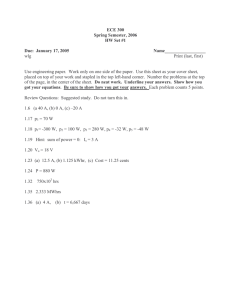

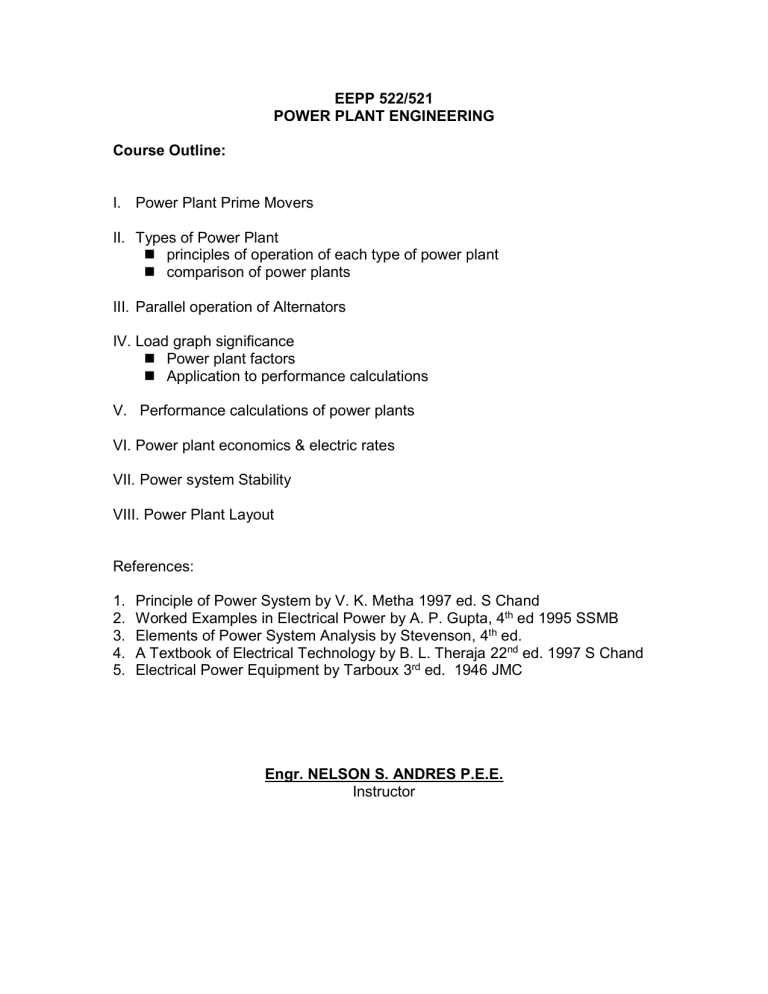

EEPP 522/521 POWER PLANT ENGINEERING Course Outline: I. Power Plant Prime Movers II. Types of Power Plant principles of operation of each type of power plant comparison of power plants III. Parallel operation of Alternators IV. Load graph significance Power plant factors Application to performance calculations V. Performance calculations of power plants VI. Power plant economics & electric rates VII. Power system Stability VIII. Power Plant Layout References: 1. 2. 3. 4. 5. Principle of Power System by V. K. Metha 1997 ed. S Chand Worked Examples in Electrical Power by A. P. Gupta, 4th ed 1995 SSMB Elements of Power System Analysis by Stevenson, 4th ed. A Textbook of Electrical Technology by B. L. Theraja 22nd ed. 1997 S Chand Electrical Power Equipment by Tarboux 3rd ed. 1946 JMC Engr. NELSON S. ANDRES P.E.E. Instructor INTRODUCTION Power Plant Engineering An art of designing and installing generating plant that will result in maximum return on investment over the expected life of equipment and also, operating this equipment to achieve reliable, continuous and cheap power service. 1. 2. 3. 4. Major Factors Affecting the Cost of Energy Operating labor & superintendence Maintenance Fuel cost Fixed charges such as taxes, interest & depreciation Sources of Energy 1. Sun - By means of reflector, heat generated can be used to raise the steam temperature and pressure and electrical energy can be produced. 2. Wind - wind energy (wind mill) is used to drive generator. For continuous supply, a charged battery is utilized. 3. Water - Power is generated by falling water that drives the turbine. 4. Fuel - either solid, liquid or gas energy is generated by means of steam engine, steam turbine or internal combustion engine. 5. Nuclear - heat is produced by nuclear fission. 1 kg of nuclear fuel can produce the same amount of energy as 5000 tons of coal. Comparison of energy Sources Particular Initial cost Running cost Reserves Cleanliness Simplicity Reliability Water Power High Less Permanent Cleanest Simplest More reliable Fuel Low High Exhaustible Dirtiest Complex Less reliable Nuclear Highest Least Inexhaustible Clean Most complex More reliable Power Plant - a station or establishment which houses the prime mover, electric generators and auxiliaries for conversion of mechanical energy, chemical energy and or nuclear energy in electrical energy. Different types of Prime Movers 1. Steam Turbine 2. Hydraulic Drive a. Impulse wheel b. Reaction wheel c. Propeller wheel 3. Internal Combustion Choice of Water Turbine Types of Turbine Propeller or Kaplan Turbine Reaction or Francis Turbine Impulse or Pelton wheel Head of Water for which is used Up to 150 ft (45 m) Up to 500 ft (150 m) 500-1000 ft (150-300 m) Range of Specific Speed (British Unit) 200 to 120 120 to 20 20 to 10 Specific Speed, Ns is defined as the speed of a geometrically similar turbine working under unit head and delivering unit power, the specific speed in British unit is given by: Ns N HP 5 H4 Where: N= Rotational Speed in rpm. H= Head of water in ft. HP = Horse Power of the wheel. For geometrically similar turbine, the following equation together with specific speed equation are used to compare the turbine performance. Q1 Q2 constant 3 N1D1 N2 D 32 H1 H2 constant 2 2 N1 D1 N22D 22 Problems (Energy Sources) 1. Coal reserves in the country are estimated to contain 2250 quads of energy. If the energy content of this coal is 11, 500 btu per lb, determine the weight of the coal reserve. 1015 btu Energy 2250 quads x 2250 x1015 btu quad 2250x10 15 btu Weight of Reserve Energy 1.957 x1010 lbs btu 11,500 lb 2. In year 2000, in a certain country the consumption of energy (in quads) from various sources was as follows; coal 16.1, Oil 32.1, natural gas 20.2, hydro 2.9 and nuclear 2.9 . Calculate the GWH of total electric energy that could be produced from these sources assuming that the average power plant conversion efficiency of 10%. 1015 btu Fuel Energy 16.1 32.1 20.2 2.9 2.9 74.2 quads x quad kwh 12 6 74.2 x1015 btu 2.17 x10 kwhr 2.17 x10 GWH 3413 btu Where: 3. Suppose that the consumption of energy in certain country has a growth rate of 4% per year. In how many years will the energy consumption be tripled? E E O e at Where: Eo- initial energy consumption E- energy consumption after time in years a- energy consumption growth rate in decimal t- time in years 3Eo Eo e 0.04 t Ln3 t 23.1 years 0.04 4. The Natural gas reserves in a certain country are estimated at 100 x 10 9 ft3, with an energy content of 0.025 Watt. yr/ft3. If the present peak power demand is 0.5GW, the power demand growth rate is 5%., and all the energy is to be supplied by natural gas, approximately how long will the reserve last? Formula: 1 a x QT t Ln 1 a PO QT (100 x10 9 ft 3 )(0.025 watt year ) 2.5 x10 9 watt year 3 ft 0.05 x 2.5 x10 9 1 t Ln 1 4.46 yrs. 0.05 0.5 x10 9 5. In a power station, 4 x 10 4GWh of energy is to be produced in 1 yr. To be supplied either Coal or Natural gas, the energy content of coal is 900 W . yrs/ton, and that of natural gas is 0.03W . yr/ft3. a. How much fuel is required if the energy is to be supplied by coal 4x1013 watt hr Weight of Coal 5.07 x106 tons watt - year 8760hrs 900 x ton yr b. How much fuel is required if the energy is to be supplied by natural gas. 4x1013 watt hr Volume of Natural Gas 1.522 x10 9 ft 3 watt - year 8760hrs 0.03 x yr ft 3 6. What is the average output of a wind turbine in kw having a blade diameter of 35 ft if the wind velocity ranges from 10 to 30 mi/hr. Formula: P 2.46x10 -3 D 2V 3 watts Where: P-wind power developed in watts D- windmill diameter in ft V- wind velocity in miles per hour Pmin 2.46x10-3 (35)2 (10) 3 3kw Pmax 2.46x10-3 (35)2 (30) 3 81kw 3 81 Average Power = 42 kw 2 7. Calculate the power that can be generated from a tidal power station with a tidal bay area of 128.6 sq.km and the tidal head available is 6m. P 0.219AH 2 MW Formula: Where: P-tidal power generated in MW A-tidal bay area in sq.km H- tidal head in meter P 0.219(126.8)(6)2 1000 MW 8. A hydraulic drive works under a head of 24 ft. and produces 2400 bhp at 250 rpm. Calculate a. Rpm under a unit head for a unit power. Specific Speed , N S N HP H 1.25 2400 231 rpm 241.25 b. Hp under a unit head at a unit rpm. HP1=2400 hp HP2=? H1=24 ft H2= 1 ft N1=250 rpm N2=1 rpm For geometrically similar turbine, HP HP N S N1 1.251 N 2 1.252 H1 H2 N S 250 (unit head) (unit rpm) HP2 11.25 HP2=53,361 hp 231 1 c. Hp & Rpm under a unit head. HP1=2400 hp HP3=? H1=24 ft H3= 1 ft (unit head) N1=250 rpm N3=? For geometrically similar turbine, the following relation can be applied H1 H H 22 2 23 2 2 2 N1 D1 N 2 D2 N 3 D3 1 24 2 2 assume D1=D3 2 2 250 D1 N 3 D3 N3 51 rpm then N S N 3 HP3 231 rpm 1.25 H3 HP 51 1.25 3 231 rpm 1 HP3=20.5 hp 9. The turbine installed in a powerhouse develops 2400 hp under a unit head of 400 ft. Find the specific speed of the turbine if it has to run at a speed of 500 rpm. If a similar turbine with runner diameter half in size of the original runs under a head of 60 ft, find the speed of rotation in rpm. 2400 N S 500 13.7 rpm 4001.25 HP1=2400 hp HP2=? H1=400 ft H2= 60 ft N1=500 rpm N2=? For geometrically similar turbine, H1 H 22 2 2 2 N1 D1 N 2 D2 60 400 2 2 2 500 D1 N 2 (0.5D1 ) 2 N 2 387 rpm D2=0.5D1 EXERCISES 1. In a certain region the growth rate of energy consumption is 6%. In how many years will the energy consumption be quadrupled? 2. A certain amount of fuel contains 15 x 1010 Btu of energy is converted into electric energy in a power station having a 12% overall efficiency. The average demand on the station over a 24-h period is 5MW. In how many days will the fuel be totally consumed? 3. A certain amount of fuel can produce 10 quads of energy. In how many days will the fuel be totally consumed if it is used to satisfy a demand of 1013Btu/day at a power plant with an overall efficiency of 20%? 4. In a power station, 4 x 10 4GWh of energy is to be produced in 1 yr, one third from coal and two thirds from natural gas. The energy content of coal is 900 W . yrs/ton, and that of natural gas is 0.03W . yr/ft3. A. How much coal will be required? B. How much natural gas will be required? 5. In a certain country the equivalent fuel reserve for power generation is 3 x 106 MW . yrs. The present peak power demand is 200GW, and the expected power consumption growth rate is 2.1%. How long will the fuel reserve last? 6. A model turbine has a size 1/8th of the actual turbine. It is tested under a head of 10 m and develops 40 hp at 600 rpm. If the actual turbine operates at a head of 45 m, what will be its speed and hp? 7. A wind mill has a blade diameter of 50 ft. Calculate the power that can be delivered for a constant wind velocity of 20 mph and overall efficiency of 80%. 8. A tidal power station has its tidal bay area of 300 sq.km and an expected tidal head of 5.6 m. Calculate the power that can be developed. Also, calculate to power that can be generated if the overall efficiency is 85%. TYPES OF POWER PLANT (AS TO SOURCE) 1. Thermal Power Plant a. Oil-fired Thermal Plant - Makes use of heavy fuel or bunker oil. b. Coal-Fired Thermal Plant - makes use of pulverized coal as fuel. c. Dendro-Thermal Plant - makes use of wood (ipil-ipil) d. Nuclear Power Plant - makes use of steam generated in a reactor by heat from the fission process of nuclear fuel. (Uranium 235 & 238) e. Gas Turbine Plant - makes used of combustible gases. f. Geothermal Power Plant - makes use of heat generated from inherent steam from earth’s magma. g. Solar steam Plant - makes use of steam generated from solar radiation. 2. Hydro-Electric Power Plant a. Run of River Plant - using pondage of steam flow as it occurs. b. Plant with storage Capacity - associated with large reservoir. This permits regulated supply of water for constant power output. c. Pumped-Storage Plant - Energy is generated during periods of high system demand using water which has been pumped into a reservoir usually during periods of low system demand. 