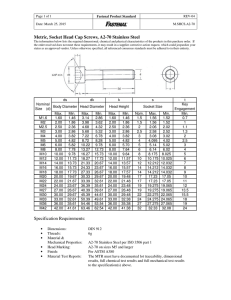

WWW.VORONDESIGN.COM VORON VORON TRIDENT ASSEMBLY We build space shuttles with gardening tools so anyone can have a space shuttle of their own. VERSION 2021-08-30 1 INTRODUCTION WWW.VORONDESIGN.COM Before you begin on your journey, a word of caution. In the comfort of your own home you are about to assemble a robot. This machine can maim, burn, and electrocute you if you are not careful. Please do not become the first VORON fatality. There is no special Reddit flair for that. Please, read the entire manual before you start assembly. As you begin wrenching, please check our Discord channels for any tips and questions that may halt your progress. Most of all, good luck! THE VORON TEAM 2 TABLE OF CONTENTS WWW.VORONDESIGN.COM Introduction 04 Print Bed 126 Hardware 06 Afterburner 144 Frame 14 Wiring Prep 172 A/B Drive and Idler 24 Electronics 188 Y Axis 42 Wiring 206 Z Axis 62 Skirts 232 X Axis 98 Panels 252 Belts 120 3 INTRODUCTION WWW.VORONDESIGN.COM PART PRINTING GUIDELINES The Voron Team has provided the following print guidelines for you to follow in order to have the best chance at success with your parts. There are often questions about substituting materials or changing printing standards, but we recommend you follow these. 3D PRINTING PROCESS INFILL TYPE Fused Deposition Modeling (FDM) Grid, Gyroid, Honeycomb, Triangle or Cubic MATERIAL INFILL PERCENTAGE ABS Recommended: 40% LAYER HEIGHT WALL COUNT Recommended: 0.2mm Recommended: 4 EXTRUSION WIDTH SOLID TOP/BOTTOM LAYERS Recommended: Forced 0.4mm Recommended: 5 PRINT IT FORWARD (PIF) Often times community members that have issues printing ABS will bootstrap themselves into a VORON using our Print It Forward program. This is a service where approved members with VORON printers can make you a functional set of parts to get your own machine up and running. Check Discord if you have any interest in having someone help you out. 4 INTRODUCTION WWW.VORONDESIGN.COM HOW TO GET HELP If you need assistance with your build, we’re here to help. Head on over to our Discord group and post your questions. This is our primary medium to help VORON Users and we have a great community that can help you out if you get stuck. https://discord.gg/voron THIS IS JUST A REFERENCE This manual is designed to be a simple reference manual. Building a Voron can be a complex endeavour and for that reason we recommend downloading the CAD files off our Github repository if there are sections you need clarification on. It can be sometimes be easier to follow along when you have the whole assembly in front of you. https://github.com/vorondesign DOCS https://docs.vorondesign.com/ 5 HARDWARE WWW.VORONDESIGN.COM BUTTON HEAD CAP SCREW (BHCS) Metric fastener with a domed shape head and hex drive. Most commonly found in locations where M5 fasteners are used. ISO 7380-1 FLAT HEAD COUNTERSUNK SCREW (FHCS) Metric fastener with a cone shaped head and a flat top. ISO 10642 SOCKET HEAD CAP SCREW (SHCS) Metric fastener with a cylindrical head and hex drive. The most common fastener used on the Voron. ISO 4762 SELF TAPPING SCREW Fastener with a pronounced thread profile that is screwed directly into plastic. HEX NUT Hex nuts couple with bolts to create a tight, secure joint. You’ll see these used in both M3 and M5 variants throughout this guide. LOCK NUT Hex nut with a nylon filled center which prevents the components from loosening. ISO 10511 / DIN 982 ISO 4032 POST INSTALL T-SLOT NUT (T-NUT) Nut that can be inserted into the slot of an aluminium profile. Used in both M3 and M5 variants throughout this guide. 6 HAMMER HEAD NUT Nut that can be inserted into the slot of an aluminium profile. Used exclusively for panel mounting, all other components use T-Slot nuts. HARDWARE WWW.VORONDESIGN.COM F695 BEARING A ball bearing with a flange used in various gantry locations. SHIM Not to be confused with stamped washers. These are used in all M5 call-out locations in this manual. DIN 988 HEAT SET INSERT Heat inserts with a soldering tip so that they melt the plastic when installed. THUMB NUT As the plastic cools, it solidifies around Used in the print bed as a spacer. the knurls and ridges on the insert for DIN 466-B excellent resistance to both torque and pull-out. PULLEY GT2 pulley used on the motion system of the Voron. IDLER GT2 idler used in the motion system of the Voron. 7 INTRODUCTION WWW.VORONDESIGN.COM BLIND JOINT BASICS Blind Joints provide a cost effective and rigid assembly method. The head of the BHCS is slid into the channel of another extrusion and securely fastened through a small access hole in the extrusion. https://voron.link/onjwmcd 8 INTRODUCTION WWW.VORONDESIGN.COM BALL-END DRIVER Some parts of this design require the use of a ball-end hex driver for assembly. We recommend you get a 2.5mm and 3mm one. 2.5MM HEX DRIVER The 2.5mm hex driver will see a lot of use in this build. A quality driver is strongly recommended. Refer to the sourcing guide for suggestions. 