say at room temperature (at 5 MHz), an increase in ultrasonic velocities (both longitudinal and shear) and a decrease in attenuation with increase of SiO2 (B43–B45) content were observed. A further increase in SiO2 content (B45–B50 & B55), leads to a decrease in velocities and hence, an increase in attenuation. The SiO2 dependent density shows a linear decrease as shown in Fig. 3. An initial increase in bulk 3. Theory The elastic moduli of all bioactive glasses were determined [26] from the experimental values of density (r), longitudinal velocity (UL ) and shear velocity (US ) using the relations Longitudinal modulus L ¼ UL2 r; ð6Þ Shear modulus G ¼ US2 r; ð7Þ Bulk modulus K ¼ L Poisson’s ratio s ¼ 4 G; 3 ðL 2GÞ ; 2ðL GÞ Young’s modulus Y ¼ ½1 þ s 2G: ð8Þ ð9Þ ð10Þ The average velocity of ultrasonic waves in bioactive glasses was used to determine the Debye temperature (yD ) as h 3PN 1=3 yD ¼ Um ; ð11Þ KB 4V p where h is the Planck constant, KB the Boltzmann constant, N the Avogadro number, V the molar volume calculated from the effective molecular weight and density (i.e., M=r), P the number of atoms in the molecular formula and Um the mean sound velocity Fig. 2. XRD pattern with CuKa radiation of B43, B45, B50 and B55 bioactive glasses showing the amorphous nature before heat treatment. B43: 43% SiO2–25.5% Na2O–25.5% CaO–6% P2O5; B45: 45% SiO2– 24.5% Na2O–24.5% CaO–6% P2O5; B50: 50% SiO2–22% Na2O–22% CaO–6% P2O5; B55: 55% SiO2–19.5% Na2O–19.5% CaO–6% P2O5. V. Rajendran et al. / Biomaterials 23 (2002) 4263–4275 (K) and Young’s (Y ) modulus up to 45 wt%, which is followed by a gradual decrease in K & Y after showing a minimum at 45 wt% of SiO2 content is observed as shown in Fig. 4. Debye temperature (yD ), which depends on SiO2 content, shows a similar variation as that of density with change in SiO2 content (Fig. 5). On the other hand, the variation in Poisson’s ratio (Fig. 5) with change in SiO2 content is almost negligible. The hardness (H), fracture toughness (KIC ) and fracture surface energy gf of the bioactive glasses (Fig. 6) show a similar variation as that of velocities (Table 1) with change in SiO2 content including the observed maximum at 45 wt% of SiO2 content. However, a gradual increase in hardness, fracture toughness and fracture surface energy with increase in Young’s modulus from 76.74 to 84.02 GPa (on the other hand, SiO2 content decreases from 55 to 45 wt%) which is followed by a decrease in H; KIC and gf with further increase in Young’s modulus from 84.02 to 83.57 GPa (while SiO2 content decreases from 45–43 wt%) has been noticed as represented in Fig. 7. The frequency dependence of attenuation coefficient shows more or less a linear variation as illustrated in Fig. 8. The temperature dependence of both longitudinal and shear velocities for all bioactive glasses are shown in Fig. 9. The observed results indicate that both longitudinal and shear velocities decrease gradually with increase in temperature in all bioactive glasses (elastic moduli were not shown graphically after 300 K, since the shear velocity was not measured after 300 K; Density (x10-3 kgm-3) 2.9 2.8 2.6 42 49 4267 56 Content of SiO2 (wt.%) Fig. 3. Variation in density with change in SiO2 content on SiO2– Na2O–CaO–P2O5 bioactive glasses at 303 K. The lines are guides to the eyes. Table 1 Experimental velocities (UL and US ), attenuation (a) at 5 MHz of SiO2–Na2O–CaO–P2O5 glasses at 303 K along with glass transition temperature (Tg ) Sample B43 B45 B50 B55 UL US a Tg a SiO2 wt% Na2O wt% CaO wt% P2O5 wt% m s1 m s1 dB cm1 1C 43 45 50 55 25.5 24.5 22.0 19.5 25.5 24.5 22.0 19.5 6 6 6 6 6025 6156 6098 6041 3416 3434 3424 3347 1.49 1.14 1.26 2.08 509 530 484 452 86 64 80 59 E K Y K 74 42 Bulk modulus (GPa) The error in the measurement of Tg is o71%. Young's modulus (GPa) a Nominal composition 49 54 56 Content of SiO2 (wt.%) Fig. 4. Variation in Young’s (Y ) and bulk (K) modulus with change in SiO2 content on SiO2–Na2O–CaO–P2O5 bioactive glasses at 303 K. The lines are guides to the eyes. V. Rajendran et al. / Biomaterials 23 (2002) 4263–4275 0.31 367 0.28 θD Series1 Serie σ 2 42 385 121 449 (a) Fracture toughness (MPa m1/2) Fig. 5. Variation in Debye temperature (yD ) and Poisson’s ratio (s) with change in SiO2 content on SiO2–Na2O–CaO–P2O5 bioactive glasses at 303 K. The lines are guides to the eyes. (b) K IC γf 1.09 (b) 7.95 7.62 1.15 KCIC γf Fracture surface energy (Jm-2) 1.21 7.29 42 75 7.29 85 80 Young's modulus (GPa) Fig. 7. Relation between (a) hardness (H) and (b) fracture toughness (KIC ) and fracture surface energy (gf ) with change in Young’s modulus (Y ) on SiO2–Na2O–CaO–P2O5 bioactive glasses at 303 K. The lines are guides to the eyes. 385 1.09 85 7.95 7.62 1.15 417 49 1.8 Attenuation (dBcm-1) Hardness (MPa) 417 0.24 56 49 Content of SiO2 (wt.