3. Diesel Power Plant - a plant of internal combustion engine prime mover using diesel as fuel in producing energy. 4. Wind Mill Plant - using series of windmills as prime movers. 5. Sea waves/Ocean Tides Plant - makes use of natural rising of tides to simulate flowing water. 6. Solar or Photo-voltaic Plant - Chemical conversion of radiant energy of the sun to electric (dc) energy. Types of Power Plant (as to use) 1. Base load Plant - Plant that is normally assumed load requirements under normal condition. 2. Peaking Plant - Plant that is normally operated to provide power only during peak periods. 3. Regulating Power Plants - Plants capable of carrying load for time interval during off-peak or peak periods and usually responds to changes in system frequency 4. Reserve or Standby Plant - for peak or system deficiency. Types of Plant Reserve 1. Cold Reserve - a portion of the installed reserved, kept in operable condition and available for service but not for immediate loading. 2. Hot reserve - refers to the units available, maintained at operating temp. & ready for service although not in actual operation. 3. Spinning Reserve - Generating unit connected to the bus and ready to take load. Comparison of Hydro & Steam Plant Steam plant - can be built very near the load center. Hydro Plant -must be built at a considerable distance away hence high voltage transmission line must be used to connect hydro plant to load center. Most Important Factors in the comparison of Hydro versus Steam 1. Cost of energy at load center. 2. Continuity of reserve. 3. Reliability of service. Choice of Proper Location of any Plant Important factors to consider: 1. Steam Plant station a. accessibility b. coal and ash handling c. water supply d. stability of foundation e. facility of extension f. cost of real estate g. restriction due to surrounding 2. Hydro-Electric Plant a. water privileges b. required fall c. water supply d. facility of extension e. accessibility f. stability of foundation Hydro Electric Power Plant Principles of Operation: Hydro electric power stations are generally located at hilly areas where dams can be built conveniently and large water reservoir can be obtained. In a hydro-electric power station, water head created by constructing dams across a river or lake. From the dam, water is led to a water turbine. The water turbine captures the energy in the falling water and changes the hydraulic energy into mechanical energy at the turbine shaft. The turbine drives the alternator which converts mechanical energy into electrical energy. The hydro-electric power station are becoming very popular because the reserves of fuel are depleting day by day, they have the added importance for flood control, storage of water for irrigation and water for drinking purposes. Hydraulic Structures: 1. Dam - a barrier which stores water and created water head. 2. Spillway - Discharges the Surplus water from storage reservoir into the river on the down stream side of the dam. 3. Head works - diverts flooding debris and sediments. Also it has valve for controlling the flow of water into the turbine. 4. Surge Tank - is a small reservoir or tank in which water level rises or falls to reduce pressure swings in the conduit. It is located near the beginning of the conduit. 5. Penstock - an open or closed conduits which carry water to the turbine. It is made of reinforced concrete or steel. Advantages of H.E.P.P. 1. It requires no fuel as water is used for the generation of electrical energy. 2. It is quite neat & clean as no smoke or ash produced. 3. It requires very small running charges because water available is free of cost. 4. It is comparatively simple in construction and requires less maintenance. 5. It does not require very long starting time as steam power station. In fact, such plant can be put into service instantly. 6. Such plant serves many purposes. In addition to generation of electric energy, they also help in irrigation and controlling floods. 7. Although such plant requires the attention of highly skilled person at the time of construction, yet for operation a few experienced person may do the job. Disadvantages of H.E.P.P. 1. It involves high capital cost due to construction of dam. 2. There is uncertainty about the availability of huge amount of water. 3. Skilled and experienced hands are required to build the plant. 4. It requires high cost of transmission lines and the plant is located in hilly areas which are quite away from the consumer. Problem1 (Hydro): At a potential hydro- electric site the average elevation of the head of water is estimated at 600 m. The tail water elevation is estimated at 495 m. The average annual flow of water was determined to be equal to that volume flowing through a rectangular channel 9.1 m wide with a depth of 1.2 m and an average velocity of 6.1 m/sec. Find the annual energy that the site will produce with a water turbine efficiency of 85%, a generator efficiency of 95% and loss in the head equal to 3% of the available head. Difference in Elevation 600 - 495 105m Head loss 3%(105m) Effective Head, H 105 - 0.03(105) 101.85m Discharge, Q ChannelArea x Ave Velocity 9.1x1.2x6.1 66.612m3 / sec Generator Power Output, Po Qwh T g (66.612m3 / s)(9810 N / m3 )(101.85m)(0.85)(0.95) PO 53,743,389 watts 53.7 MW Annual Energy Ave Po (8760hrs / yr ) 53.7(8760) 470,792 MWHr Problem 2 (Hydro): Calculate the average power in kW and the annual energy that can be generated in a hydro electric project from the following data: Catchment Area , A = 150 sq. km. Annual rainfall, F = 1.25 m Effective Head, H = 300 m Yield factor , K= 50% Efficiency of the plant, 80% If the load factor is 34%, what should be the rating of the generator installed? Effective Water Level FxK 1.25(0.5) 0.625m 1000 m 2 Volume of Water for Generation A * h 150km 2 ( ) 0.625m 93.75 x106 m3 km Annual Energy available in kwh Volh 93.75 x106 m3 (9810 N / m3 )(300m)(0.8) N m 3.6x106 3.6 x106 kwhr 61,312,500kwhr Annual Energy 61,312,500kwhr 7000kw time 8760hrs Average Power Annual Average Power Load Factor Maximun Demand 7000KW 20,588kw 0.34 Therefore , Generator Rating 20,000kw Maximum Demand Problem 3 (Hydro): A factory located near the water fall, the usable head for power generation is 25m. The factory requires continuous power of 400 kW throughout the year. The river flow in a year is 10 cu. m per sec. for 4 months 6 cu. m per sec. for 2 months 1.5 cu.m per sec. for 6 months a. If the site is developed as run-of- river type of plant without storage, determine the standby capacity to be provided. Assume that overall efficiency of the plant is 80 %. Power Output, Po Qh When dischage is 10 m3 / s Po 1962kw When dischage is 6 m3 / s Po 1177kw ok since greater than 400kw ok since greater than 400kw When dischage is 1.5 m / s Po 294kw Not ok since less than 400kw Therefore, the required capacity of standby unit is (400-294) =106KW. 3 b. If a reservoir is arranged upstream, will any standby unit be necessary? What will be the excess power available. As plant with storage Capacity, the annual water discharge canbe regulated as 10(4) 6(2) 1.5(6) m3 Q ave 5.083 12 sec Ave. annual Output Power (5.083m 3 / s(9810 N / m 3 )(25m)(0.8) 997 kw Therefore, the excess Power 997 400 597 kw Problem 4. A hydro-power station has a reservoir of area 1.1 sq. mile and a capacity of 180 million cu. ft. The net head of water at the turbine is 200ft. If the efficiency of the turbine be 85% and generator be 90%, calculate the total energy in kwh that can be generated from this power station. Area 1.1sq. mile 2847769 .1 m2 Volume of water 180x106ft 3 5100948.9m3 Effective Head. H 200ft 60.98m Volh Annual Energy available in kwh 3.6x106 5100948 .9m3 (9810 N / m3 )(60.98m)(0.85 x0.9) 648,388kwhr N m 3.6 x106 kwhr If a load of 25 MW is being supplied for 6 hours, how much feet the level of water in the reservoir falling? Vol 5100948.9 Original Water Level, h 1.8m 5.88 ft Area 2847769.1 Energy Output is proportion al to water level h Energy Available power x time h h 648,388kwh 25,000kw(6hrs ) 5.88 ft h h 1.36 ft Coal-Fired Thermal Power Plant A generating station which converts coal combustion into electrical energy Principles of Operation A steam power station basically works on the Rankine process. Steam is produced in the boiler by utilizing the heat of the coal combustion. The steam expanded in the prime mover and is condensed in the condenser to be fed in the boiler again. The steam turbine drives the alternator which converts mechanical energy of the turbine into electrical energy. This type of station is suitable where coal and water are available and large amount of power is to be generated. Stages of Coal fired thermal Plant 1. Coal & ash handling arrangement 2. Steam Generating plant a. Boiler b. Super heater c. Economizer d. Air pre-heater 3. Steam Turbine 4. Alternator 5. Feed Water 6. Cooling Arrangements Advantages of Coal-fired 1. fuel is quite cheap 2. Less initial cost 3. It can be installed at any place irrespective of existence of coal. Coal is transported by rail or road. 4. Requires less space as compared with hydro-electric plant. 5. Cost of generation is lesser than diesel Plant. Disadvantages of coal fired: 1. It pollutes the atmosphere due to production of large amount of fumes and smokes. 