Implementation of Best Practices for

Improvements in Reformer

Performance and Reliability

Ya,a imernationai operates manu/acluring/acilities globally which include twelve operating

ammonia plants. Ya,a has developed a global best practice document which outlines the important

parameters to be used in managing the reform ers within these plants for efficient, safe, and reliable

operation. Quest Integrity has assisted Yara in the implementation of elements o/Steam Reformer

Best Practice to have Q l..'onsistent approach to the strategic management o/their sleam reformers

worldwide.

This paper discusses the best practice elements of the Yara Reformer Catalyst Tube Lifecycle

Management and the management process used to implement these objectives. Included in the paper

are examples offacility training performed for plant operators and reliability groups, implementation

of reformer tube temperature management, and performance and reliability of monitoring performed

for steam reformers. The paper will conclude with the short and long-term benefits to Yara as realized

through tlris implementation.

Giuseppe Franceschini

Process Owner Inspection, Yara International

Giuseppe.Franceschini@yara.com

James R. Widrig

Manager, Advanced Engineering, Quest Integrity, LLC

J .Widrig@Questlntegrity.com

fonn and could be improved. The number and

frequency of tube failures occurring at some of

the sites was indicative of the improvement opportunity. More efficient, safe and reliable operation of these assets was viewed as criti cal to the

company's success and reason for the focus on a

spec ific best practice. Quest Integrity was recognized by Yara for their reliability expertise in the

ammonia and broader syngas industry, specific

servi ce and technology for reformers, and as a

Introduction

T

he implementation of a best practice fo r

the life cycle management of reformer

tubes was an enterpri se-wide goal for

Yara International. Yara management

recognized that they operated a large number of

steam-methane reformers (refonners) globally

and the management of these assets was not uni-

2015

115

AMMONIA TECHNICAL MANUAL

provider of world class products and services.

Together, Yara and Quest Integrity developed a

project scope and a plan to provide training for

operators and reliability groups, implementation

of tube temperature management, and reforme r

performance and reliability surveys of this global

set of assets. These best practice program elements of Reformer Care were implemented for

all of the Yara International reformer assets during the time span ofmid-20l3 to early 20 15.

Basic Elements of Yara Catalyst

Tubes Management Best Practice

Reformer catalyst tube reliability involves the

whole Production Facility Organization (Inspection, Production, and Maintenance) in order to

systematically address all the phases of the tube

life-cycle. Yara' s approach to the life cycle management of reformer tubes, as documented in the

best practice document Yara BP63 (BP63), involves training of personnel at both an operating

and management level to ensure that they have

an understanding of materials, common damage

mechanisms, and inspection and monitoring

techniques. This knowledge is used to evaluate

manufacturing or fabrication deficiencies, deterioration or damage in service and the life cycle effects of operation deviations. The goal is to make

optimum use of the refonuer tubes (plus the pigtai ls and headers) over the expected li fe and

avoid untime ly and costly premature failures.

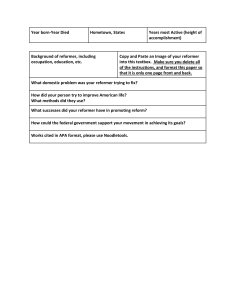

Overview of Yara Reformers

Yara has 12 operating ammonia plants located

worldwide. These ammonia plants and reformers

vary in process technology, reformer design, capacity, and age as well as production efficiency

and reliabi lity. The reformers are a combination

of Top-Fired, Side-Fired and Terrace Wall designs (Table I). The oldest reformer in the system is the Yara Le Havre, France, reformer

commissioned in 1967 and the newest reformer

is the Yara Tertre, Belgium, reformer commissioned/rebuilt in 20 I0 following a firebox explosion. There are a total of 3, 180 tubes in these 12

reformers. The oldest tubes were installed in

1977 in Porsgrunn, Norway, and Ferrara, Italy.

The average age of the installed reformer tubes is

around 20 years.

