Indian Standard

( Reaffirmed 2001 )

SPECIFICATION FOR

PVC INSULATION AND SHEATH OF

ELECTRIC CABLES

(

First Revision )

Fourth Reprint JANUARY 1998

UDC 621.315.221.8:621.315.616.96[678.743.22]

B U R E A U QP I N D I A N BTANDARDI

MANAlL EHAVAN, 9 BAHADUR SHAH ZAPAR INAltONEW DELHI 110002

s#pmbn 1984

IS : 5831.1984

Indian Standard

SPECIFICATION FOR

PVC INSULATION AND SHEATH OF

ELECTRIC CABLES

( First Revisiop )

Power Cables Sectional Committee, ETDC 59

Chairman

SEIRI M. L. DON~RE

M-3, Satyam,

88, Sion Circle, Bombay

Represent&g

Bharat Heavy Electricals Ltd, Hyderabad

Members

SHRI J. P. ANAL

S HRI B. P. RAI ( Alternate)

S HRI M. R. BEAT

SHRI D. K. BASU ( Alternate )

CHIEF ENGINEER ( EL E C T R I C A L ) I

WORKS

S URVEYOR o F

( ELECT ) V ( Alternate )

D R K. DAS G U P T A

Tata Consulting Engineers, Bombay

Central Public Works Department, New Delhi

Calcutta Electric Supply Corporation ( India )

Ltd, Calcutta

S HRI P. NEOQI ( Alternate )

Central Power Research Institute, Bangalore

D IRECTOR

S HRI M. C. RATRA (Alternate )

S AFETY Directorate General of Mines Safety, Dhanbad

D IRECTOR OR M I N E S

( ELECT ) ( HQ )

D IRECTOR OF, MINES SAFZTY

( ELECT ) ( Alternate )

Cable and Conductor Manufacturers’ Association

S HRI R AVI K. DU T T

of India, New Delhi

SHRI S. R. SARAN ( Alternate )

Indian Cable Co Ltd, Jamshedpur

SIIRI P. Grrosu

SHRI K. V. R. Rao ( Alternate )

Cable Corporation of India Ltd, Bombay

SHRI M. M. H~NAVAR

\

SIIRI S. R. PAUMAN~BHAN ( Alternate J

Directorate

of Technical Development & ProducSI~I D. K. J AIN

tion ( Air ), New Delhi

SIII~I V. K. Snanaa~ ( Alternate )

Bombay Suburban Electric Supply Ltd, Bombay

SIII<I K. S. Josrrr

Srirtr R. K. Ssaoa~ ( Alternate )

( Continued on page 2 )

@ CoPYright 1984

BUREAU OF INDIAN STANDARDS

This publication is protected under the Indian Copyright Act (XIV of 1957 ) and

reproduction in whole or in part by any means except with written permission of the

publisher shall be deemed to be an infringement of copyright under the said Act.

IS:!X?l- 1984

( Continuedfrom page 1

)

Members

Representing

SHRI S. L. KA K R A R

Universal Cables Ltd, Satna

SHRI R. C. AQRAWAL ( Alternate )

S HRI R AJ K. MI T A L

Delhi Electric Supply Undertaking, New Delhi

SHRI V. K. SAEHUJA (Alternate )

S HRI R. V. NA R A Y A N A N

Directorate General of Supplies & Disposals

( Inspection Wing ), New Delhi

S HRI D. R. C HANDRA ( Altevuzte )

S HRI H. M. PAI

The Federation of Electricity Undertakings of

India, Bombay

SEEIMATI C. BALI~A ( Alternate )

SHRI S. N . PARWAL

The Premier Cable Co Ltd, Eranakulam

( Kerala )

Asian Cables Corporation Ltd, Bombay

S HRI A. K. RA~AN

S HRI S. M. SA E H A L K A R

Bombay Electric Supply & Transport Undertaking, Bombay

S HRI S. V. U PASANI ( Alternate )

S HRI L. K. SAN~HI

Fort Gloster Industries Ltd, Howrah

SHRI A. S. BZIATTACHARJEE ( Alternate )