2. Its running cost is higher than Hydro-electric plant. Overall Thermal Efficiency The heat of combustion of the coal fired in the boiler is not wholly converted into electrical energy as there are heat losses in the boiler and turbine and also mechanical and electrical losses in the alternator. The overall efficiency of the station is depends upon the efficiencies of boiler, turbine and alternator. Overall thermal Efficiency= Heat...equivalent... per...kwh Coal..consumed.. per...kwh.x..Calorific...Value...ofCoal In modern steam power Station, the overall thermal efficiency is about 30% Heat equivalent per kwh (MKS units) 1 kwh=3,600X1000 watt-sec 1 Calorie = 4.18 joules 1 kwh = 860 kcal Heat equivalent per kwh (English units) 1 Btu = 252 calories 1 kwh = 3413 btu Heat or Calorific Value (HHV) Is the amount of heat produced by complete combustion of a unit weight of coal and is expressed in btu per pound of coal or kcal per kg. of coal. Range: 11,500 – 13,000 btu/lb. Station Heat Rate- defined as the heat energy in fuel devided by the station output in kwh and is expressed in btu per kwh or kcal per kwh. The station heat rate gives us an idea of the performance of the power station related to its overall thermal efficiency by the following formula: Station...Heat...Rate.. 3413btu / kwh Overall...thermal...Efficiency Station...Heat...Rate.. 860..Kcal / kwh Overall...thermal...Efficiency Diesel Power Station In a diesel power station, diesel engine is used as the prime mover. The diesel burns inside the engine and the product of this combustion acts as “ working fluid” to produce mechanical energy. The diesel engine drives the alternator which converts mechanical energy into electrical energy. As the generation cost is considerable due to high price of diesel, therefore, such power station are only used to produce small power. The plant is also used as standby sets for continuity of supply such as in hospitals, radio stations, cinema and telephone exchanges. Advantages: 1. The design and layout of the plant is quite simple. 2. It occupies less space as the number and size of auxiliaries are small. 3. It can be located at any place. 4. It can be started quickly and can pick-up load in short time. 5. There are no standby losses. 6. It requires less quantity of water for cooling. 7. The overall cost is much less than steam of the same capacity. 8. Thermal efficiency is higher than steam power station. 9. It requires less operating staff. Disadvantages: 1. High running charges as the fuel used is costly. 2. Does not work satisfactorily under over load. 3. Generate small power. 4. Cost of lubrication is generally high. 5. The maintenance charges are generally high. Auxiliaries: 1. Fuel supply system storage tank strainer fuel transfer pump fuel tank 2. Air intake system Pipes for the supply of fresh air to the engine manifold Filter to remove dust particle. 3. Exhaust system A silencer usually incorporated to reduce noise level. 4. Cooling system water source pump cooling tower 5. Engine starting systems manual for small set compressed air for large unit Problem 1 A 55 MW coal fired thermal power plant working at a load factor of 80% has a boiler, turbine and alternator efficiency of 35%, 86% and 93% respectively. Coal with heating value of 13,000 btu/lb. cost P1.50 / lb . a. What is the overall efficiency? Overall Efficiency, bTg ((0.35)(0.86)(0.93) 0.28 b. What is the coal consumption in tons per day ? Energy balance: Input Heat to the Plant=Energy Released by Fuel KWo (3413btu / kwh ) m f xHHV overall Where: KWo=average power output mf= mass of fuel intake to the boiler in pounds/hr HHV-high heating value of fuel in btu/pound Ave output=(Load Factor)(Maximum demand) Substituting the values, 55,000(0.8) KW (3413btu / kwh ) m f x13,000btu / lb. 0.28 m f 41,256lbs. / hr 450tons / day c. What is the fuel cost in producing one kWh? Fuel Cost per kwhr=P1.50/lb(consumption in lb. per kwhr) m (3413btu / kwh ) 3413btu / kwhr Fuel Consumptio n per kwhr f kwo ( ) HHV (0.28)13,000btu / lb. 0.94lb. / kwhr Therefore; Fuel cost Component=1.5(0.94)=P1.41/kwhr Problem 2 A 100 MW power plant with a heating value of 13,000 btu per lb. has a heat rate of 2.88x106 Calories per kWh. it is a base load plant and runs at full load 24 hrs a day. a. How many tons of coal is needed per day ? KWo (3413btu / kwh ) m f xHHV overall Station Heat Rate 3413btu / kwhr overall KWo ( Heat Rate) m f xHHV As base load plant, at full load : KW o 100,000 100,000 KW (2.88 x106 cal / kwhr ) m f (13,000btu / lb)(252cal / btu )(2200lb / ton) m f 40tons / hr 960tons / day b. calculate the cost of producing one kwh if the coal cost P2.50/lb ( Heat Rate ) m 2.88 x106 cal / kwhr Fuel Consumptio n per kwhr f kwo HHV 13,000btu / lb.(252cal / btu ) 0.879 lb. / kwhr Therefore; Fuel cost Component=2.5(0.879)=P2.2/kwhr Problem 3 A 55 MW steam power plant uses coal of heating value of 12,000 btu/lb. The fuel consumption when supplying full rated load is 32,550 lbs/hr. a. What is the overall efficiency of the station? KWo (3413btu / kwh ) m f xHHV overall 55,000 KW (3413btu / kwh ) overall overall 48% (32,550lbs / hr )(12,000btu / lb) b. What is the annual cost of coal if coal cost P2.50 per lb. Annual fuel consumption 32550lbs. / hr(8760hrs) 285,138,000lbs Annual fuel cost P2.50 / lb(285,138,000lbs) P712,845,000 Problem 4(assignment) A 75 MW steam power station working at 80% load factor has an overall thermal efficiency of 30%, the coal burnt has a calorific value of 6950 kcal/kg. Calculate a. Overall heat rate of the plant in kcal/kwh b. the coal consumption in kg per kwh generated, c. the fuel cost of producing one kwh if the coal cost P2500/ton. d. the coal consumption in tons per day. Problem 5 A diesel generator set burns with heating value of 19,500 btu/lb. The diesel engine has an efficiency of 30% and alternator efficiency of 90%. The specific weight of fuel is 800 kg/m3 a. Determine the fuel cost component of producing one kWh if diesel cost P28/liter. KWo (3413btu / kwh ) m f xHHV overall Fuel Consumptio n per kwhr mf (3413btu / kwh ) 3413btu / kwhr kwo ( g )(eng ) HHV (0.3)(0.9)19,500btu / lb. 3 kg m 1000liters 0.648 lb. / kwhr 0.368liters / kwhr m3 2.204lb 800kg Therefore; Fuel cost Component=P28/liter(0.268liters/kwhr)=P10.29/kwhr b. if the generator delivers 100 kW, calculate the volume of fuel in liters used per day. Volume of fuel used / day 0.368liters/ kwhr(100kw)(24hrs / day) 883.2liters Gas Turbine Plant In a gas turbine plant, air is used as working fluid. The air is compressed by the compressor and is led into a combustion chamber where heat is added to air, thus raising the temperature. Heat is added to the compressed air either by burning fuel in the chamber or by the use of air heater. The hot and high pressure air from their combustion chamber is then passed to the gas turbine where it expands and does mechanical work. Since the compressor, gas turbine and alternator are mounted on the same shaft, the plant is being used as standby plant for hydro electric power stations, as starting plant for driving auxiliaries in power plant etc. Main Components: 1. Compressor 2. Regenerator 3. Combustion chamber 4. Gas Turbine 5. Alternator 6. Starting Motor Advantages of Gas Turbine Plant 1. It is simple to design as compared with steam power station since no boiler & auxiliaries required. 2. It is much smaller in size as compared with steam power plant of the same capacity. 3. The initial and operating cost are much lower than equivalent steam power plant. 4. It requires comparatively less water and no condenser used. 5. The maintenance charges are very small. 6. Gas turbine is simpler in construction and operation than steam turbine. 7. It can be started quickly from cold conditions. 8. There is no standby loss. Disadvantages 1. There is problem in starting the unit because compressor has to be operated for which external power is required. But when it get started, external supply is not needed. 2. The net output is low since greater power developed by the turbine is used in driving the compressor. 3. The overall efficiency is low because the exhaust gases from the turbine contains sufficient heat. 4. The temperature of combustion chamber is quite high(3,000°C) so that the life is comparatively low. Nuclear Power Plant A generating station in which the energy is converted into electrical energy. Heavy element such as uranium U235 or Thorium Th232 are subjected to nuclear fission is utilized in raising the steam at high temperature and pressure. The steam runs the steam turbine which convert energy into mechanical energy. Nuclear reactor - an apparatus which nuclear fuel is subjected to nuclear fission. It controls the chain reaction that start once the fission is done. Fission - the breaking up of nuclei of heavy atoms into two equal parts with release of huge amount of energy. Chain Reaction - The nuclear fission is done by bombarding uranium nuclei with slow moving neutrons. This split uranium nuclei which release huge amount energy and emission of neutrons. These fission cause for that fission. If this power continuous, then is a very short time huge amount of energy will be released and cause explosion. But in a reactor, controlled chain reaction is allowed. This is done by, something symmetrically removing the fission neutrons from the reactor. The greater the number of fission neutrons remove, the lesser the intensity of energy is released. Parts of a nuclear reactor 1. Fuel rod - uranium 2. Moderator - slows down neutron before they bombard 3. Control rods - are of cadmium, as string neutron absorber and regulates the supply neutron for fission. Types of a nuclear reactor 1. Boiling Water reactor (BWR)- simplest type 2. Pressurized Water Reactor (PWR) 3. CANDU – Canadian advance 4. The Breeder Type – in this reactor, the fissionable type of fuel is produced more than fuel consumed. Advantages of Nuclear Power station 1. The amount of fuel is quite small. Therefore savings in the cost of fuel transportation 2. Requires less space. 3. Low running charges 4. Economical for producing bulk electric power 5. Can be located near the load centers, therefore the cost of primary distribution is reduced. 