INTRODUCTION TO

ENGINEERING MATERIALS

Chapter 3 -

Materials Science

- Study of the properties of solid

materials and how those properties

are determined by the material's

composition and structure, both

macroscopic and microscopic

Chapter 3 -

Materials of Engineering

- refers to selecting the correct

materials for the application in which

the engineered part is being used.

- This selection process includes

choosing the material, paying attention

to its specific type or grade based on

the required properties.

Chapter 3 -

Materials

• Over 70,000 different kinds and grades of engineering

materials

• This number grows daily

• 1,000 different materials

make up an

automobile

Chapter 3 -

The Three Basics:

• Metals

• Polymers

– Composites

• Ceramics

Chapter 3 -

Metal

• Cast Iron

• Steel

– Mild steel, medium carbon steel, high carbon steel

• Specialty steel

– Stainless (tin plated or galvanized)

• Alloys (two or more pure metals)

– Steel= iron & carbon

– Brass= copper & zinc

– Bronze= copper & tin

Chapter 3 -

Polymers

• Natural

–Animal cellulose

• Synthetic–Thermoplastics

–Thermosets

Chapter 3 -

Natural Composites

• Hardwood

–Deciduous Trees

• Softwood

–Coniferous

Chapter 3 -

Hardwoods

•

•

•

•

•

•

•

•

•

Ash

Beech

Birch

Cherry

Mahogany

Maple

Oak

Poplar

walnut

Chapter 3 -

Softwoods

•

•

•

•

•

•

Cedar

Cypress

Fir

Pine

Redwood

Spruce

Chapter 3 -

Ceramics

• Clay based

– Structural clay-tile, brick

– Porcelain

• Refractories

– Heat resistant (fire bricks)

• Glasses

• Inorganic cements

Chapter 3 -

Manufactured Wood

• Particle Board

–flake board, particle board

• Laminar

–plywood, laminated beams

Chapter 3 -

Composite

Lamborghini carbon

fiber materials

chassis. Carbon

Fiber Reinforced

Plastics

Space Shuttle Reusable

Ceramic Tiles

Chapter 3 -

Semiconductor

Chapter 3 -

Biomaterials

Chapter 3 -

Nano engineered material

Chapter 3 -

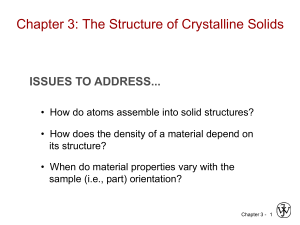

The Structure of Crystalline Solids

• How do atoms assemble into solid structures?

• How does the density of a material depend on

its structure?

• When do material properties vary with the

sample (i.e., part) orientation?

Chapter 3 -

17

Energy and Packing

• Non dense, random packing

Energy

typical neighbor

bond length

typical neighbor

bond energy

r

Energy

• Dense, ordered packing

typical neighbor

bond length

typical neighbor

bond energy

r

Dense, ordered packed structures tend to have

lower energies.

Chapter 3 -

18

Materials and Packing

Crystalline materials...

• atoms pack in periodic, 3D arrays

• typical of: -metals

-many ceramics

-some polymers

crystalline SiO2

Adapted from Fig. 3.23(a),

Callister & Rethwisch 8e.

Noncrystalline materials...

• atoms have no periodic packing

• occurs for: -complex structures

-rapid cooling

"Amorphous" = Noncrystalline

Si

Oxygen

noncrystalline SiO2

Adapted from Fig. 3.23(b),

Callister & Rethwisch 8e.

Chapter 3 -

19

Metallic Crystal Structures

• How can we stack metal atoms to minimize

empty space?

2-dimensions

vs.

Now stack these 2-D layers to make 3-D structures

Chapter 3 -

20

Simple Cubic Structure (SC)

• Rare due to low packing density (only Po has this structure)

• Close-packed directions are cube edges.