Controllerate of Inspection Electronics, Bangalore

LT-COL S. R. SEN

S HRI S. K. MALHOTRA C Alternate )

Punjab Research Institute, Rajpura

D R M. S. SUKIIIJA

National Test House, Calcutta

SHRI U. S. VERMA

S RRI R. RAI~AERISIXNA ( Alternate )

Oriental Power Cables Ltd, Kota

S HRI K. G. WARRIER

S HRI B. K. M UNDHRA ( Alternafc)

Director General, IS1 ( Ex-o&id Mumber )

S HRI S. P. SAC~DEV,

Director ( Elec tech )

Secretary

S HRI K. M. B H A T I A

Senior Deputy Director ( Elec tech ), IS1

Panel for Elastomeric and Thermoplastic Cables, ETDC 59/P4

Convener

Fort Gloster Industries Ltd, Howrah

Members

S HRI A. S. B HATTACHARJEE ( Alternale to

Shri L. K. Sanghi )

The Calcutta Electric Supply Corporation

SHRI B. R OY CHOWDHURY

( India ) Ltd, Calcutta

S HRI P. NEO~I ( Alternate )

Indian Cable Co Ltd, Jamshedpur

S HRI P. GHOSR

S HRI K. V. R. R AO (Alternate )

Cable Corporation of India Ltd, Bombay

SHRI M. M. HO N A V A R

S RRI S. R. PADMANABHAN ( Alternate )

Universal Cables Ltd, Satoa

S HRI S. L. KA K K A R

SHRI R. C. AORAWAL ( Altsmafe )

The Ahmedabad Electricity Co Ltd, Ahmadabad

S HRI J. V. ME H T A

Oriental Power Cables Ltd, Kota

S HRI B. K. MIJNDHRA

Delhi Electricity Supply Undertaking, New Delhi

S HRI A. S. PINTO

Industrial Cables ( India ) Ltd, Rajpura

S HRI S. R. SA R A N

SlsRIL.K.SANQHI

2

IS:5831-1984

Indian Standard

SPECIFICATION FOR

PVC INSULATION AND SHEATH OF

ELECTRIC CABLES

( First Revision)

0. FOREWORD

0.1 This Indian Standard ( First Revision ) was adopted by the Indian

Standards Institution on 30 April 1984, after the draft finalized by the

Power Cables Sectional Committee had been approved by the Electrotechnical Division Council.

0.2 This standard was originally published in 1970 with d view to bring

under a single cover the various requirements for PVC insulation and

sheath of different types of cables.

0.3. This revision has been undertaken to update it in the li~llt of further

experience and developments and to align with international practice,

where appropriate. Details about methods of test have been, by and large,

taken out from this standard and are now covered in a separate standard,

to which reference has been made at appropriate places.

U.4 This standard is complementary to the individual specification for

different types of cables.

0.5 In preparing this standard, considerable assistance has been derived

from IEC Publication 502 ( 1983 ) ‘ Extruded solid dielectric insulated

power cables for rated voltages from 1 kV up to 30 kV ‘, issued by the

International Electrotechnical Commission ( IBC ) .

0.6 For the purpose of deciding whether a particular requirement of this

standard is complied with, the final value, observed or calculated, expressing the result of a test shall be rounded off in accordance with IS : 2-1960*.

The number of significant places retained in the rounded off value should

be the same as that of the specified value in this standard.

*Rules for rounding off numerical values ( revised ).

3

IS : 5831. 1984

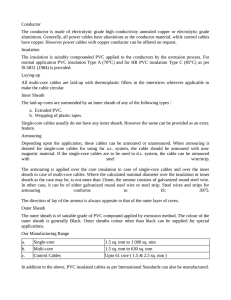

1. SCOPE

1.1 This standard specifies the physical and electrical requirements for

PVC insulation and sheath of electric cables.

1.2 The types of PVC compounds covered by this standard are given

below:

General purpose insulation for maximum rated conductor

Type A

temperature 70°C intended for cables with rated voltages

U,/U up to and including 3.313.3 kV.

