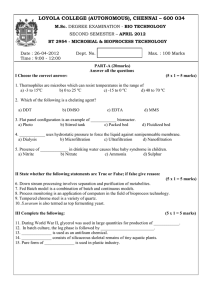

See discussions, stats, and author profiles for this publication at: https://www.researchgate.net/publication/320226383 Design of STR Bioreactor for Production of Saccharomyces cerevisiae (Upstream processing) Poster · April 2014 DOI: 10.13140/RG.2.2.14560.58881 CITATIONS READS 0 2,528 3 authors, including: Nasser Madkhali Saleh Matar King Abdulaziz City for Science and Technology Jazan University 1 PUBLICATION 0 CITATIONS 20 PUBLICATIONS 156 CITATIONS SEE PROFILE Some of the authors of this publication are also working on these related projects: Design of STR Bioreactor for Production of Saccharomyces cerevisiae (Upstream processing) View project Design of STR Bioreactor for Production of Saccharomyces cerevisiae (Upstream processing) View project All content following this page was uploaded by Nasser Madkhali on 05 October 2017. The user has requested enhancement of the downloaded file. SEE PROFILE Design of STR Bioreactor for Production of Saccharomyces cerevisiae (Upstream processing) Nasser Madkhaly, Othman Mohammed-Abdu, Advisor: Dr. Saleh Matar Department of Chemical Engineering, University of Jazan, Kingdom of Saudi Arabia (KSA) . Abstract The purpose of this work was to design a bioreactor to simulate the standard design factors of the bench-top scale. An air sparger was designed for pumping 2 vvm sterile air and a mechanical stirrer was used for agitation while a two blade type rushton impeller is designed for agitation. The designed model was operated by running the Saccharomyces cerevisiae (baker`s yeast) in batch mode cultivation. The optimization of growth was identified in a shake flasks to establish the optimized condition of temperature, pH and agitation. The results showed that the optimum temperature, pH and agitation were 34°C, 5.3 and 500 rpm respectively. The cultivation process in the designed prototype was conducted under the obtained optimized parameters. The growth curve reached to the maximum biomass production of 35.9 g/l i.e. 100% more than those produced in shake flask (17.99g/l). Operational procedure The experimental procedures were conducted in two main steps: determination the optimum condition in Shake flasks for temperature, pH and agitation and confirmation the results in the designed bioreactor. The derivatives for biomass generation with respect to time, is related to specific growth rate which is defined as follows: The following equation was used to predict the cell growth in batch experiments. Introduction Bioreactors in some form or another have been around for thousands of years, although up until the 1900s their use was limited to the production of potable alcohol. It was really from the 1940s onwards that fermentation as it is known today began to appear with the need to produce antibiotics during World War Two. Deep understanding of bioprocessing may require actual knowledge of biology and microbiology in the applications of Biochemical processes. It is very interesting to demonstrate bench-scale experiments and make use of large-scale advanced technology. However, application of the bioprocess in large-scale control of microorganisms in 100,000 liters of media may not be quite so simple to manage. The main objective of this project was to design a bench-top bioreactor, taking into account the standard design criteria. Designed prototype model was directed to evaluate the optimum condition for the ability of growing microorganism in batch culture as an up-stream processing. This work focused mainly on studying the optimum operational condition such as temperature, agitation and pH, as well as the kinetics and growth behavior of Saccharomyces cerevisiae (baker`s yeast) during cultivation. Problem Definition and Design Key goals of the project were determined from the problem of maximizing the biomass production and expanded into a complete list of objectives and constraints. The list was split into objectives for the bioreactor design and objectives for the bio-production of Saccharomyces cerevisiae in batch process optimization study an comparison charts were used to weigh the importance of each objective and constraint. Instillation of designed bioreactor with associated utilities. Cultivation in Shake Flask The experimental procedures were conducted in two main steps: determination the optimum condition in Shake flasks for temperature, pH and agitation and confirmation the results in the designed bioreactor. Optimization of Agitation Optimization of pH Optimization of temperature Cultivation in Bioreactor Bioreactor constituents and connected parts on head plate Growth of S. cerevisiae was determined with respect to the determined optimized condition of temperature, pH and agitation. The controlling of fermentation process was conducted in the model designed bioreactor as the preparation of bioreactor operation procedures started with inoculation the bioreactor with the 200 ml broth shake flask incubated in 34 ºC and pH = 5.3. the inoculated amount was maintained at 15% of pre-culture. The objectives were broken further into sub-objectives and both were compiled to accomplish the controlled fermentation process. After an in-depth discussion on what features, attributes and functions the bioreactor should satisfy, objectives and constraints for the bioreactor were determined. In order to fulfill the goal function, the bioreactor was designed to produce a biomass or metabolic bio-product in a glass reactor and the yeast cell population reproduces according to the kinetic model behavior. Variation of biomass with time lnX vs time in the xponential growth phase Future Work This work was conducted in batch mode cultivation and this is the simplest and the easiest bioprocess in bioreactor for any microorganism. It may be recommended to check the cultivation in the other modes of fermentation like as continuous and fed batch fermentation. In addition to this the larger scale can be designed. This will help in driving the cultivation of microorganism to operate in scale-up processes. On the other side this prototype can use to investigate the other microorganisms such as bacteria and algae and use different processing behavior without or in the presence aeration. References Bioreactor working volume, Vworking = volume of broth with 20% - 30% over-design as a safety factor. In the designed bioreactor, the desired working volume of 1300 ml was selected for cultivation experiments. Accordingly, the head space for the selected reactor vessel become 28.5 % in relation to the total volume which calculated as follow: Vworking = 1300ml / 0.71.5 ≈ 1818 ml. View publication stats 1. Anke, S., Schneppe, B., McCarthy, J. E. G., Deckwer, W.-D. and Rinas, U. (1995), Comparison of temperature and isopropyl-β-D-thiogalactopyranoside-induced synthesis of basic fibroblast growth factor in high cell density cultures of recombinant Escherichia coli. Enzyme and microbial technology, 17, 947-953. 2. Barnett, J.A., Payne, R.W., Yarrow, D. (Eds). 1990. Yeasts: Characteristics and Identification (2nd Edition), Cambridge University Press, New York, 1002. 3. Elibol, M. 2004. Optimization of medium composition for actinorhodin production by Streptomyces coelicolor A3 (2) with response surface methodology. Process Biochem. 39, 1057-1062. 4. Saleh M. Matar (2001): Bioprocessing of genetically modified Escherichia coli in stirred tank bioreactor for valuable protein production. Ph.D. Thesis, Minia University.