• Coordination # = 6

(# nearest neighbors)

Click once on image to start animation

(Courtesy P.M. Anderson)

Chapter 3 -

21

Atomic Packing Factor (APF)

Volume of atoms in unit cell*

APF =

Volume of unit cell

*assume hard spheres

• APF for a simple cubic structure = 0.52

atoms

unit cell

a

R=0.5a

APF =

volume

atom

4

p (0.5a) 3

1

3

a3

close-packed directions

contains 8 x 1/8 =

1 atom/unit cell

Adapted from Fig. 3.24,

Callister & Rethwisch 8e.

volume

unit cell

Chapter 3 -

22

Body Centered Cubic Structure (BCC)

• Atoms touch each other along cube diagonals.

--Note: All atoms are identical; the center atom is shaded

differently only for ease of viewing.

ex: Cr, W, Fe (), Tantalum, Molybdenum

• Coordination # = 8

Click once on image to start animation

(Courtesy P.M. Anderson)

Adapted from Fig. 3.2,

Callister & Rethwisch 8e.

2 atoms/unit cell: 1 center + 8 corners x 1/8

Chapter 3 -

23

Atomic Packing Factor: BCC

• APF for a body-centered cubic structure = 0.68

3a

a

2a

Adapted from

Fig. 3.2(a), Callister &

Rethwisch 8e.

R

a

Close-packed directions:

length = 4R = 3 a

atoms

volume

4

p ( 3a/4) 3

2

unit cell

atom

3

APF =

volume

3

a

unit cell

Chapter 3 -

24

Face Centered Cubic Structure (FCC)

• Atoms touch each other along face diagonals.

--Note: All atoms are identical; the face-centered atoms are shaded

differently only for ease of viewing.

ex: Al, Cu, Au, Pb, Ni, Pt, Ag

• Coordination # = 12

Adapted from Fig. 3.1, Callister & Rethwisch 8e.

Click once on image to start animation

(Courtesy P.M. Anderson)

4 atoms/unit cell: 6 face x 1/2 + 8 corners x 1/8

Chapter 3 -

25

Atomic Packing Factor: FCC

• APF for a face-centered cubic structure = 0.74

maximum achievable APF

Close-packed directions:

length = 4R = 2 a

2a

a

Adapted from

Fig. 3.1(a),

Callister &

Rethwisch 8e.

Unit cell contains:

6 x 1/2 + 8 x 1/8

= 4 atoms/unit cell

atoms

volume

4

3

p ( 2a/4)

4

unit cell

atom

3

APF =

volume

3

a

unit cell

Chapter 3 -

26

FCC Stacking Sequence

• ABCABC... Stacking Sequence

• 2D Projection

B

B

C

A

B

B

B

A sites

C

C

B sites

B

B

C sites

• FCC Unit Cell

A

B

C

Chapter 3 -

27

Hexagonal Close-Packed Structure

(HCP)

• ABAB... Stacking Sequence

• 3D Projection

c

a

• 2D Projection

A sites

Top layer

B sites

Middle layer

A sites

Bottom layer

Adapted from Fig. 3.3(a),

Callister & Rethwisch 8e.

• Coordination # = 12

• APF = 0.74

• c/a = 1.633

6 atoms/unit cell

ex: Cd, Mg, Ti, Zn

Chapter 3 -

28

Theoretical Density, r

Density = r =

r =

where

Mass of Atoms in Unit Cell

Total Volume of Unit Cell

nA

VC NA

n = number of atoms/unit cell

A = atomic weight

VC = Volume of unit cell = a3 for cubic

NA = Avogadro’s number

= 6.022 x 1023 atoms/mol

Chapter 3 -

29

Theoretical Density, r

• Ex: Cr (BCC)

A = 52.00 g/mol

R = 0.125 nm

n = 2 atoms/unit cell

Adapted from

Fig. 3.2(a), Callister &

Rethwisch 8e.

atoms

unit cell

r=

volume

unit cell

R

a

2 52.00

a3 6.022 x 1023

a = 4R/ 3 = 0.2887 nm

g

mol

rtheoretical = 7.18 g/cm3

ractual

atoms

mol

= 7.19 g/cm3

Chapter 3 -

30

Densities of Material Classes

In general

rmetals > rceramics > rpolymers

30

Why?

Metals have...

Ceramics have...

