Version of Record: https://www.sciencedirect.com/science/article/pii/S0306454920300736

Manuscript_5df852681d641628371f59f36c7df39e

Numerical Study on Convective Heat Transfer and Friction Characteristics of Molten Salts

in Circular Tubes

Sheng Zhanga, Xiaodong Suna,*, and Elvis E Dominguez-Ontiverosb

a Department of Nuclear Engineering and Radiological Sciences, University of Michigan, Ann Arbor, MI 48109, United States

b Oak Ridge National Laboratory, Oak Ridge, TN 37831, United States

ABSTRACT

Molten salts including fluoride, nitrate, chloride, and carbonate salts have been proposed for heattransfer and thermal energy storage applications due to their superior thermal performance at

elevated temperatures. Since it is expensive to perform molten salt heat transfer experiments due

to the high working temperatures, a numerical analysis is carried out to investigate thermal and

hydrodynamic performance of molten salts using a Computational Fluid Dynamics (CFD) tool,

STAR CCM+, and validate the numerical model using existing experimental data and convective

heat transfer correlations, including Dittus-Boelter, Gnielinski, Hausen, and Sieder-Tate

correlations. The analysis shows the hydrodynamic and thermal performance, such as the

hydrodynamic/thermal entrance length, friction factor, and Nusselt number of molten salts in

laminar and turbulent flow regimes can be appropriately modeled. In addition, the widely used

convective heat transfer correlations provide good predictions for molten salt heat transfer.

KEYWORDS

Molten Salts; Convective Heat Transfer; Darcy Friction Factor; Entrance Length; Numerical Study.

*: Corresponding author at: University of Michigan, 2355 Bonisteel Blvd., Ann Arbor, MI 48109-2104, USA.

E-mail address: xdsun@umich.edu

© 2020 published by Elsevier. This manuscript is made available under the Elsevier user license

https://www.elsevier.com/open-access/userlicense/1.0/

1. INTRODUCTION

Molten salts, such as fluoride, nitrate, chloride, and carbonate salts, could be used as heat transfer

fluids (HTFs) and thermal energy storage (TES) fluids. Specifically, fluoride salts including FLiBe

(LiF-BeF2, 66-34 mol%,), FLiNaK (LiF-NaF-KF, 46.5-11.5-42 mol%), and KF-ZrF4 (58-42

mol%) are promising reactor coolants for Fluoride-salt-cooled High-temperature Reactors (FHRs)

due to their good thermophysical and nuclear properties [1]. Nitrate salts, such as KNO3- NaNO2KNO3 (53-40-7 wt%), chloride salts, such as MgCl2-KCl (68-32 mol%), and carbonate salts, such

as Li2CO3-Na2CO3-K2CO3 (32-33-35 wt%), are promising candidates for HTFs and TES media in

Concentrating Solar Power (CSP) plants considering their thermophysical properties, cost,

material compatibility, stability, and flammability [2]. Due to their wide applications as heat

transfer media, it is therefore necessary to investigate thermal and hydrodynamic performance of

these molten salts, especially considering their relatively large Prandtl number.

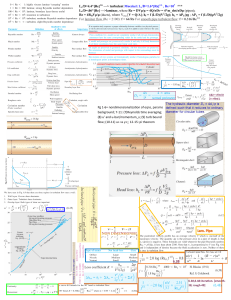

Figure 1 shows the Prandtl number for six molten salts, with air and saturated water included as

references. The Prandtl number of molten salts as shown in Figure 1 are in the range of 2 to 32 at

their respective potential working temperatures. The high Prandtl number may lead to different

heat transfer characteristics of conventional fluids, such as water and air. Normally, molten salts

work at elevated temperatures to achieve high electric power conversion efficiencies and maintain

large safety margins to avoid potential salt solidification. Due to their high working temperatures,

construction and operation of a high-temperature molten salt facility to investigate molten salt

thermal and hydrodynamic performance is expensive. It is therefore proposed to first numerically

investigate heat transfer and friction characteristics of molten salts, and validate the numerical

results using experimental data from molten salt experiments.

2

35

LiF-BeF (66-34 mol%)

2

LiF-NaF-KF (46.5-11.5-42 mol%)

KF-ZrF (58-42 mol%)

30

4

NaNO3-KNO3 (60-40 wt%)

25

KNO -NaNO -NaNO (53-40-7 wt%)

3

2

3

MgCl -KCl (68-32 mol%)

2

20

Water

Air

15

10

5

0

0

100

200

300

400

500

600

700

800

Temperature (°C)

Figure 1 Prandtl numbers of various molten salts, air, and saturated water

In the literature, experimental studies on molten salt related to the salt thermal hydraulics started

in 1950s. In 1954, Grele and Gedeon [3] investigated the heat transfer characteristics of FLiNaK

in an electrically heated Inconel tube at a temperature range of 540 to 730 °C. The heat transfer

coefficient values estimated from the experimental data were at about 40% of the values given by

the Dittus-Boelter correlation. Formation of a thermal resistance layer due to the intergranular

corrosion to the Inconel tube by the salt was proposed as the reason for the much lower heat transfer

coefficients in the experiments. Later in 1955, Hoffman and Lones [4] experimentally studied the

heat transfer of FLiNaK flowing in three tubes made of Nickel, Inconel, and Stainless Steel (SS)

316. The heat transfer coefficients estimated from the experimental data obtained from the Nickel

and SS 316 tubes agreed well with the Dittus-Boelter correlation results, while the heat transfer

coefficient from the Inconel tube deviated significantly from the Dittus-Boelter correlation results.

This much lower heat transfer coefficient obtained from the experiments was explained due to the

existence of an interfacial thermal resistance in the FLiNaK-Inconel system. However, this

3

conclusion conflicted with Vriesema’s finding in 1979 [5] where the experimental data obtained

from a FLiNaK-Inconel system matched reasonably well the Dittus-Boelter correlation results,

within ±20% uncertainties. The contradictory conclusions may be resulted from different

thermophysical property values used for FLiNaK when the heat transfer coefficient was deduced

[3-5]. Therefore, it is necessary to identify accurate thermophysical properties for FLiNaK when

reducing salt experimental data.

In addition to FLiNaK, other molten salts, including salts with dissolved nuclear fuels, i.e., fuel

salts, were widely investigated as well [6-13]. In 1960, Hoffman and Cohen [6] investigated heat

transfer performance of KNO3-NaNO2-NaNO3 (53-40-7 wt%) in an Inconel tube at a temperature

range of 290 to 442 °C. In recent years, KNO3-NaNO2-NaNO3 (53-40-7 mol%) was studied by

Chen, et al., [7] and Qian, et al., [8-9]. In addition, Wu, et al., [10] and Liu, et al., [11] studied

convective heat transfer of one same molten salt, LiNO3, but proposed different convective heat

transfer correlations. Fuel salts for Molten Salt Reactors (MSRs), such as LiF-BeF2-ThF4-UF4 with

different molar fractions, were studied by Silverman, et al., [12] and Cooke and Cox [13]. In

addition, friction factor of molten salts was experimentally investigated by Vriesema [5], and Jeong

and Bang [14].

It is inconvenient to use various heat transfer coefficient and friction factor correlations for same

molten salts and difficult to acquire local information of interest from the experiments, such as salt

temperature profiles. In addition, it is not cost-effective and perhaps unnecessary to perform extra

experiments for other molten salts of similar ranges of the Prandtl number of the molten salts that

have been widely investigated. The thermal and hydrodynamic characteristics of molten salts, such

4

as the hydrodynamic and thermal entrance lengths, friction factor, and Nusselt number for molten

salts in circular tubes are therefore numerically investigated in this paper.

2. NUMERICAL MODELING

2.1. Numerical Model

A three-dimensional Computational Fluid Dynamics (CFD) tool, STAR CCM+ was used to

investigate the thermal-hydraulic performance of molten salts, including FLiNaK and LiF-BeF2ThF4-UF4 (71.7-16-12-0.3 mol%) in circular tubes. The fluid domain molten salt (FLiNaK and

LiF-BeF2-ThF4-UF4) and solid domain a circular tube made of SS 316 were constructed in STAR

CCM+. The circular tube has an inner diameter of 4 mm and tube thickness of 1 mm as shown in

Figure 2. The tube length is 15 m when the flow in the tube is laminar, while 1 m for turbulent

flow cases. Several mesh models, such as polyhedral mesher, surface remesher, prism layer

mesher, and extruder were enabled for meshing. Boundary conditions include a uniform velocity

inlet at 500 °C, an atmospheric pressure outlet, and constant wall heat fluxes 4 and 100 kW/m2 on

the wall outer surface for laminar and turbulent flows, respectively. In addition, the realizable k-ɛ

two-layer model is used for modeling turbulent flows.