General purpose insulation for maximum rated conductor

Type B

temperature 7OW intended for cables with rated voltages

U,/U above 3-313.3 kV.

Heat

resisting insulation for maximum rated conductor

Type C

temperature 85°C intended for cables with rated voltages

up to and including 1 100 volts.

Type ST1 General purpose sheath intended for use in cables operating at a maximum rated conductor temperature 70°C.

Type ST2 Heat resisting sheath intended for use in cables operating at a maximum rated conductor temperature 90°C.

2. TERMINOLOGY

2.0 For the purpose of this standard, the definitions given in IS : 1885

( Part 32 )-1971* shall apply, in addition to the following.

2.1 Variation - Difference between the median value obtained after

ageing and the median vaIue obtained without ageing, expressed as a

percentage of the latter.

3. COMPOSITION

5.1 The insulation or sheath shail consist of a compound based on one of

the following materials, which have been suitably compounded and processed to meet the requirements of this standard:

a) Polyvinyl chloride ( PVC ),

b) Suitable co-polymers of which the major constituent shall be vinyl

chloride,

c) Mixture of (a) and (b).

4. TEST

REQUIREMENTS

4.1 The insulation and sheath shall satisfy the test requirements stated in

Tables 1 and 2 respectively, to the extent specified in the relevant cable

standard.

+Electrotechnical vocabulary : Part 32 Cables, conductors and accessories for electric

SUPPlY -

4

IS : 5831 - 1984

TABLE 1

TEST REQUIREMENTS FOR PVC INSULATION

( c1uusc 4.1 )

SL

No.

(1)

T EST

(2)

i) Volume resistivity, Min

a) at 27°C ($81 Note 1 )

b) at maximum

rated

temperature ( ice 1.2 )

ii) Insulation resistance constant, Min

a) at 27*C ( see Note 1 )

b) at maximum rated

temperature ( se.9 1.2 )

iii) Without ageing

a) Tensile strength, Min

b) Elongation at break,

Min

iv)

After ageing in air oven

f Tempera1 ture (tolea) Treatment { rance

I rt2”C)

[Duration

b) Tensile strength

1) gfiue after ageing,

2) Variation, Max

c) Elongation at break

1) Vr&ue after ageing,

2) Variation, Max

v)