%) Fracture toughness (MPam1/2) (a) Fracture surface energy (Jm-2) 352 449 Hardness (MPa) 382 Poisson's ratio Debye temperature (K) 4268 B43 B45 B50 B55 1 56 Content of SiO2 (wt.%) Fig. 6. Relation between (a) hardness (H) and (b) fracture toughness (KIC ) and fracture surface energy (gf ), with change in SiO2 content on SiO2–Na2O–CaO–P2O5 bioactive glasses at 303 K. The lines are guides to the eyes. however, the measured longitudinal velocity shows a continuous decrease up to 500 K, which is not included in Fig. 9). The bulk and Young’s modulus (Fig. 10) follow the same trend of variation as that of velocities (Fig. 9) with increase in temperature. The temperature dependence of longitudinal and shear modulus shows a similar trend of variation as that of bulk and Young’s 0.2 4 13 22 Frequency (MHz) Fig. 8. Frequency dependence of attenuation on SiO2–Na2O–CaO– P2O5 bioactive glasses for different SiO2 contents at 303 K. The lines are guides to the eyes. For key please refer to Fig. 2. modulus, and hence is not represented graphically. The percentage variation in ultrasonic velocities as a function of temperature for different SiO2 contents is represented in Fig. 11. The temperature dependence of attenuation coefficient shows anomalies in the temperature range V. Rajendran et al. / Biomaterials 23 (2002) 4263–4275 6 (a) B43 B45 B50 B55 6225 5950 Relative percentage change (%) Longitudinal velocity (ms-1) 6500 3530 B43 B45 B50 B55 3430 310 225 Relative percentage change (%) Shear velocity (ms-1) (b) 3330 140 Fig. 9. Dependence of (a) longitudinal (UL ) and b) shear (US ) velocity on SiO2–Na2O–CaO–P2O5 glasses with change in temperature for different SiO2 contents. The lines are guides to the eyes. For key please refer to Fig. 2. (b) B43 B45 B50 B55 2 310 225 Temperature (K) 4 56 90 Young's modulus (GPa) 0 3 (a) 64 B43 B45 B50 B55 3 Fig. 11. Relative percentage change of (a) longitudinal velocity (DUL =UL ) and (b) shear velocity (DUS =US ) with change in temperature on SiO2–Na2O–CaO–P2O5 glasses for different SiO2 contents. The lines are guides to the eyes. For key please refer to Fig. 2. Attenuation (dBcm-1) Bulk modulus (GPa) 72 B43 B45 B50 B55 (a) B43 B45 B50 B55 0 140 Temperature (K) (b) B43 B45 B50 B55 3 1 140 340 Temperature (K) 540 Fig. 12. Temperature dependence of attenuation on SiO2–Na2O– CaO–P2O5 glasses for different SiO2 contents. The lines are guides to the eyes. For key please refer to Fig. 2. 82 74 140 4269 225 310 Temperature (K) Fig. 10. Dependence of (a) bulk (K) and (b) Young’s (Y ) modulus on SiO2–Na2O–CaO–P2O5 glasses with change in temperature. The lines are guides to the eyes. For key please refer to Fig. 2. 260–310 K, in all bioactive glasses as noticed in Fig. 12. A gradual decrease in a which is followed by an increase after showing a dip with increase in temperature was noticed in all bioactive glasses. It is interesting to note that as the content of SiO2 increases, the observed dip in attenuation coefficient curve is shifted towards the low temperature and also the dip area broadens as shown in Fig. 12. V. Rajendran et al. / Biomaterials 23 (2002) 4263–4275 4270 5. Discussion 5.1. XRD, density and Tg studies Typical XRD pattern of all bioactive glasses (as prepared) showing the amorphous nature is shown in Fig. 2. The absence of any diffraction peak in XRD pattern in all bioactive glasses confirms the amorphous nature. The glass transition temperature (Tg ) plays a vital role in understanding the physical properties of bioactive glasses. In bioactive glasses, it is particularly sensitive in optimisation of the composition of the bioactive glasses. The glass transition temperature as a single linear function of composition of Na2O (in wt%) has been developed theoretically using regression analysis as Tg ð1CÞ ¼ 232:223 þ 11:4451 ðNa2 O in wt%Þ; R2 ¼ 84:45%; ð14Þ o ¼ 11:431C; where R2 is the regression coefficient and o the residual standard deviation. Eq. (14) explains the importance of Na2O content in bioactive glasses. The decrease in Tg values according to Eq. (14) is about 11.431C for every wt% unit of Na2O that is replaced by any other component in the present bioactive glasses. In all bioactive glasses, it can be seen that there is a fairly good agreement between the estimated Tg values using linear equation and the experimentally determined values. It is inferred from the above studies that the above model is more useful in optimisation of the bioactive glass composition. A similar linear dependence of the Na2O content in SiO2–Na2O–CaO–P2O5–Al2O3– B2O3 bioactive glass [31] system has been discussed with the influence of Na2O. From Eq. (14), it is clear that the value of Tg depends on the Na2O composition as reported in SiO2–Na2O–CaO–P2O5–Al2O3–B2O3 glasses [31] in or near the bioactive region. Density is an effective