L = 15 m for laminar flows

L = 1 m for turbulent flows

ro = 3 mm

Tube

ri = 2 mm

Molten salt

Figure 2 Dimensions for fluid and solid domains

5

2.2. Grid Independence Study

A grid independence study was first performed to investigate the spatial convergence of numerical

results, which could be characterized by the Grid Convergence Index (GCI) [15] as follows,

=

where Fs, r, p, and

(1)

are the safety factor, grid refinement ratio, order of convergence, and

estimated variable, respectively. The safety factor Fs is empirically set to be 1.25. The grid

refinement ratio for mesh options 1 and 2, r2-1, and order of convergence p [15] are defined as

=

(2)

=

(3)

r3-2 is the grid refinement ratio for mesh options 2 and 3. s and h are respectively the sign function

[15] and grid size [16], which are defined as

= sgn !

$

ℎ = ! &% "

"

(4)

⁄'

(5)

where Vt and N are the grid total volume and quantity, respectively.

A total of six sets of grid size were used for the grid independence study for laminar (Re = 1,800)

and turbulent (Re = 10,000) flows, and results are summarized in Table 1. The GCI values of the

Darcy friction factor and temperature difference between the inlet and outlet for laminar flows are

significantly small, 0.15 and 0.08%, respectively. In addition, the GCI values of the Darcy friction

factor and temperature difference for turbulent flows are 0.62 and 0.48%, respectively. The

simulation results using fine mesh options 1 and 4 are therefore considered to be mesh independent,

6

which are adopted in this study for the thermal and hydrodynamic analyses of molten salts in

laminar and turbulent flow regimes, respectively.

Table 1 Results of grid independence study for FLiNaK

Mesh option

Cell quantity (103)

Grid size (mm)

f

ΔT (°C)

Laminar flow (Re = 1,800)

1 (Fine)

384.16

1.03

0.03338

12.27

2 (Medium)

160.78

1.38

0.03302

12.29

3 (Coarse)

73.93

1.80

0.03020

12.35

GCI (%)

N/A

N/A

0.15

0.08

Turbulent flow (Re = 10,000)

4 (Fine)

139.74

0.59

0.03108

3.87

5 (Medium)

59.86

0.78

0.03101

3.90

6 (Coarse)

24.29

1.05

0.03090

4.01

GCI (%)

N/A

N/A

0.62

0.48

2.3. Data Reduction

The Darcy friction factor used to estimate the frictional pressure loss is defined as

)=

*+,-

./01

Δ

3

(6)

where D, Af, 41, 5, Δpf, and Δz are the inner diameter, cross-sectional area of the tube, mass flow

rate, fluid density, frictional pressure drop, and axial distance, respectively. The average heat

transfer coefficient is defined as

7

ℎ6 =

71

,89 :;689 ;6- <

(7)

whereQ&, Aiw , T iw , and T f are the heat transfer rate, heat transfer area of the tube inner surface,

area-average temperature of the tube inner surface defined by Eq. (8), and arithmetic mean of the

fluid bulk inlet and outlet temperatures defined by Eq. (9), respectively.

=6>? =

=63 =

,-

@ ;89 A,

,89

(8)

B=6>C + =6EFG H

(9)

The fluid bulk inlet (or outlet) temperature is defined as

=6>C =

@ *I $;8J A,

@ *I $A,

(10)

where V and cp are the fluid velocity in the tube axial direction and specific heat capacity,

respectively.

3. REVIEW OF MOLTEN

SALT EXPERIMENTS AND THERMOPHYSICAL

PROPERTIES

3.1. Molten Salt Experiments

Considering the convenience to extract original experimental data for comparison with the CFD

and correlation results, the authors selected eleven salt heat transfer experiments [3-13] and two

hydrodynamic experiments [5,14], which are summarized in Table 2. The working fluids used in

these experiments [3-14] include FLiNaK (LiF-NaF-KF, 46.5-11.5-42 mol%), KNO3-NaNO2NaNO3 (53-40-7 wt% and 53-40-7 mol%), LiNO3, NaBF4-NaF (92-8 mol%), and LiF-BeF2-ThF4UF4 (71.7-16-12-0.3 mol% and 67.5-20-12-0.5 mol%). The salt temperature ranges from 200 to

830 °C.

8

Table 2 Information of the selected molten salt experiments

Molten salt

FLiNaK

(LiF-NaF-KF, 46.511.5-42 mol%)

Heat

transfer

Flow

channel

material

Flow channel

configuration

Inconel X750

Nickel

Inconel

Dimension

(length L and

ID) (mm)

Heating

/cooling

609.6 and 6.23

1182 and 2.98

Circular tube

SS 316

Inconel

600

Salt

temperature

(°C)

Reference

540-730

Grele

(1954) [3]

530-745

Hoffman

(1955) [4]

Heating

1182 and 4.45

1182 and 4.57

2050 and 26

Cooling

575-675

Vriesema

(1979) [5]

Heating

290-442

Hoffman

(1960) [6]

KNO3-NaNO2-NaNO3

(53-40-7 wt%)

Inconel

Circular tube

241.3 and 4.57

KNO3-NaNO2-NaNO3

(53-40-7 mol%)

Inconel

600

Circular tube

1200 and 20

200-300

Chen

(2016) [7]

KNO3-NaNO2-NaNO3

(53-40-7 mol%)

Shell-tube heat

exchanger

(molten salt on

tube side)

350 and 10.45

200-300

Qian (2016)

[8]

KNO3-NaNO2-NaNO3

(53-40-7 mol%)

Shell-tube heat

exchanger

(molten salt on

tube side)

Gas cooled

HX:

350 and 10.45

Molten salt to

salt HX: 500

and 10

258-298

Qian (2017)

[9]

Stainless

steel

Cooling

272-441

LiNO3

Circular tube

1000 and 20

294-441

NaBF4-NaF (92-8

mol%)

LiF-BeF2-ThF4-UF4

(71.7-16-12-0.3 mol%)

Circular tube

Hastelloy

N

LiF-BeF2-ThF4-UF4

(67.5-20-12-0.5 mol%)

Friction

factor

FLiNaK

(LiF-NaF-KF, 46.511.5-42 mol%)

Circular tube

Circular tube

Inconel

600

Circular tube

3500 and

10.52

3500 and

10.52

450-610

Silverman

(1976) [12]

550-765

Heating

622.3 and 4.57

580-830

1200 and

41.25

Adiabatic

575-675

650 and 1.4

Heating

595-620

9

Wu (2009)

[10]

Liu (2009)

[11]

Cooke

(1973) [13]

Vriesema

(1979) [5]

Jeong

(2010) [14]

Three experiments [3-5] investigated FLiNaK heat transfer performance in circular tubes made of

different metals, such as Inconel X-750, Inconel 600, nickel, and SS 316. Although the same type

of FLiNaK salt was investigated in these experiments, inconsistent thermophysical properties were

used during the data reduction for these experiments [3-5] as summarized in Table 3. The

maximum discrepancies in the FLiNaK density, specific heat capacity, thermal conductivity, and

dynamic viscosity used in the data reduction of these experiments [3-5] are 7, 11, 246, and 45%,

respectively. The significant discrepancies in FLiNaK thermophysical properties used in these

experiments, especially the one in the thermal conductivity, result in large differences in the Prandtl

number, Reynolds number, and Nusselt number calculations.