Loss of mass in air oven

[Tempera1 tllre ( tolea) Treatment{ rance

I. ,!:,:I2

U NIT

T YPE OF INSULATION

~~~~~h~_~~~~

C

A

B

(3)

(4)

(5)

(6)

Ohm-cm

Ohm-cm

1 x 10’3

1 x 10’0

1 x 1014

1 x 10’s

I x 1010

I x 1011

M ETHOD

OB TE S T

~zz?G:.

OB IS:

10810+ )

(7)

43

43

MQkm

MS&km

36’7

0.037

367

0’37

36.7

0.037

N/mms

percent

12’5

150

12.5

135

12’5

125

“C

80

100

135

days

7

7

7

12’5

7

II

N/mm*

12’5

12’5

percent

f 20

f 25

percent

150

125

percent

f 20

f 25

“C

80

days

7

-

-

f 25

125

* 35

-

10

( conrirmd )

5

ISr!ml-1984

TABLE I

TEST REQUIREMENTS FOR PVC INSULATION - Contd

SL

No.

TEST

(1)

(2)

UNIT

T YPE OB INEIULATJON

F-_-h_---~

B

C

A

(3)

(4)

(5)

(6)

“C

80

80

95

hours

4

6

50

-

vi) Hot deformation test

Test temperature

( tolerance f 2°C )

Time under load ( MC

Note 2 )

First case

Second case

Depth of indentation,

Max

METHOD

T EST

( R EB TO

P ABT No.

OP IS :

108105 )

OF

(7)

15

hours

percent

6

50

6

50

14

vii) Heat shock test

r TemperaI ture (tolea) Treatment{ rance

I *2”c)

[Duration

b) Visual examination

“C

150

150

150

I

I

1

No signs of cracks or scales

hour

-

12

viii) Shrinkage test

r Tempera) ture ( tolea) Treatment { rance

I f 2°C)

LDuration

b) Shrinkage, Max

“C

150

150

150

minutes

percent

15

4

15

4

15

4

20

ix) Cold bend test

(for diameter < 12’5 mm)

a) Test temperature ( tolcrancc * 2°C )

b) Visual examination

“C

- 15

- 5

- 15

No signs of cracks or scales

21

x) C o l d i m p a c t trst ( for d i a m e t e r > 12.5 IllIn )

a) Test t?mpt’rature ( tole-

“C

- 5

b) Visual examination

-

No signs of cracks or scales

r a n c e f 2%

)

- 5

- 5

( Continued )

6

Isr5831-1984

TABLE

1 TEST REQUIREMENTS FOR PVC INSULATION - Contd

TEST

(2)

(1)

xi)

xii)

T YPE OB INSULATION

C__-h--7

C

B

A

U NIT

(8)

Colour fastness to daylight

exposure, Mitt

Colour fastness to water

C Tempera1 ture ( tolea) Treatment{ rance

(4)

4

rating

“C

70

(Duration

hours

b) Visual examination

xiii) Thermal stability

“C

a) Test temperature

( tolerance * 0’5OC )

minutes

b) Time, Min

xiv) Bleeding and blooming test

( Tempera“C

( ture ( tolea) Treatment{ rance

I f 2°C)

1 Duration

hours

b) Observation

Water absorption test

( gravimetric )

f TemperaI t u r e ( totea) Treatment {’ rance’

I l PC 1

1 Duration

b) Water absorbed, Max

(8)

4

( I~C Note 3 )

I f 2OC)

xv)

(5)

4

METHOD

OB TEST

( REP TO

P ART No.

OF IS :

10810* )

(7)

18

70

70

48

48

48

fret from traces of colour

( w Note 4 )

200

200

200

80

100

100

50

50

50

19

72

72

72

no appreciable staining of

indicator compound or

filter paper

33

*Cl

85

days

mg/cms

-

14

10

-

-

NOTE 1 - V o l u m e resis_tivity and insulation resiattnce tests mpy be done at

room temperature instead oi 27°C. However, in case of doubt or disputr, the test

results shall bc confirmed by testing at 27°C.

N OTE 2 - Time under load:

First case- Cab1t.s having a rated voltage not exceeding 3*3/3*3’3 kV

and a wnductor cross-section notexceeding 35 mm*.

Second cate-Cables not covered under first case.

Now 3 - Undrr preparation. In the meantime, test method given in Appendix