9 EXTRUSION REFERENCE “A EXTRUSION” Qty 9 “B EXTRUSION” Qty 4 “C EXTRUSION” Qty 1 10 WWW.VORONDESIGN.COM EXTRUSION REFERENCE “D EXTRUSION” Qty 1 WWW.VORONDESIGN.COM EXTRUSION CALL OUTS To avoid confusion we will call out the extrusions by the names shown on these reference pages. To help assembly along you may want to label the extrusions or print the reference for a faster lookup. “E EXTRUSION” Qty 1 ALL UNITS ARE METRIC If a unit is not specified assume it’s metric. “F EXTRUSION” Qty 1 11 WWW.VORONDESIGN.COM “G EXTRUSION” Qty 1 “H EXTRUSION” Qty 1 FOR WHAT SIZE IS THIS? WHAT ABOUT OTHER SIZES? The graphics shown here as well as the dimensions called out in this manual are for the 250mm version of the design. For other sizes please consult the configuration on the Voron website. 12 WWW.VORONDESIGN.COM This page intentionally left blank. 13 FRAME 14 WWW.VORONDESIGN.COM COMPONENT PREP WWW.VORONDESIGN.COM GETTING EXTRUSIONS TOGETHER Separate the extrusions you’re going to need for this section of the build. We’ve laid out all the parts you should have and highlighted the ones that will be used in the following sections. 15 FRAME WWW.VORONDESIGN.COM M5x16 BHCS H Extrusion A Extrusion C Extrusion M5x16 BHCS M5x16 BHCS LOWER BACK EXTRUSION This extrusion will be used throughout the manual to mark the lower back of the printer. 16 PREPARE 8 EXTRUSIONS 8 of the 9 extrusions are going to be used in this section. Prepare them as shown above. FRAME WWW.VORONDESIGN.COM BUILD ON A FLAT SURFACE Build the frame on a glass or granite surface B Extrusion to ensure you can get it as square as possible. FIRST BLIND JOINT This design relies on blind joints to assemble the frame. We outlined the basics of blind joints on page 8. If you’ve never assembled one before we recommend you watch the linked guide. C Extrsuion MIND ACCESS HOLE POSITION We do our best to call out things that may bite you later in the assembly process but may skip things that seem obvious to us. If in doubt please refer to the CAD model, it might save you some considerable time down the road. https://voron.link/onjwmcd A Extrusion 17 FRAME WWW.VORONDESIGN.COM B Extrusion H Extrusion A Extrusion 18 FRAME WWW.VORONDESIGN.COM E Extrusion COVER IN TAPE We’ll be using an extrusion as a spacer. Apply a single layer of tape to the ends to prevent scratches. If you’re not confident in the length and squareness of your extrusions print the included spacer instead. FINDING THE RIGHT POSITION We’ll use a 330mm extrusion as a spacer to locate the Y extrusions. Alternatively you can print the spacer that is included in the released files. 19 FRAME WWW.VORONDESIGN.COM A Extrusion FINDING THE RIGHT POSITION Using the 330mm extrusion as a spacer insert the Y rail and secure it using the access holes in the upright extrusions. Make sure that the extrusions sit at an 90° angle and are free of any rotation/twist. The outsides of the extrusions should be flush. 20 FRAME WWW.VORONDESIGN.COM A Extrusion RINSE AND REPEAT Remove the spacer and repeat the steps for the other Y extrusion. 21 FRAME WWW.VORONDESIGN.COM A Extrusion 22 FRAME WWW.VORONDESIGN.COM 23 A/B DRIVE AND IDLER 24 WWW.VORONDESIGN.COM OVERVIEW WWW.VORONDESIGN.COM B Drive A Drive B Idler A Idler WHY IS THAT HERE? As you likely skipped right over the advice to flip through the entire manual we added graphics like these to allow you get a sense of the part orientation before you actually put them on the printer. 25 COMPONENT PREP WWW.VORONDESIGN.COM HEAT SET INSERTS This design relies heavily on heat Heat Set Insert set inserts. Make sure you have the proper inserts (check the hardware reference for a close up picture). If you’ve never worked with heat set inserts before we recommend you watch the linked guide. https://voron.link/m5ybt4d 26 COMPONENT PREP WWW.VORONDESIGN.COM Heat Set Insert * * WHERE’S THAT PRINT PART? Look for asterix next to the part. It indicates that this is an accent part. M5 Nut 27 A IDLER WWW.VORONDESIGN.COM F695 Bearing ASSEMBLY AID This screw is used to align components and will be removed in a later step. M5x40 SHCS 28 M5 Shim A IDLER WWW.VORONDESIGN.COM M5x40 SHCS M3 Washer REMOVE ASSEMBLY AID Remove the screw and slide the tension arm into place. M3x40 SHCS 29 B IDLER WWW.VORONDESIGN.COM F695 Bearing M5 Shim ASSEMBLY AID This screw is used to align components and will be removed in a later step. M5x40 SHCS 30 B IDLER WWW.VORONDESIGN.COM M5x40 SHCS M3 Washer M3x40 SHCS REMOVE ASSEMBLY AID Remove the screw and slide the tension arm into place. 31 FRONT IDLERS WWW.VORONDESIGN.COM WHAT ARE THOSE CIRCLES? We use those circles to draw your attention to a certain feature/orientation/important bit .. quite often without adding 32 additional text. CHECK YOUR WORK If you see any of those pay attention. the graphics shown here. Compare your assembled parts to A DRIVE WWW.VORONDESIGN.COM M5x30 BHCS 33 A DRIVE WWW.VORONDESIGN.COM M5 Shim F695 Bearing UPSIDE DOWN ASSEMBLY For ease of assembly we recommend to assemble the A and B drives upside down. DON’T OVER TIGHTEN The M5 screws are threaded directly into plastic. 