Table 3 Thermophysical properties for FLiNaK used in the experiments [3-5]

5 (kg/m3)

KL (J/kg-K)

M (W/m-K)

N (kg/m-s)

Maximum

Grele (1954) [3]

Hoffman (1955) [4]

Vriesema* (1979) [5]

2555-0.6T(K)

2555-0.6T(K)

2729-0.73T (K)

2093.4

1883

1890

11%

4.5

4.5

1.3

246%

2.5 × 10 U V WXYZ⁄;B[H

2.5 × 10 U V WXYZ⁄;B[H

8.44 × 10

'

3.94 × 10

'

5.50 × 10

2.39 × 10

'

'

discrepancy**

7% for T from 773

to 1073 K

at 773 K

at 873 K

at 973 K

45%

for T from 773 to

1073 K

at 1073 K

*: The kinematic viscosity used by Vriesema is converted to the dynamic viscosity

**: The maximum discrepancy is estimated by |a − c|⁄a × 100%, where a is smaller than b

10

Figure 3 shows the Prandtl number, Reynolds number, and Nusselt number of FLiNaK using

thermophysical properties in the experiments [3-5]. These characteristic numbers, Pr, Re, and Nu

are normalized using their respective maximum value at a temperature range of 500 to 800 °C. The

discrepancies in the normalized Prandtl number, Reynolds number, and Nusselt number are

respectively 100 to 280%, 0 to 35%, and 230 to 235% for T = 500 to 800 °C. Therefore, it is

necessary to identify accurate thermophysical properties for FLiNaK and re-process the original

Normalized Pr

Normalized Re

experimental data to determine the thermal and hydrodynamic characteristics of molten salts.

(a)

(b)

1

0.8

Grele

Hoffman

Vriesema

0.6

0.4

0.2

500

550

600

650

700

750

800

Temperature (°C)

(c)

Figure 3 Comparison of (a) Pr, (b) normalized Re and (c) normalized Nu using FLiNaK

thermophysical properties in the references [3-5]

11

In addition to FLiNaK, the heat transfer performance of KNO3-NaNO2-NaNO3 were widely

investigated as well [6-9]. It should be noted that two different compositions of KNO3-NaNO2NaNO3 were used in the literature [6-9]. Hoffman et al. [6] used a heat transfer salt [17], a eutectic

mixture of KNO3, NaNO2, and NaNO3 based on 53-40-7 weight percent, while Chen, et al. [7] and

Qian, et al. [8-9] used KNO3-NaNO2-NaNO3 based on 53-40-7 molar percent. The eutectic mixture

of KNO3, NaNO2, and NaNO3 at 53-40-7 weight percent is equivalent to the eutectic mixture of

KNO3, NaNO2, and NaNO3 at 44-49-7 molar percent. As these two salts have very similar

chemical compositions, they are expected to thermodynamically behave similarly.

3.2. FLiNaK Properties

Density

Grimes, et al. [18] demonstrated that the rule of additivity of molar volumes was useful to predict

the fluoride salt mixture density:

∑J & f

8

50 = ∑J 8& $8 B;H

8

(11)

8 8

where 50 , h> , i> , and l> B=H are the mixture density, molar fraction of component i, molecular

weight of component i, and molar volume of component i at a temperature of T, respectively. Using

the measured densities of the three fluoride constituent salts LiF, NaF, and KF at two temperatures

of 600 and 800 °C [18], the FLiNaK density can be estimated by the rule of additivity of molar

volumes. The uncertainty in estimating the salt mixture density using Eq. (11) is within 5% [1, 19].

In addition to the model prediction of the FLiNaK density, a number of experimental investigations

were conducted on the FLiNaK density [20-23]. In 2003, Chrenkova, et al., [20] experimentally

measured the FLiNaK density for T = 667 - 897 °C with ±0.4% uncertainties, which was later

12

demonstrated by Cibulkova [21]. Kubikova, et al., [22] and Cheng, et al., [23] in 2013 measured

the FLiNaK density for T = 483 - 609 °C without specifying the associated uncertainty and for T

= 480 - 700 °C with ±0.25% uncertainties. Figure 4 shows a comparison of the FLiNaK density

values used in the references [20-23]. The maximum discrepancy in the FLiNaK density in a

temperature range of 500 - 800 °C is 3.5%. This relatively good agreement demonstrates Eq. (11)

can predict accurately the FLiNaK density. It is recommended to use the Chrenkova’s correlation:

5Bkg⁄m' H = 2408.9 − 0.624=B℃H

(12)

for the FLiNaK density at T = 500 - 800 °C with ±1% uncertainties to cover both Grimes’s and

Cheng’s results.

2200

Model - Grimes; William

Experiment - Chrenkova; Cibulkova

Experiment - Kubikova

Experiment - Cheng

2150

2100

2050

2000

1950

1900

500

550

600

650

700

750

800

Temperature (°C)

Figure 4 The FLiNaK density values used in the references [20-23]

Dynamic Viscosity

In 1963, Powers, et al., [24] measured the dynamic viscosity of FLiNaK for T = 500 - 800 °C with

±20% uncertainties. Chrenkova, et al., [20], Cibulkova, et al., [21] and Kubikova, et al., [25] also

experimentally measured the dynamic viscosity of FLiNaK respectively for T = 500 - 700 °C with

13

±2% uncertainties in 2003, T = 660 - 890 °C with ±2.5% uncertainties in 2006, and T = 529 - 630

°C without specifying uncertainties in 2012 using the torsion pendulum method. In 2014,

Merzlyakov, et al., [26] measured the kinematic viscosity of FLiNak for T = 454 - 871 °C without

specifying the uncertainties. In our current study, the kinematic viscosity of FLiNaK obtained by

Merzlyakov, et al., [26] is converted to the dynamic viscosity using the recommended FLiNaK

density correlation, Eq. (12).

As shown in Figure 5, the FLiNaK dynamic viscosity estimated in the references [18, 20, 24-26]

are within the ±20% uncertainty range of the Powers’ prediction. It is therefore recommended to

use the Powers’ correlation,

N BPa ∙ sH = 4 × 10 U V W

XZ⁄s;B℃H

X'. Ut

for the FLiNaK dynamic viscosity for T = 500 - 800 °C with ±20% uncertainties.

Figure 5 The FLiNaK dynamic viscosity values used in the references [18, 20, 24-26]

Specific Heat Capacity

14

(13)

The specific heat capacity of FLiNaK was given as 1904.8 J⁄Bkg ∙ KH for T = 477 - 557 °C with

±3% uncertainties by Janz, et al., [27] and 1880 J⁄Bkg ∙ KH for T = 500 - 700 °C with ±4%

uncertainties by An, et al., [28]. These values generally agree with Rogers’s prediction [29] as

shown in Figure 6. It is recommended to use

KL BJ⁄Mw ∙ x H = 1880

(14)

for the FLiNaK specific heat capacity for T = 500 - 700 °C with ±5% uncertainties to cover both

Rogers’ and Janz’s results.

Figure 6 The FLiNaK specific heat capacity values used in the references [27-29]

Thermal Conductivity

Rosenthal, et al., [30] suggested the following equation for estimation of the thermal conductivity

of fluoride mixtures.

;

⁄

* ⁄

CHz⁄{

y

M0 = 0.0119 Bf

⁄

(15)

where M0 , =0 , 5, i, and | are the thermal conductivity (W/m·K), melting temperature (K), density

(kg/m3), molecular weight (g/mol), and ion number of fluoride mixtures, respectively. Utilizing

15

the FLiNaK melting temperature 454 °C [31], the recommended Chrenkova correlation for the

FLiNaK density, and ion number n = 2, the FLiNaK thermal conductivity could be estimated by

Eq. (15) as a function of the salt temperature.

Janz, et al., [27], Smirnov et al., [32], and An et al., [28] proposed polynomial equations to estimate

the FLiNaK thermal conductivity for T = 527 - 647 °C with ±25% uncertainties in 1981; T = 517

- 807 °C with ±4% uncertainties in 1987; and T = 500 - 700 °C with ±3.5% uncertainties in 2015,

respectively. Cooper, et al., [33] proposed values of 1.682, 1.508, and 1.45 W⁄Bm ∙ KH for the

FLiNaK thermal conductivity for T = 690, 540, and 620 °C with uncertainties of 13, 8, and 8%,

respectively.

Figure 7 shows a comparison of the FLiNaK thermal conductivity in the references [27-28, 30, 3233]. The maximum discrepancy could be as high as 250% for T = 500 °C and 400% for T = 800

°C. The significant differences may result from the different approaches adopted to measure the

FLiNaK thermal conductivity and impurities in the FLiNaK salt used in these experiments.

Figure 7 The FLiNaK thermal conductivity values used in the references [27-28, 30, 32-33]

16

Janz, et al., [27] and Cooper, et al., [33] used the parallel plate method to measure the FLiNaK

thermal conductivity, which is estimated using the plate temperature difference and heat flux. The

effects of the thermal radiation, natural convection, and axial conduction between the hot and cold

plates result in larger values for the thermal conductivity. In addition, metal impurities, i.e., Fe, Al,

Ni, Pb, Mn, and Mg, etc., presented in FLiNaK salt would lead to overpredicted FLiNaK thermal

conductivity from the experiments.