tool in exploring the change in structure, co-ordination and cross-link density of glasses [32]. The addition of SiO2 in Na2O–CaO–P2O5 bioactive glasses shows a monotonic decrease in density (Fig. 3) from 2.8348 to 2.6792 103 kg m–3 without showing any anomalies. However, it is inferred from the above results that by the addition of SiO2, even though the ratio of Ca/P changes from 4.3 to 3.3 wt%, the percentage change in density and volume initially increases (respectively, 1.37–2.33% and 1.51–2.46% for density and volume) up to 45 wt% of SiO2, which is followed by a decrease in the same after showing a maximum at 45 wt% of SiO2 (2.33–1.89% and 2.46–2.03%, respectively, for density and volume). The decrease in density with addition of SiO2 content leads to an increase in volume due to the loose packing of atoms resulting in structural softening. In vitreous SiO2, all of the oxygens were shared between two SiO4 tetrahedra, forming a fully polymerised network. In alkali silicate glasses, non-bridging oxygens are successively formed by the addition of alkali oxide (Na2O) and hence, the splitting of the network takes place [33]. The formation of non-bridging oxygens causes a weakening of the glass structure. The incorporation of the divalent oxide (CaO) into the glass structure can be described in a very similar way as the introduction of an alkali oxide. It seems that the presence of high percentage of both Na2O and CaO (respectively, 24.5 and 24.5 wt%) in bioactive glass than their ratios (respectively 16% and 6%) in traditional soda-lime–silica glasses used for the preparation of sheet and table-ware glasses, leads to somewhat different chemical and physical behaviour. Alkaline sodium hydroxide solution was found [34] to corrode traditional soda-lime–silica glass far more than the corrosion by acidic solutions, while the reverse is obtained in bioactive glass. It has been shown [35] that the base bioactive glass and the related compositions are easily nucleated in contrast to traditional soda-lime– silica glass with the main phase of Na2O–2CaO–3SiO2. Mastelaro et al. [36] assumed that there must be a relationship between the nucleation of Na2O–2CaO– 3SiO2 bioactive glass and a short-range order in its structure. Short-range order or polymerisation in alkali and alkaline earth silicate glasses is commonly denoted by Qn ; where n is the number of non-bridging oxygens per tetrahedral cation [37]. The average value of n is determined by the glass composition. A recent work by Schneider et al. [38] using MAS & NMR studies shows that the structural units in the range of the two easily nucleated glasses of the compositions Na2O–2CaO– 3SiO2 and 2Na2O–CaO–3SiO2 are mainly made up of Q2 groups (two bridging and two non-bridging oxygen). They also added that further work is needed to check whether there is or not a general trend for glasses near the metasilicate composition. Thus, softening of the network structure in bioactive glasses is expected to be different at high SiO2 (>45 wt%) content through density measurements rather than at low SiO2 (p45 wt%) content. This is because at high SiO2 content, the internal structure of the bioactive glass is assumed to consist mostly of Q3 units. Similarly, the structure of the silicate glasses has been discussed based on the density measurements [39]. 5.2. Ultrasonic studies In the present bioactive glasses, the SiO2 content lies between 43 and 55 wt% (o60 wt%), while the content of Na2O and CaO also ranges between 25.5 and 19.5 wt%, in addition to Ca/P ratios varying between 4.3 and 3.3 wt%. Thus, the composition of the bioactive glasses selected in the present study has abundant alkali and alkaline earth oxides content, and is highly reactive when it is exposed to an aqueous medium [6]. It is V. Rajendran et al. / Biomaterials 23 (2002) 4263–4275 inferred from the earlier study that the high Ca/P ratio aids the ability to form bond to bone [6]. On the other hand, bioactive glasses with low Ca/P ratio will not bond to bone [40]. The following are the changes observed, in view of the presence of SiO2 content in the range from 43 to 55 wt% in silicate glasses: (i) In bioactive glass B43, the total network modifiers Na2O+CaO content is higher than the network formers SiO2 and P2O5 (invert glass). In this bioactive glass, the internal structure seems to consist of discrete or separate units. The silicate groups are believed to be mainly of Q1 units (without bridging oxygens). (ii) Increasing the SiO2 content in bioactive glass B45, the total Na2O+CaO content is higher than the SiO2 content alone. In this bioactive glass, the internal structure is believed to contain Q1 units (with the bridging oxygen) plus Q1 units. (iii) By further increasing the SiO2 content in bioactive glasses B50 and B55, the modifier Na2O