Validation Guidelines for Systems, Utilities, and Equipment

advertisement

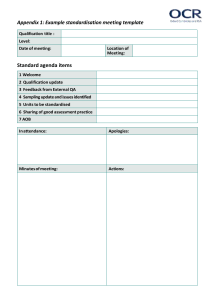

Working document QAS/16.673 June 2016 Draft document for comment 1 4 GUIDELINES ON VALIDATION – APPENDIX 6 VALIDATION ON QUALIFICATION OF SYSTEMS, UTILITIES AND EQUIPMENT 5 (June 2016) 6 DRAFT FOR COMMENTS 2 3 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 Should you have any comments on the attached text, please send these to Dr S. Kopp, Group Lead, Medicines Quality Assurance, Technologies, Standards and Norms (kopps@who.int) with a copy to Ms Marie Gaspard (gaspardm@who.int) by 15 August 2016. Medicines Quality Assurance working documents will be sent out electronically only and will also be placed on the Medicines website for comment under “Current projects”. If you do not already receive our draft working documents please let us have your email address (to bonnyw@who.int) and we will add it to our electronic mailing list. . 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 © World Health Organization 2016 All rights reserved. This draft is intended for a restricted audience only, i.e. the individuals and organizations having received this draft. The draft may not be reviewed, abstracted, quoted, reproduced, transmitted, distributed, translated or adapted, in part or in whole, in any form or by any means outside these individuals and organizations (including the organizations' concerned staff and member organizations) without the permission of the World Health Organization. The draft should not be displayed on any website. Please send any request for permission to: Dr Sabine Kopp, Group Lead, Medicines Quality Assurance, Technologies, Standards and Norms, Regulation of Medicines and other Health Technologies, Department of Essential Medicines and Health Products, World Health Organization, CH-1211 Geneva 27, Switzerland. Fax: (41-22) 791 4730; email: kopps@who.int. The designations employed and the presentation of the material in this draft do not imply the expression of any opinion whatsoever on the part of the World Health Organization concerning the legal status of any country, territory, city or area or of its authorities, or concerning the delimitation of its frontiers or boundaries. Dotted lines on maps represent approximate border lines for which there may not yet be full agreement. The mention of specific companies or of certain manufacturers’ products does not imply that they are endorsed or recommended by the World Health Organization in preference to others of a similar nature that are not mentioned. Errors and omissions excepted, the names of proprietary products are distinguished by initial capital letters. All reasonable precautions have been taken by the World Health Organization to verify the information contained in this draft. However, the printed material is being distributed without warranty of any kind, either expressed or implied. The responsibility for the interpretation and use of the material lies with the reader. In no event shall the World Health Organization be liable for damages arising from its use. This draft does not necessarily represent the decisions or the stated policy of the World Health Organization. Working document QAS/16.673 page 2 49 50 51 52 53 54 SCHEDULE FOR THE PROPOSED ADOPTION PROCESS OF DOCUMENT QAS/16.673: GUIDELINES ON VALIDATION – APPENDIX 6 VALIDATION ON QUALIFICATION OF SYSTEMS, UTILITIES AND EQUIPMENT 55 56 Discussion of proposed need for revision in view of the current trends in validation during informal consultation on data management, bioequivalence, GMP and medicines’ inspection Preparation of draft proposal for revision of the main text and several appendices by specialists in collaboration with the Medicines Quality Assurance Group and Prequalification Team (PQT)-Inspections, based on the feedback received during the meeting and from PQTInspections, draft proposals developed on the various topics by specialists, as identified in the individual working documents. Presentation of the progress made to the fiftieth meeting of the WHO Expert Committee on Specifications for Pharmaceutical Preparations Discussion at the informal consultation on good practices for health products manufacture and inspection, Geneva Preparation of revised text by Dr A.J. van Zyl, participant at the above-mentioned consultation, based on the feedback received during and after the informal consultation by the meeting participants and members of PQT-Inspections Circulation of revised working document for public consultation Consolidation of comments received and review of