6. Large deposit of nuclear fuel is available all over the world. therefore, such plant ensures continuous supply of energy for thousands of years. 7. It ensures reliability of operation. Disadvantages 1. The fuel used is expensive and difficult to recover 2. The fuel cost is very high 3. The construction and commissioning of the plant requires greater technical know-how. 4. The fission by-products are generally radioactive. 5. Maintenance charges are high due to lack of standardization. High salaries of trained personnel, etc. 6. Nuclear power plant are not suitable for varying loads as the reactor does not respond to the load fluctuation efficiently. 7. Disposal of radioactive products is the big problem. GEOTHERMAL POWER PLANT Basic Component: 1. 2. 3. 4. Steam wells Steam pipes Steam separator Steam conditioning General Evaluation of Power Plants 1. Site Anywhere: Diesel 2. Initial Cost Highest: Nuclear Lowest: Diesel 3. Running Cost Highest: Diesel Lowest: Hydro 4. Limitation of source HEPP – dependable Diesel - limited reserve Coal - Limited reserve Nuclear – Sufficient 5. Fuel Cost Lowest: HEPP Highest: Steam 6. Cleanliness & Simplicity Simple and clean –HEPP Least Clean – Steam 7. Overall efficient Most efficient – HEPP Less efficient – Steam 8. Starting Longest - Steam Shortest – Diesel Easy – Nuclear PP 9. Space required Less space – Nuclear Large Space – HEPP 10. Maintenance Cost Highest: Nuclear Lowest: Diesel 11. Transmission and Distribution Cost Least: Diesel Highest: HEPP 12. Standby losses Lowest: HEPP Highest: Steam Load Graph and Significance Load Graph & Load Curve - is a graphic record showing the power demands for every instant during a certain time interval. Load graph can be obtained by: a. Use of recording graphic meter. b. Manually plotting values of power indicated by wattmeter. Importance: 1. The load curve shows variation of load on the power station during different hours. 2. The area under a load gives the number of kWh generated a day. 3. The highest point in the load curve represents maximum demand on the station on that day. 4. The load curve helps in selecting the size and number of generating units. 5. The load curve helps in preparing operating scheduling of the station. Load Duration Curve – when the load elements of a load curve are arranged in the order of descending magnitudes, the curve thus obtained is called a load duration curve. Important Terms and Factors 1. Connected Load (CL) - the sum of continuous rating of the equipment connected to the supply system. 2. Maximum Demand (MD) - it is the greatest demand of the load on the power station during a given period. It helps in determining the installed capacity of the station. 3. Demand Factor (DF) - the ratio of the maximum demand of the station to its connected load. MD DF 1.0 CL It is vital in determining the capacity of the plant equipment. 4. Average load or average Demand(AL) - the average load occurring on the power station in a given period(day/month/year). No. of kwh Generated/day Daily Ave. Load = periodic Hrs.in a Day No. of Kwh Generated/ mo. Monthly Ave. Load = No. of Hrs. in a Month No. of Kwh Generated/ yr 8,760 hr yr 5. Load Factor (LF)- is the ratio of the average load to the maximum demand during a given period. It plays key role in determining overall cost/KWh. The higher the load factor of the station, the lesser will be the cost per kwh generated. Yearly Ave. Load = LF Total Energy Produced (TEP) MD Service Hour. Note: If the Service hour is equal to periodic hour LF Ave.Load MD 5. Diversity Factor (Div. F) - the ratio of the sum of individual maximum demand to the simultaneous maximum demand on the power station. Div.F MD's > 1.0 TMD The greater Div. F, the lesser the cost of generation of power. 6. Coincident factor (Co. F) - the reciprocal of diversity factor Co.F TMD MD's 7. Capacity Factor (CF) - is the ratio of the actual energy produced to the maximum possible energy to have been produced during a given period. CF TEP Ave Load IC Pr IC where: IC - installed Capacity Pr - periodic hr. It is an indication of the reserve capacity of the plant Reserve Capacity = Plant Capacity - MD 8. Plant Use Factor (PUF) - is the ratio of energy generated to the product of plant capacity and the number of hours for which plant was in operation. PUF TEP IC Sr where: Sr – actual number of service hours 9. Utilization Factor (UF) - the ratio of maximum generator demand to the generator capacity. UF MD IC Note: If the plant is in operation, UF Station Output Kwh Capacity Hrs. of Use Problem 1: A power station has a daily load cycle as under 275 MW for 6 hrs 250 MW for 8 hrs 200 MW for 4 hrs 150 MW for 6 hrs If the power station is equipped with 4 sets of 75 MW each, calculate: a. TEP per day of the plant TEP Area under load curve TEP 275MW (6hrs ) 250 MW (8hrs ) 200 MW (4hrs ) 150 MW (6hrs ) 5350 MWHr b. Daily load factor Total Energy Produced (TEP) 5350MWHrs Daily LF 81% MD Service Hour. 275MW (24Hrs) c. Capacity factor TEP 5350MWHrs d. dail Daily CF 74.3% y requirement if the IC Pr 300MW (24Hrs) heating value of oil used were 19,500 btu/lb. and average heat rate of the station were 2650 btu/kwh.. Problem 2: The daily demands of four consumers are given below. Time Consumer 1 Consumer 2 Consumer 3 12 MN-8 AM 1,400 w 1,500 w 1,500 w 8 AM-4 PM 2,500 w 1,200 w 2,800 w 4 PM-10 PM 1,500 w 1,900 w 1,500 w 10 PM-12 MN 4,000 w 900 w 1,200 w Consumer 4 3,500 w 1,500 w 2,500 w 1,800 w Plot the load curve and find a) Maximum demand of each consumer; b) Daily energy consumption of each consumer; c)Load factor of each consumer; d) Diversity factor of the system; e) Station Load factor. a. Maximum demand of all individual consumers MD1=4000W MD2=1900W MD3=2800W MD4=3500W b. Daily Energy consumption of individual consumer, E E1=1400W(8hrs)+2500W(8hrs)+1500W(6hrs)+4000W(2hrs)=48,200Whrs E2=1500W(8hrs)+1200W(8hrs)+1900W(6hrs)+900W(2hrs)=34,800Whrs E3=1500W(8hrs)+2800W(8hrs)+1500W(6hrs)+1200W(2hrs)=45,800Whrs E4=3500W(8hrs)+1500W(8hrs)+2500W(6hrs)+1800W(2hrs)=58,600Whrs c. Load factor of individual consumers Energy 1 48200 Hrs LF1 50.2% MD1 Sr. 4000W (24 Hrs) Energy 2 34800 Hrs LF2 76.3% MD2 Sr. 1900W (24 Hrs ) Energy 3 45800WHrs LF3 68.2% MD3 Sr. 2800W (24 Hrs ) Energy 4 58600WHrs LF4 69.8% MD 4 Sr. 3500W (24 Hrs ) d. Diversity factor Overall Demand for each period are: Time Horizontal 12 MN-8 AM 7900 w 8 AM-4 PM 8000 w 4 PM-10 PM 7400 w 10 PM-12 MN 7900 w MD' s 7900 8000 7400 7900 System Div.F 1.925 TMD 8000 e. Load factor of the station System LF Total Energy (48200 34800 45800 58600)WHrs 97.6% TMD Sr. 8000W (24 Hrs ) Problem 3: A power station has to meet the following demand Group A: 200 MW between 8 AM and 6PM Group B: 300 MW between 6 AM and 10 AM Group C: 150 MW between 10 PM and 4 AM Group D: 175 MW between 10 AM and 6 PM & 75MW between 6 PM and 6 AM Plot the load curve and determine a) Diversity Factor; b) Energy Generated per day; c) Load Factor. Solutions: a. Diversity Factor Total Maximum demand is 300+200MW occurs at time 8:00am-10:00am MD' s 200 300 150 175 Div.F 1.25 TMD 500 b. Energy generated per day E=200MW(10hrs)+300MW(4hrs)+150MW(6hrs)+175MW(8hrs)+75MW( 12hrs)=6050MWhrs c. Load Factor Daily LF Total Energy 6050 MWHrs 50.46% TMD Sr. 500 MW (24 Hrs ) Problem 4: The yearly duration curve of a certain plant be considered as a straight line from 40 MW to 20 MW for 5840 hours and 20 MW to 16 Mw for the remaining hours. To meet this load, three (3) turbo-generators of two rated 20 MW and one at 10 MW are installed. Determine a) Installed capacity; b) TEP of the Plant; c) Plant Factor. Solutions: a. The installed capacity IC=20+20+10=50MW b. TEP of the plant. TEP=Area under load curve 1 1 = 40 20(5840hrs) 20 16(2920hrs) 227,760MWH rs 2 2 c. Plant Factor. Total Energy 227,760 MWHrs Annual CF 52% IC Pr. 50MW (8760 Hrs ) Problem 5: The maximum demand on a power station is 100 MW. If the annual load factor is 50% and the capacity factor is 40%, calculate a) Annual average load in KW, b) Annual energy generated in KWh, c) Plant Capacity or Installed Capacity, d) Reserve capacity Solutions: a. Annual average load in KW Ave.Load Ave.Load LF 0.5 Ave Load=50MW MD 100MW b. Annual energy generated in KWh Under this condition, Sr=Pr=8760hrs TEP TEP LF 0.5 TEP=438,000MWHrs MD Sr. 100MW 8760hr. c. Plant Capacity or Installed Capacity 50MW TEP CF 0.4 IC Pr. IC IC=125MW d. Reserve capacity Reserve Capacity=IC-MD=125MW-100MW=25MW Problem 6: A generating station has a maximum demand of 100 MW, annual load factor of 70%, annual plant capacity factor of 52.5% and a plant use factor of 60% Calculate: a. the number of hours not in service per year b. the annual energy produced c. the reserve capacity of the plant Since PUF is not equal to CF, then Sr is not equal to Pr. Then use energy equations TEP TEP LF 0.7 -------- 1 MD Sr. 100 Sr TEP TEP 0.525 CF --------2 IC Pr. ICx8760 TEP TEP PUF 0.6 --------3 IC Sr. ICxSr a. Solving for Sr, equate 2 and 3, thus 0.525(8760) 0.6( Sr ) Sr=7665hrs Then, Hours Not in Service=8760-Sr=8760-7665=1095hrs b. Solving for TEP, substitute Sr value to equation 1. Thus, TEP=0.7(100MW)(7665hrs)=536,550MWHrs c. Solving for IC, substitute TEP value to equation 2. Thus, 536,550 IC= 116MW 0.525(8760) Therefore, Reserve Capacity=IC-MD=117-100=17MW Problem 7: The annual peak load on a 15,000 kW power plant is 10,500 kW. Two substations are supplied by this plant. The annual energy dispatched through substation A is 27,500,000 kWh with a peak at 8,900 kW while 16,500,000 kWh are sent through b with peak at 6,650 kW . Calculate: a. Diversity Factor b. Capacity Factor c. Utilization Factor MD' s 8900 6650 1.48 a. Div.F TMD 10500 b. Annual CF c. UF Total Energy (27,500,000 16,500,000) MWHrs 33.5% IC Pr. 15,000 MW (8760 Hrs ) MD 10,500MW 70% IC 15,000MW Problem 8: At the end of a three phase 240-volts power distribution system a certain feeder supplies group of customers whose connected are as follows: Feeder Connected load Demand Factor Diversity of group F-1 85 kw 0.6 1.4 F-2 125 kw 0.7 2.5 F-3 75 kw 0.8 1.6 If the diversity factor among feeder is 1.5, load factor is 60% and the power factor is 80%. Find the following: a. Maximum demand kw at each feeder. b. Minimum kva capacity of the transformer c. Annual energy supplied by the substation Solutions: a. Div.F MD' s (CL * DF ) TMD TMD 85kw(0.6) 36.4 KW MDF-1= 1.4 125kw(0.7) 35 KW MDF-2= 2.5 75kw(0.8) 37.5KW MDF-3= 1.6 b. TMD MD' s MD Div. F F-1 MD F-2 MD F-3 36.4 35 37.5 72.6 KW Div. F 1.5 72.6 KW 91 KVA TMD= 0.8 Pf Use 100 KVA transformer KVA c. Annual Energy supplied= MD*LF*Pr=72.6KW(0.6)(8760hrs)=381,586 KWHrs LOAD CURVES & SELECTION OF GENERATING UNITS The load on the Power Station varies from time to time. A single generating unit will not be economical because it will have very poor efficiency during periods of light load on Power Station. Therefore, in actual practice, the number of generating units of different sizes are installed in the Power Station. The selection of the number and sizes of the units is decided from the annual load curve of the station. The number and size of the units are selected in such a way that they correctly fit the station load curve. Important Points in the Selection of units 1. The number of units should be so selected that they approximately fit the annual load curve of the station. 