34 A DRIVE WWW.VORONDESIGN.COM GT2 20 Tooth Pulley GRUB SCREWS aka the root of all issues Insert both grub screws and use thread locker on all grub screws. Loose grub screws account for the majority of issues that our users report. Save yourself hours of troubleshooting and apply thread locker to all grub screws during the build. See the products application notes for instructions. NEMA17 Stepper MOTOR ORIENTATION Pay attention to the orientation of the cable exit. 35 A DRIVE WWW.VORONDESIGN.COM M3x30 SHCS CHECK YOUR WORK Compare your assembled part to the graphic shown here. Pay attention to the pulley orientation and alignment with the bearing stack ups. 36 B DRIVE WWW.VORONDESIGN.COM M5x30 BHCS 37 B DRIVE WWW.VORONDESIGN.COM M5 Shim F695 Bearing UPSIDE DOWN ASSEMBLY For ease of assembly we recommend to assemble the A and B drives upside down. DON’T OVER TIGHTEN The M5 screws are threaded directly into plastic. 38 B DRIVE WWW.VORONDESIGN.COM GT2 20 Tooth Pulley NEMA17 Stepper MOTOR ORIENTATION Pay attention to the orientation of the cable exit. 39 B DRIVE WWW.VORONDESIGN.COM M3x30 SHCS CHECK YOUR WORK Compare your assembled part to the graphic shown here. Pay attention to the pulley orientation and alignment with the bearing stack ups. 40 WWW.VORONDESIGN.COM This page intentionally left blank. 41 Y AXIS 42 WWW.VORONDESIGN.COM OVERVIEW WWW.VORONDESIGN.COM 43 Y AXIS WWW.VORONDESIGN.COM T-NUTS? IN A VORON MANUAL? Please let is know what you think. Are they really required? M5 T-Nut M5 T-Nut T-NUT ORIENTATION Insert the t-nuts as shown in highlight. M5 T-Nut 44 M3 T-Nut M5 T-Nut Y AXIS WWW.VORONDESIGN.COM M5 T-Nut M5 T-Nut T-NUT ORIENTATION Insert the t-nuts as shown in highlight. M5 T-Nut M5 T-Nut 45 Y AXIS WWW.VORONDESIGN.COM M5x10 BHCS M5x10 BHCS SLIDE INTO PLACE Slightly loosen the M5 screw and slide into place. 46 Y AXIS WWW.VORONDESIGN.COM M5x10 BHCS M5x10 BHCS SLIDE INTO PLACE Slightly loosen the M5 screw and slide into place. 47 Y AXIS WWW.VORONDESIGN.COM M5x10 BHCS SLIDE INTO PLACE Loosen the screws and slide into place. 48 M5x10 BHCS Y AXIS WWW.VORONDESIGN.COM M5x10 BHCS SLIDE INTO PLACE Loosen the screws and slide into place. 49 Y AXIS WWW.VORONDESIGN.COM HALL EFFECT ENDSTOP? If you are using a Hall Effect Endstop board remove the highlighted part and insert a magnet in its place. M5x16 BHCS * M3x12 SHCS 50 REAR BRACE WWW.VORONDESIGN.COM M5 T-Nut D Extrusion T-NUT ORIENTATION Insert the t-nuts as shown in highlight. 51 REAR BRACE WWW.VORONDESIGN.COM SLIDE INTO PLACE The rear crossbar can be slid into place. You may need to loosen the M5 screws. M5x10 BHCS 52 REAR BRACE WWW.VORONDESIGN.COM M5 T-Nut M5x10 BHCS 53 Z EXTRUSION WWW.VORONDESIGN.COM ADJUST POSITIONING Adjust the position of the rear extrusion to match the dimensions shown on the right. Ensure that the rear is parallel with the frame uprights. 54 Z EXTRUSION WWW.VORONDESIGN.COM M5x10 BHCS 55 Y AXIS UPSIDE DOWN ASSEMBLY For ease of assembly we recommend to flip the printer on its head for the next steps. 56 WWW.VORONDESIGN.COM Y AXIS WWW.VORONDESIGN.COM T-NUT ORIENTATION M3 T-Nut MGN9 Rail Insert the t-nuts as shown in highlight. Every other hole in the rail will be left empty. MIND THE CARRIAGE The carriages are designed to slide along the rail easily. This unfortunately also includes sliding off the rails. Dropping the carriage likely irreparably damages it. 57 Y AXIS WWW.VORONDESIGN.COM M3x8 SHCS CENTERED RAIL INSTALLATION GUIDE Use the guides to position the rail in the center of the extrusion prior to fastening the screws. 58 Y AXIS WWW.VORONDESIGN.COM M3 T-Nut T-NUT ORIENTATION Insert the t-nuts as shown in highlight. MGN9 Rail 59 Y AXIS WWW.VORONDESIGN.COM M3x8 SHCS CENTERED RAIL INSTALLATION GUIDE Use the guides to position the rail in the center of the extrusion prior to fastening the screws. 60 WWW.VORONDESIGN.COM This page intentionally left blank. 61 Z AXIS 62 WWW.VORONDESIGN.COM OVERVIEW WWW.VORONDESIGN.COM Z Rear Z Left Z Right 63 PART PREPARATION WWW.VORONDESIGN.COM Heat Set Insert GENERIC CABLE CHAIN IGUS CABLE CHAIN The 3 hole pattern is usually IGUS chain have 2 mounting found on generic cable chains. holes. CABLE CHAIN MOUNTING PATTERN There are multiple mounting patterns for cable chains on the market. Pick the part that matches with the hole pattern on your mounting chain. The remainder of the manual will only show the “generic” pattern. 64 Z AXIS WWW.VORONDESIGN.COM M5 T-Nut 65 Z AXIS WWW.VORONDESIGN.COM M5x10 BHCS 66 Z AXIS WWW.VORONDESIGN.COM T-NUT ORIENTATION Insert the t-nuts as M3x8 SHCS shown in the highlight. M3 T-Nut MGN9 Rail CENTERED RAIL INSTALLATION GUIDE Use the guides to position the rail in the center of the extrusion prior to fastening the screws. 67 Z AXIS WWW.VORONDESIGN.COM M3 Hammerhead Nut * M3x8 SHCS BOTTOM GAP Leave a small gap between the printed part and the rail. 1-2mm is fine. 68 Z AXIS WWW.VORONDESIGN.COM M5 T-Nut T-NUT ORIENTATION Insert the t-nuts as shown in the highlight. 69 Z AXIS WWW.VORONDESIGN.COM M5x10 BHCS 70 Z AXIS WWW.VORONDESIGN.COM T-NUT ORIENTATION Insert the t-nuts as shown in the highlight. M3 T-Nut MGN9 Rail M3x8 SHCS 71 Z AXIS WWW.VORONDESIGN.COM M3 Hammerhead Nut * M3x8 SHCS BOTTOM GAP Leave a small gap between the printed part and the rail. 1-2mm is fine. 72 Z AXIS WWW.VORONDESIGN.COM M5 T-Nut T-NUT ORIENTATION Insert the t-nuts as shown in the highlight. 73 Z AXIS WWW.VORONDESIGN.COM M5x10 BHCS 74 Z AXIS WWW.VORONDESIGN.COM M3 T-Nut MGN9 Rail M3x8 SHCS T-NUT ORIENTATION Insert the t-nuts as shown in the highlight. 