R. Io ......

''''

Bell. Pial ....

036001

F. rrara .

B201

Side·

FlIOI

Pilbara,

101-MP

FIIlId

P ..... gNnn ,

F201

Slul. kll.

H401

Slul. kll.

"~,

T. r1 ..,

BIOI

Tr1nldad,

H2030

Tr1nldad,

"'"

Trinidad,

H901D

,, -'',,,-Side·

L"Hn ·r••

Slul. kll.

H301

,,'-

Side·

Side·

"....

,,'"

Side·

....

Terrace

W.II

Terrace

W. II

Yea.

buill

'"~

~~n

'"~

Design

TulH.

4.16

"'

".

{MP'I

m,

."

1975

'"

3.73

HK40

'"

3.80

~,

4.0 1

'"

3.30

"'

"'

"'

"'

"'

"'

,~.

,,~

m'

1983

1987

".

".

".

."

,.g

3.62

3.62

,.~

"" '"

3.79

1986

3.76

~,

HOof

TuIHMa·

ter1a l

P

Modified

Modified

Modlfifll

'"

,~

,~

Modified

'"

Modified

'"

Modified

Modified

"'

Modified

"'

"'

"'

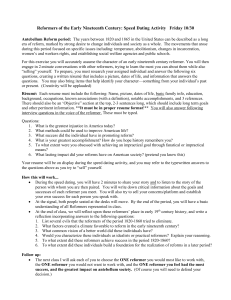

Specific steps are defined and accomplished to

manage reformer tubes over each operating cycle

fo r the reformer. The operating cycle is defined

as the period of time between two consecutive

turnarounds, typically 4 or 5 years (Figure I).

These asset management steps include an initial

survey of the reformer conditions during operation soon after start-up, continuing visual inspection and tube temperature surveys on a regular

basis, life assessment of reformer tubes and

components prior to a scheduled turnaround, inspection and assessment during a turnarounds,

and careful observation and execution of start-up

and commissioning (Table 2). The cycle of the

activities is then repeated.

1.Operlltion: Sta rt-up

Acfivilies: " 2

".

5. T/A e.>tecution

Acfivilies: B, 9, 10, 11, 12, 13, 14

,~

'"

Modified

'"

Modified

'"

... Operation: TlA preparation

(typica lly 1 yearbelore TIA)

Acfiviries: 6, 7

".

'"

""

'"

Table I. OvervIew ofYara reform ers

Terrace

Wall

AMMONIA TECHNICAL MANUAL

2. Operation: lew weeks after

start-up

Activities: 14

J. Operation: NNormal"

Acfiviries: 5

Figure I. Catalyst tube operating cycle

Modified

116

2015

Pha5e

Activity

Respon5ible

1.0peratioo:

Start-up

1. Regular and frequent vlSlJallnspeclions of the tube to avoid over-flring during start-up

2. If the loca l firing is reduced (to bealty decrease the tube temperature) it is advisable not

increasing the genera l level of fi ring in order to avoid the "wind-6own" effect

1. 2 First Line Maintenance

(operationa l personnel. Production)

3. On-line reformer survey few weeks after TIA

a. Physical condition of the bume.-s

b. Bowing evidence and colour variation between the rerom-tubes

c. RefractO!)' condition

d. Reformer operaUng parameters as compared to the design basis

e. Maximum allowable temperature (MAT) calculation

f. Tube metal temperature meaSlJrements Vs MAT

g. Temperature spread between reformer tubes

h. Carbon formation margin

Monrtoring catalyst performa nce· activity and pressure drop are within expectations for

a catalyst of a given age

j . Combusbon survey

2. Operation:

few weeks after

start-up

3, 4. First Line Maintenance

(operationa l personnel. Production )"

Extemal Specialized Contractor

,

4. Fumace balancing

5. On-line inspection and monitoring:

a. Visua l inspecUon (every sh ift) ·

L Sign ifICant colour variations or presence of hot bands

ii

iii.

