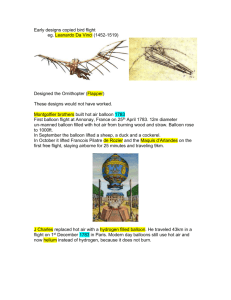

Cargo Airships Prospective A. Tatievsky*, S. Tsach† Israel Aerospace Industries (IAI), Ben Gurion Intl. Airport, 70100, Israel Giant Zeppelins, the masters of the skies of the early 20th century, are going through renaissance, in its renewed form and role of hybrid cargo airships. Several leading aerospace companies, along with few airship start-ups, have shown interest in possible applications of current era technologies for materialization of the concept, driven with continuously rising cargo conveying market. I. Introduction Lighter-than-air (LTA) era began with the flight of a hot air balloon by the Montgolfier brothers in 1783. With time, hot air balloons became more popular and sophisticated, but the need for powered, controllable air vehicle became clearly needed. Not until the early years of the 20th century that such combination appeared, in form of the well known Zeppelin (called by the name of its inventor). Zeppelins, in their various versions, were powered, rigid, hydrogen filled airships that carried cargo and passengers for varying distances in relative comfort and safety (compared to fixed wing aircraft of these days). On the other hand, advancing development of aircraft, along with non-stable political situation and several notorious airship disasters (Hindenburg disaster in 1937 was the most famous one), gradually made airships obsolete and diminished their glory. Only in the last decades of the 20th century, some LTA vehicles based activities have been resumed. Most of them were related to LTA military applications, in form of tethered aerostats, but as the concepts advanced and technologies matured, the idea of modern civil airship for cargo missions was forming to become reality. II. Market Need Growing world population, its expansion and inevitable search for new resources locations, are the drivers for constantly growing airborne cargo traffic, as can be seen trough the history. Airships appearance on the cargo market is aimed on specific niche that it is not optimally served with current transportation means. It can be forecasted, that with time, with higher confidence in airship operations and wider scope of their applications, airships could take over of some of the airborne cargo market as well, due to their obvious advantages. * † Engineer, Advanced Programs Department, atatiev@iai.co.il Director, Advanced Programs Department, stsach@iai.co.il Figure 1. World Air Cargo Traffic Forecast (Boeing World Air Cargo Forecast 2010-2011)[1]. World's constantly growing GDP and population over the last century, assures constantly growing need for cargo transportation. Many remote communities, oil platforms and wind turbine sites are served today with non reliable network of ground transportation or with very expensive airborne means. Process of transferring the needed equipment, supplies and commodities to the site, in the needed quantities, can take therefore several days or even weeks and cost a fortune. Roads and rail cannot be easily constructed, due to huge cost of transport network establishment in the remote areas, because of topographical and weather limitations, or just because of insufficient financial justification for such endeavor. Airstrip or a heliport at the site is a plausible option in most cases, but due to high operational cost of aircraft and relatively small payload volume they can take, it is not the best solution for large cargo hauling. This is the playground for the cargo airship. While it is much slower than conventional fixed wing aircraft, airship can carry the same payload for a fraction of the cost and can be designed to operate without any special infrastructure in the delivery site. It is closer by operational costs to ground vehicles, but unlike them, it's not restricted by terrain obstacles and lacks the need of roads and rails. Airship can be designed in such way, that the cargo would be underslung beneath its gondola, allowing it to transport oversized payloads in one piece (for example wind turbine blade), to inaccessible and remote location, thus simplifying the logistics and allowing high cost reduction. Insufficient ground transportation network, in developing areas or in countries with large territories, could benefit from airship type of transportation as well. Figure 2. Airship could be very much handy in such cases Hybrid cargo airship operational costs, place the airship in its own niche of the market, somewhere between ground and sea transportation to aircraft options. UK based Hybrid Air Vehicles (HAV) company, has estimated cargo operational cost somewhere between 0.2-1.4 [$*ton/km] (the larger the airship, the lesser the cost), while seaborne cargo vessels cost is around 0.08 [$*ton/km] (although this value can vary depending on supply & demand) and finally the fixed-wing aircraft costs are in the range of 10-30 [$*ton/km]. Figure 3. Cargo transportation market niches classification [2]. Please note, that the future hybrid cargo airships type, fills the gap between existing ground and airborne means of transportation. III. What a Hybrid Airship is? First it is important to understand what an airship actually is and how it works. Airship can differ in size, internal structure concept and even its operational concept. Modern designs of cargo airship use the same basic principles as zeppelins, albeit in the same time they