75 Z AXIS WWW.VORONDESIGN.COM M3 Hammerhead Nut * M3x8 SHCS BOTTOM GAP Leave a small gap between the printed part and the rail. 1-2mm are fine. 76 LEFT Z JOINT WWW.VORONDESIGN.COM M5 Nut * M3x6 BHCS 77 LEFT Z JOINT WWW.VORONDESIGN.COM M3x12 SHCS Leadscrew Nut DON’T FULLY TIGHTEN For best results do not tighten fully. M3 Lock Nut 78 RIGHT Z JOINT WWW.VORONDESIGN.COM M3x6 BHCS * M5 Nut 79 RIGHT Z JOINT WWW.VORONDESIGN.COM M3x12 SHCS Leadscrew Nut M3 Lock Nut DON’T FULLY TIGHTEN For best results do not tighten fully. 80 REAR Z JOINT WWW.VORONDESIGN.COM M3x12 SHCS Leadscrew Nut M5 Nut DON’T FULLY TIGHTEN For best results do not M3 Lock Nut tighten fully. 81 OVERVIEW WWW.VORONDESIGN.COM Z Rear Z Left 82 Z Right LEFT Z JOINT WWW.VORONDESIGN.COM M3x12 SHCS 83 RIGHT Z JOINT WWW.VORONDESIGN.COM M3x12 SHCS 84 REAR Z JOINT WWW.VORONDESIGN.COM M3x8 SHCS 85 Z AXIS WWW.VORONDESIGN.COM FLIP UPSIDE DOWN Turn the printer upside down for the next assembly steps. 86 RIGHT Z MOTOR WWW.VORONDESIGN.COM APPLY LUBRICATION Apply a thin layer of grease to the lead-screw to prevent rust and ensure a smooth operation. M3x12 SHCS 87 LEFT Z MOTOR WWW.VORONDESIGN.COM M3x12 SHCS APPLY LUBRICATION Apply a thin layer of grease to the lead-screw to prevent rust and ensure a smooth operation. 88 REAR MOTOR WWW.VORONDESIGN.COM APPLY LUBRICATION Apply a thin layer of grease to the lead-screw to prevent rust and M3x12 SHCS ensure a smooth operation. 89 FEET WWW.VORONDESIGN.COM M3x6 BHCS * ASSEMBLE FOUR FEET Repeat the instructions and assemble all four feet. 90 FEET WWW.VORONDESIGN.COM M5 T-Nut M3 T-Nut M3 T-Nut M5 T-Nut M5 T-Nut M3 T-Nut M5 T-Nut M3 T-Nut 91 FEET WWW.VORONDESIGN.COM M3x8 SHCS M5x10 BHCS 92 FEET WWW.VORONDESIGN.COM M5x16 BHCS Rubber Feet M5 Nut MIND THE PART ORIENTATION The profile shown above are towards the front and rear of the printer. 93 FEET WWW.VORONDESIGN.COM M3x8 SHCS 94 M5x10 BHCS FEET WWW.VORONDESIGN.COM M5x16 BHCS Rubber Feet M5 Nut MIND THE PART ORIENTATION The profile shown above are towards the front and rear of the printer. 95 FEET WWW.VORONDESIGN.COM MIND THE PART ORIENTATION The profile shown above are towards the front and rear of the printer. 96 WWW.VORONDESIGN.COM This page intentionally left blank. 97 X AXIS 98 WWW.VORONDESIGN.COM OVERVIEW WWW.VORONDESIGN.COM Right XY Joint X Carriage Left XY Joint 99 PART PREPARATION WWW.VORONDESIGN.COM * Heat Set Insert 100 RIGHT XY JOINT WWW.VORONDESIGN.COM M5x40 SHCS M5 Shim F695 Bearing 101 RIGHT XY JOINT WWW.VORONDESIGN.COM M5 Nut 102 RIGHT XY JOINT WWW.VORONDESIGN.COM M5x40 SHCS GT2 20 Tooth Idler 103 RIGHT XY JOINT WWW.VORONDESIGN.COM M5x40 SHCS DON’T OVER TIGHTEN The screw is used to position the idler and is screwed directly into plastic. The idler must spin freely. 104 LEFT XY JOINT WWW.VORONDESIGN.COM M5 Shim F695 Bearing M5x40 SHCS 105 LEFT XY JOINT WWW.VORONDESIGN.COM M5 Nut 106 LEFT XY JOINT WWW.VORONDESIGN.COM M5x40 SHCS GT2 20 Tooth Idler 107 LEFT XY JOINT WWW.VORONDESIGN.COM M5x40 SHCS DON’T OVER TIGHTEN The screw is used to position the idler and is screwed directly into plastic. The idler must spin freely. 108 X CARRIAGE WWW.VORONDESIGN.COM M3 Nut 109 X CARRIAGE WWW.VORONDESIGN.COM M3x40 SHCS M3x30 SHCS 110 X CARRIAGE WWW.VORONDESIGN.COM PROBE WIRES Cut the probe’s wires to about 15cm. Strip the isoloation of the wire. M3x30 SHCS Inductive Probe 111 X AXIS WWW.VORONDESIGN.COM M5 T-Nut T-NUT ORIENTATION Insert the t-nuts as shown in the highlight. M5 T-Nut E Extrusion M3 T-Nut M5 T-Nut 112 M5 T-Nut X AXIS WWW.VORONDESIGN.COM MGN 12 Rail CENTERED RAIL INSTALLATION GUIDE Use the guides to position the rail in the center M3x8 SHCS of the extrusion prior to fastening the screws. 113 X AXIS WWW.VORONDESIGN.COM M5x10 BHCS LEAVE LOOSE Lightly tighten the screws. M5 Shim M5x30 BHCS 114 X AXIS WWW.VORONDESIGN.COM LEAVE LOOSE Lightly tighten the screws. M5 Shim M5x30 BHCS 115 X AXIS WWW.VORONDESIGN.COM MISSING SOME SCREWS? The other two screws will be installed later. M3x16 SHCS 116 M3x16 SHCS XY CABLE BRIDGE WWW.VORONDESIGN.COM M5x16 BHCS 117 X AXIS SQUARING WWW.VORONDESIGN.COM SQUARING THE GANTRY Move the gantry all the way back until it hits the A and B drive on both sides. Fully tighten all screws on the X axis. https://voron.link/cekh81l 118 WWW.VORONDESIGN.COM This page intentionally left blank. 119 BELTS 120 WWW.VORONDESIGN.COM BELTS WWW.VORONDESIGN.COM THE VORON BELT PATH Voron printers use a belt path based on the popular CoreXY pattern. The individual belt paths are stacked on top of each other and the crossing often found in CoreXY designs is omitted. Compared to many other implementations, the motors are moved to a less intrusive position. To learn more about the principles behind CoreXY visit https://voron.link/ ef72dd6 Equal belt tension is important to the proper function of a CoreXY motion system. We recommend to run one belt to get the required length, remove the belt from the printer and cut the second belt to the exact same length. As both belt paths have the same length this is an easy way of getting a consistent tension. 