and CaO content progressively decreases, and the SiO2 increases on the same ratio. In these two bioactive glasses namely B50 and B55, the internal structure is assumed to contain Q2 units+Q1 and Q1 units. The ratio of the first two units is possibly dominant in the network. The observed initial increase in velocities (both UL and US ) and decrease in attenuation (a) up to 45 wt% of SiO2 result from the rearrangement of structural units in the glass network. Even though, a monotonic decrease in density was observed (Fig. 3), the observed increase in percentage change in density and the observed maximum percentage variation at 45 wt% of SiO2 content support the previous observation. A further addition of SiO2 content causes the formation of different structural units. Therefore, the formation of such new units results in the change in rigidity and hence, velocities as observed in Table 1. Thus, the decrease in velocities contributes a decrease in modulus (Fig. 4) with increase in SiO2 content. For high alkali and alkaline earth oxide content (NaO+CaO), the concentration of non-bridging oxygens and the isolation of SiO4 tetrahedra are expected to be very high. It is inferred from our recent investigation [41] that NBOs and bridging oxygen between SiO4 tetrahedra on the same bioactive glasses are known to exist. The earlier study on silicate and borate [42] glasses reveals that the strength of the glass network increases up to a least wt% of alkali and then, the appearance of NBO in the case of saturation results in the breaking of the network. The bulk modulus [43] is more sensitive in exploring the change in cross-link density and bond stretching force constant. The initial increase in velocities (Table 1) 4271 and moduli (Fig. 4) at low SiO2 (p45 wt%) content is presumed to the conversion of three connected (PO3/2) tetrahedra into four connected (PO4/2) tetrahedra in the network and hence, the formation of NBO is expected to be very less. The existence of either single or polymer chain network of SiO4 and phosphate (PO4) groups is reported in our recent IR studies [41]. Damodran et al. confirmed the increase in velocities and moduli due to the transformation of (POO3/2) units into (PO4/2) units in PbO–MoO3–P2O5 glasses [44] with addition of PbO, which support the observation made in the present study. The alkali ions are incorporated into the interstitial sites in the glass network through NBOs and hence, the structure compactness of the present glasses is weaker than with vitreous silica [33] as it has lower binding energy than Si–O bonds. Thus, the increase in rigidity or change of structural group arrangement (increase in velocities) up to 45 wt% of SiO2 and then a decrease in rigidity (decrease in velocities) of the network up to 55 wt% of SiO2 content lead to an initial increase in moduli, which is followed by a decrease in moduli as shown in Fig. 4. It is evident from the modulus data that the increase in the strength of the bridging bonds up to 45 wt% of SiO2 content beyond which the formation of Q1 and Q2 units accompanied with structural rearrangement and polymerisation are known to exist. Generally, the change in cross-link density is measured from the magnitude of the Poisson’s ratio [26] i.e., a high cross-link density will have a low Poisson’s ratio and vice versa. In the present glass, even though a maximum in Poisson’s ratio (Fig. 5) at 45 wt% of SiO2 has been noticed, the overall change in Poisson’s ratio is negligible i.e., it changes from 0.263 to 0.278 when the SiO2 content increase from 43 to 55 wt%. Thus, the change in Poisson’s ratio suggests that the change in cross-link density of these specific bioactive glasses is less pronounced. The observed results support the observation made on moduli, velocities and attenuation studies. Debye temperature (yD ) is another useful parameter to understand the change in structure and the semiconducting properties of the glasses. The observed yD values (Fig. 5) are in good agreement with those reported on similar oxide glasses. The decrease in yD is very negligible for the initial change in SiO2 (43– 45 wt%), which is followed by a steep decrease in yD with further addition of SiO2 content shows the possible change in network structure. The change in slope of the compositional dependence of yD after 45 wt% of the SiO2 content indicates that the rearrangements of the glass network will contribute more to yD : The increase in softening of the glasses with increase in NBO has been revealed by Rajendran et al. and Mallawany et al., respectively, on V2O5–Bi2O3–TeO2 [45] and V2O5–TeO2–Ag2O [46] glasses. V. Rajendran et al. / Biomaterials 23 (2002) 4263–4275 4272 5.3. Hardness, fracture toughness and fracture surface energy processes such as plastic deformation, crack, branching and vibrational