are much different. Understanding the airship concept is essential for understanding the potential that modern cargo airships can have in the cargo market. Airship is in fact a non-permeable bag, filled with lighter-than-air gas (which density is lower than surrounding atmosphere), powered and steerable. It uses, usually, several sources for achieving lift and has several different structural approaches, who defines its nature. In the next two paragraphs, we will try to explain its main operational and structural principles, to shed some light of this long forgotten, but promising type of transportation. A. Operational Concept Modern cargo airship design configurations mainly appear as an advanced semi-rigid structure airship, in so-called "hybrid" multi-sourced-lift form configuration; filled with lighter-than-air, non-flammable helium gas. Its lift achieved mainly by buoyancy of helium, but in part by aerodynamic lift as well, created by an airflow over its hull. The aerodynamic lift, achieved due to movement of the lifting-body-shaped hull or by purpose built wings, attached to the hull or by any combination of the above. Additional common ways of creating lift in airship is by tilting its engines vertically, or by dedicated rotors that are designed to create thrust to overcome some of the weight, as it happens in rotorcraft designs. Hybrid design concept therefore, stands for achieving the total lift force from several sources and by this contributing to a smaller overall size for a given payload, compared to conventional cigar- shaped airships. Achieving smaller size of the airship is pretty much wanted, because it affects directly the needed size of the infrastructure, namely the hangar. Figure 4. Hybrid airship three sources of lift – Aerostatic, Vectored thrust and Aerodynamic lifts (Hybrid Air Vehicles (HAV) website) An important feature, found typically in non-rigid or semi-rigid airships, is the ballonets. When the airship change its altitude, the most important factor influencing it, is the differential between the lifting gas density, inside the airship, to the density of the ambient atmosphere. This way, when the airship climbs, the lifting gas inside it expands, activating pressure on its envelope. In order to avoid such condition (due to heavy penalty induced on the weight of the envelope material capable of withstanding higher than atmospheric pressures), ballonets are used. Ballonets are in fact non-permeable pockets inside the airship, designed to be filled with outside air. When the airship rises, and the lifting gas expands, occupying more volume inside and reducing its density, the air flows out of these pockets, allowing to keep the airship's hull form and same internal pressure over all extent of flight. When the airship reaches the height, in which the ballonets are fully deflated, it is called airship's pressure height and it is usually the maximum designed height the airship allowed to reach. In the emergency case that the airship rises beyond this limit, due to weather conditions or direct sunlight, emergency procedures are usually implemented, by releasing some of the lifting gas in order to relieve pressure and descend. Pressure height can be designed, by allocating enough volume for the maximum expansion of the ballonets and filling the airship with specific amount of lifting gas. For example, for airship designed for pressure height of 10,000 ft in normal ISA conditions (typical pressure height value for most of the modern cargo airship designs), it is needed to allow about one quarter of its volume to the maximum expansion of the ballonets at the sea level (SL) (where the atmosphere pressure is the highest). This way, the higher the designed height pressure altitude would be chosen, the higher lifting gas volume for given payload will need to be assigned (larger airship). Figure 5. Ballonets at Takeoff, Climb, and Pressure Height – System for equalizing inside pressure in order to maintain airship shape, used mainly in non-rigid and semi-rigid airships [3] More complicated are the ascent / descent procedures of an airship. It can be achieved by several means. In hybrid airships, with some of the total lift achieved due to aerodynamic properties (about 30% of the total lift), varying the airspeed alone can achieve the required change in lift. Additionally, pitching the hull nose-down can reduce the lift or even reverse its direction, in order to descend, and vice-versa for ascending. Thrust vectoring, allowing usage of force in the needed direction, used as well. Thus, usually several methods are used concurrently, in order to achieve desired result. Due to its buoyant nature and relatively low cruise speed, the reaction of the airship to a force application is rather slow, so there is need to allow for slow and continues response of the complicated system architecture for changing the airships height (it applies for more methodical piloting). It is worth to mention that the airships usually fly in neutral or heavier-than-air conditions (supplementing the additionally needed lift by other means than buoyancy, as mentioned), in order to have easier height control. Another way, used in the past, for controlling height and weight of the airship, is by extracting water from engines emissions (suitable mostly to internal combustion engines), to compensate for fuel weight loss. Proposed additional methods