Tunable On-Chip Inductors up to 5 GHz with Permalloy Laminations

advertisement

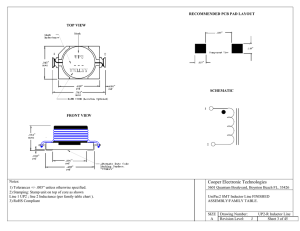

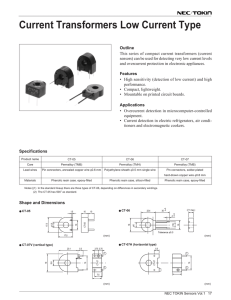

See discussions, stats, and author profiles for this publication at: https://www.researchgate.net/publication/224630967 Tunable on-chip inductors up to 5 GHz using patterned permalloy laminations Conference Paper in Electron Devices Meeting, 1988. IEDM '88. Technical Digest., International · January 2006 DOI: 10.1109/IEDM.2005.1609516 · Source: IEEE Xplore CITATIONS READS 37 104 3 authors, including: James Bain C. Patrick Yue Carnegie Mellon University The Hong Kong University of Science and Technology 244 PUBLICATIONS 2,770 CITATIONS 181 PUBLICATIONS 5,654 CITATIONS SEE PROFILE Some of the authors of this publication are also working on these related projects: Wireless Power Transmission View project Magnetization Dynamics View project All content following this page was uploaded by C. Patrick Yue on 08 March 2015. The user has requested enhancement of the downloaded file. SEE PROFILE Tunable On-Chip Inductors Up to 5 GHz Using Patterned Permalloy Laminations James Salvia, James A. Bain, and C. Patrick Yue Department of Electrical & Computer Engineering Carnegie Mellon University, Pittsburgh, PA 15213, USA Abstract This paper presents the design criteria, processing techniques, and measurement results for an on-chip inductor that uses a permalloy (Ni80Fe20) film to achieve a tunable reactance. Eddy currents and ferromagnetic resonance are suppressed in the thin permalloy film using patterning and laminations to enable operation in the RF range. Measurements results show a 40% increase in inductance, a 15% tuning range, and a Q between 5 and 11 up to 5 GHz. Introduction High-quality variable reactance is an essential component in tunable RF filters and oscillators. In existing tunable RF ICs, varactors are used exclusively. Tunable on-chip inductors have been demonstrated using active circuits [1] and MEMS technologies [2-3]. However, excess noise and processing complexity has prevented the wide adoption of these techniques. Using magnetic materials for boosting on-chip inductor performance has been reported. However, previous attempts have been limited to fixed inductances operating below 1 GHz [4] or with low quality factors [5]. In this work, tunable on-chip inductors utilizing high-µ permalloy (Ni80Fe20) thin films are reported for the first time. The permeability of permalloy is adjusted through the application of external DC magnetic fields, thereby making the inductance tunable. Tunable Inductor Design A. Magnetic Circuit Model The tuning range and improvement in inductance for a conductor is proportional to the portion of its magnetic flux path that is filled with magnetic material. To help visualize this concept, consider the magnetic circuit shown in Fig. 1(a), which models the magnetic flux generated by a single conductor that is surrounded by four different materials (Fig. 1(b)). In this circuit, the magnetomotive force (MMF) produced by current flowing in the conductor (Io) generates magnetic flux (Φ). This flux flows through four reluctances (R ) which are inversely proportional to the corresponding relative permeabilities (µr’s) of the materials surrounding the conductor. The inductance is related to the µr’s as follow: L= ∝ Φ 1 MMF = I o I o ℜ top + ℜ right + ℜ bottom + ℜ left 1 1 µ top + 1 µ right + 1 µ bottom + 1 µ left µtop 1 R top ~ µ top R left MMF Φ R bottom R right µleft Io µright Φ µbottom (a) (b) Figure 1. Equivalent magnetic circuit model of a conductor surrounded by four materials with different µr. In the case that only the space on top of the conductor is occupied by a high permeability material (µtop >> 1), R top is essentially shorted. As a result, the flux generated by the conductor would increase by 33.3%, producing in the same enhancement in inductance. However, other factors such as the finite permeability and finite thickness of the magnetic material significantly reduce the actual improvements that can be realized in practice. An 11% improvement in inductance is demonstrated in [6] with the addition of a single layer of magnetic material to one side of a conductor. Surrounding the conductor on all four sides with high-µ material would yield the largest improvement in inductance by shorting all four reluctances. However, to facilitate postprocessing on standard ICs, in our design, the permalloy film is deposited on the surface of the inductor traces. As a result, each conductor is wrapped around on three sides by the permalloy, thus shorting R top, R left, and R right. B. Processing Steps As shown schematically in Fig. 2, a conformal NiFe deposition followed by a photoresist lift-off results in a permalloy film that wraps around three sides of the conductors. This design simplifies the