3. Operation·

"Normal"

"

"

Sa. First Line Maintenence

Tubes away from each other, tube bowing

SignifICant tube bent resuHing in a horizontal displacement

Burner. evidence of backfiring. fou ling or deposit

Refractory damage

(operationa l personnel , Production)

5b. First Line Maintenance

(operationa l personnel. Production)

b. Tube temperature measurement with an optical pyrometer (every month)

5c Inspection

c. Tube temperature analysis and operation recommendation development (every mont h)

L Temperature spread among the tubes Vs maximum recommended spread (50"C)

ii

Maximum skin metal temperature values Vs MAT

6. Preliminary tube residual me assessment. damage ctass projection. prel iminary lubes retirement planning (preliminary estimation of the number of tubes 10 be replaced at next

TIA)

4. Operation:

TIA preparation

(typOcally 1 year

before TIA)

7. Tube purchasing : Quality Control

6.7. Inspection and Maintenance

a. Accurate Manufacturer selection

b. Certificate and NOT report revKiw

c_Workshop visrt

d.IO Lase~ baseline meaSlJrement

8 _TIA catalyst tube inspection·

8 _Maintenance. Inspection +

Extemal SpecialiZed Contractor

a.lf catalyst is replaced (10 access) 10 Laser Profile + EC

b _11 catalyst is not replaced. (00 access): 00 Laser Profile + EC

9.

Reformer tubes cond ition assessment: coupling inspection and residua l life calculation ,

damage class projection at the next operating period, applying retirement criteria

10. Reporting reformer tubes condition assessment results: reformer tubes creep damage

class mapping

5 _TIA execution

"

"

"

Tubes replacement according

to assessment results at point 10 above

Metallurgical analysis of retired tube samples

Cil-l<Il~1 <;hil-rging:

instrument

pressv~

to oonfirm the creep damage class

QrQP meil-"I,"ement Qf Ci!-lil-I~t in

e~

t\lbe with PQrtil-ble

14 Burners: visuil-I inspection. maintenance il-nd testing beforE! sl<lrt-up to avoid Ioc<II overhealing due to burners malfunctioning

9. Inspection ..

Extemal Specialized Contractor

10_Inspection +

Extemal Specialized Contractor

"

Maintenanoe

12: Inspection +

Extemal Specialized Contractor

13: First Line Maintenance

(operationa l personnel. Production) +

Extemal Specialized Contractor

14. Maintenance

Table 2. Catalyst tubes management actlvlfles

2015

117

AMMONIA TECHNICAL MANUAL

During the 201 3 survey, a Cost-Benefit analysis

was performed to estimate the potential benefit

of a full and unifonn implementation of BP63.

Thi s analysis was executed according to API 581

[2] ca lcu lating the tube probabi lity of failure due

to creep in the follo wing 2 conditions:

Reformer Survey and Cost-Benefit

Analysis - Why Yara asked for

assistance for its BP63

implementation

In 20 13, two years after the deve lopment of

BP63, Yara performed a survey on all of the reformer assets. From the survey, Yara recognized

that the management of these assets was not unifonn and could be improved (Table 3). The catalyst tubes failure hi story data included in the survey detennined that an average of 8 tube failures

every 3 years were occurring (not inc luding tube

fai lures due to incidents/trips), It was also clear

that the a reas with the greatest room for improvement were the temperature monitoring progra m and the residual life assessment of the catalyst tubes.

•

•

Full impl ementation of Yara BP63:

" hi ghly effective" inspecti on, monitoring

and assessment program

2013 Basis or actual situation: "fairly effective" inspection, monitoring and assessment program

The result of the analysis showed a significant

potentia l benefit (Table 4).

