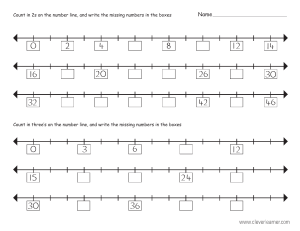

1- Introduction The problem of determining the optimal loading pattern for putting identical boxes into a rectangular loading pallet, known as the pallet loading problem (PLP), emerges often in logistics. Two major parameters are L x W and l x w are the main components and determines the number of boxes pallet will be loaded. In this research, it is investigated, how a L x W pallet would loaded optimally with l x w x h sized boxes based on following three main assumptions: (1) As illustrated in Figure 1, it is presumed the boxes can be placed on their bottom, side, or end surface. (2) The unit load is separated layer by layer, meaning each box height must be same at the matching level. (3) The loading pattern is vastly important throughout transportation part. The unit load will be more stable if the loading pattern is appropriately structured, which will improve shipping stability, assist to limit transportation damage, and reduce the quantity of packing material required. 2- The Big Question Has the best approach found in the past on Pallet Loading Problem (PLP)? 3- Summarize background in five sentences or less (a) Looking for patterns that form rectangular blocks of boxes is a basic yet effective strategy. (b) The boxes fit properly around the pallets' edges, and the pattern is then stretched into the layer's middle. (c) While utilizing heuristic approaches, it is critical to understand how close one is going to be to the ideal solution when applying PLP heuristics. (d) By using compacting, centering blocks, and distributing gaps procedures, Bischoff generated more stable layouts which is the second main objective. 4- Identify the SPECIFIC QUESTION(s) I. How do we utilize maximum area in L X W sized pallets using l x w x h sized boxes II. How do we optimally pack as many boxes as possible from a given set of rectangular-shaped parts onto a three-dimensional rectangular pallet? III. Is it possible to generate more stable layers by using Bischoff-Downsland algorithm. 5- Identify the Approach The approach, which incorporates practical factors, consists of five steps that maximize the degree of stability and the greatest cube utilization of a unit load. 6- Read the methods section. Draw a diagram for each experiment, showing exactly what the authors did This section contains three different phases. Phase 1: Determining the maximum number of boxes for each three possible types of layers. Three type of layers is shown in Figure 1 as B-type, S-type, and E-type layers. As the author mentioned as in three main assumptions, in this pallet loading problem, layer heights must be equal. The boxes comprise of metrics l x w x h, from H/l, H/w, and H/h three different layers are obtained. Phase 2: Constructing three related patterns for each type of layer Phase 3: Finding the maximum number of boxes that can be included in the loading cube of the pallet. Using a mathematical model shown in below, maximum number of boxes is computed. Figure 1: Flowchart of Phase 1 Phase 4: Computing the stability coefficients of 144 possible interfaces. In phase 3, 12 different layer type probability provided. So, there are 144 stability coefficients for 144 possible interfaces. Phase 5: Determining the stacking sequence of patterns that will construct a unit load with maximum total stability. 7- Read the results section There are many results, and the comparisons are intricate. In the proposed method, the stability of the unit load is the secondary objective, after the major objective, cube utilization. According to results based on different techniques, Phase 1 and Phase 2 had accomplished. With 3D method, %92.049 cube utilization, which was our first objective, provided. Phase 4 and Phase 5 results, mostly about second objective, stability, had not discussed on this paper. 8- Do the results answer the SPECIFIC QUESTION(S)? What do you think they mean? The results answer only the part of first objective which is the “maximum number of boxes” and “space utilization” but the second objective “stability” is not discussed in results entirely. 9- Read the conclusion/discussion The article has created a solution method for the three-dimensional pallet loading problem based on past article solutions and with additions as solving mathematical models with LINDO and including integer programming in the problem. 10- Now go back to reading abstract • • • Problem is to find optimal layout for packaging identical boxes onto a rectangular loading pallet. One of the objectives is while increasing cube utilization, do not compromise from the stability of the unit load. The method consists of five phases that maximize the degree of stability and the maximum cube utilization of a unit load. (Liu & Hsiao, 1997) 11- What do other researchers say about this paper? 1.1 Bibliography Liu, F.-H. & Hsiao, C.-J., 1997. A Three-Dimensional Pallet Loading Method for Single-Size Boxes.