An, et al., [28] used the laser flash technique developed by Parker, et al., [34] to measure the

FLiNaK thermal conductivity. In their experiments, the thickness of the liquid FLiNaK in their

container was 1.5 mm. Therefore, it is appropriate to assume that the convective heat transfer in

the liquid FLiNaK could be neglected in the experiment. In addition, the FLiNaK salt used in their

experiment was first prepared under an H2/HF environment to reduce the impurity level to be lower

than 0.01 wt%. Therefore, it appears appropriate to assume that the prediction given by An, et al.,

for the FLiNaK thermal conductivity is more accurate.

Smirnov, et al., [32] used the coaxial platinum cylinder method to measure the FLiNaK thermal

conductivity. In their experiments, FLiNaK was purified to reduce the impurity level and therefore

effect of corrosion. In addition, the radiative heat transfer was considered in the experiments.

Therefore, Smirnov’s correlation was suggested by Romatoski and Hu [35] for the FLiNaK

thermal conductivity. Since both Ann’s and Smirnov’s correlations are assumed more accurate

than those by the other references, the following correlation

M sW⁄Bm ∙ KHt = 0.005 + 0.00093=BxH

17

(16)

an arithmetic mean of their results, is recommended for the FLiNaK thermal conductivity for T =

500 - 800 °C with ±10% uncertainties. The thermophysical properties for FLiNaK summarized in

Table 4 are therefore adopted to re-process the original experimental data in the literature [3-5]

and to develop new convective heat transfer correlations for FLiNaK.

Table 4 Adopted thermophysical properties for FLiNaK

Temperature

Uncertainty at 95%

range (K)

confidence level

FLiNaK

Recommendation

Density (kg/m3)

2579.3-0.624 T(K)

±1%

1880

±5%

Specific heat capacity

(J/kg-K)

Thermal conductivity

(W/m-K)

Dynamic viscosity

(kg/m-s)

0.005 + 9.3 × 10

4 × 10 U V W

W

=BKH

773-1073

XZ⁄;B~H

±10%

±20%

The original reported experimental data may change significantly after data reprocessing using

more accurate salt thermophysical property data summarized in Table 4. The three characteristic

numbers, Pr, Re, and Nu originally in Grele’s experiment [3] are compared with their modified

values using recommended thermophysical properties for FLiNaK as shown in Figure 8. It is clear

that these modified values of the characteristic numbers deviate significantly from their original

values, especially for Prandtl and Nusselt numbers. The discrepancies between the original and

modified values of the Prandtl, Reynolds, and Nusselt numbers are 283 to 328%, 17 to 33%, and

331 to 431%, respectively. These large discrepancies are mainly due to the different thermal

conductivity and dynamic viscosity used for FLiNaK in Grele’s experiment [3] and this paper. In

18

addition, the recommended thermophysical properties for FLiNaK result in a significant change

of Nu/Pr1/3 values as shown in Figure 9, which lead to a different heat transfer correlation.

20

104

2.5

2

15

1.5

10

1

5

0.5

0

0

5

10

15

0

20

0

0.5

Original Pr

1

1.5

Original Re

2

2.5

104

(b)

(a)

(c)

Figure 8 Comparison of (a) Pr, (b) Re, and (c) Nu using FLiNaK thermophysical properties

in Grele’s experiment [3] and recommended properties in this paper

19

Figure 9 Comparison of the original heat transfer data in Grele’s experiment [3] and modified

data using the recommended thermophysical properties for FLiNaK

4. RESULTS AND DISCUSSIONS

It is necessary to compare the numerical results with existing molten salt experimental data as well

as friction factor and convective heat transfer correlations summarized in Table 5 to identify their

applicability for the molten salts of interest. In addition, the hydrodynamic and thermal entrance

lengths of molten salts flowing in circular tubes are investigated as well.

20

Table 5 Heat transfer and friction factor correlations for internal flows (circular tube)

Reynolds

Correlation

•⁄€ ≈ 0.05Re

Hydrodynamic

•⁄€ ≈ 4.4Re

Thermal

(fully-developed

flow)

Re ≥ 10W

ڠ

•⁄€ ≈ 0.05RePr

Re ≤ 2,300

) = 64⁄Re

Re ≤ 2,300

•⁄€ ≈ 10

entrance length

factor

Re ≤ 2,300

10 ≤ •⁄€ ≤ 60

entrance length

Darcy friction

number

Re ≥ 10W

Š 10†

‹

) = 0.0055 ˆ1 + ‰2 × 10

+

€ Re

W

) = 0.316⁄Re

⁄'

Œ

⁄W

) = B0.79•|Re − 1.64H

Dittus-Boelter correlation

Nu = 0.023ReZ.• P

4,000 ≤ Re

≤ 5 × 10•

Re ≤ 10U

Convective heat

transfer

--

[36]

---

[38]

--

[39]

0.7 ≤ Pr ≤ 100

Z. W

[36]

--

Re ≥ 10W

Re ≥ 10W

References

[37]

--

C

:N3 ⁄N? <

--

≤ 5 × 10†

Sieder-Tate correlation for turbulent flow:

⁄'

--

3,000 ≤ Re

| = 0.4 for heating and 0.3 for cooling

Nu = 0.027ReZ.• Pr

Prandtl number

[36]

0.7 ≤ Pr

≤ 16,700

Gnielinski correlation:

Nu = 0.012BReZ.•X

− 280HPr

+ B•⁄€ H

Z.W

2300 ≤ Re

™1

⁄'

š:› 3 ⁄› ? <

Z.

Hausen correlation:

Nu = 0.116:Re

⁄'

− 125<Pr

⁄'

≤ 10

†

:N3 ⁄N? <

Z. W

3500 ≤ Re

≤ 1.2 × 10W

Sieder-Tate correlation for laminar flow

Nu = 1.86Re

⁄'

Pr

⁄' B

•⁄€ H

⁄'

:N3 ⁄N? <

Re ≤ 2300

Z. W

21

0.6 ≤ Pr ≤ 10U

[40]

0.7 ≤ Pr ≤ 3

[41]

0.7 ≤ Pr

≤ 16700

[42]

4.1. Hydrodynamic Characteristics

The hydrodynamic characteristics, including the hydrodynamic entrance length, thermal entrance

length, and friction factor of FLiNaK flowing in a horizontal tube are numerically investigated

using the recommended thermophysical properties summarized in Table 4. Reynolds number of

FLiNaK investigated ranges from 100 to 1,800 for laminar flows and 10,000 to 100,000 for

turbulent flows.

4.1.1 Entrance Length

Hydrodynamic Entrance Length

The radial velocity of FLiNaK is set to be uniform at the tube inlet z = 0 to investigate the

hydrodynamic entrance length. Figure 10 shows the computed radial velocity profiles of FLiNaK

for a laminar flow (Re = 400) at different axial locations. The x and y axes are respectively the

nondimensional radial location r/R and velocity l/ B , œH⁄l0 , where R is the tube radius and l0 is

the mean velocity. The radial velocity profile, i.e., the radial distribution of the axial velocity,

changes in the hydrodynamically developing flow region (hydrodynamic entrance region), while

it remains unchanged (both the magnitude and shape) in the hydrodynamically fully-developed

flow region. If the relative change of the local velocity, |sl/ B , œH − l/ B , œ′Ht⁄l/ B , œH|, is less than

1%, the flow is considered to be hydrodynamically fully developed. The hydrodynamic entrance

length for FLiNaK is therefore identified to be 25D at Re = 400.

22

2

1.8

1.6

1.4

z/D = 0

z/D = 2.5

z/D = 5

z/D = 10

z/D = 15

z/D = 20

z/D = 25

z/D = 50

1.2

1

0.8

0.6

0.4

0.2

-1

-0.5

0

0.5

1

r/R

Figure 10 Radial velocity profiles of FLiNaK at different axial locations (Re = 400)

Figure 11 shows the non-dimensional hydrodynamic entrance length Lhyd/D for different Reynolds

numbers in a range of 100 to 1,800, where Lhyd and D are the hydrodynamic entrance length and

tube inner diameter, respectively. The CFD results show that the non-dimensional hydrodynamic

entrance length is linearly dependent on FLiNaK Reynolds number. The relative discrepancy

between the modeling results and a widely used correlation for hydrodynamic entrance length of

laminar flows [36]

•žŸ0>CŸ

,

¡ ⁄€

≈ 0.05¢V

(17)

is within 30% for Re = 100 – 1,800, which was also observed by Srivastava, et al. [43]. Therefore,

the uncertainty of Eq. (17) can be as high as 30% for Re = 100 to 1,800 using the CFD numerical

results as a reference.