Number of fa ilures il J yeiltS {cillcuJarion ilccot;(/ing 10 AP1581 : comlf'mH(

illhe ilClUillslluarion, by retexmer survey)

CalOJlaled failulefreQl.Jl!ncy. lf2 [n'oflailures /(years • n' of tubes )]

Full implemenla~c:noIYara SP63 (high ty ellective inspection

ITKInnoringandassessmel1)

•

5.84E.()4

CalOJlaled failureheQUency. 1f1(n' offailures /{ye ars 'n' oltubes)]

2013, Actual situ abon (fairly effective inspection, monitorl1g and

assessment)

2.77E'()3

Tolal number of tubes

3180

EsUmaled number of tubes with ITKIre than 25 years 01 service, n

,5<

TIme period forthe Cost.senelit analysis,t [Years]

3

Tube failures in 3years, F2 ,,112' t ' n

Full implemenlatic:noIYaraSP63

Tube failures in 3years, Fl - fll' t' n

2013,Actual situation

Tube failures lHferenee in 3yea rs , F2-FI

U

7.'

6.3

Cos/.Bener-/f analysis rex 12 Ammooia Unirs

Economic COnSeQIIJence 01' Failure, COF [I(E I Failure)

Inspection, MoMoring,Assessment Cost Estimation for 12

Ammonia Units in3years, C2 [k€)

1000

1434

Full implemenlatic:noI YaraBP63

Inspection, Monnoring,Assessment Cost Estimation for 12

Ammon ia Units in3years , CI [k€)

360

2013,Actual situation

Cost 2"· (F2'COF + C2) [k€J

Full implementatiooolYaraBP63

Cost 1 ". (FI'COF" CI ) [k€I

-il260

2013,Actual situation

Benefil in J years, (CosI2

·3134

COSlf) {I!€}

5126

Annual bener-If, (Cosr 2 - Cosr 1)1 J {Iff}

1708

Table 4. BP63 lmplementatron: Cost-Benefit

Table 3. Yara reformer survey result

AMMON IA TEC HNICAL MANUAL

118

2015

Based upon the 2013 reformer survey and the estimated potential benefit, Yara selected Quest Integrity to assist with the global implementation

of BP63 through a specialized program of "Reformer Care" with the ultimate objective to reduce the number and frequency of catalyst tube

failures.

and identity and recommend performance

and reliability strategies for improvement

These elements were chosen by Yara to close the

gaps (against BP63) identified during the 2013

reformer survey, with particular focus on Maxi mum Allowable Temperature (MAT) determination, temperature monitoring and residual life assessment of the catalyst tubes.

"Reformer Care"

"Reformer Care" Implementation

Example

Quest Integrity's "Reformer Care" includes data

analysis, remaining life assessment, and engineering solutions. These services can be applied

individually to address a specific issue or may be

grouped to together to apply to a wide-range of

integrity issues.

The implementation of the "Reformer Care" services was accomplished according to a schedule

developed by Yara. The schedule was based upon Yara's evaluation of several factors including

the turnaround timing of the reformers, histOIY of

operational and reliability issues, age of reformer

tubes and planned replacements, and availability

of site personnel.

These services offer a unique solution to attain

operational safety and reliability goals, enable

proactive decision making, eliminate premature

harvesting of reformer tubes, improve knowledge

of turnaround requirements and reduces costs

with proper planning, increase the understanding

of reformer operation and limitations, and addresses all reformer systems.

The Yara Global Inspection Group had the overall responsibility for coordinating on-site training

activities and coordination of information about

the reformers to Quest Integrity ahead of the onsite work. Information exchanged included operating and design information, inspection results,

and fai lure and replacement history. This information was used to develop specific training materials for each of the reformers, provide background information for evaluation of the

reformers, and to customize the temperature correction software application for each reformer.

Site work and training was completed in 4-5 days

per reformer.