2. The units should be preferably of different capacities to meet the load requirements, although the use of identical units ensure savings in cost, they often do not meet load requirement. 3. The capacity of the plant should be 15% to 20% more than the maximum demand to meet the future load requirements. 4. There should be a spare generating unit so that repairs and overhauling of working units can be carried out. 5. The tendency to select the large number of units of small capacity in order to fit the load accurately should be avoided. It is because the investment cost per kw capacity increases as the size of unit decreases. BASE LOAD AND PEAK LOAD ON THE POWER STATION Base load - unvarying load which occurs almost the whole day on the station. Peak load - Various peak demand of load over and above the load of the station. Methods of Meeting the load To achieve overall economy, the best method to meet the load is the interconnect two different Power Stations. The most efficient plant can be used as base load station while less efficient plant used to supply peak loads. Interconnected Grid systems the connection of several generating station in parallel Advantages of interconnected systems 1. Exchange of peak load – If the load curve on the power station shows a peak demand that is greater than the rated capacity of the plant, then the excess load can be shared by other stations interconnected with it. 2. Use of older plants - older and less efficient plant can carry short peaks of load when interconnected with modern power plants. 3. Ensures economical operation – sharing among the stations is arranged in such a way that more efficient station work continuously throughout the year at a high load factor and the less efficient plants work for peak load hours only. 4. Increase diversity factor - load curves of different interconnected station are generally different, reduced total maximum demand improves the diversity factor and increases the capacity of the system. 5. Reduces the plant reserve capacity – when several units are in parallel, the reserve capacity of the system is much reduce, this increases the efficiency of the system. 6. Increase reliability of the supply – If a major breakdown occurs in one station, continuity of supply can be maintained by other healthy stations. Conditions Involved in Determining minimum cost/kWh 1. To deliver a given peak load, the total installed capacity of a plant increases as the number of units is decreased if a reverse unit is provided in each case. 2. For a given installed capacity of plant, fixed charges increases with the increased number of units. 3. For a given installed capacity of plant, maintenance charges increases with a number of units. 4. As general rule, large units have better efficiency than small units. 5. For a given total capacity of standby equipment, the standby losses increase with the number of units, particularly in steam plant. 6. For a given installed capacity of plant, the operating cost increase with the increase number of units. 7. The total costs per kWh decreases as the load factor of the load increases. Problem 1: A proposed station has the following annual load cycle. Month Jan Feb Mar Apr May June July Aug Sept Oct Nov Dec Load in MW 20 40 50 35 70 40 20 50 70 80 90 100 Draw the load curve and select suitable generator units from 10, 20, 25, 30 MW. Prepare the operation schedules for the machines selected. Problem 2: The annual load duration curve of a typical heavy load shown below is being serve by steam station, Diesel station and hydroelectric station and the kWh supplied by the station are as follows: Steam : Hydro : Diesel 7 : 4 : 1 The Steam station is capable of generating power continuously and work as base load plant. The diesel station work as a peak load plant. Determine: a. Maximum demand of each station. b. Load factor of each station. Solution: MW hrs Annual load Graph TEP of the system= Area under the load curve 1 = 200 100(8760hrs ) 1.314,000 MWHrs 2 Energy Supplied by each Station based on the energy supplied Ratio TEP of Steam Station=(7/12)(1,314,000MWHrs)=766,500MWHrs TEP of Hydro Station=(4/12)(1,314,000MWHrs)=438,000MWHrs TEP of Diesel Station=(1/12)(1,314,000MWHrs)=109,500MWHrs a. Solving for MD of each Station MD of Steam Station Area under the curve TEP of Steam 766,500 MWHrs 87.5MW = base Pr 8760 Hrs MD of Diesel Station, y 1 Triangular Area= TEP of Diesel=109,500= xy 2 y 100 x 87.6 y By similar triangle, x 8760 Combining the equations 1 109,500 (87.6 y 2 ) y=50 2 MD of Diesel=y=50MW Also Sr of Diesel=x=4380hrs MD of Hydro= 200-MD of Steam- MD of Diesel=200-87.5-50=62.5 MW b. Solving For LF of each Station 766500MWHrs 100% (87.5)(8760hrs) 438000MWHrs LF of Hydro= 80% (62.5)(8760hrs) 109,500MWHrs LF of Diesel= 50% (50)(4380hrs) LF of Steam= ECONOMIC DISPATCH OF GENERATORS PARALLEL OPERATION AND LOAD SHARING OF ALTERNATORS Since a large number of generating stations are linked together in any given power system and in each of the station the number of generating units could be more than one, the problem of parallel operation of alternators, their sharing of loads and speed regulation are of considerable interest of power engineers. The operation of alternators is known as “synchronizing” and certain conditions have to be fulfilled before this can be accomplished. CONDITIONS OF PARALLEL OPERATION OF TWO ALTERNATORS 1. The terminal voltage of the incoming machine must be equal to busbar voltage. 2. The phase sequence of the machines must be the same as that of the busbars. 3. The frequency of the machine voltages must be equal to that of the busbar voltage. STEPS TO SYNCHRONIZE GENERATORS 1. Make sure that the breaker of generator 2 is open 2. Bolt the disconnect links of generator 2 to the connecting bars Switch the voltage regulator to automatic 3. Start the engine or turbine of the generator 2 and bring up to speed 4. Using the governor control switch, adjust the frequency of generator 2 to approximately 1/10 cycles higher than the bus frequency 5. Using field regulator, Adjust the voltage of generator 2 to approximately equal or slightly higher than the bus voltage 6. Switch the synchroscope to generator 2 and adjust the frequency until pointer revolves slowly in fast direction 7. Close the circuit breaker of generator 2 at the instant the synchroscope pointer passes into zero position 8. Turn off the synchroscope 9. Adjust the governor switch of generator 2 switch to “raise” and generator 1 to “lower” until the desired KW load for each machine is obtained 10. Adjust the field regulator switch of generator 2 switch to “raise” and generator 1 to “lower” until the desired KVAR load or power factor for each machine is obtained LOAD SHARING BETWEEN TWO ALTERNATORS Effect of change of excitation When two alternators are operating in parallel the amount of kw load taken by each alternator is governed by the fuel input i. e. the steam supply to its prime mover. If the excitation of one of the alternators is changed it will only change the reactive power taken by the alternator, its Kw power output remaining the same. As regards the reactive component of the entire load, the strongly excited machine takes a larger portion of it. Effect of change in steam supply If we increase supply to the prime mover of one of the alternators then the machine can be made to take up an increased share of the load. In that case the load on the other alternators should be decreased by the amount by a adjusting its steam supply. MACHINE CONNECTED TO INFINITE BUSBARS Consider an a.c. generator (cylindrical rotor machine) connected to infinite busbar (constant voltage and constant frequency busbar) and let the excitation voltage of the generator remain constant as E 1 and the infinite busbar voltage be E2. Then if the steam supply to the prime mover of the machine is increased the machine will be loaded. With E1 and E2 remaining constant, there is a definite limit of power which the generator can supply to the load, the expression for which can be derived. SAMPLE PROBLEMS 1. Two 2500 kVA ac generators running in parallel supplies the total loads of 2,500 kW at 0.80 p.f. lagging . One machine is loaded to 1000 kW at 0.7 p.f. lagging. Calculate the kw load and operating power factor of the other machine. 