23

120

CFD modeling

Lhyd / D = 0.05Re

100

L hyd / D

80

60

40

20

0

0

500

1000

1500

2000

Re

Figure 11 Hydrodynamic entrance length for FLiNaK in laminar flow regime

A similar simulation has also been performed for FLiNaK in turbulent flow regime. Figure 12

shows the non-dimensional hydrodynamic entrance length Lhyd/D for different Reynolds numbers

in a range of 10,000 to 100,000. The modeling results agree well with a widely used correlation

for hydrodynamic entrance length of turbulent flows [36]

10 ≤ •GF

£Fž¤CG,

¡ ⁄€

≤ 60

(18)

However, the modeling results deviate from the correlation [37]

•GF

£Fž¤CG,

¡ ⁄€

≈ 4.4¢V

ڠ

(19)

by 35%, which was also observed by Ferng, et al. [44]. Therefore, the uncertainty of Eq. (19) can

be as high as 35% for Re = 10,000 to 100,000 using the CFD numerical results as a reference.

24

L hyd / D

Figure 12 Hydrodynamic entrance length for FLiNaK in turbulent flow regime

Thermal entrance length

A constant wall heat flux 4 kW/m2 is applied for laminar flows and 100 kW/m2 for turbulent flows

to investigate the thermal entrance length. In addition, the FLiNaK temperature is set to be uniform

at the tube inlet z = 0. Figure 13 shows the computed radial temperature profiles of FLiNaK for a

laminar flow (Re = 400) at different axial locations. The x and y axes are respectively the

nondimensional radial location r/R and temperature = ∗ B , œH, which is defined as

™=3 B , œH − =6? BœHš¦™=3 B0, œH − =6? BœHš, where =3 and =6? are the fluid temperature and azimuthally

averaged wall temperature, respectively. The shape of the FLiNaK radial temperature profile

changes in the thermally developing flow region, while it remains unchanged in the thermally

fully-developed region. If the relative change of the temperature difference over a certain axial

distance §¨™=6? BœH − =3 B , œHš − ™=6? Bœ′H − =3 B , œ′Hš©¦™=6? BœH − =3 B , œHš§, is less than 1%, the

flow is considered to be thermally fully developed. The thermal entrance length is therefore

25

identified to be 500D at Re = 400 and Pr = 22.8 for FLiNaK at 500 °C, which has a 9.6%

discrepancy compared to the results estimated by [36]

•žŸ0>CŸ

,; ⁄€

≈ 0.05¢V›

(20)

A similar simulation has also been performed for FLiNaK in turbulent flow regime. The thermal

entrance length for FLiNaK is identified to be 12.5D at Re = 10,000, which has a 20% discrepancy

compared to [36]

•GF

£Fž¤CG,; ⁄€

≈ 10

(21)

1

0.8

z/D = 15

z/D = 25

z/D = 50

z/D = 125

z/D = 250

z/D = 500

z/D = 750

0.6

0.4

0.2

0

-1

-0.5

0

0.5

1

r/R

Figure 13 Radial temperature profiles of FLiNaK at different axial locations (Re = 400)

4.1.2 Friction Factor

The Darcy friction factor in the developing and hydrodynamically fully-developed regions are

numerically investigated for Re = 100 – 1,800 and 10,000 – 100,000. The friction factor decreases

significantly along the flow direction in the developing flow region, while it remains nearly

constant in the fully-developed flow region as shown in Figure 14(a) for laminar flows and Figure

26

14(b) for turbulent flows. The laminar flows shown in Figure 14(a) are hydrodynamically fully

developed at z/D > 115 or earlier, while they are thermally fully developed at z/D > 2,050 or earlier

under the conditions investigated. In addition, the turbulent flows shown in Figure 14(b) are

hydrodynamically fully developed at z/D > 40 or earlier, while become thermally fully developed

at z/D > 20 or earlier under the conditions investigated. These CFD results of FLiNaK in the

hydrodynamically and thermally fully-developed flow regions will be used to estimate

hydrodynamic and thermal performance of molten salts in circular tubes.

0.08

Re = 10 4

Re = 2 x 104

0.07

Re = 4 x 10

0.06

4

Re = 6 x 104

Re = 8 x 104

0.05

Re = 10 5

0.04

0.03

0.02

0.01

0

0

10

10

1

10

2

10

3

z/D

(a)

(b)

Figure 14 Darcy friction factor at different axial locations for FLiNaK in (a) laminar and (b)

turbulent flow regimes

Figure 15 shows comparisons of the Darcy friction factor among our CFD results for FLiNaK in

hydrodynamically and thermally fully-developed flow regions, FLiNaK experimental data, and

widely used friction factor correlations for flows in smooth and rough tubes. No data reprocessing

is needed for the experimental data, such as the Reynolds number and friction factor in the

literature [14] for laminar flows of FLiNaK due to the negligible differences between the

27

thermophysical properties of FLiNaK used in the literature [14] and recommended values in this

paper. As shown in Figure 15(a), the CFD results agree well with both the experimental data and

the correlation for fully-developed laminar flows [36]

) = 64⁄Re

(22)

The relative discrepancies between the CFD results and the experimental data, CFD and

correlation (Eq. (22)) results are within 13.7% and 6.3%, respectively. It is therefore appropriate

to use f = 64/Re for friction factor estimation of FLiNaK in fully-developed laminar flow regime.

0.06

FLiNaK - CFD modeling

FLiNaK - Experiment (Vriesema)

f = 0.316/Re

0.05

1/4

f = (0.79lnRe - 1.64)-2

Darcy friction factor

f = 0.0055[1 + (2 x 10 4 /D + 10 6/Re) 1/3], /D = 10 -3

Darcy friction factor

f = 0.0055[1 + (2 x 10 4 /D + 10 6/Re) 1/3], /D = 3 x 10 -3

0.04

f = 0.0055[1 + (2 x 10 4 /D + 10 6/Re) 1/3], /D = 5 x 10 -3

0.03

0.02

0.01

0

0

2

4

6

8

10

Re

12

10 4

(b)

(a)

Figure 15 Darcy friction factor of FLiNaK in (a) laminar and (b) turbulent flow regimes

The numerical results of the friction factor for hydrodynamically fully-developed FLiNaK

turbulent flows are compared with the experimental data as shown in Figure 15(b). Due to the large

differences between the FLiNaK thermophysical properties used during data reduction in the

literature [5] and recommended values in this paper (Table 4), the original experimental data [5]

has been reprocessed by adopting the recommended properties of FLiNaK. In addition, it needs to

be noted that there is one typo in a figure summarizing the experimental data in Reference [5]: The

28

pressure loss of FLiNaK in a straight-tube test section was misplaced in the column for the pressure

loss of FLiNaK in a Venturi tube. The pressure drop over a Venturi tube was used to calculate the

FLiNaK velocity, which was used to compute the FLiNaK Reynolds number. This typo is

recognized because: (1) The pressure loss in the Venturi tube should be several times larger than

that in the straight-tube test section based on the methodology adopted in Reference [5]. However,

this is the opposite in Figure 3.3-7 of Reference [5]; and (2) The computed friction factor after this

correction (switch the pressure drop experimental data for the straight-tube test section with that

in the Venturi tube) completely agrees with the friction factor plot Figure 3.3-9 in Reference [5].

The Darcy friction factor of FLiNaK for turbulent flows in smooth tubes obtained from our CFD

simulations is compared with two correlations [36,39]:

) = 0.316⁄Re

⁄W

(23)

) = B0.79lnRe − 1.64H

(24)

The relative discrepancy between the CFD and correlation (Eqs. (23) and (24)) results is within

9.7% as shown in Figure 15(b). However, it is in general significantly lower than the experimental

values. This large discrepancy may be due to the increased roughness of the tube inner surface

considering the corrosion effect of the FLiNaK to the test section wall at high temperatures. In

viewing this, we used three relative roughness, ɛ/D = 10-3, 3×10-3, and 5×10-3, to estimate the

friction factor of turbulent flows in a rough tube using the following correlation [38]:

«

) = 0.0055 ª1 + !2 × 10W +

+

Z{

¬-

"

⁄'

®

(25)

The FLiNaK friction factor based on Eq. (25) for ɛ/D = 3×10-3 agrees well (±23.6% uncertainties)

with 95% of the experimental data.