feedback Presentation to the fifty-first meeting of the WHO Expert Committee on Specifications for Pharmaceutical Preparations Any other follow-up action as required 88 89 90 57 58 59 60 61 July 2015– 62 April 2016 63 64 65 66 67 68 12–16 October 2015 69 70 71 4–6 April 2016 72 73 May 2016 74 75 76 77 78 June 2016 79 August–September80 81 2016 82 17–21 October 2016 83 84 85 … 86 87 29 June– 1 July 2015 Working document QAS/16.673 page 3 91 92 93 94 95 96 97 98 99 100 101 102 103 104 105 106 107 108 109 110 111 112 113 114 115 116 117 118 119 120 121 122 123 124 125 126 127 128 129 130 131 132 133 134 135 Background information The need for revision of the published Supplementary guidelines on good manufacturing practices: validation (World Health Organization (WHO) Technical Report Series, No. 937, 2006, Annex 4) was identified by the Prequalification of Medicines Programme and a draft document was circulated for comment in early 2013. The focus of the revision was the Appendix on non-sterile process validation (Appendix 7), which had been revised and was adopted by the Committee at its forty-ninth meeting in October 2014. The main text was sent out for consultation as Working document QAS/15.639 entitled “Guidelines on Validation” which constitute the general principles of the new guidance on validation. The draft on the specific topics, the appendices to this main text, will follow. One of them, i.e. the Validation on qualification of systems, utilities and equipment, constitutes this working document. The following is an overview on the appendices that are intended to complement the general text on validation: Appendix 1 Validation of heating, ventilation and air-conditioning systems will be replaced by cross-reference to WHO Guidelines on GMP for HVAC systems for considerations in qualification of HVAC systems (update - working document QAS/15.639/Rev.1) Appendix 2 Validation of water systems for pharmaceutical use will be replaced by cross-reference to WHO Guidelines on water for pharmaceutical use for consideration in qualification of water purification systems Appendix 3 Cleaning validation – consensus to retain Appendix 4 Analytical method validation will be replaced by update - working document QAS/16.671 Appendix 5 Validation of computerized systems will be replaced by update - working document QAS/16.667 Appendix 6 Qualification of systems, utilities and equipment – updated text proposed in this working document Working document QAS/16.673 page 4 136 137 138 139 Appendix 7 Non-sterile process validation – update already published as Annex 3, WHO Technical Report Series, No. 992, 2015 Working document QAS/16.673 page 5 GUIDELINES ON VALIDATION – APPENDIX 6 VALIDATION ON QUALIFICATION OF SYSTEMS, UTILITIES AND EQUIPMENT 140 141 142 143 144 145 146 147 148 149 150 151 152 153 154 155 156 157 158 159 160 161 162 163 164 165 166 167 168 169 170 171 172 173 174 175 176 177 178 179 180 181 182 183 184 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. Principle Scope Glossary General User requirement specifications Factory acceptance test and site acceptance test Design qualification Installation qualification Operational qualification Performance qualification Requalification Qualification of “in use” systems and equipment 1. PRINCIPLE 1.1 Systems, utilities and equipment should be appropriately designed, located, installed, operated, cleaned and maintained to suit their intended purpose. 1.2 Products should be manufactured on qualified equipment to ensure batch-to-batch consistency 1.3 Procedures should be in place to ensure that systems, utilities and equipment remain in a qualified state throughout the life of the system, utility and equipment. 2. SCOPE 2.1 These guidelines describe the general aspects of qualification for systems, utilities and equipment. 2.2 The principles in this guideline may also be applied to the qualification of instruments and testing devices, where appropriate. 2.3 Systems, utilities and equipment that may have an impact on the quality of products, should be appropriately qualified. These may include, where appropriate: computerized systems; water purification systems; heating, ventilation and air conditioning systems; compressed air systems; steam systems; production and quality control of equipment and instruments. 