energies. Young’s modulus (Y ), hardness (H) and fracture toughness (KIC ) play a key role in elucidating the physico-chemical and mechanical properties of bioactive glasses. In general, as discussed earlier, the change in chemical bond and bond strength in the glass structure are normally incorporated in Young’s modulus, while the hardness explores the information about the elastic strength and surface behaviour of glasses. On the other hand, Y is one of the important parameters in determining the fracture behaviour involved in glasses. Similar to Y (Fig. 4), hardness (Fig. 6) of bioactive glasses increases up to 45 wt% of SiO2 and then, the same was found to decrease with further increase in SiO2 content. The initial increase in H and Y is ascribed to the increase in bond strength in unit volume as studied in densification of magnesium and meta–phosphate glasses [47]. Similarly, the decrease in H and Y is correlated with the structural unit arrangement and the number of bridging and non-bridging oxygens as studied in Na2O–K2O–SiO2 bioactive glasses [48] by Rizkalla et al. Fracture surface energy gf was obtained using the relation [49] 5.4. Effect of frequency 2 gf ¼ KIC ½1 2s ; 2Y ð15Þ where KIC and Y are, respectively, the fracture toughness and Young’s modulus. According to Eq. (15), the fracture surface energy (gf ) mostly depends on the average bond strength in the fracture path and hence, the introduction of Si–O bond into the glass network lowers the fracture toughness. The value of both KIC and gf initially increase with increase in Y and then show a monotonic decrease with further increase in Y : The relationship obtained between KIC and Y ; and gf and Y (Fig. 7b) in the present bioactive glasses shows a similar trend as observed in CaO–P2O5 and MgO–P2O5 glasses [47], while it shows an opposite trend of behaviour when compared with the general relationship between KIC and Y ; and gf and Y in meta-phosphate glasses [50]. It is interesting to note that the abundance of nonbridging than bridging oxygens plays a dominant role in controlling Young’s modulus, hardness, fracture toughness and fracture surface energy. A decrease in Y ; H and KIC due to the existence of NBOs and weakening of Si–O bonds has been studied by Rizkalla et al. [48] on Na2O–K2O–SiO2 glasses. Similarly, in lead silicate glasses [51], the introduction of weaker Pb–O bonds at high PbO content lowers the fracture toughness and fracture surface energy in the glass structure. Attempts have been made [22,30,51] to explore the crack propagation at the crack tip employing irreversible In general, the attenuation in a solid material can be related as a ¼ a1 aa þ a2 ab þ ac þ ad ; ð16Þ where aa is the true absorption, ab the scatter absorption, ac the coupling absorption and ad the diffraction absorption. The other losses which contribute to attenuation are non-parallelism of the bioactive glass surfaces and surface conditions. However, in the present study, the total contribution to the attenuation is only true, coupling and diffraction absorption, since the parallelism of the bioactive glass surface and surface condition are taken care. Therefore, a ¼ a1 aa þ ac þ ad ; ð17Þ machine oil and non-aqueous stopcock grease with very less thickness have been used as couplant, respectively, for high temperature and low temperature studies between the bioactive glass and transducer. By adding the couplant corrections (both separately for machine oil and non-aqueous stopcock grease) to the measured attenuation and neglecting the absorption and diffraction, the ac and ad terms are neglected (Fig. 12). It is also inferred from the variation of a with change in frequency (Fig. 8), the contributions due to scattering absorption is less and hence, prevails only true or thermo-elastic absorption as studied in BaTiO3 doped lead bismuth semiconducting oxide glasses [29]. The attenuation can be written as a ¼ af ; ð18Þ where a is a constant depending on bioactive glass and its composition. The absence of any rapid changes in a with increase in frequency indicates (Fig. 8) that the dispersion effect is less pronounced in the present bioactive glasses. A similar trend of attenuation with increase in frequency has been studied on alkali borate glasses [52]. 