29

4.2. Thermal Characteristics

4.2.1 Laminar Flow Regime

For high-Prandtl number fluids, such as molten salts, the thermal entrance length in a circular tube

can be significantly large for laminar flows. Taking D = 0.01 m, Re = 1,000, and Pr = 10 as an

example, the thermal entrance length L can be as high as 5 m using Eq. (20). It is therefore difficult

to ensure that the flow is thermally developed prior to entering the test section in a limited

laboratory space. The molten salt experimental data presented in References [12, 13] were obtained

in hydrodynamically fully developed, but thermally developing laminar flows in a circular tube.

Therefore, the Nusselt number obtained from these experiments [12, 13] should be larger than

4.36, a theoretical Nu value for thermally fully-developed laminar flows in circular tubes under

constant wall heat flux conditions. As shown in Figure 16(a), the Nusselt number in these two

experiments is about 0.6 – 2.4 times larger than the theoretical value Nu = 4.36, while the CFD

results for thermally fully-developed laminar flows of FLiNaK and LiF-BeF2-ThF4-UF4 agree well

with the theoretical value within 6.9% difference.

16

FLiNaK-CFD modeling

LiF-BeF 2 -ThF 4 -UF4 -CFD modeling

14

LiF-BeF 2 -ThF 4 -UF4 - Exp. (Cooke, et al.)

LiF-BeF 2 -ThF 4 -UF4 - Exp. (Silverman, et al.)

12

Constant heat flux: Nu=4.36

Nu/Pr 1/3

10

8

6

4

2

0

0

500

1000

1500

2000

2500

Re

(b)

(a)

Figure 16 Nusselt numbers of FLiNaK and LiF-BeF2-ThF4-UF4 laminar flows compared with (a)

Nu = 4.36 (constant heat flux) and (b) Sieder-Tate laminar flow correlation

30

The Sieder-Tate correlation (laminar flow) [42]

Nu = 1.86Re

⁄'

⁄' B

• ⁄€ H

Pr

⁄'

(26)

is compared with the experimental data from References [12, 13] as shown in Figure 16(b).

Compared to the theoretical value, Nu = 4.36 for fully-developed laminar flows in circular tubes,

the Sieder-Tate correlation (laminar flow) results are closer to the experimental data by taking the

thermal entrance effect into consideration. However, the maximum discrepancy between the

results of Sieder-Tate correlation and the experimental data is still significant, 26.9%. This large

discrepancy is likely to be resulted from the radiative heat transfer presented in the experiments at

high temperatures. Further investigation of the thermal radiation properties of LiF-BeF2-ThF4-UF4,

such as its absorption coefficient, is therefore suggested. In this study, a curve is fitted based on a

least square regression analysis of the experimental data, which results in

Nu = ReZ.WWU Pr

⁄' B

• ⁄€ H

⁄'

(27)

The experimental data are generally within a ±15% uncertainty range of the above revised

Sieder-Tate correlation, i.e., Eq. (27).

4.2.2 Transitional and Turbulent Flow Regimes

The Nusselt number computed based on the CFD simulations are compared with the experimental

data in molten salt experiments summarized in Table 2 and convective heat transfer correlations

summarized in Table 5 for transitional and turbulent flows, such as the Dittus-Boelter Eq. (28),

Gnielinski Eq. (29), Sieder-Tate (turbulent flow) Eq. (30), and Hausen Eq. (31) correlations.

Nu = 0.023ReZ.• P

C

(n = 0.4 for heating and 0.3 for cooling)

Nu = 0.012BReZ.•X − 280HPr Z.W ™1 + B•⁄€ H

31

⁄'

š:› 3 ⁄› ? <

Z.

(28)

(29)

Nu = 0.027ReZ.• Pr

Nu = 0.116:Re

⁄'

⁄'

− 125<Pr

(30)

⁄'

(31)

Comparison with the Dittus-Boelter Correlation

As shown in Figure 17, the CFD results of FLiNaK and LiF-BeF2-ThF4-UF4 in general agree well

with the experimental data. In addition, both the CFD results and 90% of the total experimental

data points fall within a ±20% uncertainty range of the Dittus-Boelter correlation. Therefore, the

Dittus-Boelter correlation is generally good for modeling salt heat transfer in turbulent flow

regime.

+20%

-20%

Figure 17 Comparison among the CFD results, experimental data, and Dittus-Boelter correlation

for salt heat transfer coefficient

32

Comparison with the Gnielinski Correlation

Similarly, the CFD results of FLiNaK and LiF-BeF2-ThF4-UF4 are within a ±11.4% uncertainty

range of the Gnielinski correlation as shown in Figure 18. In addition, nearly 90% of the

experimental data points fall within a ±20% uncertainty range of the Gnielinski correlation, while

5% of the experimental data points deviate from the Gnielinski correlation results significantly, by

40% and the remaining 5% data points deviate by 150%. Except for the experimental data from

Hoffman [4] who used nickel and SS 316 tubes in the experiments, the Gnielinski correlation in

general predicts accurately the molten salt heat transfer behavior for 2,300 ≤ Re ≤ 50,000.

+20%

-20%

Figure 18 Comparison among the CFD results, experimental data, and Gnielinski correlation for

salt heat transfer coefficient

33

In Hoffman’s experiments, nickel, Inconel, and SS 316 were used as the tube materials. Since the

Nusselt values derived from the FLiNaK-Inconel experimental data are much lower than those

derived from their other two experiments, i.e., FLiNaK-nickel and FLiNaK-SS 316 experiments,

Hoffman concluded that the significant deviation was due to the formation of a corrosion layer on

the inner tube surface during the FLiNaK-Inconel experiment [3]. However, Ambrosek, et al., [45]

and Yoder, et al., [46] disputed the explanation since Inconel and SS 316 should exhibit similar

corrosion resistance to FLiNaK at similar temperatures.

Table 6 summarizes the nominal compositions of Inconel 600, Nickel 200, and SS 316. Chromium

(Cr) contents in Inconel 600 and SS 316 are in very similar ranges. Chromium is more likely to

dissolute in FLiNaK compared with Ni and Fe due to the least formation free energy of CrF2 as

summarized in Table 7 [48]. Therefore, the salt corrosion effect on FLiNaK heat transfer

experiments using Inconel 600 and SS 316 as the tube materials should behave similarly if the

initial purity level in FLiNaK is the same for the three tests and the rest of testing conditions are

very similar, including the salt temperature, salt volume, and test period. A number of publications

[49-51] demonstrated that compared with Inconel 600, SS 316L/316H has a similar or even lower

corrosion rate in FLiNaK salt environment. However, the experimental data from Hoffman’s

FLiNaK-SS 316 experiment are about 100% higher than those from their own FLiNaK-Inconel

experiment. In addition, Nickel 200 is corrosion resistant to FLiNaK, but the experimental data

using the nickel tube show significantly higher values than those using Hastelloy N, another

corrosion resistant alloy to FLiNaK. It is therefore hypothesized that there were most likely some

abnormal conditions un-attended in Hoffman’s FLiNaK-SS 316 and FLiNaK-Nickel experiments.

New heat transfer experiments for FLiNaK in SS 316 and nickel tubes would be necessary.

34

Table 6 Nominal compositions of Inconel 600, nickel 200, and SS 316 (wt%) [47]

Ni

Cr

Fe

Mo

Mn

Si

C

Inconel 600

> 72.0

14.0-17.0

6.0-10.0

--

< 1.0

< 0.5

< 0.15

Nickel 200

> 99.0

--

--

--

< 0.35

< 0.35

< 0.15

SS 316

10.0-14.0

16.0-18.0

Balance

2.0-3.0

< 2.0

< 0.75

< 0.08

Table 7 Formation free energy of fluorides at 1000 K [48]

Compound

CrF2

FeF2

NiF2

MoF6

Free energy (kJ)

-314

-280

-230

-209

Comparison with the Sieder-Tate and Hausen Correlations

Since most of the heat transfer experimental data presented in the literature are in the form of

Nu/Pr1/3, the CFD results are written in the same format and compared with these experimental

data and Sieder-Tate (turbulent) and Hausen correlations as shown in Figure 19. The experimental

data using oil as the working fluid [52] are included as well. The CFD results of FLiNaK and LiFBeF2-ThF4-UF4 agree well with the experimental data, except again for the data derived from

Hoffman’s experiments. In addition, both the CFD results and most of the experimental data are

within a ±20% uncertainty range of the Sieder-Tate correlation (turbulent) for 10,000 ≤ Re ≤

120,000. In addition, Hausen correlation predicts the molten salt heat transfer coefficient with

±20% uncertainties for 5,000 ≤ Re ≤ 10,000, while ±40% uncertainties for 2,300 ≤ Re ≤ 5,000.