A shall be folloued.

Norr~ 4 - Under p r e p a r a t i o n . I n t h e m e a n t i m e , t e s t m e t h o d s g i v e n i n

Appendix U shall be followed.

*Methods of tryst for cables.

7

1s : 5831 - 1984

TAELE 2

TEST REQUIREMENTS FOR PVC SHEATH

( Clause 4.1

TEST

T YPE OB SH E A T H

_--h-_--,

ST2 ’

ST1

UNIT

l%.

(1)

(2)

(3)

(4)

(5)

N/mm%

percent

12’5

150

12’5

150

“C

80

100

days

7

7

N/mm*

12.5

12.5

percent

f 20

f 25

percent

150

150

percent

z!z 20

f 25

“C

80

100

days

mg/cma

7

2

7

2

“C

80

30

hours

hours

percenl

:

50

ti

6

50

i) Without ageing

a) Tensile strength, Min

b) Elongation at break,

Min

11

Min

2) Variation, Max

iii)

10

Loss of mass in air oven

(TemperaI ture ( tolea) Treatment{ rance

I f 2°C)

(Duration

b) Loss of mass, MUX

15

iv) Hot deformation test

a) Test temperature

( tolerance l 2°C )

b) Time under load

( see Note 1 )

First case

Second case

c) Depth of indentation,

Max

(6)

7

ii) After ageing in air oven

r Temperature ( tolea) Treatment .! rance

i f 2oc)

1Duration

b) Tensile strength

1) Value after ageing,

Min

2) Variation, Max

c) Elongation at break

1) Value after ageing,

hhWHODOB

TEST (REP

PART No. or

IS: 10810* )

( Confinucd )

8

fSr5831-1984

TABLE 2

SL

No.

(1)

TEST REQUIREMENTS FOR PVC SHEATH - Confd

TEST

(2)

U NIT

TYPEOFSHEATH

_-h_l-y

‘ST1

ST2

(3)

(4)

“C

150

150

1

1

(5)

v) Heat shock test

(TemperaI ture f tolea) Treatment{ ran&

I * 2°C )

1Duration

b) Visual examination

hour

-

150

150

minutes

15

15

b) Shrinkage, M UX

percent

(6)

4

4

20

“C

- 15

- 15

No signs of cracks

or scales

b) Visual examination

21

“C

- 5

b) Visual examination

-

ix) Colour fastness to daylight

exposure, Min

rating

No signs of cracks

or scales

4

4

- 5

18

( See Note 2 )

x) Colour fastness to water

f TemperaI ture ( tolea) Treatment{ rance

i 2°C )

i, Duration

b) Visual examination

OP

12

“C

viii) Cold impact test for diameter > 12.5 mm

a) Test temperature

( tolerance * 2°C )

No.

No rigyc;racks or

CTempera1 ture ( tolea) Treatment{ rance

I -f 2 ° C )

LDuration

Cold bend test for diameter

< 12’5 mm

1) Test temperature

( tolerance * 2°C’

PAR;

I S : 10810* )

14

vi) Shrinkage test

vii)

M ETHOD OF

T EST f REPTO

“C

hours

-

70

70

48

48

Free from traces

of colours

( Confinued )

9

ISr!5831- 1984

TABLE 2 TEST REQUIREMENTS FOR PVC SHEATH - Contd

SL

No.

TEST

U NIT

(1)

(2)

(3)

T YPE OF S HEATH

~---_*_-~~

ST1

ST2

(4)

(5)

( See Note 3)

xi) Thermal stahility

a) Test temperature

( tolerance f 0’5%

M ETHOD OF

T EST ( REP TO

P ART No. O F

IS : l;)lo* )

)

bj Time, Min

OC

200

200

minutes

40

80

“C

50

50

72

72

xii) Bleeding and blooming

[Tempera/ ture \ ( tolea) Treatment{ rance

I f 2°C)

1 Duration

19

hours

appreciable

No

staining of indicator

compound or filter

pap&

b) Observations

-

xiii) Oxygen index

( Under consideration )

NOTE 1 - Time under load:

First case-4 hours for test piece having an outer diameter not

exceeding 12’5 mm.

Second case--6 hours for test piece having an outer diameter

exceeding 12’5 mm.

NOTE 2 - Under preparation. In the meantime, test method given in Appendix