1000 S1 -arcos0.7=1428.7 45.57 0 0.7 2500 SL arcos0.8 3125 36.87 0 0.8 S2 SL S1 3125 36.870 1428.7 45.570 1500 j854.76 1726 - 29.7o kVA P2 1500 KW 854.76 Pf 2 cos arctan 0.87 lagging 1500 2. Two identical three-phase generators operating in parallel share, equally a load of 700 Kw at 6,000 volts and a power factor of 0.8 lagging. The excitation of the machine is changed and its current adjusted to 40 amps at a lagging power factor: find (a) the current delivered by the second machine and (b)the power factor of each machine. 700,000 IL ar cos(0.8) 84.2 36.87 0 3 (6000)(0.8) When sharing equally, 1 I1 I 2 (I L ) 42.1 36.87 0 33.68 j 25.26 2 When the excitation is changed, the current of unit 1 is adjusted to 40Amp, while no change in energy input 33.68 0 I1 ' 40 ar cos 40 32.648 40 Pf1 ' cos(32.648 0 ) 0.842 lagging I 2 ' I L I1 ' 84.2 36.870 40 32.6480 33.68 j 28.94 I 2 ' 44.4 40.67 0 Pf 2 ' cos(40.67 0 ) 0.76 lagging 3. Two identical alternators each rated 2500 KW are connected to the same busbars in a power station. The governor droop of one machine is such that the speed drops uniformly from 60 c/s on no load to 59.2 c/s on full load. The corresponding uniform speed drop for the second machine is from 60 to 58.8 c/s. Find how the two machine will share a load (a) 4000 Kw (b) What would be the maximum load, that can be delivered without overloading either machine. a) P1 P2 4000 - - - - - -1 by similar triangle, 60 59.2 60 f then, P1 3125(60 f ) -------2 2500 P1 60 58.8 60 f then, P2 2083.33(60 f ) -------3 2500 P2 Substitute equation 2 and 3 to equation 1, 3125(60 f ) 2083.33(60 f ) 4000 f 59.23 Hz P1 2400 KW P2 1600 KW b) For maximum load without overloading either machine, the system frequency must be 59.2 Hz. Pmax=3125(60-59.2)+2083.33(60-59.2)=4167kw 4. The speed regulation of two 1000 Kw alternators A and B running is parallel are 4% & 3% respectively. How will the two alternators share a load of 1750 Kw? No load Frequency- Full Load Frequency Speed/Frequency Regulation x100% Full load Frequency assume full load frequency=60 Hz f NL1 60(1.03) 61.8Hz f NL 2 60(1.04) 62.4 Hz To share the load, By similar triangle, 61.8 60 61.8 f 1000 PB 62.4 60 62.4 f 1000 PA PA PB 1750 ---------------------1 then, PB 555.5(61.8 f ) -------2 then, PA 416.67(62.4 f ) -----3 Substitute equation 2 and 3 to equation 1 555.55(61.8 f ) 416.67(62.4 f ) 1750 f 60.26Hz PB 856 KW PA 892 KW 5. A three phase turbo-alternator has a reactance of 10 ohm and negligible resistance. The machine delivers an armature current of 150-amps at 0.8 p.f. lagging when running on 11,000 volts infinite busbars: (a) If the steam admission is constant but the e.m.f.(excitation) is reduced by 5% calculate the value of the armature current and p.f. (b) If the excitation is held constant but the steam admission is reduced by 5% calculate the value of the armature current and p.f. (c) If both steam supply and excitation are reduced by 5% simultaneously. Solution When supplying 150 Amp at 0.8 power factor lagging, I 150 36.870 120 j90 , the excitation emf is 11,000 0 E V I Z S 0 150 36.870 (0 j10) 7349.59.4 0 3 a) When excitation is reduced by 5%, while steam admission is held constant E ' 0.95(7349.5) 6982 volts V ' V 6350.85 volts since infinite bus I ' I e ' jI q ' 120 jIq' Ie' 120A Using the voltage equation, E ' V 'I ' Z S since constant steam admission 6982 6350.85 + (120 jIq' )(0 j10) 6982 (6350.85 10Iq' ) j1200 (6982) 2 (6350.85 10Iq' ) 2 (1200) 2 Iq' 52.7 The new current is, I ' 120 j52.7 131 23.7 0 Amp Pf’=cos 23.7o=0.92 lagging b) If the steam admission is reduced by 5% while excitation is held constant. since constant excitation E ' ' E 7349.5 volts V ' ' V 6350.85 volts since infinite bus I ' ' I e ' ' jI q ' ' 114 jIq' ' Ie' ' 0.95(Ie) 0.95(120) 114A Using the voltage equation, E ' ' V ' 'I ' ' Z S 7349.5 6350.85 + (114 jIq' )(0 j10) (7349.5) 2 (6350.85 10Iq' ) 2 (1140) 2 Iq' 90.97A The new current is, I ' ' 114 j90.97 145.8 38.6 0 Amp Pf’’=cos 38.6o=0.781 lagging c) If the excitation and steam admission is reduced by 5% simultaneously. E ' ' ' 6982volts since infinite bus V ' ' ' V 6350.85 volts I ' ' ' I e ' ' ' jI q ' ' ' 114 jIq' ' ' Ie' ' 0.95(Ie) 0.95(120) 114A Using the voltage equation, E ' ' ' V ' ' 'I ' ' ' Z S 6982 6350.85 + (114 jIq' )(0 j10) (6982) 2 (6350.85 10Iq' ) 2 (1140) 2 Iq' 53.7A The new current is, I ' 114 j53.7 126 25.2 0 Amp Pf’=cos 25.2o=0.91 lagging Exercises: 1. Two 2500 kVA ac generators running in parallel supplies the total loads of 4000 kW at 0.80 p.f. lagging . One machine is loaded to 2000 kW at 0.7 p.f. lagging. Calculate the kw load and operating power factor of the other machine. 2. Two identical alternators each rated 2500 KW are connected to the same busbars in a power station. The governor droop of one machine is such that the speed drops uniformly from 60 c/s on no load to 59.6 c/s on full load. The corresponding uniform speed drop for the second machine is from 60 to 59.2 c/s. Find how the two machine will share a load (a) 4000 Kw (b) 5000 kw, (c) What would be the maximum load, that can be delivered without overloading either machine. 3. Two alternators are driven by shunt motors. The shunt motors have speed-load droop characteristics of 3 % and 4 % respectively. The alternators are in parallel and each carrying 50 kW. There is no automatic speed-load control. An additional 50 kW load is switched on. What are the resulting loads of the alternators assuming that the speed-load control of each is not adjusted? 4. A 3 ,Y-connected, 6.6 kV, 1000 kVA alternator has a reactance of 20% but negligible resistance. When supplying full load at 0.8 pf lagging to a large power system, If the excitation is reduced by 20%, determine the new current and power factor ECONOMICAL LOADING OF GENERATING UNITS In order to determine the optimum load distribution between various generating units in a steam power station, it is necessary to plot the input/output curve of each generating unit. The curve is plotted in terms of fuel input in kcal/hr versus output in Mw. The slope of the input/output curve gives the incremental fuel rate expressed in kcal/kwh. The cost of fuel in Peso per kcal is determined to convert the input/output curve in Peso per hour versus output in Mw. The curve may be expressed mathematically as: F = (C0+C1P+C2P2) Peso/hour Where: P – is the power output in MW F – the cost in pesos Co,C1 & C2 - constants The slope of this curve gives the incremental fuel cost for the unit in peso per Mwh. For Optimum load distribution between two generating units A & B, the incremental fuel cost of Unit A must be equal to the incremental fuel cost of unit B. Thus, dFA dFB dPA dPB EXAMPLE The incremental fuel costs for two units of a generating plant are: dF1 0.1P1 20 dP1 and dF2 0.15P2 15 dP2 where F1 and F2 are in pesos per hour and P is in Megawatts. What is the most economical manner in which a total power of 100 Mw can be allotted between these two units? Determine also the corresponding incremental cost. SOLUTION For economical load division between units 1 and 2 incremental fuel costs must be equal. 0.1 P1 + 20 = 0.15 P2 +15 or P1-1.5 P2 + 50= 0 …(i) If the total load is 100 Mw Then P1 + P2 = 100 …(ii) Subtracting (1) from (2) we get, 2.5 P2 = 150 or P2 = 60 MW & P1 = 40 MW Thus unit 1 and 2 should take 40 MW and 60 MW power respectively. dF1 Incremental cost, = 0.1 P1 + 20=0.1 X 40 + 20 dP1 = Rs. 24/MWHR If the load is shared equally between each plant, what will be the loss per day compared with the economical sharing of the loads. 2 P1 P F1 (0.1P1 20)dP1 0.1 20P1 0 2 When P1=40MW, F1=P880/hr When P1=50MW, F1=P1125/hr Loss=880-1125=P245/hr F2 (0.15P2 15)dP2 0.15 2 P2 15P2 2 When P2=60MW, F2=P1170/hr When P2=50MW, F2=P937.5/hr Gain=1170-937.5=P232.5/hr 0P Combined Operation Cost=F1+F2= -245+232.5=P-12.5/hr Loss per day for operating at 50% sharing is, Loss per day=(P12.5/hr)(24hrs/day)=P300/day ECONOMICS OF POWER GENERATION The art of determining the per unit (one kWh) cost of production of electrical energy. A power station is required to deliver power to a large number of consumer to meet their requirements. While designing and building a power station, efforts should be made to achieve overall economy so that the per unit cost of production is as low as possible. This will enable the electric supply company to sell electrical energy at a profit and ensure reliable service. Terms used in the economics of power generation: 1. Interest - the cost of used money 2. Depreciation - the decrease in value of the power plant equipment and building due to constant use. Cost Of Electrical energy 1. Fixed cost - It is the cost which is independent of maximum demand and units generated. The fixed cost is due to the following: a. annual cost of central organization, b. interest on capital cost of land and c. salaries of high ranking officials. 2. Semi-fixed Cost - it is the cost which depends upon the maximum demand but it is independent of units (kWh) generated. The semi-fixed cost is directly proportional to the maximum demand on power station and is an account of a. annual interest and depreciation on the capital investment of building equipment, b. taxes and salaries of management and clerical staff. 3. Running or Operating Cost - it is the cost which depends only upon the number of units generated. The running cost is an account of annual cost of fuel, lubricating oil, maintenance, repairs and salaries of operating staff. Expression for Cost of Electrical energy. 