Yara selected a sub-set of these "Reformer Care"

serv ices or program elements to assist with their

global implementation of BP63. This set provided Yara with a specialized program of "Reformer

Care" to assist with the strategic management of

the twelve reformers located in eight production

complexes around the globe. These key elements

included:

•

•

•

•

•

2015

Training for operators on visual inspection of reformers including tubes conditions, burner operation, and general condition

Training for operators on tube temperature measurement practices

Implementation of reformer tube temperature correction procedures

Recommendations for maximum allowable tube metal temperatures

Reformer Performance Monitoring to

evaluate the current condition in service

Training

The on-site training for Yara personnel was accomp lished in both a classroom and field environment. Typical training attendance was 10-20

people and a mixture of operation, reliability, and

inspection personnel. Quest Integrity senior engineers delivered the training, performed equipment field surveys, demonstrations and practical

application of methods presented in the cl assroom. The training classroom and field applica-

119

AMMONIA TECHNICAL MANUAL

tion portions of the work were accomplished in

2-days and split between reformer performance

monitoring and reformer tube temperature measurement and corrections.

common reformer tube fai lures. This training included normal and abnormal tube conditions,

bowed tubes, hot spots, bulges, cold tubes, and

conditions due to catalyst damage and poisoning.

Training specific to burners in operation was included to address burner characteristics and design, correct ope ration of the burner, adjustments, maintenance, and troubleshooting.

Practical training on tube and reformer visual inspection during operator rounds was discussed in

the classroom and then practiced in the field by

participants using specifically prepared check list

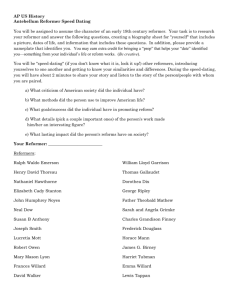

(Figure 2).

Reformer Performance Monitoring

The topics covered in the training included background information on reformer reliability management, recognition and troubleshooting of reformer performance issues, reformer tube

damage mechanisms and inspection, fitness-forservice and remaining life of reformer tubes, and

how to recognize, troubleshoot and prevent

A

Q/tJ:!:::;,;::..:::::::

MONITORING CHECKLIST

REFORMER PERFORMANCE

FIRE BOX INSPECTION

TO BE PERFORMED EVERY SHIFT

TO BE PERFORMED EVERY SHIFT

TI\RGET

...cTUAL

c::::J c::::::J

c::::::J c::::::J

c::::J c:::::::J

c::::J c:::::::J

c::::J c:::::::J

c::::J c::::::J

c::::J c::::::J

c::::J c:::::::J

c::::J c::::::J

DRAFT

O2ICO/NOX

BRIOGEWALL T EMPERATURE

STACK TE MPERATURE

FUEL PRESSURE

PILOT FUEL PRESSURE

PREHEAT AIR TEMPERATURE

PROCESS INIOUT TE MPERATURE

o

o

o

o

o

o

o

o

o

STEAM TO CARBON RATIO

RADIANT SECTION

TUBE BULGING. BOWING. HOTSPOTS

TUBE COlOR

TUBE EXTERNAL SCALING

CATALYST ISSUES

REFRACTORY COLOR

FLOOR REFRACTORY

WALL REFRACTORY

TUNNEL REFRACTORY

ROOF REFRACTORY

BURNER INSPECTION

TO BE PERFORMED EVERY SHIFT

T"mparal""

BURt£RNO.

Color Guida

. -•

UNSTABLE FLAME

~~

•

_

_ _ _ _ BAD FLAME PATIERN

(1"-0_ ....,..•_ ....)

_ _ _ _ PLUGGED TIPS

_ _ _ _ COOL BURNER TILE

•

_ _ _ _ PILOT TIP NOT GLOWING

0

-_.