A shall be followed.

N OTE 3 - Under preparation. In the meantime, test method given in Appendix

B shall be followed.

*Methods of test for cables.

10

IS: !%831-1984

APPENDIX A

[ Tuble 1, Item ( xii ) and Table 2, Item ( x ) ]

TEST FOR COLOUR FASTNESS TO WATER

A-l. A piece about 100 mm long of insulation or sheath is out into small

pieces and immersed for the specified period in about 10 times its own

volume of distilled water maintained at the specified temperature. At the

end of the period, the water shall be examined. It shall be free from any

trace of colour.

APPENDIX B

[ Table 1, Item ( xiii ) and Table 2, Item ( xi) ]

THERMAL STABILITY TEST

B-l. Testing Equipment

El.1 Class tubes closed at one end 110 mm long with an outer diameter

of approximately 5 mm and an inner diameter of 4.0 f 0.5 mm.

B-l.2 Universal indicating paper with a PH range of 1 to 10.

B-1.3 Thermostatically controlled heating apparatus for the specified

temperature.

B-l.4 Thermometer calibrated in divisions of O*l”C.

B-1.5 Stop-watch or a suitable time meter.

B-2. Testing M e t h o d

a) From the insulation of each core to be tested or from the sheath

to be tested, three samples, each of 50 f 5 mg, shall be taken in

the form of strip, if possible. For small thickness the sample

may consist of two or more strips. Each sample shall be inserted

into a glass tube as specified in B-1.1. The sample shall occupy

the bottom of the tube and not project more than 30 mm above

the bottom.

b) A strip of dry universal indicating paper as specified in B-1.2,

about 15 mm long and 3 mm wide, shall be inserted into the

open end ( top ) of the glass tube so that the strip protrudes

a b o u t 5 mm out of the tube and can be bent to keep it i n

position.

11

k3 : 5831 - 1984

c) The glass tube shall be placed into the heating apparatus, as

specified in B-1.3, which has already attained the test temperature specified. The glass tube shall be inserted. into the heating

apparatus for a depth of 60 mm.

4

The time taken for the universal indicating paper to change

colour from a pH value of 5 to a pH value of 3 shall be measured,

or the test continued for the specified duration without the

colour change occurring. The colour change point shall be considered to have been reached when the red colouring of the

universal indicating paper characteristic of a @H value of 3 is just

becoming visible. The universal indicating paper shall be

renewed ( especially for long duration stabilities ) ‘towards the

end of the expected test time every 5 to 10 min, so that the

change point is better visible.

B-3. Evaluation

B-3.1 The average value of the thermal stability times of the three samp

les shall not be lower than the value specified in Table 1 or Table 2 as

applicable.

12

BUREAU OF INDIAN STANDARDS

Headqiarters:

Manak Bhavan, 9 Bahadur Shah Zafar Marg, NEW DELHI 110002

Telephones: 323 0131, 323 3375,323 9402

Fax : 91 11 3234062,91 11 3239399,91 11 3239382

Telegrams : Manaksanstha

(Common to all Offices)

Central Laboratory:

Telephone

8-77 00 32

Plot No. 2019, Site IV, Sahibabad Industrial Area, Sahibabad 201010

Regional Offices:

Central : Manak Bhavan, 9 Bahadur Shah Zafar Marg, NEW DELHI 110002