1. Three part Form Total Annual Cost = Fixed cost(constant) + Semi-fixed cost (Proportional to MD) +Running cost (Proportional to KWh) = P a bKwMD cKwhr 2. Two Part Form Total Annual Cost = Fixed Sum per KWMD + Running Charge per KWHR = PB Kw MD C Kwhr Where: a – a fixed cost representing the annual cost due to cost of central organization interest on capital cost of land and salaries of high ranking officials. b - annual interest and depreciation on the capital investment of building equipment, taxes and salaries of management and clerical staff express in P/KWMD c - annual cost of fuel, lubricating oil, maintenance, repairs and salaries of operating staff. express in P/KWH Problem 1: The annual working cost of a power station is represented by the formula P a b Kw MD c kwh where the various terms has their usual meaning. Determine the values of a, b, and c for a 50 MW station working at annual LF of 40% from the following data: a. Capital cost of building and equipment is P 50M b. Annual cost of fuel, oil taxes and wages of operating staff is P15M. c. Interest and depreciation on building and equipment are 10% per annum. d. Annual cost of central organization is P 50,000.00 Solution: Fixed Cost, a=P50,000 Semi-fixed cost=annual interest and depreciation = 10%(Capital cost) = 10%(P50M)= P5M Semi - fixed cost P5,000,000 Semi - Fixed Charge P100/kW KW Maximum Demand 50,000 kw Operating Cost= annual cost of fuel, oil, taxes etc = P15M Operating or Running Charges, C Operating cost 15,000,000 P0.085/kwhr TEP per year 50,000kw (0.4LF)(8760hrs) Therefore, the three part form of Annual Charges=P(50,000+100/kW+0.085/kWh) Problem 2: A certain generating station has the following data: Plant Capacity 50MW Annual load factor 40% Capital cost P3.6B Annual cost of wages, taxation etc. (25% fixed) P400T Annual Cost of fuel, lubrication, maintenance etc. P35M Annual interest and depreciation 10% a. Calculate the fixed charge per kw maximum demand and running charge per kwh generated b. Calculate the overall generation charge per kwh generated. Solution: TEP per year=MD(LF)(8760hrs)=50,000(0.4)(8760)= 175.2x106kwhr Annual Depreciation Annual fixed salaries, taxes etc Fixed Charge KW Maximum Demand Fixed Charge 10%(P3,600,000,000) 25%(P400,000) P7,202/kW 50,000kw Running Charge Annual Cost of Fuel etc Anual wages etc of Operating Staff Total energy produced/year P35,000,000 75%(P400,000) P0.2/kWhr 175.2x10 6 kwhr Overall Charges=P7202/kw+P0.2/kWhr Running charge Overall Generation charge/kWhr Overall Generation cost Fixed cost Annual Wages Annual cost of fuel TEP per year TEP 10%(P3,600,000,000) P400,000 P35,000,000 P2.26 / kwhr 175.2 x10 6 kwhr Problem 3. The capital cost of a hydro electric power station of 50 MW capacity is P1000 per kw. The annual depreciation charges are 10% of the capital cost. A royalty of P1 .00 per kw per year and P0.01 per kwh generated is to be paid for using the river water for generation of power. The maximum demand on the power station is 40MW and annual load factor is 60%. The annual cost of salaries, maintenance charges etc. is P700,000. If 20% of this expenses is also chargeable as fixed charges, calculate the generation cost in two part form. Solution Capital cost=P1000/kw(50,000 kw)=P50,000,000 MD=40,000 kw TEP/year=(40,000kw)(0.6LF)(8760 hrs)=210.24x106 kwhr Annual Depreciation Annual Wages, taxes etc. Annual Royalty per kw KW Maximum Demand 10%(P50,000,000) 20%(P700,000) P1.00/kw P129.50/kW 40,000kw Annual Wages, taxes etc Running Charge Part of Annual Royalty per kwhr TEP/year 80%(P700,000) P0.01/kwhr P0.01267/kwhr 210.24x10 6 kwhr Therefore, the two part form is Annual Charges=P129.50/kW+P0.01267/kWhr Fixed Sum, B CHOICE OF POWER PLANTS AND THEIR COMBINED GENERATING COST When making a selection between steam and hydro-power plants a comparison has to be made of the overall generating cost per unit for each type of power plant and whichever is more economical to operate should be selected. Important Factors Governing the choice of Power Plants (Thermal and Hydro) 1. Initial cost of hydro is quite heavy due to large amount of excavation, and earth work, due to the land and water rights and cost of rehabilitation of population from areas that may be inundated by pondage 2. Running or operating cost of steam power station due to high consumption of coal, lubricants etc. 3. In hydro-station, another important factor is the cost of HV transmission line, there is loss of energy which increases the cost per unit of power delivered. Problem 1 A power station having a maximum demand of 75 Mw has a load factor of 60%. It is to be supplied by either of the following schemes. a. A steam power station in conjunction with HEPP. The latter is supplying 125 106 kwh per annum with maximum output of 30 Mw. b. A steam station capable of supplying the whole load. c. A hydro station capable of supplying the whole load. The following data are as follows: STEAM HEPP Capital cost/kw installed capacity P 8,000 P 12,000 Interest/depreciation on capital cost 12% 10% Operating cost/kWh P 0.25 P0.025 Transmission cost/kWh Negligible P 0.006 Calculate the overall cost/kWh in each scheme (neglect spares) Solutions: Scheme A: Mixed capacity Overall TEP per year=MD*LF*Pr=75,000kw(0.6)(8760 hrs)=394.2x106 kwhr Annual Generation Cost=Running Cost + Fixed Cost FOR HYDRO: Generation cost =(P0.025+0.006/kwhr)(125x106kwhr)+10%(P12,000/kwx30,000kw) =P39.875x106 FOR STEAM MD=75MW-30MW=45MW TEP per year=394.2-125)x106=269.2x106 kwhr Generation cost =P0.25/kwhr(269.2x106 kwhr+12%(P8,000/kw)(45,000kw) =P110.5x106 COMBINED GENERATION COST=P39.875M+P110.5M=P150.375M Combined Generation cost P150,375,000 Overall Cost per kwhr P0.38/kwhr Oveall TEP per year 394.2x106 kwhr Scheme B: Steam Station operating alone Annual Interest & Depreciation Oveall TEP per year 12%(P8000/kw * 75,000kw) P0.25 / kwhr P0.43/kwhr 394.2x10 6 kwhr Cost per kwhr Operating Cost per kwhr Scheme C: Hydro Station operating alone Annual Interest & Depreciation Oveall TEP per year 10%(P12000/kw * 75,000kw) P0.025 / kwhr P0.006/kwhr P0.259/kwhr 394.2x10 6 kwhr Cost per kwhr Operating Cost per kwhr Problem 2: A load having a maximum demand of 150,000 kW can be supplied by either HEPP or Steam Power Plant. The cost are as follows: Steam HEPP Capital Cost P 7,000/kw P16,000/kw Operating Cost P0.13/Kwh P0.016/kwh Interest & Dep. 7% 7% a. Calculate the overall generation cost/kWh for each at 50% load factor. b. Calculate the minimum LF above which the HEPP will be more economical. Solution Overall Generation Cost per kwhr=Running Charges + Fixed Charges Annual Interest & Depreciation Overall Cost per kwhr Operating Cost per kwhr Oveall TEP per year FOR STEAM STATION: 7%(P7000/kwx150,000kw) P0.13/kwhr P0.242/kwh 150,000kw(0.5LF)(8760kwhr) FOR HYDRO STATION: 7%(P16000/kwx150,000kw) P0.016/kwhr P0.272/kwh 150,000kw(0.5LF)(8760kwhr) Therefore, at 50% load factor Steam Station is cheaper than Hydro FOR MINIMUM LOAD FACTOR @ which Hydro is economical, annual Cost of steam must be equal to annual cost of hydro, thus Let X- be the minimum LF 7%(P16000/kwx150,000kw) 7%(7000kwx150,000kw) P0.016/kwhr P0.13wh 150,000kw(X)(8760hr) 150,000KW(X)8760hr Minimum LF=X=63.1% Problem 3. (Assignment) A load having a maximum demand of 100,000 kW can be supplied by either HEPP or Steam Power Plant. The cost are as follows: Steam HEPP Capital Cost P 8,000/kw P16,000/kw Operating Cost P0.25/Kwh P0.026/kwh Transmission cost/kWh Negligible P 0.006 Interest & Dep. 12% 12% 1. Calculate the overall generation cost/kWh for each at 38% load factor. 2. Calculate the overall generation cost/kWh for each at 55% load factor. 3. Calculate the minimum LF above which the HEPP will be more economical. TARIFF The rate at which electrical energy is supplied to the consumer Objectives: 1. Recovery of cost of producing electrical energy at the power station 2. Recovery of cost on the capital investment in transmission and distribution systems. 3. Recovery of cost of operation and maintenance of supply of electrical energy e.g. metering equipment, billing etc. 4. A suitable profit on the capital investment Desirable Characteristic of a Tariff 1. Proper return 2. Fairness 3. Simplicity 4. Reasonable profit 5. Attractive Types of Tariff 1. Simple tariff – there is a fixed rate per unit energy consumed Disadvantages a. no discrimination between different types of consumer since every consumer has to pay equitably for the fixed charges. b. The cost per unit delivered is high. 2. Flat rate – different types of consumers are charged at different uniform per unit rates. Disadvantages: a. Since the flat rate varies according to the way the supply is used, separate meters are required for lighting load, power load etc.. This makes the application of such tariff expensive and complicated. b. A particular class of consumer is charged at the same rate irrespective of magnitude of energy consumed. However a big consumer should be charged at a lower rate as his case the fixed per unit are reduced. 3. Block rate Tariff – a given block of energy is charged at specified rate and the succeeding blocks of energy are charged at progressively reduced rates 4. Two Part Tariff – the rate of electrical energy is charged on the basis of maximum demand of the consumer and the units consumed. Advantages: a. it is easily understood by the consumer b. it recovers fixed charges which depends upon the maximum demand of the consumer but independent of units consumed. Disadvantages: a. The consumer has to pay the fixed charges irrespective of the fact whether he as consumed or not consumed the electrical energy. b. There is always error in assessing the maximum demand of the consumer. 5. Power factor tariff – the tariff in which the power factor of the consumer is taken into consideration. A low power factor increases the rating of equipment and line losses, therefore a consumer having low power factor must be penalized. 