121 BELTS 122 WWW.VORONDESIGN.COM BELTS WWW.VORONDESIGN.COM 123 BELTS WWW.VORONDESIGN.COM M3x8 SHCS BELT CLAMP? The belt is clamped against the rail carriage. There are no extra parts. To initially tighten the belts leave the mounting screws slightly loose and pull the belt taut. 124 WWW.VORONDESIGN.COM This page intentionally left blank. 125 PRINT BED 126 WWW.VORONDESIGN.COM PRINT BED WWW.VORONDESIGN.COM Magnet Sheet Build Plate MAGNET APPLICATION Clean the plate with isopropyl alcohol or similar cleaner prior to applying the magnet. Use the edge of a plastic object or a small roller to firmly press the magnet on the plate to get a good bond. If you have never done this before we recommend you watch the linked guide. https://voron.link/rm6tpld 127 PRINT BED WWW.VORONDESIGN.COM HEATER APPLICATION The heater is installed in the same fashion as the magnet. Centre it on the underside of the build plate and make sure to firmly press it on the build plate. 128 PRINT BED WWW.VORONDESIGN.COM M3x8 SHCS THERMISTOR WIRES HEATER WIRES THERMAL FUSE While not required to operate the printer, a thermal fuse attached to the build plate adds an additional layer of protection against potentially dangerous malfunctions. The thermal fuse is wired in-line with the heater wires. 129 PRINT BED WWW.VORONDESIGN.COM PRESS FIT GT2 Pulley Apply the required force to fully seat the pulley in the printed part. M2x10 Self Tapping REMOVE FLANGE & GRUB SCREWS Microswitch Use a bottle opener or some pliers to remove the top flange. Remove the grub screws from the pulley. SWITCH W/OUT LEVER This parts requires a switch without lever to be installed in the shown orientation. You can remove the lever from microswitches by gently pressing on the lever’s hinge point. 130 PRINT BED WWW.VORONDESIGN.COM 5mm Shaft SOLDER CONNECTOR Solder a small length of wire from the outer two terminals of the microswitch to the connector. 131 BED FRAME WWW.VORONDESIGN.COM H Extrusion F Extrusion M5x16 BHCS 132 BED FRAME WWW.VORONDESIGN.COM M5 T-Nut M3 T-Nut M5 T-Nut M3 T-Nut M3 T-Nut M5 T-Nut M3 T-Nut 133 BED FRAME WWW.VORONDESIGN.COM GE5C Bearing M3x6 BHCS DON’T OVER TIGHTEN The screws are used to position the bearing and are screwed directly into plastic. 134 BED FRAME WWW.VORONDESIGN.COM M5x10 BHCS 135 BED FRAME WWW.VORONDESIGN.COM M3x6 BHCS GE5C Bearing DON’T OVER TIGHTEN The screws are used to position the bearing and are screwed directly into plastic. 136 BED FRAME WWW.VORONDESIGN.COM M5x10 BHCS 137 BED FRAME WWW.VORONDESIGN.COM M3x6 BHCS GE5C Bearing DON’T OVER TIGHTEN The screws are used to position the bearing and are screwed directly into plastic. 138 BED FRAME WWW.VORONDESIGN.COM M5x10 BHCS 139 BED FRAME M5x16 BHCS WWW.VORONDESIGN.COM M5x16 BHCS M5x16 BHCS 140 BED FRAME WWW.VORONDESIGN.COM LOOSEN AND RETIGHTEN Slightly loosen the screws that hold the bed frame to the printed parts and gently shake the bed frame before retightening them. 141 BED FRAME WWW.VORONDESIGN.COM M4 Thumb Screws M3x16 SHCS 142 BED FRAME WWW.VORONDESIGN.COM M3x20 SHCS ADJUST Z ENDSTOP POSITION The shaft of the Z Endstop must not touch the print bed. Adjust the position if required. 143 AFTERBURNER 144 WWW.VORONDESIGN.COM OVERVIEW WWW.VORONDESIGN.COM Clockwork Fan Assembly X Carriage Tool Cartridge 145 HEAT SET INSERTS WWW.VORONDESIGN.COM * Heat Set Insert HEAT SET INSERTS You will need to install heat set inserts into various plastic parts. If you need help on the correct procedure, ask in Discord. 146 HEAT SET INSERTS WWW.VORONDESIGN.COM Het Set Insert 147 TOOL CARTRIDGE WWW.VORONDESIGN.COM AVAILABLE MOUNTS Heat Set Insert We also provide mounts for the Slice Engineering Mosquito and TriangleLab/Phaetus Dragon Hotend. They are assembled in a similar manner. 148 TOOL CARTRIDGE HEATER AND SENSOR We do not show the heater and WWW.VORONDESIGN.COM E3D V6 Hot End temperature sensor cartridge in the drawing. Install them prior to assembling the toolhead. 149 TOOL CARTRIDGE WWW.VORONDESIGN.COM PTFE Tube M3x16 SHCS 150 TOOL CARTRIDGE WWW.VORONDESIGN.COM PTFE STICKOUT The PTFE tube should end 10mm above the surface of the printed part. M3x40 SHCS 151 TOOL CARTRIDGE WWW.VORONDESIGN.COM WIRING PATH Guide the wires in the highlighted path. CHECK ORIENTATION The heater block must point forwards. 152 TOOL CARTRIDGE WWW.VORONDESIGN.COM 153 TOOL CARTRIDGE WWW.VORONDESIGN.COM M3x12 SHCS MOTOR ORIENTATION The screws are used to index the tool cartridge. Leave them slightly loose so that the cartridge can be slid out. 154 MOTOR PLATE WWW.VORONDESIGN.COM MOTOR ORIENTATION BMG Drive Pinion Rotate the motor in such a way that the connector/wires are on the left side when looking at it from the back. This side will be covered by the cable cover later. 155 MOTOR PLATE WWW.VORONDESIGN.COM M3x8 SHCS ADJUSTABLE MOTOR POSITION The motor position is adjustable to allow for a proper meshing of the drive gears. Start in the top most position of the slot. 156 DRIVE GEAR WWW.VORONDESIGN.COM CHECK BEARING FIT BMG Drive Gear The bearings must slip on and off the shaft easily to allow the gear to self centre. Do not shim into position. Pressing the bearings on the shaft will MR85 Bearing damage them. Lightly sand the shaft if required. CHECK PLACEMENT Make sure the filament drive gear is fully seated against the drive shaft gear. 157 MAIN BODY WWW.VORONDESIGN.COM M3x30 SHCS CHECK FOR CLEARANCE The drive shaft must not touch the motor housing. Check if the shaft has sufficient clearance when fully seated. Sand the face of shaft if required. 