0

:,\'::f 0

r,:=:", 0

......... RUI

.;oo.,)OOf

•

_ _ _ _ AIR REGISTER STUCK

IN/OUT PIGTAILS

TUBE HANGER/SPRINGS

CONVECTION/DUCTS

Io/FD FANS

~...,

TRAMP AIR

'- - '

TUBE PENETRATIONS

SIGHT PORTS FUNCTIONAL (SEA L)

EXPLOSION DOORS, FLANGES,

HOLES, LEAKING AIR IN BOX

0

0

~"F 0

. ="_"'t'

PILOT AIR NOT WORKING

EXTERNAl

OR NOT WORKING

_ _ _ _ AIR REGISTER OPEN

WHILE BURNER OFF

_ _ _ _ FUEL VALVE PINCHED

Figure 2. Tube and reformer visual inspection check list

AMMONIA TECHNICAL MANUAL

120

2015

required to obtain consistent temperature measurements. The classroom training was followed

by practical application of the techniques to gain

familiarity and a level of proficiency with the IR

measurement instruments. Temperatures recorded in the field were then corrected through

demonstration and practical experience with

Quest Integrity's CorrectIR™ software application.

Reformer Tube Temperature Management

Accurate measurement of reformer tube-skin

temperatures is a crucial input to a tube life prediction model (not directly based upon measured

creep damage) and is also critical in optimizing

productivity and ensuring optimum reformer operation. Radiation thermometry is a practicable

and reliable method for determining tube-skin

temperatures in reformers provided certain

measurement corrective practices are used. Radiation thermometry in reformers is prone to a

number of errors arising principally from the effects of tube emissivity, reflected radiation and

flue gas (Figure 3). Radiation thermometer readings and thermal images must have corrections

applied in order to obtain the tme tube-skin temperatures. These corrections depend in a complex

way on the geometry of the reformer, the temperature distribution of objects surrounding any

individual tube, and the location of that tube in

the reformer. The corrections also depend on the

operating characteristics of the radiation thermometer or thermal imager used to make the

measurements.

~

r

"T

"...,

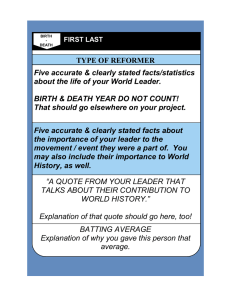

Temperature Correction - CorrectlRTM

As an element of the Reformer Care implementation, Yara implemented an lR temperature correction program to establish the actual reformer

tube metal temperatures. In order to determine

the true tube temperatures, corrections must be

made to the thermometer readings based on the

geometry of the furnace, the emissivity of the

tube material, atmospheric effects, and

knowledge of the operating characteristics of the

thennometer itself. The correction of refonner

radiance temperature readings (measured without

correction) to corrected temperatures is accomplished using Quest Integrity's CorrectIR™

software (Figure 4) and method. The methodology and software is based upon the work of Dr.

Peter Saunders. CorrectIR™ accomplishes:

,

1. Corrects radiance measurements for calibration, size of source effect, flue gas

emissions and other instrument and environmental errors

2. Calculates the uncertainty associated with

individual factors

3. Calculates the effective background temperature taking into account rigorous geometry for each tube

4. Calculates the Tube Corrected "true" tube

temperature and the total uncertainty

~~.. ···::::'·········· 1

~...........

.. . . . . . . . I

Figure 3. Radiation thermometry errors: effects

o/tube emissivity, reflected radiation and flue

gas

The second day of classroom and field training

was dedicated to the Infrared Radiation (IR)

temperature measurement theory and techniques

for reformer tubes. The classroom training discussed the application of IR pyrometers and imaging cameras for monitoring reformer tube temperatures along with the operator techniques

2015

A sample output of the temperature corrections

performed using CorrectIR™ is shown in Figure

4. Tubes are referenced by the Tube Row, Tube

Number, Height (location of the temperature

measurement point from the reformer floor), and

Sight Door from which the temperature was

measured. The Tube Reading is the uncorrected

121

AMMONIA TECHNICAL MANUAL

temperature measured by the IR instrument. CorrectIR ™ performs the calculation of the Tube

Corrected "true" temperature and the total uncertainty for the "true" temperature.

Implementation o f the CorrectLR™ across the

twelve (12) reformers in the Yara system is a key

reliability element to sustainin g reformer tube

of the

assets.

life

and

optimization

I) Cotr«t1R • North Zo<w 1 Rl CoI.ot

fiIt.~~J:!<Ip

o~

B

.. .