2.4 Documented impact assessments should support decisions for the exclusion of systems, utilities and equipment from qualification. Working document QAS/16.673 page 6 185 186 187 188 189 190 191 192 193 194 195 196 197 198 199 200 201 202 203 204 205 206 207 208 209 210 211 212 213 214 215 216 217 218 219 220 221 222 223 224 225 226 227 228 229 3. GLOSSARY design qualification. Documented evidence that the premises, supporting systems, utilities, equipment and processes have been designed in accordance with the requirements of good manufacturing practices. factory acceptance test. A test conducted at the vendor’s premises to verify that the system, equipment or utility, as assembled or partially assembled, meets expected specifications. (new) installation qualification. The performance of tests to ensure that the installations (such as machines, measuring devices, utilities and manufacturing areas) used in a manufacturing process are appropriately selected and correctly installed and operate in accordance with established specifications. operational qualification. Documented verification that the system or subsystem performs as intended over all anticipated operating ranges. performance qualification. Documented verification that the equipment or system operates consistently and gives reproducibility within defined specifications and parameters for prolonged periods. (In the context of systems, the term “process validation” may also be used.) site acceptance test. A test conducted at the site of use to verify that the system, equipment or utility, as assembled or partially assembled meets expected specifications. (new) system. A regulated pattern of interacting activities and techniques that are united to form an organized whole. user requirement specifications. An authorized document that defines the requirements for use of the system, equipment or utility in its intended production environment. (amended) utility. A system consisting of one or more components to form a structure designed to collectively operate, function or perform and provide a service such as electricity, water, ventilation or other. (new) 4. GENERAL 4.1 The validation master plan, or other relevant document, should specify the policy, organization, planning, scope and stages applied in qualification for systems, utilities and equipment and should cover, e.g. production, quality control and engineering. 4.2 The scope and extent of qualification and requalification should be determined based on the principles of impact assessment and risk assessment. Risk management principles should be considered in all areas of the scope and stages of qualification. Working document QAS/16.673 page 7 230 231 232 233 234 235 4.3 Where appropriate, new systems, utilities and equipment should pass through all stages of qualification including the preparation of user requirement specifications (URS), design qualification (DQ), installation qualification (IQ), operational qualification (OQ) and performance qualification (PQ) (see Figure 1 as an example). Figure 1. Examples of stages of qualification V-Model for Direct Impact Systems PQ Test Plan User Requirement Specification Performance Qualification Design Qualification (incl. UAT) OQ Test Plan Functional Design Specification Operational Qualification (incl. FAT) DQ Test Plan IQ Test Plan Detail Design and Configuration Specifications (incl. PDI) Installation Qualification Build & Project Implementation 236 237 238 239 240 241 242 243 244 245 246 247 248 249 250 251 252 253 254 (Note: For description of stages, see below) 4.4 Scientific justification should be provided where it is decided that not all stages of qualification are required. [Note from the Secretariat: The references below will be updated upon finalization of the related texts.] 4.5 See WHO TRS XXX for aspects to be considered for inclusion in qualification of water purification systems 4.6 See WHO TRS XXX for aspects to be considered for inclusion in qualification of heating, ventilation and air-conditioning (HVAC) systems. 4.7 See WHO TRS XXX for aspects to be considered for inclusion in qualification and validation of computerized systems. Working document QAS/16.673 page 8 255 256 257 258 259 260 261 262 263 264 265 266 267 268 269 270 271 272 273 274 275 276 277 278 279 280 281 282 283 284 285 286 287 288 289 290 291 292 293 294 295 296 297 298 4.8 Qualification should be done in accordance with predetermined and approved qualification protocols. 4.9 The results of the qualification should be recorded and reflected in qualification reports. 4.10 Rooms or areas, as appropriate, should be qualified prior to the qualification of utilities. 4.11 Utilities should be qualified prior to the qualification of equipment. 4.12 Equipment should qualified and brought into routine use only once there is documented evidence that it is fit for its intended purpose. 