• less dense packing

• often lighter elements

Polymers have...

r (g/cm3 )

• close-packing

(metallic bonding)

• often large atomic masses

• low packing density

(often amorphous)

• lighter elements (C,H,O)

Composites have...

• intermediate values

Metals/

Alloys

20

Platinum

Gold, W

Tantalum

10

Silver, Mo

Cu,Ni

Steels

Tin, Zinc

5

4

3

2

1

0.5

0.4

0.3

Titanium

Aluminum

Magnesium

Graphite/

Ceramics/

Semicond

Polymers

Composites/

fibers

Based on data in Table B1, Callister

*GFRE, CFRE, & AFRE are Glass,

Carbon, & Aramid Fiber-Reinforced

Epoxy composites (values based on

60% volume fraction of aligned fibers

in an epoxy matrix).

Zirconia

Al oxide

Diamond

Si nitride

Glass -soda

Concrete

Silicon

Graphite

PTFE

Silicone

PVC

PET

PC

HDPE, PS

PP, LDPE

Glass fibers

GFRE*

Carbon fibers

CFRE*

Aramid fibers

AFRE*

Wood

Data from Table B.1, Callister & Rethwisch, 8e.

Chapter 3 -

31

Single vs Polycrystals

• Single Crystals

E (diagonal) = 273 GPa

Data from Table 3.3,

Callister & Rethwisch

8e. (Source of data is

R.W. Hertzberg,

Deformation and

Fracture Mechanics of

Engineering Materials,

3rd ed., John Wiley and

Sons, 1989.)

-Properties vary with

direction: anisotropic.

-Example: the modulus

of elasticity (E) in BCC iron:

• Polycrystals

-Properties may/may not

vary with direction.

-If grains are randomly

oriented: isotropic.

(Epoly iron = 210 GPa)

-If grains are textured,

anisotropic.

E (edge) = 125 GPa

200 mm

Adapted from Fig.

4.14(b), Callister &

Rethwisch 8e.

(Fig. 4.14(b) is courtesy

of L.C. Smith and C.

Brady, the National

Bureau of Standards,

Washington, DC [now

the National Institute of

Standards and

Technology,

Gaithersburg, MD].)

Chapter 3 -

32

Polymorphism

• Two or more distinct crystal structures for the same

material (allotropy/polymorphism)

iron system

titanium

liquid

, -Ti

1538ºC

-Fe

BCC

carbon

1394ºC

diamond, graphite

-Fe

FCC

912ºC

BCC

-Fe

Chapter 3 -

33

Crystal Systems

Unit cell: smallest repetitive volume which

contains the complete lattice pattern of a crystal.

7 crystal systems

14 crystal lattices

a, b, and c are the lattice constants

Fig. 3.4, Callister & Rethwisch 8e.

Chapter 3 -

34

Point Coordinates

z

Point coordinates for unit cell

center are

111

c

a/2, b/2, c/2

y

000

a

x

½½½

b

Point coordinates for unit cell

corner are 111

z

2c

b

y

Translation: integer multiple of

lattice constants identical

position in another unit cell

b

Chapter 3 -

35

Crystallographic Directions

z

pt. 2

head

Example 2:

pt. 1 x1 = a, y1 = b/2, z1 = 0

pt. 2 x2 = -a, y2 = b, z2 = c

y

x

pt. 1:

tail

=> -2, 1/2, 1

Multiplying by 2 to eliminate the fraction

-4, 1, 2 => [ 412 ]

where the overbar represents a

negative index

families of directions <uvw>

Chapter 3 -

36

Crystallographic Directions

z

Algorithm

1. Vector repositioned (if necessary) to pass

through origin.

2. Read off projections in terms of

unit cell dimensions a, b, and c

y 3. Adjust to smallest integer values

4. Enclose in square brackets, no commas

[uvw]

x

ex: 1, 0, ½ => 2, 0, 1 => [ 201 ]

-1, 1, 1 => [ 111 ]

where overbar represents a

negative index

families of directions <uvw>

Chapter 3 -

37

Linear Density

• Linear Density of Atoms LD =

Number of atoms

Unit length of direction vector

[110]

ex: linear density of Al in [110]

direction

a = 0.405 nm

# atoms

a

Adapted from

Fig. 3.1(a),

Callister &

Rethwisch 8e.