5.5. Effect of temperature Elastic moduli are more sensitive to structural changes as a function of temperature. A gradual decrease in velocities (Fig. 9) and moduli (Fig. 10) with increase in temperature without showing any anomalies were noticed. The absence of anomalies and gradual decrease in velocities and moduli indicates the nonexistence of structural phase changes as observed in many other glasses such as V2O5–Bi2O3–TeO2 glasses [45]. As temperature increases, the softening of the network structure takes place due to the easier ionic V. Rajendran et al. / Biomaterials 23 (2002) 4263–4275 motion as a result of structural relaxation. The continuous decrease in relative percentage change in velocities (Fig. 11) from high value (4.83% (B43), 3.72% (B45), 3.76% (B50), 2.92% (B55) and 1.46% (B43), 1.11% (B45), 1.14% (B50), 2.15% (B55), respectively, for longitudinal and shear velocities) to zero supports the softening of the network as the temperature increases. The recent studies on the relative percentage change in velocities of vanadate based [45,53] glasses support the softening of the glass network as observed in the present study. The observed anomalies in attenuation coefficient as a function of temperature from 150 to 500 K are similar to that observed for V2O5–PbO glasses [53] and are different from the behaviour of glasses such as V2O5– GeO2 [54] and CuO–P2O5 glasses [55], wherein a peak in attenuation was noticed. The observed anomalies in attenuation in V2O5–GeO2 [54] and CuO–P2O5 [55] glasses have been explained based on the existence of the different valence states of transition metal ions (TMI) namely vanadium and copper in the respective glasses, with change in composition. The existence of such valence states of TMI has been studied through the electrical properties in the above glasses. The earlier study [56] on the stability of the glass network suggest that the stable glasses will have close packed structures while unstable glasses will have loose packed ones. Thus, the structure of the present bioactive glasses becomes loose packed when the SiO2 content exceeds 45 wt%. The anomalies and the magnitude of the dip observed in the attenuation coefficient broaden when SiO2 content increases from 43 to 55 wt%, which also support the above observations. Out of the different compositions studied in the present work, the 45SiO2–24.5Na2O– 24.5CaO–6P2O5 (45S5s) glass is the first bioactive glass prepared by Hench [6]. In most of the bioactive glasses studied, the content of SiO2 was between 45 and 55 wt%. At low SiO2 content, it dissolves easily into the surrounding body fluids [57]. The observed distinct behaviour in the measured velocities (Fig. 9b), Young’s modulus (Fig. 10b) and attenuation (Figs. 8 and 12) of B55 bioactive glass is presumed due to the incorporation of high content of SiO2 (55 wt%) which is comparatively 12% higher than the 45S5 glass. The addition of more SiO2 content (>50 wt%), which leads to the change of the state of polymerisation or the presence of different Q units as discussed at the beginning of our discussion is responsible for the observed distinct behaviour in UL ; US ; K; Y and a: 6. Conclusions The bioactive glasses in the (942x)SiO2–xNa2O– xCaO–6P2O5 system have been prepared for different SiO2 contents by keeping the Ca/P ratio between 4.3 and 4273 3.3 wt%. The following are the conclusions made in the present investigation: (a) The measured acoustical parameters such as velocities, attenuation, moduli, Debye temperature and Poisson’s ratio suggest that the strength (compactness) of the glass network continues up to 45 wt% of SiO2 content. (b) With further addition of SiO2 (>45 wt%), a decrease in the above parameters after showing a maximum at 45 wt% reveals the breaking of Si–O– Si bonds and the formation of non-bridging oxygen (NBO) results in the softening of the glass network. (c) A linear relation between KIC and Y ; and gf and Y of the bioactive glasses have been revealed. The Y ; H; KIC ; and gf have been observed as a function of chemical and physical properties of bioactive glasses. (d) The developed linear Eq. (14) explores the importance and the influence of Na2O content on Tg values in bioactive glasses. (e) The frequency-dependent attenuation indicates the prevailing nature of true absorption and less dispersion effect. (f) A continuous decrease in elastic moduli and velocities as a function of temperature in all bioactive glasses reveals the existence of structural softening in the glass network. (g) The relative percentage change in velocities as a function of temperature, and attenuation coefficient reveals that the bioactive glasses with low SiO2 (p45 wt%) content are different in structural arrangement than those with high SiO2 (>45 wt%) content. (h) The observed distinct behaviour in velocities, Young’s modulus, and attenuation coefficient in B55 bioactive glass are presumed to the change in the state of polymerisation or the presence of different Q units. The present investigation confirms that the ultrasonic non-destructive characterisation of bioactive glasses are more informative in exploring the structural changes, stability and mechanical properties, which are essential for optimisation of the bioactive glasses for different biomedical applications. Acknowledgements The authors (VR and AN) are grateful