I'uwf _ _

Ta.dvoord c.... 1TIbo."....... I

0 1..,._(5_/Io>; .. T.........)

0 """"," T..,.I....,. (1<81 ""'tnJouI...-;-,gj

O ~ldrn.Ii«"'

" i Row

T_

' 0,

"

"

"

""

""

.,

"

""'" ,,

,.,

.,

'"

.,

'"

,

"

B

"

"

"

""

V

U

"

'", ""

",

"

~

. ..

__

to ..... boo. Ho:/oIIt (m)

0.76

0.76

0.76

0.76

0.7f>

0.76

0.76

0.7f>

0.7f>

0.76

0.76

0.76

0.76

0.76

0.76

0.76

0.76

0.76

0.76

0.7f>

0.7f>

T..,.o...

V..,.T.....

...'- ".,

""

""

""

""

""

""

""

""

""

""

""

""

""

""

""

""

""

""

"AA

•

ea......... c-.:t... ·r

T_R.~""f

,~,

"AA

"AA

,~,

""

1591

,~

1591

,~

,~o

1520.91

154o.a6

1533.17

154'.22

1542.22

1554.16

1541.86

1S58.C]

T.... o:o..«t.oI · f

1471.14

14'>4.B9

14B!i.72

1~.~7

14%.82

1512.05

1496.116

1516.156

1484.74

""

1533.15

1545.21

1552.23

1556.18

153S.Oti

1546.17

1527.22

1540.22

1549.16

1554.05

1611

1560.'"

,~

1~7U.18

)jU.ll

If>10

155'.21

1511.18

,,~

,~,

,~,

,~,

""

1574

,~

,~

14~.7S

1~.156

151U2

1487.~

1500.98

1476.73

1493.21

lS04.76

1511.44

1518.12

T..... I T ..... """""' . . . . . .

15.97

14.n

15.5]

14.58

15.03

14.2

15.26

14.41

If>.16

15.41

14.92

".,.

16.07

15.45

"n

15.17

15.2

14.7

14.49

14.01

14.71

Figure 4. Results of Temperature Correction with Quest Integrity's CorreclfRTM software

stances when compared to operating temperature

limits, these corrected "true" temperatures would

allow for increase firing and ammonia production currently.

Baseline Reformer Tube lR Survey and T ube

Wall Temperature Limits

As an element of Reformer Care, Quest Integrity

completed reformer tube temperatures surveys of

each of the Yara refonners. These surveys were

conducted using IR Imaging Cameras and in

some cases IR pyrometers.

Quest Integrity also provided recommended

TWT limits (Maximum Allowabl e Temperature,

MAT) for each of the Yara reformers. Quest Integrity has developed a unique creep material

model for HP Alloys that accounts for material

aging and creep strain rate with respect to stress,

temperature and time. This proprietary creep materia l model is called LifeQuest™ Refonner.

LifeQuest™ Refonner was used to defi.ne Reliable and Safe tube metal temperature operating

The surveys provided Yara with a baseline survey of tube metal temperatures which were corrected using CorrcctIR™. The corrected tube

wall temperatures (TWT) were lower than the

measured radiance temperatures. In many in-

AMMONIA TECHNICAL MANUAL

122

2015

limits for the Yara reformers. The main difference between the original design life estimates

provided by the tube manufacturer or the furnace

designer and the Quest Integrity service life estimate is that for the original design the tubes are

assumed to have retained their original mean or

lower bound as manufactured creep properties

whereas the Quest Integrity model takes into account that the creep properties will progressively

degrade (Figure 5). This information was also

provided as a creep rupture life curve for each reformer.

-

er in operation to assist with balancing the refonner firing and to deliver a reliability strategy

to ensure the safe and reliable long term operation of the reformers. The survey and reliability

strategy included the following essential elements to achieve optimum performance and reliability of the reformers.

1.

2.