include air compression or lifting gas compression for weight control, or lifting gas heating for increased buoyancy, but each method has to be well considered for its trade-offs. B. Airship Structure Along with airship classification by its lifting sources, another sorting is by its internal structure. There are three distinct types of LTA vehicles configurations: rigid, semi-rigid and non-rigid. Non-rigid airship, usually called "blimp", is actually an inflated powered balloon, in which the cigar-shaped form is created by a small over-pressure of the lifting gas. As previously mentioned; in order to keep its form in-flight, a rather complex system of internal air bags, called ballonets, inflate and deflate, using the surrounding air, in the objective of maintaining internal pressure constant in various altitudes and temperature conditions. There is no load bearing internal structure in a blimp; the gondola, tails and engines connected directly to the hulls skin. Hull's shape maintained and loads distributed by material local patches, coupled with internal cable system (catenary curtain). This configuration allows significant structure weight reduction, but on the same time, does not allow high loads; literally only slow cruise speed and small payload is allowed. Thus blimps are usually the smallest in the variety of airships, and used mainly for purposes of local surveillance, airborne advertising and as a small tour vehicle. Fully rigid airships, as were the giant zeppelins of the past, are at the opposite side of scale. They have full internal framework that is not only intended for the loads but for keeping the external form as well. This makes ballonet system unnecessary to some point, but on the other hand, increases vastly the structure weight, on the expense of the potential useful load. Semi-rigid airships are basically a trade-off option between the two. It is similar to non-rigid ones, with the difference of owing some sort of load-bearing internal structure; by this achieving higher load tenability, with reasonable penalty of the additional weight. Progress in the field of the building materials, as will be presented in the next paragraph, has allowed building stronger and tougher semi-rigid airships, thus making them a preferred option. While not utterly disbanded, rigid airship designs are rare nowadays and most of the current designs are based on semi-rigid hulls for cargo airships and non-rigid for lighter applications. Figure 6. Three examples of main airship structure types presented. From left to right: Goodyear nonrigid blimp, Zeppelin NT semi-rigid airship and USS Shenandoah rigid zeppelin. IV. Technologies History of flight is fully bound with the technological progress. New technology development, has allowed incremental improvement of the flight vehicles, beyond the previously known frontiers. Same principle is relevant for all types of aircraft and for lighterthan-air vehicles as well. The evolution of advanced designs and its competitive advantages (compared to the past), took place mostly because of technological progress in materials, avionics, systems and propulsion. With no doubt, one of the greatest progress advances in airship technology was made in the areas of structure and materials. Massive metal internal structure was substituted by lightweight and strong composite framework. Implementing aircraft based experience on composites, lead to building much lighter gondola, engine nacelles and systems casing. Polymer based, multi-layered, impervious and durable envelope material took place of former heavier and more permeable fabrics of the airship's envelope. Zeppelin's skin was usually made from heavy cotton fabric, which was soaked with rubberized coating and externally laminated with aluminum coating for better weathering durability. The lifting gas was stored inside it, in separate gas cells, made from intestines of cattle and goats. Contemporary airship's skin is usually made of at least three layers – load bearing layer made of tough material (like Kevlar or Vectran), non-permeable layer made of Mylar and additional polymer coating (like Tedlar), for increased imperviability and weathering resistance. The results of improving envelope materials are; lesser weight, better lifting gas sealing and higher structural strength. Constantly improving synthetic and fiber materials development and manufacturing processes, allows assuming further empty to total weight ratio reduction. This is the main reason why most of the present cargo airship projects, presents concepts of semirigid airship, as a default. Fly-by-wire (FBW) controls for engines and control surfaces, coupled with advanced avionics and systems enhance stability and control, as well as navigation. Large size of the airship's hull, derived from its nature, require the use of fly-by-wire system much more than in fixed wing aircraft. FBW can contribute for a weight saving of airship's systems, which is an important feature in a platform, where each kilogram counts. FBW, coupled with specialized computerized avionics system, simplifies control and navigation of an airship. As the airship is more susceptible to gusts, compared to fixed wing aircraft, due to its large cross-section, an active control system is required. Finally, airships today use smaller, more powerful but more fuel efficient internal combustion engines than before. In