323 76 17

‘Eastern : 1114 CIT Scheme VII M, V.I.P. Road, Maniktola, CALCUTTA 700054

337 86 62

Northern : SC0 335-336, Sector 34-A, CHANDIGARH 160022

60 38 43

Southern : C.I.T. Campus, IV Cross Road, CHENNAI 600113

235 23 15

TWestern : Manakalaya, E9, Behind Marol Telephone Exchange, Andheri (East),

MUMBAI 400093

832 92 95

Branch Offices:

‘Pushpak’, Nurmohamed Shaikh Marg, Khanpur, AHMEDABAD 380001

550 1348

$ Peenya Industrial Area, 1st Stage, Bangalore-Tumkur Road,

BANGALORE 560058

839 49 55

Gangotri Complex, 5th Floor, Bhadbhada Road, T.T. Nagar. BHOPAL 462003

55 40 21

Plot No. 62-63, Unit VI, Ganga Nagar, BHUBANESHWAR 751001

40 36 27

Kalaikathir Buildings, 670 Avinashi Road, COIMBATORE 641037

21 01 41

Plot No. 43, Sector 16 A, Mathura Road, FARIDABAD 121001

8-28 88 01

Savitri Complex, 116 G.T. Road, GHAZIABAD 201001

8-71 19 96

5315 Ward No:29, R.G. Barua Road, 5th By-lane, GUWAHATI 781003

541137

5-8-560, L.N. Gupta Marg, Nampally Station Road, HYDERABAD 500001

201083

E-52, Chitaranjan Marg, C-Scheme, JAIPUR 302001

37 29 25

1171418 8, Sarvodaya Nagar, KANPUR 208005

21 68 76

Seth Bhawan, 2nd Floor, Behind Leela Cinema, Naval Kishore Road,

,LUCKNOW 226001

23’89 23

NIT Building, Second Floor, Gokulpat Market, NAGPUR 440010

52 5: 71

Patliputra Industrial Estate, PATNA 800013

26 23 05

32 36 35

T.C. No. 1411421,

621 17

owringhee Approach, PO. Princep Street,

lty Chambers, Grant Road, MUMBAI 400007

271085

309 65 28

222 39 71

Printed at Simco Printing Press, Delhi

AMENDMENT NO. 1

APRIL 1985

TO

IS:5831 -1984 SPECIFICATION FOR PVC INSULATION

AND SHEATH OF ELECTRIC CABLES

(First Revision)

[Page 5, Table 1, SZ No,(v), itm (a)] - Insert

the following after this iten:

‘(1)

(2)

b) Loss of

mass,

(3)

m&cm2

(4)

(5)

2

(6)

-

(7)

-

I

MZX

[Page 6, Table I, SZ No, (vi), itm (b), first

case, co1 (611 - Substitute '4' for '-'.

[Page 7, Table 1, LZ No. (xv)]:

a) - Substitute 'tolerance' for 'toterance'.

b) - Substitute 'absorbed' for 'absortd'.

[Page 8, Table 2, 5'2 No.(iv), item(a), co2 (5)] abstitute '80' for '30°.

,kTge 11, clause A-l, line 1) - Substitute 'cut'

fop

I0

(Page 11, clause B-1.1, 'line 1) - Substitute

'Glass' for 'Class'.

(ETDC 59)

Printed a! Simco Printing Press, Delhi, India

AMENDMENT NO. 2

DECEMBER 1995.

IS 5831 I 1984 SPEC%CATlON FOR PVC

SHEATH OF ELECTRIC CABLES

INSULAT ION A ND

( Puge 4, clmse I.2 ) -- Add the following matter between ‘Type

C’ and ‘Type ST1 :

‘Type II General purpose insulation for maxiinum rated conduct o r temncruture 7 0 ’ C intended Tar flexible c a b l e s wit)1

up to and including R-3/3*3 kV.’

the I’ollowi~r~ new pata for Type S.1’3

sheath intended for use in flexible

at maximum rated conductor tem-

‘_I..

I able 1 ( C’onriftued )

‘/

!

I

/

,2) Variation, dfw

u i r oven *

Teniperaturc

( tolcrnnce f’ 2°C )

R) TMtdcnt

1

Ihr:iliori

b) L o s s o f ntass. ,Ifax '

7) Losvotninss

’

.;

.

I

’

( lolcrluce f 2X’ )

b\ Tinlr nnder land ( .le~’ Note 2 )

1) Firal case

2) scconh CnFC

N/IIWP

?tiii)

pcrccnl

pcrccnf

c

Terr~pc~;~lurc

tolerance f 2°C)

. . .

” ‘-b) Visual cxnniinnjiou

I’

tl3ys

mg/cm*

,

EO

7

2

; 2:

bows

4