158 GEAR LASH CHECK WWW.VORONDESIGN.COM CHECK GEAR PLAY The gear should have a slight play and should not be fully tight against the pinion. Adjust the position of the motor until you have a faint play. 159 GUIDLER WWW.VORONDESIGN.COM BMG Idler Assembly LUBRICATE BEARINGS A lubrication film is required to ensure smooth operation and longevity. Refer to the BOM for lubricant options. * 160 GUIDLER & LATCH WWW.VORONDESIGN.COM * M3x20 SHCS M3x30 SHCS 161 CABLE COVER WWW.VORONDESIGN.COM BMG Thumb Screw REMOVE SCREWS Carefully remove the screws from the left side of the motor. They will be replaced with new screws in the next step. 162 WWW.VORONDESIGN.COM M3x20 SHCS * M3x8 SHCS 163 CLOCKWORK 164 WWW.VORONDESIGN.COM CLOCKWORK WWW.VORONDESIGN.COM M3x20 SHCS M3x30 SHCS 165 FAN ASSEMBLY WWW.VORONDESIGN.COM 4020 Blower 4010 Fan REMOVE TOP COVER Split the fan open by bending the tabs on the side. 166 FAN ASSEMBLY WWW.VORONDESIGN.COM * WIRING PATH Route the wires through the large opening in the back. 167 FAN ASSEMBLY WWW.VORONDESIGN.COM M3x16 SHCS DON’T OVER TIGHTEN The screws are threaded directly into plastic. 168 FAN ASSEMBLY WWW.VORONDESIGN.COM WIRING PATH Guide the wires in the highlighted path. Filament 169 FAN ASSEMBLY WWW.VORONDESIGN.COM M3x30 SHCS M3x12 SHCS 170 WWW.VORONDESIGN.COM This page intentionally left blank. 171 WIRING PREP 172 WWW.VORONDESIGN.COM Z CHAIN ANCHOR WWW.VORONDESIGN.COM M3x8 SHCS Heat Set Insert M3 Hammerhead Nut 173 Z CHAIN ANCHOR 174 WWW.VORONDESIGN.COM CABLE COVER WWW.VORONDESIGN.COM M3x8 SHCS M3 Hammerhead Nut 175 CABLE COVER WWW.VORONDESIGN.COM M3x8 SHCS M3 Hammerhead Nut 176 DECK PANEL WWW.VORONDESIGN.COM 177 DECK PANEL WWW.VORONDESIGN.COM TWIST TO LOCK Rotate the deck supports by 90° to lock them in place. 178 DECK PANEL WWW.VORONDESIGN.COM TWIST TO LOCK Rotate the deck supports by 90° to lock them in place. 179 DIN RAILS WWW.VORONDESIGN.COM M5 T-Nut M5 T-Nut 180 DIN RAILS WWW.VORONDESIGN.COM 181 DIN RAILS SPACING Roughly centre the DIN rails and space them about 80mm apart. SLIDE INTO POSITION Slide the mounts all the way to the extrusions. 182 WWW.VORONDESIGN.COM DIN RAILS WWW.VORONDESIGN.COM M5x16 BHCS M5x16 BHCS 183 DIN RAILS WWW.VORONDESIGN.COM M3x8 SHCS M3x8 SHCS DON’T OVER TIGHTEN The screws are used to keep the DIN rails from sliding and are screwed directly into plastic. 184 ZIP TIE LOOPS WWW.VORONDESIGN.COM TWIST TO LOCK Rotate the zip tie loops by 90° to lock them in place. 185 ZIP TIE LOOPS WWW.VORONDESIGN.COM TWIST TO LOCK Rotate the zip tie loops by 90° to lock them in place. 186 WWW.VORONDESIGN.COM This page intentionally left blank. 187 ELECTRONICS 188 WWW.VORONDESIGN.COM RASPBERRY PI WWW.VORONDESIGN.COM M2x10 Self Tapping 189 RASPBERRY PI WWW.VORONDESIGN.COM Raspberry Pi M2x10 Self Tapping 190 5V PSU WWW.VORONDESIGN.COM M3x6 BHCS RS25-5 PSU 191 24V PSU WWW.VORONDESIGN.COM M4x6 BHCS 192 CONTROLLER BOARD WWW.VORONDESIGN.COM M2x10 Self Tapping 193 CONTROLLER BOARD WWW.VORONDESIGN.COM WHY DOES IT LOOK THAT WAY? We used a dummy to keep the file size of the printers cad manageable. The wiring section will have a fully featured image. M3x6 BHCS 194 POWER INLET WWW.VORONDESIGN.COM Filtered Inlet Heat Set Insert Switch M3x12 FHCS 195 POWER INLET WWW.VORONDESIGN.COM M3x8 SHCS 196 PSU MOUNTING WWW.VORONDESIGN.COM 197 PSU MOUNTING WWW.VORONDESIGN.COM M4x6 BHCS M5x10 BHCS 198 SSR MOUNTING WWW.VORONDESIGN.COM SPRING LOADED Use a flat head screw driver to pull the latch open. It will lock open. Be careful when releasing the latch, it will snap back into place. Mind your fingers. 199 PSU MOUNTING 200 WWW.VORONDESIGN.COM RASPBERRY PI MOUNTING WWW.VORONDESIGN.COM 201 CONTROLLER BOARD MOUNTING 202 WWW.VORONDESIGN.COM XY END-STOP POD WWW.VORONDESIGN.COM Microswitch M2x10 Self Tapping END-STOP SWITCHES FOR X AND Y End-stops are wired in a “Normally Closed” configuration. On microswitches those are the 2 outer terminals indicated by C and NC. Prepare the switches for X and Y by soldering 150mm of wire to each of the outer terminals. 203 XY END-STOP POD WWW.VORONDESIGN.COM M3x30 SHCS 204 WWW.VORONDESIGN.COM This page intentionally left blank. 205 WIRING 206 WWW.VORONDESIGN.COM PSU VOLTAGE CHECK WWW.VORONDESIGN.COM INPUT VOLTAGE SWITCH Check the input voltage switch of the power supply. It is located in the highlighted area behind the metal mesh. Make sure the selection matches your local mains voltage. Refer to the Mean Well LRS-200 datasheet for possible settings (https://voron.link/e0szdyh). 207 POWER INLET WWW.VORONDESIGN.COM ATTACH 250MM OF WIRE Cables should be at least 0.75mm² (AWG18) or thicker depending on local regulations. MAINS INLET WIRING We show the wiring in the IEC colour scheme. Depending on your region the colour scheme and wiring standards will differ. Mains wiring should only be done by qualified personnel trained in local regulations and safety standards. Failure to observe those could result in bodily harm. 208 MAINS WIRING L N PE -V +V WWW.VORONDESIGN.COM 1 3 LOAD INPUT 2 4 MAINS WIRING CONTINUED Secure the wires with cable clips / cable tie anchors. The bed heater is powered by AC voltage and is grounded in a later step. Observe your local regulations in regards to grounding the frame/other components. 