35

+20%

-20%

Figure 19 Comparison with the Sieder-Tate and Hausen correlations

It is believed that the larger experimental data compared to the CFD results and Hausen correlation

for Re = 2,300 – 3,000 results from the effect of radiative heat transfer in the experiments.

However, the comparison appears to suggest that the effect of radiative heat transfer in molten salts

could be neglected for flows of large salt Reynolds numbers, such as Re > 3,000 because of

significantly increased convective heat transfer coefficient. A curve is fitted based on a least square

regression analysis of the experimental data located in the transitional flow region as

36

Nu = 0.116BRe

/'

− 115HPr

/'

(32)

The experimental data fall within a ±20% uncertainty range of the above revised Hausen

correlation, i.e., Eq. (32).

5. CONCLUSION

This paper numerically investigated the thermal and hydrodynamic characteristics of molten salts

in circular tubes using a CFD tool, STAR CCM+. The numerical results were validated by

comparing with (1) modified experimental results using more accurate and consistent

thermophysical properties of molten salts and (2) widely used convective heat transfer coefficient

and friction factor models/correlations. Several concluding remarks are summarized as follows:

(1) For the hydrodynamic and thermal entrance lengths of molten salts in laminar and turbulent

flows, the discrepancy between the CFD results and related correlations, Eqs. (17) to (21),

is 9.6% to 35%;

(2) For the friction factor of molten salts in fully-developed laminar flows, the discrepancy

between the CFD results and Eq. (22) is within ±6.3% uncertainties. However, the molten

salt friction factor values in fully-developed turbulent flows estimated by STAR CCM+

and related correlations, Eqs. (23) and (24), are much lower than those from the

experimental data. This large discrepancy most likely results from the increased surface

roughness of the tube due to corrosion by salts in high temperature environments. If a

relative roughness ɛ/D = 3×10-3 is adopted in Eq. (25) to consider the increased surface

roughness due to corrosion, the discrepancy between the correlation results and the

experimental data will decrease to 23.6%;

37

(3) For molten salt heat transfer in laminar and turbulent flow regimes, the Nusselt number

estimated by STAR CCM+ is within ±20% uncertainties of convective heat transfer

correlations, including the Dittus-Boelter, Gnielinski, and Sieder-Tate correlations.

(4) The Dittus-Boelter correlation predicts the molten salt heat transfer coefficient with ±20%

uncertainties for 10,000 ≤ Re ≤ 50,000 and 4 ≤ Pr ≤ 12;

(5) The Gnielinski correlation predicts molten salt heat transfer coefficient with ±20%

uncertainties for 2,300 ≤ Re ≤ 50,000 and 4 ≤ Pr ≤ 19;

(6) The Sieder-Tate correlation for turbulent flows predicts molten salt heat transfer coefficient

with ±20% uncertainties for 10,000 ≤ Re ≤ 120,000 and 4 ≤ Pr ≤ 27, while the Sieder-Tate

correlation for laminar flows underpredicts the molten salt heat transfer coefficient by

26.9% for 400 ≤ Re ≤ 2,300 and 5 ≤ Pr ≤ 10. The larger heat transfer coefficient values

obtained from experimental data in the laminar flow regime result from the effect of

radiative heat transfer in molten salt experiments, while this effect is not considered in our

numerical analyses due to unknown radiation properties of the salts under the conditions

investigated. A revised Sieder-Tate correlation, Nu = ReZ.WWU Pr

/' B

•/€H

/'

, predicts the

molten salt heat transfer coefficient within ±15% uncertainties for 400 ≤ Re ≤ 2,300 and 5

≤ Pr ≤ 10;

(7) The Hausen correlation predicts the molten salt heat transfer coefficient with ±20%

uncertainties for 5,000 ≤ Re ≤ 50,000 and 4 ≤ Pr ≤ 27, while ±40% uncertainties for 2,300

≤ Re ≤ 5,000 and 4 ≤ Pr ≤ 27. A revised Hausen correlation, Nu = 0.116BRe

115HPr

/'

/'

−

, predicts the molten salt heat transfer within ±20% uncertainties for 2,300 ≤ Re

≤ 10,000 and 4 ≤ Pr ≤ 27;

38

ACKNOWLEDGMENTS

This research was performed using funding received from the Department of Energy (DOE) Office

of Nuclear Energy’s Nuclear Energy University Program (NEUP). The authors appreciate the

financial support from the DOE NEUP office and technical support from the technical point of

contact Dr. David Holcomb of the Oak Ridge National Laboratory.

REFERENCES

[1] D. F. Williams, L. M. Toth, and K. T. Clarno, “Assessment of Candidate Molten Salt Coolants

for the Advanced High-Temperature Reactor (AHTR),” ORNL/TM-2006/12, Oak Ridge National

Laboratory (2006).

[2] M. Mehos, C. Turchi, J. Vidal, M. Wagner, and Z. Ma, “Concentrating Solar Power Gen3

Demonstration Roadmap,” NREL/TP-5500-67464, National Renewable Energy Laboratory

(2017).

[3] M. Grele and L. Gedeon, “Forced Convection Heat Transfer Characteristics of Molten FLiNaK

Flowing in an Inconel X System,” NACA RM E53L18, National Advisory Committee for

Aeronautics (1954).

[4] H. Hoffman and J. Lones, “Fused Salt Heat Transfer, Part II: Forced Convection Heat Transfer

in Circular Tubes Containing NaF-KF-LiF Eutectic,” ORNL-1777, Oak Ridge National

Laboratory (1955).

[5] I. Vriesema, “Aspects of Molten Fluorides as Heat Transfer Agents for Power Generation,”

Delft University of Technology, Doctor Dissertation, Netherlands (1979).

[6] H. Hoffman and S. Cohen, “Fused Salt Heat Transfer, Part III: Forced Convection Heat Transfer

in Circular Tubes Containing the Salt Mixture NaNO2-NaNO3-KNO3,” ORNL-2433, Oak Ridge

National Laboratory (1960).

39

[7] Y. Chen, Y. Wang, J. Zhang, X. Yuan, J. Tian, Z. Tang, H. Zhu, Y. Fu, and N. Wang, “Convective

Heat Transfer Characteristics in the Turbulent Region of Molten Salt in Concentric Tube,” Applied

Thermal Engineering, 98, pp. 213-219 (2016).

[8] J. Qian, Q. Kong, H. Zhang, Z. Zhu, W. Huang, and W. Li, “Performance of a Gas Cooled

Molten Salt Heat Exchanger,” Applied Thermal Engineering, 108, pp. 1429-1435 (2016).

[9] J. Qian, Q. Kong, H. Zhang, Z. Zhu, W. Huang, and W. Li, “Experimental Study for Shell-andtube Molten Salt Heat Exchangers,” Applied Thermal Engineering, 124, pp. 616-623 (2017).

[10] Y. Wu, B. Liu, C. Ma, and H. Guo, “Convective Heat Transfer in the Laminar-turbulent

Transition Region with Molten Salt in a Circular Tube,” Experimental Thermal and Fluid Science,

33, pp. 1128-1132 (2009).

[11] B. Liu, Y. Wu, C. Ma, M. Ye, and H. Guo, “Turbulent Convective Heat Transfer with Molten

Salt in a Circular Pipe,” International Communications in Heat and Mass Transfer, 36, pp. 912916 (2009).

[12] M. Silverman, W. Huntley, and H. Robertson, “Heat Transfer Measurements in a Forced

Convection Loop with `Two Molten-Fluoride Salts: LiF-BeF2-ThF4-UF4 and Eutectic NaBF4NaF,” ORNL/TM-5335, Oak Ridge National Laboratory (1976).

[13] J. Cooke and B. Cox, “Forced Convection Heat Transfer Measurements with A Molten

Fluoride Salt Mixture Flowing in a Smooth Tube,” ORNL-TM-4079, Oak Ridge National

Laboratory (1973).