fabrication in comparison to using the high-µ material as the inductor core [4] or as an underlying shield [5]. Figure 3 shows the loop inductor test structure with Signal-Ground-Signal RF probe pads. SEM photos of the top and cross-sectional view of the inductor trace covered with permalloy are shown in Fig. 4 and Fig. 5, respectively. C. Permalloy with Tunable Permeability . (1) r Permalloy has a preferred magnetic orientation ( M ) which lies in the plane of the film along its easy axis (Fig. 6). High r permeability, which stems from the rotation of M , is attained only when the permalloy film is excited by the inductor’s 0-7803-9269-8/05/$20.00 (c) 2005 IEEE r magnetic field that is perpendicular to M and in the plane of the film. Based on this insight, the loop inductor design with two long sides was chosen to allow the majority of the magnetic material to operate with a single preferred magnetization direction that is parallel to the long dimension of the inductor. During the sputter deposition of the permalloy film, the NiFe crystal structure is oriented using a r in-situ DC magnetic field such that the easy axis ( M ) of the r film is perpendicular to the RF magnetic field ( H RF ) r associated with the RF currents ( I RF ) in the long sides of the inductor (Fig. 6). This arrangement in turn enables high frequency domain rotation. As a result, by applying an r r external DC magnetic bias field ( H Bias ) parallel to M , the permeability of the permalloy can be varied, thereby tuning the inductance, as described by the model in [7]. The tunable permeability as a function of the bias field magnitude (HBias ) is given by Ms , (2) µr = 1+ H k + H Bias where Ms is the saturation magnetization and Hk is the internal shape-induced anisotropy field of the permalloy film. From measured results, Ms and Hk are extracted to be 800 kA/m and 28 kA/m, respectively. D. Eddy Currents Because of the high-µ permalloy’s high electrical conductivity, eddy currents tend to circulate in a permalloy film when it is driven in the RF range. The eddy currents generate resistive losses in the film and significantly lower the permalloy’s effective µr. Two techniques are employed to suppress eddy currents and thus extend the inductor usable frequency range. First, instead of a single layer of permalloy, ten thin laminations (120 nm) separated by nine laminations of silicon dioxide (10 nm) were used. Second, to prevent displacement currents from flowing between individual laminations through capacitive coupling (C in Fig. 6), the r laminations are patterned in the direction perpendicular to M (along d in Fig. 6) to cut off the eddy current path. The width of the patches is designed to be 29 µm (Fig. 4). This dimension was chosen using the eddy current model of patterned laminated films described in [7] and verified using the Ansoft HFSS field solver. E. Ferromagnetic Resonance Permalloy films undergo ferromagnetic resonance (FMR) at high frequencies [8]. Beyond the frequency of FMR (fFMR), the permeability of the film drops below zero. Patterning the r permalloy stripes in the direction parallel to M (along w in Fig. 6) is used to create a shape-induced anisotropy field r r ( H k ). The presence of H k increases fFMR at the expenses of establish DC magnetic bias fields for tuning the inductance. In practical IC implementation, the DC current flowing through the inductor itself or another closely coupled inductor could be used as the source of magnetic bias field. The frequency response of the inductance and resistance for inductors with and without permalloy under the influence of a magnetic bias field are plotted in Fig. 8 and Fig. 9, respectively. A 40% improvement in inductance with the addition of the permalloy is observed up to 5 GHz without any bias field. A tuning range of 15% is achieved by varying the magnetic field strength from 0 to 80 kA/m. The measured inductance tuning range agrees very well with EM simulation as shown in Fig. 10. The roll-off in inductance (Fig. 8) and peaking in resistance (Fig. 9) with increasing frequency are due to FMR in the permalloy. At fFMR, a peak in the imaginary part of the complex permeability, which corresponds to the real part of the impedance of an inductor, creates a peak in the series resistance as observed in Fig. 9. Figure 11 shows that the applied magnetic field pushes the fFMR to a higher value and thus improves the inductor Q by negating the increase in resistance in the frequency range of interest. The linear dependence of fFMR2 on the bias field strength is shown in Fig. 12. This is used to extract the internal magnetic field, Hk, and thus the permeability of the NiFe film that is deposited on the samples. The permeability of the patterned film differs from that of a uniform film (measured with a permeameter) because of shape-induced r demagnetizing