209 BED WWW.VORONDESIGN.COM PROTECTIVE EARTH 1mm²(AWG18) or larger Z END-STOP 2x 0.25mm²(AWG24) or larger PRINT BED 2x 1mm²(AWG18) or larger BED THERMISTOR 2x 0.25mm²(AWG24) or larger 210 BED CABLE ROUTING WWW.VORONDESIGN.COM M3x6 FHCS M3x6 FHCS 211 BED CABLE ROUTING WWW.VORONDESIGN.COM ZIP TIE LOOPS Secure the wire bundle to the strain relief using small zip ties. 212 BED CABLE HOOKUP L N PE -V +V WWW.VORONDESIGN.COM 1 3 LOAD INPUT 2 4 213 DC POWER L N PE -V +V WWW.VORONDESIGN.COM CABLE CROSS SECTION Cables to the controller board should be 1mm² (AWG18) or larger. 0.5mm² (AWG20) is sufficient for the connection to the Raspberry Pi. 214 24V Controller Board 5V Raspberry Pi RASPBERRY PI WWW.VORONDESIGN.COM RASPBERRY PI POWER While we suggest that you power the Raspberry Pi via the GPIO pins you may also power it using the Controller Board 5V PSU “Power-In” USB port. Cut a suitable USB cable and wire the + and ground lines to the 5V DC/DC converter instead. 215 CONTROLLER BOARD WWW.VORONDESIGN.COM CONTROLLER BOARD The assembly manual will outline the wiring for a Fysetc Spider. You can find additional documentation and alternative configurations on docs.vorondesign.com 2x 0.25mm²(AWG24) or larger To SSR 24V PSU E0 OUT E1 OUT E2 OUT BED OUT BED IN PWR IN BED CONTROL M5 M4 X- Several jumpers may need to be configured on the controller board. Please consult our documentation on docs.vorondesign.com 216 Y- Z END-STOP 2x 0.25mm²(AWG24) or larger M2 M1 Z- FAN0 FAN1 FAN2 TE0 JUMPERS M3 EXP1 Z+ TB EXP2 BED THERMISTOR 2x 0.25mm²(AWG24) or larger Build Plate Raspberry Pi M6 B MOTOR WWW.VORONDESIGN.COM ZIP TIE LOOPS Secure the wire bundle to the strain relief using small zip ties. 217 WWW.VORONDESIGN.COM B Motor B MOTOR 4x 0.25mm²(AWG24) or larger M6 M5 E0 OUT E1 OUT E2 OUT BED OUT BED IN PWR IN X- M3 Y- M2 Z- FAN0 FAN1 FAN2 TE0 218 M4 Z+ TB EXP1 EXP2 M1 WWW.VORONDESIGN.COM HOTEND COOLING FAN 2x 0.25mm²(AWG24) or larger PART COOLING FAN 2x 0.25mm²(AWG24) or larger 4x 0.25mm²(AWG24) or larger HOTEND HEATER 2x 0.5mm²(AWG20) or larger Controller Board EXTRUDER MOTOR HOTEND THERMISTOR 2x 0.25mm²(AWG24) or larger INDUCTIVE PROBE 3x 0.25mm²(AWG24) or larger WIRES, DRAG CHAINS AND CRIMPS The wires attached to the probe, fans, heater, etc. are usually not rated for use in drag chains. Add crimp connectors at the toolhead and run suitable wire down the drag chains. Refer to the sourcing guide for options. 219 TOOLHEAD CABLE ROUTING WWW.VORONDESIGN.COM M3 T-Nut 220 TOOLHEAD CABLE ROUTING WWW.VORONDESIGN.COM M3x6 FHCS M3x6 FHCS 221 TOOLHEAD/XY END-STOP ROUTING WWW.VORONDESIGN.COM Controller Board Y END-STOP 2x 0.25mm²(AWG24) or larger ZIP TIE LOOPS Secure the wire bundle to the strain relief using small zip ties. X END-STOP 2x 0.25mm²(AWG24) or larger 222 TOOLHEAD/XY END-STOP ROUTING WWW.VORONDESIGN.COM M3 T-Nut 223 TOOLHEAD/XY END-STOP ROUTING WWW.VORONDESIGN.COM M3x6 FHCS M3x6 FHCS 224 TOOLHEAD/XY END-STOP ROUTING WWW.VORONDESIGN.COM M3x8 SHCS WIRING PATH Guide the wires in the highlighted path. 225 TOOLHEAD/XY END-STOP ROUTING WWW.VORONDESIGN.COM ZIP TIE LOOPS Secure the wire bundle to the strain relief using small zip ties. 226 XY END-STOP WWW.VORONDESIGN.COM M6 M5 M4 E0 OUT E1 OUT E2 OUT BED OUT BED IN PWR IN X- M3 M2 M1 Z- Y- FAN0 FAN1 FAN2 Z+ TB TE0 EXP1 EXP2 X END-STOP Y END-STOP 2x 0.25mm²(AWG24) or larger 2x 0.25mm²(AWG24) or larger End-Stop Pod 227 HOTEND WWW.VORONDESIGN.COM EXTRUDER MOTOR 4x 0.25mm²(AWG24) or larger M6 2x 0.5mm²(AWG20) or larger E0 OUT E1 OUT E2 OUT BED OUT BED IN PWR IN HOTEND HEATER M5 M4 X- Y- M2 M1 Z- FAN0 FAN1 FAN2 Z+ TB TE0 EXP1 EXP2 HOTEND THERMISTOR INDUCTIVE PROBE 2x 0.25mm²(AWG24) or larger 3x 0.25mm²(AWG24) or larger Hotend 228 M3 HOTEND WWW.VORONDESIGN.COM A Motor A MOTOR 4x 0.25mm²(AWG24) or larger M6 M5 M4 E0 OUT E1 OUT E2 OUT BED OUT BED IN PWR IN X- M3 Y- M1 Z- FAN0 FAN1 FAN2 TE0 M2 Z+ TB EXP1 EXP2 PART COOLING FAN HOTEND COOLING FAN 2x 0.25mm²(AWG24) or larger 2x 0.25mm²(AWG24) or larger Hotend 229 HOTEND WWW.VORONDESIGN.COM M6 M5 M4 E0 OUT E1 OUT E2 OUT BED OUT BED IN PWR IN X- M3 Y- Z- FAN0 FAN1 FAN2 TE0 M2 Z+ TB EXP1 EXP2 FAN VOLTAGE The fans recommended in the sourcing guide are 24V fans. Please check your hotend cooling (40x40x10 axial), part cooling (40x40x20 blower) and exhaust/electronics (60x60x20 axial) fans for their voltage rating and jumper the voltage selection accordingly. Refer to the Fysetc Spider manual for possible settings. 230 M1 Z AXIS WWW.VORONDESIGN.COM Z Right Motor Z Left MOTOR CONNECTIONS Z Rear Motor Z Right 4x 0.25mm²(AWG24) or larger Z Left Motor M6 E0 OUT E1 OUT E2 OUT BED OUT BED IN PWR IN Z Rear M5 M4 X- M3 Y- M1 Z- FAN0 FAN1 FAN2 TE0 M2 Z+ TB EXP1 EXP2 231 SKIRTS 232 WWW.VORONDESIGN.COM HEAT SET INSERT WWW.VORONDESIGN.COM Heat Set Insert 233 LED SCREEN WWW.VORONDESIGN.COM * FRONT COVER The front cover is held in place by the heat set Heat Set Insert Mini 12864 Screen 234 inserts. Hold the front face firmly in place while inserting the heat set inserts. LED SCREEN WWW.VORONDESIGN.COM M3x12 SHCS 235 LED SCREEN WWW.VORONDESIGN.COM M3x40 SHCS * Filament 236 SKIRTS WWW.VORONDESIGN.COM * * * LOGO INSERTS These will stay in place without any adhesive. Alternatively they can be glued in place. 