LD =

length

2

= 3.5 nm-1

2a

Chapter 3 -

38

HCP Crystallographic Directions

z

Algorithm

a2

-

a3

a1

1. Vector repositioned (if necessary) to pass

through origin.

2. Read off projections in terms of unit

cell dimensions a1, a2, a3, or c

3. Adjust to smallest integer values

4. Enclose in square brackets, no commas

[uvtw]

a

2

Adapted from Fig. 3.8(a),

Callister & Rethwisch 8e.

ex:

½, ½, -1, 0

-a3

a2

2

=>

[ 1120 ]

a3

dashed red lines indicate

projections onto a1 and a2 axes

a1

2

a1

Chapter 3 -

39

HCP Crystallographic Directions

• Hexagonal Crystals

– 4 parameter Miller-Bravais lattice coordinates are

related to the direction indices (i.e., u'v'w') as

follows.

z

[ u 'v 'w ' ] [ uvtw ]

a2

-

a3

a1

1

u = (2 u ' - v ')

3

1

v = (2 v ' - u ')

3

t = - (u +v )

w = w'

Fig. 3.8(a), Callister & Rethwisch 8e.

Chapter 3 -

40

Crystallographic Planes

Adapted from Fig. 3.10,

Callister & Rethwisch 8e.

Chapter 3 -

41

Crystallographic Planes

• Miller Indices: Reciprocals of the (three) axial

intercepts for a plane, cleared of fractions &

common multiples. All parallel planes have

same Miller indices.

• Algorithm

1. Read off intercepts of plane with axes in

terms of a, b, c

2. Take reciprocals of intercepts

3. Reduce to smallest integer values

4. Enclose in parentheses, no

commas i.e., (hkl)

Chapter 3 -

42

Crystallographic Planes

z

example

1. Intercepts

2. Reciprocals

3.

Reduction

a

1

1/1

1

1

4.

Miller Indices

(110)

example

1. Intercepts

2. Reciprocals

3.

Reduction

a

1/2

1/½

2

2

4.

Miller Indices

(100)

b

1

1/1

1

1

c

1/

0

0

c

y

b

a

x

b

1/

0

0

c

1/

0

0

z

c

y

a

b

x

Chapter 3 -

43

Crystallographic Planes

z

example

1. Intercepts

2. Reciprocals

3.

Reduction

4.

Miller Indices

a

1/2

1/½

2

6

b

1

1/1

1

3

(634)

c

c

3/4

1/¾

4/3

4 a

x

y

b

Family of Planes {hkl}

Ex: {100} = (100), (010), (001), (100), (010), (001)

Chapter 3 -

44

Crystallographic Planes (HCP)

• In hexagonal unit cells the same idea is used

z

example

1. Intercepts

2. Reciprocals

3.

Reduction

a1

1

1

1

1

a2

1/

0

0

a3

-1

-1

-1

-1

c

1

1

1

1

a2

a3

4.

Miller-Bravais Indices

(1011)

a1

Adapted from Fig. 3.8(b),

Callister & Rethwisch 8e.

Chapter 3 -

45

Crystallographic Planes

•

•

We want to examine the atomic packing of

crystallographic planes

Iron foil can be used as a catalyst. The

atomic packing of the exposed planes is

important.

a) Draw (100) and (111) crystallographic planes

for Fe.

b) Calculate the planar density for each of these

planes.

Chapter 3 -

46

Virtual Materials Science & Engineering (VMSE)

• VMSE is a tool to visualize materials science topics such as

crystallography and polymer structures in three dimensions

• Available in Student Companion Site at www.wiley.com/college/callister

and in WileyPLUS

Chapter 3 -

47

VMSE: Metallic Crystal Structures &

Crystallography Module

• VMSE allows you to view crystal structures, directions, planes,

etc. and manipulate them in three dimensions

Chapter 3 -

48

Unit Cells for Metals

• VMSE allows you to view the unit cells and manipulate

them in three dimensions

• Below are examples of actual VMSE screen shots

FCC Structure

HCP Structure

Chapter 3 -

49

VMSE: Crystallographic Planes Exercises

Additional practice on indexing crystallographic planes

Chapter 3 -

50

Planar Density of (100) Iron

Solution: At T < 912ºC iron has the BCC structure.