4.13 Certain stages of the qualification may be done by the supplier or a third party, subject to the conditions and responsibilities as defined in an agreement between the two parties. The contract giver remains responsible to ensure that the qualification is done in accordance with good manufacturing practices (GMP). 4.14 There should be a logical sequence in performing qualification. For example, operational qualification should follow after the successful completion of installation qualification. 4.15 The relevant documentation associated with qualification including standard operating procedures (SOPs), specifications and acceptance criteria, certificates and manuals should be maintained and be traceable. 4.16 Systems, utilities and equipment should be maintained in a qualified state and undergo periodic requalification where appropriate, as well as requalification after change when needed. 4.17 Processes should be validated on qualified equipment. 5. USER REQUIREMENT SPECIFICATIONS 5.1 URS should be prepared for systems, utilities and equipment, where appropriate 5.2 URS should be used to verify, at a later stage, that the purchased and supplied system, utility or equipment is in accordance with the manufacturer’s needs as specified. 6. FACTORY ACCEPTANCE TEST AND SITE ACCEPTANCE TEST 6.1 Where a system, utility or equipment is assembled, or partially assembled at a site other than that of the purchaser or end-user, testing and verification should be done to ensure that the system, utility or equipment is appropriate and ready for dispatch. 6.2 The checks and tests during assembly or partial assemble, should be recorded. Working document QAS/16.673 page 9 299 300 301 302 303 304 305 306 307 308 309 310 311 312 313 314 315 316 317 318 319 320 321 322 323 324 325 326 327 328 329 330 331 332 333 334 335 336 337 338 339 340 341 342 343 6.3 The acceptability of the assembly and overall status of the system, utility or equipment should be described in a conclusion of the report for the factory acceptance test (FAT), prior to shipment. 6.4 When the system, utility or equipment is received at the end user, tests should be performed to verify the acceptability of the system, utility or equipment. 6.5 The results of the tests should be recorded and the outcome of the acceptability of the system, utility or equipment recorded in the conclusion of the report for the site acceptance test (SAT). 7. DESIGN QUALIFICATION 7.1 URS should be considered when deciding on the specific design of a system, utility or equipment. 7.2 A suitable supplier should be selected for the appropriate system, utility or equipment. 7.3 The supplier should be approved prior to purchasing the system, utility or equipment 7.4 On delivery of the system, utility or equipment, the user should verify that it meets the agreed design specifications and satisfies the URS 7.5 Once DQ is completed, IQ may commence. 8. INSTALLATION QUALIFICATION 8.1 Systems, utilities and equipment should be correctly installed, in an appropriate location and in accordance with an installation plan 8.2 There should be documented evidence of the installation. This should be in accordance with the IQ protocol which contains all the required detail. 8.3 IQ should include identification and verification of all system elements, parts, services, controls, gauges and other components. 8.4 Measuring, control and indicating devices being installed should be calibrated. The calibration should be traceable to relevant national or international standards. Certificates should be available. 8.5 The execution of the protocol should be recorded in the IQ report. 8.6 The report should include at least the title, objective, site, details of the supplier and manufacturer, system or equipment name and unique identification number, model and serial number, date of installation, components and their identification numbers or codes, actual results Working document QAS/16.673 page 10 344 345 346 347 348 349 350 351 352 353 354 355 356 357 358 of tests and measurements, spare parts list, relevant procedures followed for tests and certificates as applicable. 8.7 All deviations and non-conformances from URS, DQ and acceptance criteria specified, observed during installation, should be recorded and investigated. 8.8 The outcome of the IQ should be recorded in the conclusion of the report, before OQ is started. 