fields ( H k ). As seen in Fig. 13, these fields reduce the dependence of the films permeability on bias field strength. Conclusions This work has identified the key physical phenomena that govern the behaviors of tunable on-chip inductors employing high-µ permalloy. The effects of eddy currents and FMR have been analyzed in detail and confirmed with measured results. By proper patterning and laminations of the permalloy film, the usable frequency range of inductors with high-µ material is extended into the 5-GHz range for the first time while achieving tunable inductance with reasonable Q’s. Acknowledgement The authors would like to thank ITRI (Taiwan) for funding support, Professor Tamal Mukherjee for advice on processing issues, and Cascade Microtech for donating an impedance standard substrate. References [1] [2] lower µr and smaller tuning range under bias fields. Results and Discussion On-wafer RF measurements were performed using the setup shown in Fig. 7. Two rows of NdFeB magnets are used to [3] D.R. Pehlke, A. Burstein and M.F. Chang, “Extremely high-Q tunable inductor for Si-based RF integrated circuit applications,” IEDM Technical Digest, pp. 63–66, Dec. 1997. H. Sugawara, H. Ito, K. Okada, K. Itoi, M. Sato, H. Abe, T. Ito and K. Masu, “High-Q Variable Inductor Using Redistributed Layers for Si RF Circuits,” Topical Meeting on Silicon Monolithic Integrated Circuits in RF Systems, pp. 187-190, Sept. 2004. I. Zine-El-Abidine, M. Okoniewski and J.G. McRory, “RF MEMS Tunable Inductor,” 15th International Conference on Microwaves, Radar and Wireless Communications, vol. 3, pp. 817-819, May 2004. [4] [5] [6] [7] [8] Y. Zhuang, M. Vroubel, B. Rejaei, and J.N. Burghartz, “Ferromagnetic RF Inductors and Transformers for Standard CMOS/BiCMOS,” IEDM Tech. Dig., pp. 475-478, Dec. 2002. A.M. Crawford and S.X. Wang, “Effect of Patterned Magnetic Shields on High-Frequency Integrated Inductors,” IEEE Transactions on Magnetics, vol. 40, no. 4, pp. 2017-2019, July 2004. M. Yamaguchi, K. Suezawa, Y. Takahashi, K. I. Arai, S. Kikuchi, Y. Shimada, S. Tanabe, and K. Ito, “Magnetic thin-film inductors for RF integrated circuits,” J. Magn. Magn. Mater., vol. 215, pp. 807, 2000. W.P. Jayasekara, J.A. Bain, and M.H. Kryder, “High frequency initial permeability of NiFe and FeAlN,” IEEE Transactions on Magnetics, vol. 34, no. 4, pp. 1438, July 1998. J.S.Y. Feng and D.A. Thompson, “Permeability of narrow permalloy stripes,” IEEE Transactions on Magnetics, vol. 13, no. 5, pp. 1521, Sept. 1977. SiO2 Si a) Photoresist NiFe Al Al SiO2 Si b) SiO2 Si c) Photoresist Al Al SiO2 Si d) SiO2 Si e) Cross section (Fig. 5) Figure 4. SEM image of an inductor trace with patterned permalloy laminations. Photoresist Al 29 µm NiFe Al Laminated NiFe SiO2 Si f) 1.3 µm ~4 µm Al .4 µm SiO2 Figure 2. Post-processing steps: a) original BiCMOS chip cross section, b) after anisotropic oxide etch, c) after photoresist coating, d) after photoresist patterning, e) after sputtering ten 120-nm layers of NiFe separated by 10-nm layers of SiO2, f) after liftoff. 13 µm Figure 5. SEM cross section of an inductor trace with patterned permalloy laminations. d SEM image (Fig. 4) w HBias M C HRF IRF Inductor Trace NiFe SiO2 Figure 6. 3D view of an inductor trace with permalloy laminations. Figure 3. Image of an inductor with (top) and without (bottom) patterned permalloy laminations. Inductance (nH) at 1 GHz Microscope 1 0.8 0.6 0.4 Simulated 0.2 Measured 0 40 60 Bias field (kA/m) Figure 10. Dependence of inductance on bias field strength. Chip Bias Field Direction Probe 0 20 80 20 Without NiFe Figure 7. On-wafer RF measurement setup with magnets to provide external magnetic bias field. 1.2 Quality Factor Magnets With NiFe, no bias field 15 With NiFe, 80 kA/m (1000 Oe) bias field 10 5 Without NiFe 0 With Nife, no bias field 0 10 Inductance (nH) With NiFe, 80 kA/m (1000 Oe) bias field 1 10 Frequency (GHz) Figure 11. Frequency response of inductor Q with and without permalloy under bias fields. 1 0.8 19 15 x 10 0.4 0 10 1 10 Frequency (GHz) Figure 8. Frequency response of inductance with and without permalloy under bias fields. 35 5 Measured Trendline 40 60 80 Bias field (kA/m) Figure 12. The dependence on bias field strength of the resonance peaks in the resistance (from Fig. 9). With NiFe, no bias field With NiFe, 80 kA/m (1000 Oe) bias field 0 20 20 Modeled, uniform film 1000 15 10 5 0 0 10 1 Measured, uniform film Modeled, patterned film 300 Measured, patterned film 100 30 10 Frequency (GHz) Figure 9. Frequency response of resistance with and without permalloy under bias fields. View publication stats Relative permeability Resistance (Ohms) 25 10 0 Without NiFe 30 2 f FMR (Hz2 ) 0.6 10 0 20 40 60 80 Bias field (kA/m) Figure 13. The effect of bias field on the permeability of NiFe laminations versus the prediction by the model in [7].