the early days of aviation, Zeppelins used the available aero-engines, which were heavy, bulky and weak. Over the time, engines of internal combustion developed further and turbojets were invented. Turbojet invention led to creation of the turboprop engines, which are most suitable for cargo airships, due to its power requirements. Turboprop engines are usually smaller than comparably powered internal combustion engines, but they are slightly less efficient. In recent years, due to environmental and regulation policies tendency, there is a trend to plan future projects, towards hybrid or even fully electrical propulsion, with integrated solar panels on the airship's hull. Figure 7. Several of the key technologies that make airship fly V. Challenges and Opportunities Along with their great potential, airships do have several inherent disadvantages. Compared to aircraft they are more limited in bad weather operations; due to their large size they are more susceptible to winds and precipitations. Their buoyancy is affected by direct sunlight and surrounding air density and temperature. Cargo airships are generally restricted to operations under 10,000ft, due to increasing typical wind speed profile and decreasing air density (reduces buoyancy lift), changing with altitude. For maintenance, manufacturing and long term storage, huge hangars are needed; and mooring devices are used in order to anchor airships to the ground for parking and maintenance. Finally, current most applicative lifting gas is the inert helium, which is solely found in relatively small quantities in some natural gas reservoirs, and thus is relatively expensive and scarce. The good news is that new technologies and designs have good chance to overcome most of the deficiencies. Modern technologies offer much improved control in various conditions, weather prediction has improved drastically and hybrid airship design introduce much more autonomous ground operation flexibility than before, along with better stability in-flight. New technologies and their anticipated future development, allows us to predict that their implementation in the airship design will allow cost-effective and reliable service of the air vehicle in diverse environmental conditions. Reduced infrastructure needs, with higher autonomy of the hybrid airship, would allow it to operate in areas with no suitable facilities. Helium forecasted to remain high priced, but with well planned operational use of the airship and execution of required maintenance schedule, its annual consumption will be negligible. Figure 8. Typical Wind Profile at Mid-Latitude Areas VI. Airship Related World Activities Rising cargo market demand, new applicable technologies, environmental issues importance increase and military LTA successful applications, make a favorite environment for new development of cargo airships. Few more or less successful projects appeared in recent years; both in military and civil sectors of the market. Large corporations, along with several aerospace "start-ups" have realized the market potential of lighter-than-air transportation. Few of them are newcomers to this renovated idea, but some have a long history of dealing with lighter-than-air application; usually with aerostats, as in case of Lockheed Martin. Now they all race with a common goal – who will be the first to release the long promised new generation of cargo airship. Lockheed Martin is one of the main leaders in this area. Lockheed Martin develops the SkyTug cargo airship, with further increment designs in the future, after flying P791 hybrid airship demonstrator in 2006. P791 is so far, the first known hybrid airship flown and was intended for testing and gaining experience for transition to truly operational cargo airship, the one that SkyTug intends to be. SkyTug intended for the low tier of cargo airship market, with proposed design point of 20 tons payload and length of 88 m and entry to service as early as 2013. Aviation Capital Enterprises, a Canadian based investment company has joined Lockheed for this project, and forecast a market for 300 airship. In the future, Lockheed plans to increase its airship lineup towards larger airships, which would allow lifting heavier loads. Another large military company, Northrop Grumman, joined UK hybrid airship venture named Hybrid Air Vehicles (HAV), to develop the hybrid Long Endurance Multi-intelligent Vehicle (LEMV) for the US DoD (Department of Defense). It has received funding of 517M$ for this project and according to recent publications, it is in final stages of developing of its hybrid airship for an operational service. It is planned to have a cargo derivative, capable of lifting of about 20 tons. In parallel, HAV works on its own family of cargo airships, with lifting capabilities from 20 to 200 tones. It was recently published that HAV has closed a preliminary deal with Discovery Air Innovation, a Canadian aviation company, for selling a fleet of its 50 ton variant airship, the HAV366 (entry to service in 2014), intended for the local mining and natural resources market. Aeros, a LTA US based manufacturer, is currently one of the few pursuing the large airship market, with rigid airship designs, named Aeroscraft and Pelican. Aeroscraft airship intended for civil market (passengers and cargo), while Pelican airship, taking form nowadays at the company’s hangar, is funded by