8.9 Requirements and procedures for calibration, maintenance and cleaning should be drawn up during installation. Figure 2. Example of an installation qualification protocol Working document QAS/16.673 page 11 359 Working document QAS/16.673 page 12 360 Working document QAS/16.673 page 13 361 Working document QAS/16.673 page 14 362 Working document QAS/16.673 page 15 363 364 365 366 367 368 369 370 371 9. OPERATIONAL QUALIFICATION 9.1 Systems, utilities and equipment should operate correctly and their operation should be verified in accordance with an OQ protocol. 9.2 Critical operating parameters should be identified. Studies on the critical variables should include conditions encompassing normal, upper and lower operating limits and circumstances (this includes “worst-case conditions”). Working document QAS/16.673 page 16 372 373 374 375 376 377 378 379 380 381 382 383 384 385 386 387 388 389 390 391 392 393 394 395 396 9.3 OQ should include verification of operation of all system elements, parts, services, controls, gauges and other components. 9.4 The results for the verification of operation should be documented in the OQ report to indicate the satisfactory operation. 9.5 SOPs for the operation should be finalized and approved during this phase of qualification. 9.6 Training of operators for the systems, utilities and equipment should be provided and training records maintained. 9.7 Systems, utilities and equipment, as appropriate, should be released for PQ or routine use after completion of OQ. 9.8 All calibration, cleaning, maintenance, training and related tests and results should be verified to be acceptable. Any discrepancy or deviation should be recorded and investigated. 9.9 The outcome of the OQ should be recorded in the conclusion of the report, before PQ is started. Figure 3. Example of an operational qualification protocol Working document QAS/16.673 page 17 397 398 Working document QAS/16.673 page 18 399 Working document QAS/16.673 page 19 400 Working document QAS/16.673 page 20 401 Working document QAS/16.673 page 21 402 Working document QAS/16.673 page 22 403 Working document QAS/16.673 page 23 404 Working document QAS/16.673 page 24 405 Working document QAS/16.673 page 25 406 Working document QAS/16.673 page 26 407 Working document QAS/16.673 page 27 408 409 410 411 412 413 414 415 416 417 418 419 420 421 422 423 424 10. PERFORMANCE QUALIFICATION 10.1 Systems, utilities and equipment should consistently perform in accordance with their design specifications. The performance should be verified in accordance with a PQ protocol. 10.2 There should be records for the PQ (report) to indicate the satisfactory performance over a period of time. Manufacturers should justify the selected period over which PQ is done. 10.3 PQ should be done once OQ is successfully completed. 10.4 Where two stages of qualification (e.g. OQ and PQ) are performed simultaneously, or where PQ is executed at the same time as process validation, appropriate justification for such a decision should be documented Figure 4. Example of a performance qualification protocol Working document QAS/16.673 page 28 425 426 427 428 429 Working document QAS/16.673 page 29 430 Working document QAS/16.673 page 30 431 Working document QAS/16.673 page 31 432 Working document QAS/16.673 page 32 433 Working document QAS/16.673 page 33 434 Working document QAS/16.673 page 34 435 Working document QAS/16.673 page 35 436 Working document QAS/16.673 page 36 437 438 439 440 441 442 443 444 445 446 447 448 449 450 451 452 453 454 455 456 457 458 459 460 461 462 463 11. REQUALIFICATION 11.1 Systems, utilities and equipment should be maintained in a qualified state through the life of the system, utility or equipment. 11.2 Routine requalification of systems, utilities and equipment should be considered based on the outcome of risk management principles which include factors such as calibration, verification and maintenance data and information. 11.3 The qualification status and requalification due dates should be documented in a defined schedule. 11.4 The scope and extent of qualification should be determined based on risk assessment when changes to an existing system, utility or equipment are made. 12. QUALIFICATION OF “IN-USE” SYSTEMS, UTILITIES AND EQUIPMENT 12.1 There should be data to support and verify the suitable design, operation and performance of systems, utilities and equipment that have been “in use” for a period of time and which have not been subjected to IQ and or OQ. 12.2 In such cases, a qualification protocol and report should be prepared where elements of design, operation and performance are verified for acceptability. These should include operating parameters and limits for critical variables, calibration, maintenance and preventive maintenance, SOPs and records. ***