6. Three Part Tariff - the total charge to be made form the consumer is split into three parts namely fixed charge, semi-fixed charge and running charge. This is generally applied to big consumers. Problem1: Calculate the annual bill of a consumer whose maximum demand is 250 kW, pf = 80% lagging and load factor = 60%. The tariff used is P 1500/Kva of maximum demand plus P1.00/kwh consumed. Solution: Annual Energy consumed=250Kw(0.6LF)(8760 hrs)=1,314,000 kwhr Maximum Dekand KW 200 Maximum Demand KVA 250 Power Factor 0.8 Annual Bill=Demand Charge(MD)+Energy Charge(Energy Consumed) = P150/kva(250 kva) + P1.00/kwhr(1,314,000 kwhr)=P1,351,500 Problem 2: A consumer requires 0ne million kwh per year and his annual load factor is 50%. The tariff enforce is P120 per kw maximum demand plus P0.05 per kwh consumed. Estimate the savings in energy charges if he improves his load factor is raised to 100%. Solution: Annual Energy Consumed LF MDx8760hrs At 50% Load Factor: 1,000,000kwhr MD 228.31 kw 0.5(8760hrs) Annual Bill=P120/kw(228.31 kw) +P0.05/kwhr(1,000,000 kwhr)=P77,397.20 At 100% Load Factor: 1,000,000kwhr MD 114.15 kw 1.0(8760hrs) Annual Bill=P120/kw(114.15 kw) +P0.05/kwhr(1,000,000 kwhr)=P63,698.00 Annual Savings=77,397.20-63698=P14,000 Problem 3. The monthly reading of consumers meter are as follows: MD = 75 kW; Energy Consumed = 36,000 kWh; Reactive Energy Consumed = 23,400 Kvar-hr. If the tariff is P 100/kw of MD plus P 0.8/kwh +P0.005 per kwh for each 1% of pf above or below 86%. Calculate the monthly bill of consumer. Solution: kvarhr 23400 Arctan 33 o kwhr 36,000 0 Power Factor= cos =cos 33 =83.9% Monthly Charges=P100/kw+P0.8/kwhr+P0.005/kwh(Reference P.F.- Actual P.F.) Monthly Bill=P100/kw(75kw)+P0.8/kwhr(36,000 kwhr + P0.05/kwh(86-83.9) (36,000 kwhr)=P7500+28,800+3780=P40,080.00 Power Factor Angle Arctan Problem 4: The following two tariff are offered: Scheme No. 1 = P (1000 + 1.00/KWH) per month Scheme No. 2 = flat rate at P 3.00/KWH per month a. Which scheme is economical? if the monthly consumption is 400 kwh, b. At what consumption in kwh is the first tariff Economical ? Solution: a. At 400 kwhr consumption: Scheme No. 1 Monthly Bill=1000+1.00(400)=P1,500 Scheme No.2 Monthly Bill=3.00(400)=P1,200 Scheme No. 2 is economical b. For Minimum Consumption at which Scheme No. 1 is economical, equate the cost. Let X- be the minimum consumption 1000+1.00(x)=3.00(x) X=500 kwhr Problem 5: A medium size industrial plant has a maximum demand of 500 KVA at 70.7% pf lagging and yearly consumption of 1 106 kwh . You have to improve the pf to 90% lagging. Using shunt capacitor. The first cost of capacitor is P2,500/KVA and the annual fixed charges is 10%. Electric rates are given as: Demand Charge = P 1,500/KVA max.-demand/yr. Energy Charge = P 4.90/kwh Calculate: a. The annual electric bill before and after pf correction. b. The net savings/yr. after putting capacitor. c. The economical operating pf that will result to maximum savings. Solution: Annual Charges=P1,500/kva+P4.90/kwhr Before Pf correction: Annual Bill=P1500/kva(500 kva)+P4.90/kwhr(1,000,000 kwhr)=5,650,000 After Pf correction: New Demand kva=500(0.707/0.9)=392.8 kva Annual Bill=P1500/kva(392.8 kva)+P4.90/kwhr(1,000,000 kwhr)=5,489,200 Gross Saving by Pf correction=5650,000-5,489,200=P160,800 Net Savings = Annual Gross savings – Annual Interest & Depreciation P = 500(0.707)=353.5 kw =arcos 0.707=450 ’=arcos 0.9=25.840 CKVAR of required Capacitor=P(tan -tan ’)=353.5(tan450-tan25.840) = 182.3 kvar Capital Cost of required Capacitor=P2500/kvar(182.3kvar)=P455,767.15 Annual Interest & Depreciation= 10%(P455,767.15)=45,476.70 Therefore, Net Savings per year = P160,800-45,576.70=P115,233.30 Economical Operating pf that will result to maximum Savings i capacitor cost/kva 100 Economical operating pf 1 Demand Charge 2 2 10% 2500 100% =98.6% Economical operating pf 1 1500 Problem 4. (Assignment) A power plant is working at its maximum kva capacity with a lagging power factor of 0.70. It is now required to increase its kw capacity to meet the demand of additional load. This can be done by raising the power factor to 85% by correction apparatus or by installing extra generating plant which cost P8000/kva. Find the minimum cost per kva of the power factor correction apparatus to make its use economical that the additional generating plant. STABILITY OF POWER SYSTEMS The term “STABILITY” denotes a condition in which the various synchronous machines of the system remain in synchronism. The system is said to be “UNSTABLE” when the machine cease to operate in parallel and violent fluctuation of voltage and frequency occurs on the system. The stability limit may be determined both under steady state as well as under transient condition. 1. Steady State Stability Limit – is the maximum flow of power through a particular point of power system without loss of stability when the power is increased gradually. 2. Transient Stability Limit – is the maximum flow of power through a point without loss of stability when a sudden disturbance occurs such as sudden change of load, short circuit or fault on the system. 1. Calculation of Steady State Stability Limit Power Limit of Transmission System VS = AVR + BIR VS/ = A/ VR/0 + B/ IR SR = PR – j QR = VR*IR P R – j QR 2 VR VS AVR = B B Equating real Parts of both sides PR 2 VR VS cos( ) AVR cos( ) = B B is variable At maximum power, = PR MAX = VR VS AVR 2 cos( ) B B For negligible shunt admittance, A=1, = 0 PR MAX = VR VS AVR 2 cos B B For negligible Shunt Admittance and Resistance, = 0 & = 900 PR MAX = VR VS X Power Limit of Two Machine System Eg = Em + IZ Eg/ = Em/0+ I(Z/ Power delivered to the motor Sm = Pm – j Qm = Em*I Pm – j Qm = EmEg Eg2 Z Z Equating real Parts of both sides Pm = EgEmcos( ) Em2 cos Z is variable At maximum power, = Pm MAX = Z EgEm Em2 cos Z Z For negligible shunt admittance, = 0 Pm MAX = EgEm Em2 cos Z Z For negligible Shunt Admittance and Resistance, = 0 & = 900 Pm MAX = EgEm X 2. Calculation of Transient Stability Consider a synchronous generator connected to an infinite busbar, the swing equation of the system is given by M d 2 dt 2 Ps Pe where Ps – the shaft power Pe – electrical power developed Eg – the voltage of the infinite busbar Em the voltage behind the transient reactance of the motor X- transient reactance of the system(sum of reactances of motor, lines &transformer) Pe = EgEm sin = P X max - the torque angle sin Effect of Sudden Increase of load The torque angle corresponding to Po Po o = sin-1 P max The torque angle corresponding to Ps Ps s= sin-1 P max On application of sudden load Ps the torque angle will begin to increase and swing between o to m around the equilibrium position s. Foe remissible maximum load which can be allowed to be taken by the motor without loosing stability, the relation be (-s-o)sins = coss + coso from the equation above,s can be calculated and the load P can be found which is the maximum permissible load which the motor can take without losing stability. Methods of Improving Stability Limit 1. For Steady State Stability – the stability can be improved by using additional machines in parallel or two lines in parallel so that total reactance of the system is reduced. The other method adopted are using higher excitation voltages and quick response excitation system. 2. For transient Stability – the stability limit can be improved by using quick acting and auto-closing circuit breakers and relays having minimum time lags. The other alternative method consist in using machines of high inertia and high speed governors. Also, the use of quick acting voltage regulators helps the system stability Problem 1 The generalized circuit constant of a nominal-pi circuit representing a three phase transmission line are: A=D= 0.9/0.3o B= 82.5 /76 C= 0.0005/90o a. Find the steady state stability of the system if the V S and VR are held constant at 110 kv. b. What is the steady state stability if shunt admittance is assumed to be zero c. What is the steady state stability limit if the shunt admittance is assumed to be zero and the series resistance is neglected. Solution: a. Pmax VS . VR B A.V2R B cos( ) Pmax 110 .110 82.5 0.9 .110 2 cos(76 0.3) 114 MW 82.5 b. If shunt admittance is zero, then A=1.0/0o Pmax Pmax c. If R=0, Pmax VS . VR B 110 .110 82.5 A . VR 2 cos B 1.0 .110 2 82.5 cos76 0 111MW X=82.5 sin76o=80 and =0, then 110.110 VS . VR = 151MW 80 B sin Problem 2 A 3-phase transmission line has a resistance and reactance of 10 ohms and 30 ohms per phase respectively. The sending and receiving end voltages are both maintained at 132 kv. Determine the maximum steady state power limit and calculate the maximum additional load which could be suddenly switched on the line without loss of stability if the line were already carrying 80 MW. Solution: ZL = 10 + j 30 then =71.6o Z = 31.6 Pmax VS . VR Z . VR 2 Z cos = 132 .132 31.6 For Negligible resistance, Pmax VS . VR .132 2 31.6 cos71.6 0 =378 MW 132.132 581MW 30 X The maximum Additional Load suddenly switched on to the line is Pmax VS . VR X sin Pmax sin Let the initial power carried by the line be Po and angle between voltages be 0 arcsin 0 Po 7.9o =0.138 rad Pmax consider the condition: (-s-o)sins = coss + coso (3.14-s-0.138)sins = coss + cos7.9o Substituting the value of o, by approximation s will give 48o The increase in load could suddenly be applied without loss of stability is = Pmax sins - Po = 581 sin 48o - 80 = 350 MW END Electric power Plant Circuit layout Important Factors in planning Power Plant layout 1. 2. 3. 4. 5. 6. 7. Flexibility Adequacy Reliability Simplicity Safety Space Cost Typical Power Plant circuit layout 1. Single bus bar, single breaker - used for small stations where simplicity and economy is the primary requisites. 2. Double bus, single Breaker System - This arrangement greatly increases the chances for continuity of service, one bus bar may be used as an auxiliary only or one may used as lighting load while the other feed a power load. 3. Double Bus, Double Breaker System- This arrangement gives the same advantage double bus, single breaker system, with double assurance against shut down to circuit breaker. 4. Ring Bus System, Bus Sectionalization - Suitable for station of medium size were great flexibility and maximum economy in cost is desired. The arrangement requires small amount of copper in the bus bar.