DARPA for 50M$ and intended to be a demonstrator for a future 60 ton payload cargo carrier. More notable projects in this market have taken place; Ohio Airships, an airship "start-up", has designed its cargo Dynalifter family, along with an ISR unmanned derivative. Small prototype flown in 2010. The proposed hybrid airship design included conventional hull with several wings for increased aerodynamic lift. Boeing developed for several years a conceptual rotorcraft airship, named Skyhook, for transporting oversized payloads. Some of its lift came from four large rotors, located on the gondola installation. CargoLifter AG was a German company, established in 1996 for creating a CL160 cargo airship (conventional configuration). After building a remarkable airship hangar and a small manned prototype, the company announced insolvency in 2002. Augur RosAeroSystems Russian LTA company, proposed ATLANT, a concept for a family of rigid hybrid cargo airships. Today there is no operational cargo airship yet, but already in the next year we're expected to witness cargo airship demonstrator floating in the skies. Figure 9. Several of the proposed cargo airships, showing the potential mission applications Few military ISR airship projects are in the works today as well. Because of the short scope of this article, we'll just mention them by name: conventional MAV6 Blue Devil II, stratospheric high-altitude Lockheed Martin ISIS & HAA and the previously mentioned Northrop Grumman / HAV LEMV hybrid airship. Figure 10. Leading airship projects in US in recent years. Images at the bottom are for scale. [4] VII. IAI Cargo Airship Activity Israel Aerospace Industries Ltd. (IAI) is a prominent worldwide leader in wide scope of aerospace market sectors, from unmanned aviation through business aircraft and satellites. It has been involved in R&D of the LTA market as well. Recently a study for potential cargo airship application has been initiated. Several potential configurations are being studied, along with applicable market and technologies research. IAI evaluates a family of advanced hybrid cargo airships, starting with Caspion 20 (20 ton payload airship) and continuing to the larger segment, with Caspion 200 (200 ton payload airship). Caspion airships family is designed to incorporate advanced technologies in structure and systems, VTOL (Vertical Take-Off & Landing) capability and offer the competitive edge compared to other means of transportation and other cargo airship projects. Caspion airships will present high autonomous operation, with improved availability and reliability in all weather conditions. Preliminary parameters of the Caspion 20 hybrid cargo airship: Payload: 20 tons Range: 2,500 nm Max. Cruise Speed: 100 kts Figure 11. IAI Caspion 20 - potential configurations for hybrid cargo airship VIII. Conclusion In our constantly developing and growing world, new boundaries are to be broken and new goals are to be achieved. Some of the progress dependant on improving and refining the best of the technologies invented. Hybrid cargo airship is offering these opportunities, allowing achieving capabilities never achievable before. It is an efficient air vehicle, tailorsuited to meet the challenges of carrying over-sized goods to hard reachable locations and can be beneficial in many other transportation mission profiles. Its technologies are within reach nowadays and offer substantial improvement over the past generations of LTA vehicles. This opens the way for utterly realistic implementation of such endeavor and can be seen in growing revival of interest for airships in many commercial companies worldwide. IAI as one of the most notable leaders of the aerospace industry has joined this area of interest and is investing in research for creating viable and competitive hybrid airship for cargo. While some may dispute some of its operational limitation, there is no doubt: it is a new dawn for giant cargo airships. List of Abbreviations DARPA – Defense Advanced Research Projects Agency (US) DoD – Department of Defense (US) FBW - Fly-By-Wire GDP – Gross Domestic Product HAA – High Altitude Airship HAV - Hybrid Air Vehicles (UK) IAI – Israel Aerospace Industries ISA – International Standard Atmosphere ISIS – Integrated Sensor Is Structure ISR – Intelligence Surveillance and Reconnaissance LEMV - Long Endurance Multi-intelligent Vehicle LTA – Lighter Than Air nm – nautical miles SL – Sea Level 1. 2. 3. 4. 5. 6. References Boeing World Air Cargo Forecast Team, "Boeing World Air Cargo Forecast 2010-2011", Boeing Commercial Airplanes, Feb. 2011, p. 8 Barry A.King II, Major, "Hybrid Airships: Well Suited for Foreign Humanitarian Assistance Operations", Air University, Maxwell Air Force Base, USAF, March 2011, p.18 Colonel Walter O. Gordon, Colonel Chuck Holland, "Logistics History – Back to the future: Airships and the Coming Revolution in Strategic Airlift", USAFR, Air Force Journal of Logistics, Volume XXIX, Number 3/4, p. 51 Alec Johnson, "Recent Development Efforts for Military Airships", Congressional Budget Office, US, Pub. No. 4239, Nov. 2011, p.6 Gabriel A.Khoury and J. David Gillett “Airship Technology,” Cambridge Aerospace Series 10, Cambridge University Press, Cambridge, UK, 1999 Raffael György, Klaus Broichhausen, Jost Seifert "Potentials of Lighter-Than-Air Technology in Future Markets – an Evaluation", Bauhaus Luftfahrt e.V., ICAS 2008 26th