[14] H.S. Jeong and K.H. Bang, “A Design of He-Molten Salt Intermediate Heat Exchanger for

VHTR,” Transactions of the Korean Nuclear Society Autumn Meeting, Jeju, Korea, October 2122 (2010).

40

[15] L. Schwer, “Is Your Mesh Refined Enough? Estimating Discretization Error using GCI,” LSDYNA Anwenderforum, Bamberg (2008).

[16] M. Chen, X. Sun, and R. Christensen, “Thermal-hydraulic Performance of Printed Circuit

Heat Exchangers with Zigzag Flow Channels,” International Journal of Heat and Mass Transfer,

130, pp. 356-367 (2019).

[17] E. Bohlmann, “Heat Transfer Salt for High Temperature Steam Generation,” ORNL -TM3777, Oak Ridge National Laboratory (1972).

[18] W. Grimes, E. Bohlmann, H. McDuffie, G. Watson, F. Blankenship, and C. Secoy, “Reactor

Chemistry Division Annual Progress Report,” ORNL-3913, Oak Ridge National Laboratory

(1966).

[19] D. Williams, “Assessment of Candidate Molten Salt Coolants for the NGNP/NHI Heattransfer Loop,” ORNL/TM-2006/69, Oak Ridge National Laboratory (2006).

[20] M. Chrenkova, V. Danek, A. Silny, and E. Polyakov, “Density and Viscosity of the (LiF-NaFKF) eut-KBF4-B2O3 Melts,” Journal of Molecular Liquids, 102, pp. 213-226 (2003).

[21] J. Cibulkova, M. Chrenkova, R. Vasiljev, V. Kremenetsky, and M. Boca, “Density and

Viscosity of the (LiF + NaF + KF)eut (1) + K2TaF2(2) + Ta2O5(3) Melts,” Journal of Chemical &

Engineering Data, 51, pp. 984-987 (2006).

[22] B. Kubikova, I. Mackova, and M. Boca, “Phase Analysis and Volume Properties of the (LiFNaF-KF)eut -K2ZeF6 System,” Monatshefte Fur Chemie, 144, pp. 295-300 (2013).

[23] J. Cheng, P. Zhang, X. An, K. Wang, Y. Zuo, H. Yan, and Z. Li, “A Device for Measuring the

Density and Liquidus Temperature of Molten Fluorides for Heat Transfer and Storage,” Chinese

Physics Letters, 30, 126501, pp. 1- 4 (2013).

41

[24] W.D. Powers, S.L. Cohen, and N.D. Greene, “Physical Properties of Molten Reactor Fuels

and Coolant,” Nuclear Science and Engineering, 71, pp. 200-211 (1963).

[25] B. Kubikova, V. Pavlik, and I. Mackova, “Surface Tension and Viscosity of the Molten (LiFNaF-KF)eut – K2ZrF6 System,” Monatshefte Fur Chemie, 143, pp. 1459-1462 (2012).

[26] A. Merzlyakov, V. Ignatiev, and S. Abalin, “Viscosity of LiF-NaF-KF Eutectic and Effect of

Cerium Trifluoride and Uranium Tetrafluoride Additions,” Nuclear Engineering and Design, 278,

pp. 268-273 (2014).

[27] G. Janz and R. Tomkins, “Physical Properties Data Compilations Relevant to Energy Storage,

IV. Molten Salts: Data on Additional Single and Multi-Component Salt Systems,” NSRDS-NBS

61, National Standard Reference Data System (1981).

[28] X. An, J.H. Cheng, H.W. Yin, L.D. Xie, and P. Zhang, “Thermal Conductivity of High

Temperature Fluoride Molten Salt Determined by Laser Flash Technique,” International Journal

of Heat and Mass Transfer, 90, pp. 872-877 (2015).

[29] D. Rogers, T. Yoko, and G. Janz, “Fusion Properties and Heat Capacities of the Eutectic LiFNaF-KF Melt,” Journal of Chemistry Engineering Data, 27, pp. 366-367 (1982).

[30] M. Rosentha, R. Briggs, and P. Kasten, “Molten Salt Reactor Program Semiannual Progress

Report,” ORNL-4344, Oak Ridge National Laboratory (1969).

[31] A. Bergman and E. Dergunov, “Fusion Diagram of LiF-KF-NaF,” Comptes Rendus Academy

of Sciences URSS, 31, pp. 753-754 (1941).

[32] M.V. Smirnov, V.A. Khokhlov, and E.S. Filatov, “Thermal Conductivity of Molten AlKali

Halides and Their Mixtures,” Electrochemica Acta, 32, pp. 1019-1026 (1987).

[33] L. Cooper and S.J. Claiborne, “Measurement of the Thermal Conductivity of FLiNaK,”

ORNL 52.8-163, Oak Ridge National Laboratory (1952).

42

[34] W.J. Parker, R.J. Jenkins, C.P. Butler, and G.L. Abbott, “Method of Determining Thermal

Diffusivity, Heat Capacity and Thermal Conductivity,” Journal of Applied Physics, 32, pp. 16791684 (1961).

[35] R.R. Romatoski and L.W. Hu, “Fluoride Salt Coolant Properties for Nuclear Reactor

Applications: A Review,” Annals of Nuclear Energy, 109, pp. 635-647 (2017).

[36] T. Bergman, A. Lavine, F. Incropera, and D. Dewitt, “Fundamentals of Heat and Mass

Transfer, seventh edition,” John Wiley & Sons (2011).

[37] Y.A. Cimbala and J.M. Cengel, “Fluid Mechanics: Fundamentals and Applications, 1st

edition,” Boston: McGraw-Hill Higher Education.

[38] L.F. Moody, “Friction Factors for Pipe Flow,” Transactions of the ASME, 66, pp. 671-684

(1944).

[39] B.S. Massey, “Mechanics of Fluids, eighth edition,” Taylor & Francis (2006).

[40] S. Kakac, Y. Yener, and A. Pramuanjaroenkij, “Convective Heat Transfer,” Third Edition,

CRC Press (2014).

[41] H. Hausen, “Neue Gleichungen fur die Wameiibertragung bei Freier oder Erzwungerner

Stromung,” Allg. Warmetchn., 9, pp. 75–79 (1959).

[42] E. Sieder and G. Tate, “Heat Transfer and Pressure Drop of Liquids in Tubes,” Industrial and

Engineering Chemistry, 28, pp. 1429-1435 (1936).

[43] A.K. Srivastava, A.M. Vaidya, N.K. Maheshwari, and P.K. Vijayan, “Heat Transfer and

Pressure Drop Characteristics of Molten Fluoride Salt in Circular Pipe,” Applied Thermal

Engineering, 61, pp. 198-205 (2013).

43

[44] Y.M. Ferng, K.Y. Lin, and C.W. Chi, “CFD Investigating Thermal-Hydraulic Characteristics

of FLiNaK Salt as a Heat Exchanger Fluid,” Applied Thermal Engineering, 37, pp. 235-240

(2012).

[45] J. Ambrosek, M. Anderson, K. Sridharan, and T. Allen, “Current Status of Knowledge of the

Fluoride Salt (FLiNaK) Heat Transfer,” Nuclear Technology, 165, pp. 166-173 (2009).

[46] G.L. Yoder, “Examination of Liquid Fluoride Salt Heat Transfer,” Proceedings of ICAPP

2014, Charlotte, NC, USA, pp. 1765-1774 (2014).

[47] https://www.specialmetals.com/, accessed on 4/20/2018

[48] C. Baes, “The Chemistry and Thermodynamics of Molten Salt Reactor Fuels,” Journal of

Nuclear Materials, 51, pp. 149-162 (1974).

[49] F. Rahnema, “Integrated Approach to Fluoride High Temperature Reactor Technology and

Licensing Challenges,” 2nd Molten Salt Reactor Workshop, Oak Ridge, TN, October 4-5 (2016).

[50] S. Zhang, M. Chen, S. Shi, X. Sun, and R. Christensen, “Corrosion Behavior of Stainless Steel

316H in LiF-NaF-KF (FLiNaK) at High temperatures,” Transactions of the American Nuclear

Society, 117, pp. 132-135 (2017).

[51] D. Feron, “Nuclear Corrosion Science and Engineering,” WP Woodhead Publishing (2012).

[52] F. Morris and W. Whitman, “Heat Transfer for Oils and Water in Pipes,” Industrial and

Engineering Chemistry, 20, pp. 234-240 (1928).

44