237 SKIRTS WWW.VORONDESIGN.COM M3 T-Nut M3 T-Nut 238 SKIRTS WWW.VORONDESIGN.COM M3x8 SHCS M3x12 SHCS 239 SKIRTS WWW.VORONDESIGN.COM M3 T-Nut M3x8 SHCS 240 SKIRTS WWW.VORONDESIGN.COM M3x8 SHCS 241 SKIRTS WWW.VORONDESIGN.COM M3 T-Nut M5 T-Nut M3 T-Nut 242 SKIRTS WWW.VORONDESIGN.COM M3x8 SHCS M3x8 SHCS 243 SKIRTS WWW.VORONDESIGN.COM APPLY VHB TAPE 3M VHB tape is a double sided adhesive tape. Other vendors have similar products that you can use as a substitute. * M5x10 BHCS 244 SKIRTS WWW.VORONDESIGN.COM M5 T-Nut M3 T-Nut M3 T-Nut 245 SKIRTS M3x8 SHCS APPLY VHB TAPE VHB Tape is a double sided adhesive tape. 246 WWW.VORONDESIGN.COM M3x8 SHCS SKIRTS WWW.VORONDESIGN.COM Controller Board ELECTRONICS COOLING FAN 2x 0.25mm²(AWG24) or larger M5x10 BHCS 247 WIRING WWW.VORONDESIGN.COM M6 M5 M4 M3 M2 M1 E0 OUT E1 OUT E2 OUT BED OUT BED IN PWR IN WARNING: DISPLAY HOOKUP Before connecting the display make sure to review the documentation on X- Y- FAN0 FAN1 FAN2 TE0 the Voron documentation site (https:// Z- Z+ TB voron.link/ypdmcb2) . EXP1 EXP2 If you are using a “FYSETC mini12864” please review section 3.3 of the FYSETC Spider documentation (https://voron.link/m6wtwnl). ELECTRONICS COOLING FAN 2x 0.25mm²(AWG24) or larger Electronics Fans Mini12864 Display https://voron.link/ypdmcb2 248 BOTTOM PANEL WWW.VORONDESIGN.COM 249 BOTTOM PANEL WWW.VORONDESIGN.COM M3x8 SHCS APPLY VHB TAPE M3x8 SHCS 250 WWW.VORONDESIGN.COM This page intentionally left blank. 251 PANELS & FINISHING TOUCHES 252 WWW.VORONDESIGN.COM PANELS WWW.VORONDESIGN.COM M5 T-Nut 253 PANELS WWW.VORONDESIGN.COM HAMMERHEAD NUTS? A drop of thread locker will turn the hammerhead nuts into a 1/4 turn quick release for the panels. Best done once the assembly is finished. M3x8 SHCS Foam Tape M3 Hammerhead Nut APPLY FOAM TAPE Use foam tape on the contact areas between the panels and the frame to mitigate noise from vibrations. 254 PANELS WWW.VORONDESIGN.COM 255 PANELS WWW.VORONDESIGN.COM Foam Tape Foam Tape APPLY FOAM TAPE Use foam tape on the contact areas between the panels and the frame to mitigate noise from vibrations. 256 PANELS WWW.VORONDESIGN.COM M3x12 SHCS Foam Tape APPLY FOAM TAPE Use foam tape on the contact areas M3 Hammerhead Nut between the panels and the frame to mitigate noise from vibrations. 257 PANELS 258 WWW.VORONDESIGN.COM PANELS WWW.VORONDESIGN.COM M3x12 SHCS Foam Tape APPLY FOAM TAPE M3 Hammerhead Nut Use foam tape on the contact areas between the panels and the frame to mitigate noise from vibrations. 259 PANELS 260 WWW.VORONDESIGN.COM PANELS WWW.VORONDESIGN.COM Foam Tape APPLY FOAM TAPE Use foam tape on the contact areas between the panels and the frame to mitigate noise from vibrations. M3x8 SHCS M3 Hammerhead Nut 261 PANELS 262 WWW.VORONDESIGN.COM PANELS WWW.VORONDESIGN.COM M3 Hammerhead Nut Magnets GLUE INTO PLACE Use a fast acting glue like super-glue. M3x8 SHCS Magnets MIND THE MAGNET POLARITY Ensure that the magnets are facing in the right direction prior to glueing them into place. 263 PANELS 264 WWW.VORONDESIGN.COM PANELS WWW.VORONDESIGN.COM M3 Hammerhead Nut M3x8 SHCS APPLY VHB TAPE VHB Tape is a double sided adhesive tape. 265 PANELS WWW.VORONDESIGN.COM APPLY VHB TAPE VHB Tape is a double sided adhesive tape. 266 PANELS WWW.VORONDESIGN.COM 267 EXHAUST WWW.VORONDESIGN.COM Heat Set Insert 268 EXHAUST WWW.VORONDESIGN.COM BSPP ADAPTER Some adapters have a small lip that prevents the PTFE tube from passing through. Inspect the adapter and if necessary use a drill to carefully remove the lip. 269 EXHAUST WWW.VORONDESIGN.COM M3x8 SHCS M3x30 SHCS 270 EXHAUST APPLY VHB TAPE VHB Tape is a double sided WWW.VORONDESIGN.COM Filter Material adhesive tape. 271 EXHAUST WWW.VORONDESIGN.COM M3x12 SHCS 272 EXHAUST WWW.VORONDESIGN.COM REMOVE TAPE BACKING 273 WIRING WWW.VORONDESIGN.COM M6 EXHAUST FAN 2x 0.25mm²(AWG24) or larger E0 OUT E1 OUT E2 OUT BED OUT BED IN PWR IN Exhaust Fan M5 X- M3 Y- M2 Z- FAN0 FAN1 FAN2 TE0 274 M4 Z+ TB EXP1 EXP2 M1 SPOOL HOLDER WWW.VORONDESIGN.COM M3x8 SHCS M3 Hammerhead Nut 275 SPOOL HOLDER WWW.VORONDESIGN.COM PTFE Tube M5x16 BHCS 276 NEXT STEPS WWW.VORONDESIGN.COM ASSEMBLY COMPLETED! ... NEXT STEP: SETUP & CALIBRATION This manual is designed to be a simple reference manual for the build process. For details on the setup of the electronics and other initial steps of your new printer please visit our documentation available on github and docs.vorondesign.com. DOCS https://docs.vorondesign.com/ https://github.com/VoronDesign/Voron-1 HOW TO GET HELP If you need assistance with your build, we’re here to help. Head on over to our Discord group and post your questions. This is our primary medium to help VORON Users and we have a great community that can help you out if you get stuck. https://discord.gg/voron 277 WWW.VORONDESIGN.COM VORON Website www.vorondesign.com 278 Github https://github.com/vorondesign Discord https://discord.gg/voron WWW.VORONDESIGN.COM 279