3.

4.

5.

6.

7.

HPNb

- HP micro

-

Lower bound

Safety and Environmental

Operating Performance

Reliability Issues

Reformer Tube Condition

Reformer Mechanical Condition

Burner Mechanical Condition

Recommended Corrective Actions for the

Reformers

eJ(·service

... As cast

•

The issues found during the survey (examples are

shown in the figures from 6 to 12) as well as other industry best practices are were addressed by a

set of corrective actions. Principled execution

towards accomplishing these strategic actions

will lead to a higher level of performance and reliability with respect to the reformer.

Ex-service

LMP Parameter

Figure 5. As Cast and Aged Reformer Tube

Material Properties

The creep rupture life curve for the reformer

tubes are used to assess the life impact from

changes in operating conditions. With a corrected

tube metal temperature (plus uncertainty) value

above the Safe limit, the creep rupture life could

potentially be extremely short resulting in tube

failure during the operating period.

Finally, during a reformer shutdown, the actual

consumed creep life may be measured and calculated by utilizing Quest Integrity's proprietary

inspection tools, LOTIS® and MANTIS™ and

the Level 3 LifeQuest™ Reformer assessment

program.

Figure 6. fara Sluiskil H50J reformer: external

scale on upper tubes

Performance and Reliability Monitoring

Quest Integrity perfonned a Reformer survey to

evaluate each of the Yara reformers. The primary

objective of the work was to observe the reform-

2015

123

AMMONIA TECHNICAL MANUAL

Figure 9. Yara Ferrara B201 reformer: bowed

tubes; uneven tube colour; flame impingement on

tubes; tramp air entering/rom burners out-of

service with air registers open

Figure 7. Yara Sluiskil H501 reformer: tube appearance as "Hot" due to external scale

Figure

Yara Ferrara

out 0/service with both primary and secondary

air register open causing tramp air

Figure 8. fara Tertre BIOI reformer: flame pattern with baking soda test

AMMONIA TECHNICAL MANUAL

124

2015

Reformer catalyst tube reliability involves the

whole Production Facility Organization (Inspection, Production, and Maintenance) to systematica lly address all the phases of the tube life-cycle.

Each phase of the tube li fe -cycle includes several

specialist activities which are described in detail

in Yara Best Practice document BP63. Together,

and only if properly executed, a ll these activities

reduce the probability of failure of catalyst tubes

with a positive impact on plant reliability.

flashback

Although is too early to evaluate the real benefit

(reduction of tube fai lure frequency) of BP63

implementation through the "Reformer Care"

program, one significant result has already been

achieved: operation, reliabili ty~ inspection and

management personnel have now a clear understanding of the service related tube damage

mechanisms, of the effects of excursions from

design conditions, and, finally, of the monitoring

and inspection techniques that have to be applied

in order to avoid premature tube failures.

Proper implementation with a structured approach, as described in Yara BP63, requires specialised technical support and personnel training.

For this reason Yara selected Quest Integrity to

develop together a program of "'Reformer Care"

to assist with the strategic management of the

twelve Yara reformers.

Figure J2. Yara Ferrara B201 reformer: thermal

image ofexternal hot spot at edge of sight door

The full set of Quest Integrity Group "Reformer

Care" services can be applied individually to address a specific issue or may be grouped to together to apply to a wide-range of integrity issues. Yara selected a sub-set of these "Reformer

Care" services or program elements to specifically assist with their global implementation of Yara

BP63.

Conclusions

References

[1 ] Yara Best Practice BP63, Life-cycle

management of reformer catalyst tubes

(Yarn Internal Document)

[2] API Publication 581 First Edition, May

Quest Integrity Group and Yara International

worked together to deliver a set of "Reformer

Care" services to Yara's Production Facilities.

The overall objective was to reduce the number

and frequency of catalyst tube failures.

2015

2000

125

AMMONIA TECHNICAL MANUAL

AMMONIA TECHNICAL MANUAL

126

2015