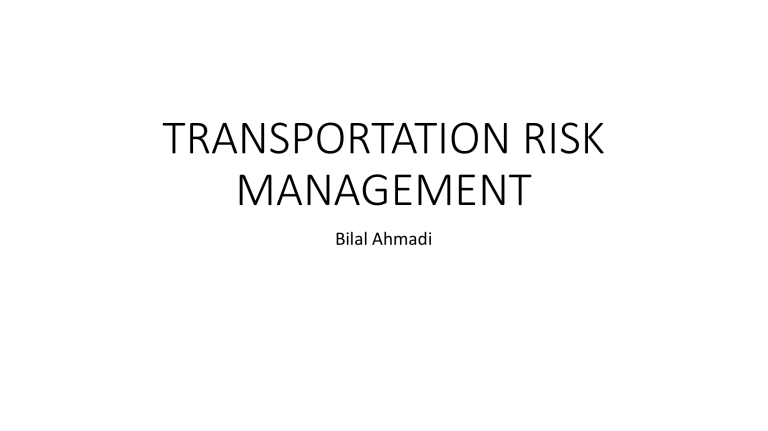

TRANSPORTATION RISK MANAGEMENT Bilal Ahmadi Introduction • As strange as it may seem, pirates really do exist in the 21st century. It’s a growing problem and not merely an action movie genre (e.g. Captain Phillips) • In 2008 alone, more than 100 vessels were attacked off the coast of Somalia. Other hot spots include the waters near Indonesia, Malaysia, India, the Philippines, Brazil, and Ecuador • Piracy is just one of the threats that organizations face when moving goods. Major incidents—hurricanes, pandemics, labor unrest, and terrorism— create societal problems and significant business challenges • Companies cannot idly stand by and hope for the best when they move freight. They must actively work to limit exposure to legitimate hazards Risk Concepts • Risk is an everyday part of life • In terms of freight transportation, the freight can potentially be stolen, damaged, lost, or delayed while in motion or at rest in a port, trucking terminal, rail yard, or other intermediate facility • Freight is at risk of many disruptions from the time it leaves the origin location until it reaches its final destination Risk Concepts • Disruption — an event that results in a displacement or discontinuity; the act of causing disorder • Transportation Disruption — an unplanned or unanticipated event that interrupts the normal flow of goods and materials through the supply chain. These disruptions expose companies within the supply chain to operational and financial risks • Risk — a hazard or a source of danger that has a possibility of incurring loss or misfortune • Transportation Risk — a future freight movement event with a probability of occurrence and the potential for impacting supply chain performance Impact of Disruptions • A 2008 Aberdeen Group study revealed that 99 percent of the companies surveyed had suffered a supply chain disruption in the past year, with 58 percent suffering financial losses as a result • At minimum, these disruptions are nuisances, creating extra work and delays. Recovery efforts hurt productivity, involve expensive expediting efforts, and require premium freight services • At worst, disruptions inflict long-term damage to a company’s image, profitability, and stock price Prevention Steps • Risk Management — the variety of activities undertaken by an organization to control and minimize threats to the continuing efficiency, profitability, and success of its operations • Business Continuity Planning — the processes and procedures an organization puts in place to ensure that essential functions can continue during and after a disruption or disaster • Risk management and business continuity planning are not simple tasks Transportation Risk Management Objectives • Define the key objectives and scope of the risk management process • Identify risk issues through structured brainstorming, data gathering exercises, and interviews • Allocate responsibilities for each identified risk, to provide further details of background, consequence, and management information • Assess each risk against an agreed consistent scale for likelihood and potential impact on operations • Compare risk significance to identify the top risks requiring urgent management attention • Develop detailed management action plans and responses for each risk • Provide a framework to implement actions and monitor their effectiveness • Provide a baseline for the process, allowing risks to be reevaluated and further threats to be identified Transportation Risk Management Process Step 1 – Risk Identification • Accurate and detailed risk identification is vital for effective risk management • This involves a concerted effort to discover, define, describe, document and communicate risks before they become problems and adversely affect freight flows • The goal of risk identification is to capture as many transportation disruption risks as possible • There are various techniques that can be used for risk identification (e.g. brainstorming, interviews and surveys, historical data and documented knowledge) Common Risk Categories • Product Loss • The International Cargo Security Council reports that cargo theft in the United States exceeds $60 billion per year • Product loss includes any type of action or negligence that leads to product not reaching the intended buyer. This includes: product pilferage, shipment jettison, piracy and hijacking • Product Damage • Product damage is a potential peril that arises every time a shipment is handled • Employee inattention, negligence, and poor training all contribute to this very costly problem • Specific damage risks include equipment accidents, poor freight handling, improper equipment loading Common Risk Categories • Product Contamination • A particular risk to food, pharmaceutical goods, and other consumables is the possibility that product becomes contaminated • Product contamination risk increases along with trip distance and time in transit • Primary freight contamination risks include climate control failure, product tampering, exposure to contaminants • Delivery Delay • There are numerous delivery delay risks, such as sourcing goods from other continent, just-in-time delivery inventory, etc. • Common delivery schedule disruptors include congestion, poor weather, equipment malfunction Common Risk Categories • Supply Chain Interruption • Many transportation risks are created by poor execution of day-to-day operations • Recent examples of transportation-altering supply chain interruptions include carrier bankruptcy, labor disruptions, capacity shortages • Security Breach • The increase in terrorist attacks, organized crime activity, and illegal immigration fosters tremendous effort to secure international borders • Common points of exposure are lax security processes, unprotected transfer facilities, shipment control failures Step 2 – Risk Assessment • Evaluating transportation risks is a challenging proposition because they do not affect organizations equally • In making this determination, two parameters are typically evaluated: • Probability — the likelihood of the risk occurring • Impact — the consequences if the risk does occur • Qualitative risk analysis provides a baseline evaluation of risks in a rapid and cost-effective manner. These judgmental approaches seek to classify each risk in terms of low, medium, or high probability and impact • Quantitative risk analysis often builds upon the foundation created by qualitative analysis. Quantitative analysis incorporates numerical estimates of frequency or probability and consequence Risk Assessment Matrix Step 3 – Risk Management Strategies • The next step is to create a coherent strategy for managing and mitigating transportation risks in a cost-effective manner • The goal is to lower the probability of risk occurrence and/or minimize the negative impact if the risk occurs • Each risk mitigation strategy should produce an action plan that identifies: • • • • roles and responsibilities for developing, implementing and monitoring the strategy resources required to carry out the planned actions timelines conditions present in order for risk level to be acceptable • These strategies typically focus on one of four techniques to manage and mitigate risk: avoidance, reduction, transfer, or retention Risk Avoidance • The simplest way to eliminate a risk is to not perform an activity that carries risk • For example, a company could avoid transportation risks by refusing to accept a customer’s order • One alternative to this very conservative pure avoidance strategy would be to take steps to remove the risk • For example, if an investigation revealed that all thefts occurred when a specific trucking company was used, the simple solution would be to never use that carrier again • Another avoidance strategy would be to sidestep the specific exposure • In the case of freight loss or damage risk, the seller could choose to work only on an F.O.B. Origin basis Risk Reduction • Given that many risks cannot be totally eliminated or avoided, it is important for companies to proactively mitigate or limit risk • For example, a company could attempt to reduce the risk of theft or hijacking by hiring armed guards to travel with high value freight • There are numerous types of strategies to pursue the goal of risk reduction • hedging strategy • postponement strategy • buffering strategy Risk Transfer • Potential problems can be too problematic to manage or mitigate by its own organization • In these situations, the organization may seek outside assistance in controlling those risks • This risk transfer strategy provides a means to place liability on a third party should the risk occur • Insurance is a common method of risk transfer • It is also possible to transfer risk to third party logistics service providers (3PLs) Risk Retention • Risks that have limited potential to negatively affect the supply chain and present an acceptable level then the organization will retain the risks • In other situations, the cost of mitigating a risk may outweigh the benefits realized • Finally, some risks are so large or catastrophic that they either cannot be reasonably mitigated or insured against Step 4 – Risk Review and Monitoring • Risk management planning is not a static, one-time process • Instead, a testing and review process must be instituted to ensure that existing risk mitigation efforts and disruption recovery processes work as intended • There are two stages to testing • First, well-communicated, controlled tests are conducted to walk the organization and their supply chain partners through the process. This identifies gaps in the risk management plan and gets everyone comfortable with reacting to each risk scenario. • Second, the surprise tests are carried out to see how the plan and people hold up under pressure. Without surprise tests, the organization doesn’t know how well it will react when a real event occurs