to Prof. G. Shanmugam, Principal and Thiru Yennarkay R. Ravindran, Correspondent, Mepco Schlenk Engineering College for their constant encouragement to this collaborative work. The authors (VR and AN) are thankful to IGCAR, Kalpakkam for providing the 4274 V. Rajendran et al. / Biomaterials 23 (2002) 4263–4275 financial support (IGC/SHINEG/SED/TPS/200-813). The authors are thankful to Mr. N. Palanivelu, SRF for his assistance in the experimental studies. The authors are thankful to the referee for his explicit comments on the above paper. References [1] Hench LL, Splinter RJ, Allen WC, Greenlee TK. Bonding mechanism at the interface of ceramic prosthetic materials. J Biomed Mater Res 1972;2(1):117–41. [2] Andersson OH, Karlsson KH, Kangasniemi K, Yli–Urpo A. Models for physical properties and bioactivity of phosphate opal glasses. Glasstech Ber 1988;16:300–5. [3] Nakamura T, Yamamuro T, Higashi S, Kokubo T, Ito S. A new glass ceramic for bone replacement: evaluation of its bonding to bone tissue. J Biomed Mater Res 1985;19:685; Nakamura T, Yamamuro T, Higashi S, Kokubo T, Ito S. Chemical reaction of bioactive glass and glass–ceramics with a simulated body fluid. J Mater Sci: Mater Med 1992;3:79. [4] Hench LL, Ehridge EC. Bioceramics: an interfacial apporoach. New York: Acadamic Press, 1982. [5] Westerland T, Hatakka L, Karlsson KH. A model for optimizing glass batch compositions. J Am Ceram Soc 1983;66:574–9. [6] Hench LL. Bioceramics: from concept to clinic. J Am Ceram Soc 1991;74(7):1487–510. [7] Kokubo T, Ito S Sakka S, Yamamuro T. Formation of a highstrength bioactive glass–ceramic in the system MgO–CaO–SiO2– P2O5. J Mater Sci 1986;21:536–40. [8] Miyazaki T, Kim HM, Kokubo T, Miyaji F, Kato H, Nakamura T. Effect of thermal treatment on apatite-forming ability of NaOH-treated tantalum metal. J Mater Sci: Mater Med 2001;12:683–7. [9] James PF. Glass ceramics: new compositions and uses. J NonCryst Solids 1995;181:1–5. [10] Peitl O, Zanotto ED, Hench LL. Highly bioactive P2O5–Na2O– CaO–SiO2 glass–ceramics. J Non-Cryst Solids 2001;292:115–26. [11] Zhang R, Ma PX. Poly(a-hydroxyl acids)/hydroxyapatite porous composites for bone-tissue engineering. I. Preparation and morphology. J Biomed Mater Res 1999;44:446–55. [12] Gross UM, Strunz V. J Biomed Mater Res 1980;14:607. [13] Santos C, Luklinska ZB, Clarke RL, Davy KWM. Hydroxyapatite as a filer for dental composite materials: mechanical properties and in vitro bioactivity of composites. J Mater Sci: Mater Med 2001;12(7):565–73. [14] Low D, Swain MV. Mechanical properties of dental investment materials. J Mater Sci: Mater Med 2000;11(7):399–405. . . [15] Szabo I, Nagy B, Volksch G, Holand W. Structure, chemical durability and microhardness of glass–ceramics containing apatite and leucite crystals. J Non-Cryst Solids 2000;272:191–9. [16] Yl.anen HO, Karlsson KH, It.al.a A, Aro HT. Effect of immersion in SBF on porous bioactive bodies made by sintering bioactive glass microspheres. J Non-Cryst Solids 2000;275:107–15. . [17] Holand W. Biocompatible and bioactive glass–ceramics—state of the art and new directions. J Non-Cryst Solids 1997;219:192–7. [18] Wang M, Chen LJ, Ni J, Weng J, Yue CY. Manufacture and evaluation of bioactive and biodegradable materials and scaffolds for tissue engineering. J Mater Sci: Mater Med 2001;12(10–12): 855–60. [19] Burg KJL, Porter S, Kellam JF. Biomaterial developments for bone tissue engineering. Biomaterials 2000;21:2347–59. [20] Tancred DC, McCormack BAO, Carr AJ. A synthetic bone implant macroscopically identical to cancellous bone. Biomaterials 1998;19:2303–11. [21] Lopes MA, Silva RF, Monteiro FJ, Santos JD. Microstructural dependence of Young’s and shear moduli of P2O5 glass reinforced hydroxyapatite for biomedical applications. Biomaterials 2000; 21:749–54. [22] Kazuyuki Hirao, Mamoru Yoshimoto, Naohiro soga, Katsuhisa Tanaka. Densification of magnesium and calcium meta-phosphate glasses. J Non-Cryst Solids 1991;130:78–84. [23] Sahar MR, Abidin AZ. Some properties of CaO–MgO–P2O5. J Mater Sci Lett 1994;13:227. [24] Rajendran V, Bera AK, Modak DK, Chaudhuri BK. Ultrasonic study of bioactive Na–Ca–B–Al–Si–P–O glasses. Acoust Lett 1997;20:168–72. [25] Vary A. Ultrasonic measurement of material properties. Research techniques in nondestructive testing, vol. 4. New York: Academic Press, 1980. p. 159–204. [26] Rajendran V, Palanivelu N, Modak DK, Chaudhuri BK. Ultrasonic investigation on ferroelectric BaTiO3 doped 80V2O5– 20PbO oxide glasses. Phys Status Solidi A 2000;180:467. [27] Rao BPC, Jeyakumar T, Bhattacharya DK, Baldev Raj. Crosscorrelation technique for precise ultrasonic velocity measurements. J Acoust Soc Ind 1992;XX(1–4):90. [28] Rajendran V, Palanivelu N, Chaudhuri BK. A device for the measurement of ultrasonic velocity and attenuation in solid materials