2D repeat unit

(100)

Planar Density =

area

2D repeat unit

1

a2

=

4 3

R

3

Radius of iron R = 0.1241 nm

Adapted from Fig. 3.2(c), Callister & Rethwisch 8e.

atoms

2D repeat unit

a=

1

4 3

R

3

atoms

atoms

19

= 1.2 x 10

2 = 12.1

2

nm

m2

Chapter 3 -

51

Planar Density of (111) Iron

Solution (cont): (111) plane

1 atom in plane/ unit surface cell

2a

atoms in plane

atoms above plane

atoms below plane

h=

3

a

2

2

atoms

2D repeat unit

4 3 16 3 2

2

area = 2 ah = 3 a = 3

R =

R

3

3

1

atoms =

= 7.0

2

Planar Density =

area

2D repeat unit

16 3

3

R

2

nm

0.70 x 1019

atoms

m2

Chapter 3 -

52

VMSE Planar Atomic Arrangements

• VMSE allows you to view planar arrangements and rotate

them in 3 dimensions

BCC (110) Plane

Chapter 3 -

53

X-Ray Diffraction

• Diffraction gratings must have spacings comparable to

the wavelength of diffracted radiation.

• Can’t resolve spacings

• Spacing is the distance between parallel planes of

atoms.

Chapter 3 -

54

X-Rays to Determine Crystal Structure

• Incoming X-rays diffract from crystal planes.

extra

distance

travelled

by wave “2”

q

q

d

Measurement of

critical angle, qc,

allows computation of

planar spacing, d.

reflections must

be in phase for

a detectable signal

Adapted from Fig. 3.20,

Callister & Rethwisch 8e.

spacing

between

planes

X-ray

intensity

(from

detector)

n

d=

2 sin qc

q

qc

Chapter 3 -

55

X-Ray Diffraction Pattern

z

z

Intensity (relative)

c

a

x

z

c

b

y (110)

a

x

c

b

y

a

x (211)

b

y

(200)

Diffraction angle 2q

Diffraction pattern for polycrystalline -iron (BCC)

Adapted from Fig. 3.22, Callister 8e.

Chapter 3 -

56

SUMMARY

• Atoms may assemble into crystalline or

amorphous structures.

• Common metallic crystal structures are FCC, BCC, and

HCP. Coordination number and atomic packing factor

are the same for both FCC and HCP crystal structures.

• We can predict the density of a material, provided we

know the atomic weight, atomic radius, and crystal

geometry (e.g., FCC, BCC, HCP).

• Crystallographic points, directions and planes are

specified in terms of indexing schemes.

Crystallographic directions and planes are related

to atomic linear densities and planar densities.

Chapter 3 -

57

SUMMARY

• Materials can be single crystals or polycrystalline.

Material properties generally vary with single crystal

orientation (i.e., they are anisotropic), but are generally

non-directional (i.e., they are isotropic) in polycrystals

with randomly oriented grains.

• Some materials can have more than one crystal

structure. This is referred to as polymorphism (or

allotropy).

• X-ray diffraction is used for crystal structure and

interplanar spacing determinations.

Chapter 3 -

58

ASSIGNMENT (by-group)

Make a power point presentation

and report on the following topics:

1.

Metals

A. Iron (group1)

B. Steel (2)

C. Aluminum (3)

D. Copper (4)

2. Polymers

A. PVC (5)

B. Rubber (6)

C. Kevlar (7)

3. Ceramics

A. Glass (8)

B. Cement (9)

4. Semiconductor (10)

The presentation outline the

discussion on the materials:

1. Discovery

2. Properties (physical and

chemical)

3. Manufacturing processes

4. Uses

NOTE: Everyone must take part in

the report.

Chapter 3 -

59