IloIlrs

65

“C

how

___

I 50

J

No signs ol cracks

or scales

15

6

-15

No signs of cr.tckc 01

scnlcs

C~~d,i~l~c~ test ( for dimueter

b) Visual cxaniinntiorr

.

.

,

0.

c

-

No signs of’ cracks or

SCillhJ

2

Illceding nrd tlloorlliIlg ICFI

a)

‘I rcnlrncnt

J(

‘l’elnp I :1111rc

Iolcr~lllcc f 7°C.)

1. I)ilt;llior~

!\(I

150

> 12‘5 111111 )

n) Test tcIIlpcrntlIlc ( IOICIilIlCC

* 2°C)

xiv)

1,) Oh5rt \';,I itrr1

.’

x)

'l~llCllllill slcibilily

b) ‘l’irllc, 11fin

“C,

Hear shock test

r

f ~Icwpcrrlfltrr

{ ( ~olcl;~llrc + ?"f? )

I_ I)ur:tlion

b) Visual cxarriitwliofl

prrccnt

pcrccnt

C) Depth of lllde~~lilli()ll. hfo.r

..__

3) l'lr:llllI~rll

“(’

a) Test tcmpcr:il~~rc

vii)

-.-

xii)

Ch)3

in

I’

1lOt dCfOfIlh7tfdl ICSt

VI)

Tea,

RI No.

c 0 ,

( tnlcrawe f 2°C )

{ Dur:ltion

h) Trn*ilc strength

I ) Valua ofltr~a~csit~g. Afln

1’

: 2) Variation. Ai8.r

I!) Elongalion 1; blc;lk

I) Vnluc alter nl:uinl~, AfIn

‘4

.._-- -... ._

(3)

IclllpcI;llurc

,‘* n) Trcnlmcnl

a-

1 ype of III~ullltlOll

Upi1

f!)

( I )

i v ) A f t e r agcinl in ait oven

‘I’nhle I ( Ch

-_

3) 'llc:l~rllclll

f T’mpernlule

i ( lotcInIlce + 3"<' 1

i lhr;ltiot~

‘I’nhle 1 ( Cortclrded )

Unit

Type of lnsulrllon

c---h-___.__

(1)

(3)

xi)

rating

(‘;I

4

“C

70

Irorirs

_-

48

Free from traces of

colour

xii)

,

xiii)

“C

it) 'ICSI lel~lpClilllllC ( ll~1CIilllCC

1

* 0'5°C)

Minute

b) ‘I’irtle, Olin

i

xiv)

i

xv)

lllccdiug nutl bloon~ing Ic5l

‘l’eilll)L I :Ilurc

a) ‘I rcnlincul 1 ( tolcralKc f

t. I)ur:iliou

11) Oh~ci\alioli

“CT

2°C’ )

hours

--

\\‘;Ilcr ;tlr~orl~liofi Ic’,,l ( g:l;iviuicliic )

I Telllpernluie

il) ‘ I Icilllncr~l 4 ( tolernnce f -?“C’ 1

1

80

l~ll~illic~ll

“C

di1J.S

nlg,‘clll~

b) \V:lter nbsol bed, Aft~.r

[ I’ugc IO, lirhle 2, rol 6, SI Ivo. ( xi ) ] ---.

‘( See No\c 3 1’.

Substitute

a(,~’ for

( I’r/ge I O , /vo/c. .J ) ’ I~clclc.

( Pn,f~es 8 , 9 (I) tl IO. Tit/j/c 2 ) -.-- Add t h e fullcl\\ing ‘[‘es! Require_

II\CII~S for tlw IICW f’\‘C C‘OIU~WLIII~ ‘Type ST3 u n d e r column heading

‘1 ypc of SI~CIIIII’ :I\ rol 6 (:I‘ Illis iiI\>le ant1 r e n u m b e r t h e existing ~01 6

3s Cfll 7 :

3

S1 No.

(1)

b’

ii)

Test

1Jlli1

(2)

(3)

,Aflcr nscing in air nvct)

I ‘I cn,pcrnturc

n) ‘I’rcnttiicnt ( (lOll!lilllCC f

0.

c

T"d:

T! pc o

hcnth

(6)

7

x0

)

\ L)lllillillll

IhI!!?

N/ inni

pclctlrt

pclcellt

pxcclll

7

10‘0

% 20

I 50

f 20

iii)

0.

c

tlnys

lll~!Iclrl~

X0

7

2’0

iv)

“t '

hours

hours

21 sccollcl c:1rc

C)

lkptli of intlccit;ilion. Jfnx

’

70

.I

6

pcrccii(

65

“C

IS0

lle;\t sllock lcsl

'ICIII~CI alille

{ t lolcrencc $2

(

U)

'I

ICilllllCl~~

b) Visllal

2°C )

hour

-

1 I~uralinn

cx;miin:itinn

1

No signs of cracks or

scalcz

vi)

‘I

;’

\ii)

’ II) ‘lest Iclllperu(lilc

(

1~) \‘i~rl;il

biii)

,’

IOITIilllCC & 2°C )

"C

-

~~;ll~iillillioll

Cold iriijxlcl

> I?‘5 111111

- I5

,

Nn signs 01 crilcks or

sc:lIc~

Icql

for di:)melcr

y:

-5

No signs nf’cr‘lcks nr

<c:, IIZS

‘4

Type of Sheath

(6)

4

”

.

(.

IIOIII~

-

70

411

I.rcc froril trnccs of

colours

“I’

700

hlinulec

40

so

72

N o ;lyprcciable stainitip, or indic:ltor coiiipound or filler paper