under different thermal conditions. Patent filed ref. no.: 699/DEL/2001; Rajendran V, Palanivelu N, Chaudhuri BK. A device for the measurement of ultrasonic velocity and attenuation in solid sample at low temperatures. Patent filed ref. no.: 14/DEL/2002. [29] Rajendran V, Palanivelu N, Palanichamy P, Jeyakumar T, Baldev Raj, Chaudhuri BK. Ultrasonic non-destructive characterisation of ferroelectric BaTiO3 doped lead–bismuth oxide semiconducting glasses. J Non-Cryst Solids 2001;296:39–49. [30] Anstis GR, Chantikul P, Lawn BR, Marshall DB. A critical evaluation of indentation techniques for measuring fracture toughness; I. Direct crack measurement. J Am Ceram Soc 1981;64:533–8. [31] Andersson OH. Glass transition temperature of glasses in the SiO2–Na2O–CaO–P2O5–Al2O3–B2O3 system. J Mater Sci: Mater Med 1992;3:326–8. [32] Barbieri L, Bonamartini Corradi A, Leonelli C, Siligardi C, Manfredini T, Carlo Pellacani G. Effect of TiO2 addition on the properties of complex alumino silicate glasses and glass–ceramics. Mater Res Bull 1997;32:637–48. [33] Scholze H. Glass nature structure and properties. New York: Springer, 1990. [34] ElBatal FHA. Preparation and studies on selected bioglasses. Ph. D. thesis, AinShams University, Cairo, 1999. [35] ElBatal HA, Azooz MA, ElBatal FH. Crystallization behaviour of some selected bioglasses. In: Rammlmair, et al., editors, Proceedings of the ICAM Applied Mineralogy. Rotterdam: Balkema, 2000. p. 123–5. [36] Mastelaro VR, Zanotto ED, Lequeux N, Cortes R. Relationship between short-range order and ease of nucleation in Na2Ca2Si3O9, CaSiO3 and PbSiO3 glasses. J Non-Cryst Solids 2000;262:191–9. [37] Merrbacher C I, White W B. The structure of alkaline earth alumino-silicate glasses as determined by vibrational spectroscopy. J Non-Cryst Solids 1991;130:18–34. [38] Schneider J, Masterlaro VR, Panepucci H, Zanotto ED. 29Si MAS–NMR studies of Qn structural units in metasilicate glasses and their nucleating ability. J Non-Cryst Solids 2000;273:8–18. [39] Ezz EL–Din FM, EL–Alaily NA, EL–Batal HA. Density and refractive index of some g-irradiated alkali silicate glasses. J Rad Nucl Chem 1992;163:267–75. [40] Hench LL, Paschall HA. Direct chemical bonding between bioactive glass–ceramic materials and bone. J Biomed Mater Res Symp 1973;4:25–42. V. Rajendran et al. / Biomaterials 23 (2002) 4263–4275 [41] El Badry KH, Moustaffa FA, Azooz MA, El Batal FH. Infrared absorption spectroscopy of some bioactive glasses before and after immersion in various solutions. Ind J Pure Appl Phys 2000;38:741–61. [42] Rajendran V, Khalifa FA, El–Batal HA. Investigation of acoustical parameters in binary x Li2O–(100x)SiO2 glasses. Ind J Phys 1995;69A(2):237–42. [43] Bridge B, Higazy AA. Acoustic and optical debye temperatures of the vitreous system cabaltous oxide cobaltic oxide phosphorous pentoxide. Phys Chem Glasses 1986;27:1. [44] Damodran KV, Selvaraj U, Rao KJ. Elastic properties of lead phosphate glasses. Mater Res Bull 1988;23:1151–8. [45] Rajendran V, Palanivelu N, Chaudhuri BK, Goswami K. Characterisation of semiconducting V2O5–Bi2O3–TeO2 glasses through ultrasonic measurements. J Non-Cryst Solids, accepted for publication. [46] El-Mallawany R, Abousehly A, Yousef E. Elastic moduli of tricomponent tellurite glasses TeO2–V2O5–Ag2O. J Mater Sci 2000;19:409. [47] Ashizuka M, Ishida E, Uto S, Bradt RC. Fracture toughnesses and surface energies of binary CaO- and MgO- phosphate glasses. J Non-Cryst Solids 1988;104:316–22. [48] Rizkalla AS, Jones DW, Miller RP. Parameters controlling indentation fracture toughness values for Na2O–K2O–SiO2 glasses. Brit Ceram Trans 1996;95:250–3. 4275 [49] Tetelman AS, Mc Evily AJ Jr. Fracture of structural materials. New York: Wiley, 1967. p. 50. [50] Ashizuka M, Bradt RC. Fracture toughness of metaphosphate glasses. J Am Ceram Soc 1982;65:C–70. [51] Maoru Yoshimoto, Naohiro Soga. The effect of composition on crack propagation in lead silicate glasses. J Non-Cryst Solids 1987;95 & 96:1039–46. [52] Singh AP, Singh KJ, Bhatti SS. Ultrasonic studies of xBaO (0.9x)B2O30.10Fe2O3 glasses. J Pure Appl Ultrason 1990;12: 70–3. [53] Rajendran V, Palanivelu N, Chaudhuri BK, Goswami K. Temperature and composition dependence of elastic properties of semiconducting (100–x)V2O5–xPbO oxide glasses. Phys Status Solidi A 2002;191(2):445–57. [54] Maiti A, Mukherjee S, Ghosh US, Basu C. Ultrasonic investi gation of CuO–P2O5 glass. J Non-Cryst Solids 1996;194: 13–22. [55] Mukherjee S, Maiti A, Ghosh US, Basu C. Ultrasonic investigation of V2O5–GeO2 glass. Phil Mag B 1993;67:823–31. [56] Hirashima H, Kurokawa H, Mizobuchi K, Yoshida T. GlassTech Ber 1988;61:151. [57] It.al.a A, Nordstrom EG, Yl.anen HO, Aro HT, Hupa M. Creation of microrough surface on sintered bioactive glass microspheres. J Biomed Mater Res 2001;56(2):282–8.