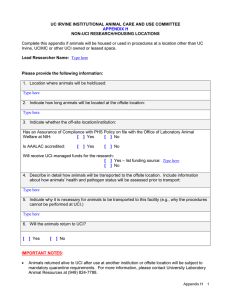

Faster, Smarter, More Efficient: Building Skills for Offsite Construction Research summary and action plan The first in a series of CITB Research White Papers on Productivity and Future Skills Foreword My 2016 review of the UK Construction Labour Model, entitled ‘Modernise or Die’ set out a stark warning to the construction industry, alongside both its clients and government. The central assertion, as the report’s title suggests, is that the construction sector needs to either embrace reform once and for all or face the prospect of resource attrition and growing delivery risks related to traditional approaches gradually rendering it unfit for purpose. It is very clear to me, even in the few months since my review was published, that the industry prognosis I set out is already starting to drive an agenda for change, whether the industry likes it or not. The sector is fundamentally underpinned by an ageing and migrant dependent workforce just at a time when Brexit is creating real uncertainty on future flows of labour and we continue to struggle to attract high quality home grown talent from a new generation that are aspiring to very different, digitally led career choices. The dangers are evident and the solutions lie in two fundamental and inter-related areas that go to the heart of productivity improvement. Firstly, adopting more integrated precision engineered ‘pre-manufacturing’ techniques, in turn supported by growing client led demand. Secondly, to evolve a new skills and training landscape alongside the more traditional pathways that enables and supports the implementation of innovative techniques and technologies. One of my review’s recommendations was for the CITB to be reformed to create a much more effective enabling function for industry which collects a levy and distributes grant in an efficient, impactful and responsible way. That wider responsibility in my view must extend to helping future proof an industry with unprecedented structural risks to its traditional mode of delivery. Any reform therefore needs to include consideration of more strategic issues such as understanding changing market demand and better prioritising future skills needs. The current ITB review initiated by the Department for Education pursuant to my report’s recommendations will be central to the question of if and how the CITB can be re-purposed in a way that addresses these issues whilst crucially rebuilding industry trust, followship and ultimately continued consensus. It is with all of this in mind that I welcome the publication of this research report and the CITB’s proactivity, at a time of considerable uncertainty for them, in addressing what is a major industry improvement theme. This decision I believe is fully validated by growing signs of industry disruption that will start to increasingly question ‘business as usual’. It also aligns to a supportive government policy environment which is actively promoting construction innovation. These two factors are both especially relevant in the residential sector of the construction industry but also have wider application. 2 I believe the approach set out in this report of identifying 6 functional skills groupings rather than trying to map them entirely onto existing job roles is the right one. The much more collaborative, integrated approach required to deliver true digitally enabled Design for Manufacture & Assembly (DfMA) challenges the definitions of these very roles and importantly the behavioural attributes that go with them. This process integration imperative does however highlight the potential limits on CITB’s ability to influence the broader agenda for training and industry reform without changes to its current scope and statutory mandate. This brings back into focus the need for a strategic and integrated approach to the ITB review and indeed, irrespective of this, for the wider industry, client community and government to all play their part in driving and leading change. It is important that the findings of this report have been heavily influenced by industry consultation, and that theme has to continue if the recommendations are to stand any chance of being hard wired to deliverable implementation plans. The immediate term actions that CITB propose offer a good start point, in partnership with industry and other stakeholders, to defining required new skills, updating worker and course accreditations, reviewing grant funding priorities and, by implication, improving the narrative and tools that industry image and outreach programmes can work with to attract quality new entrants. In my travels across industry over the last few months, I have seen some very exciting activity in manufacture led construction training and also research and development. Institutions such as Dudley College, London Design & Engineering UTC and the High Value Manufacturing Catapult Centres in Coventry and Sheffield have shown me what the future could look like for both skills and delivery in our industry. I have also met numerous progressive clients and construction businesses that recognise the time is now right for positive change. This bodes well but ultimately we still need to have much more client and industry led demand for innovation and we need it to be happening collaboratively if we are going to open the ‘productivity floodgates’. As part of this any fully reformed, client and industry aligned CITB needs to be able to help facilitate and support that shift in a way that is accessible to everyone from major businesses to SME’s. Ultimately, it’s actions not words that are needed but I’m hopeful that the scale of our industry’s problems and the unprecedented burning platform we are facing is at last forcing the modernisation debate to the very top of the industry’s agenda. Mark Farmer April 2017 3 Introduction Offsite – or prefabricated – construction is the manufacture and pre-assembly of construction elements or components in a factory environment prior to installation onsite. It potentially represents the biggest change the built environment sector has faced in generations. Currently, offsite accounts for less than 10% of total output, but this will grow as firms invest in prefabricated manufacturing factories and other offsite technology. Offsite will grow as firms invest in factories and other offsite technology Over the last 18 months, announcements of major offsite construction initiatives have included L&G’s modular housebuilding factory in Yorkshire and the China National Building Material Company’s (CNBM) investment commitment of £2.5 billion into the UK starting with the establishment of an offsite construction facility in Gloucestershire. Home building is likely to be the first major beneficiary of offsite – or modular – construction, but there is also scope for improved offsite methods to have a profound influence on the pipeline of major infrastructure projects across the UK. It has the potential to be revolutionary in its impact on quality, productivity, build times and costs. The Farmer Review highlights a “window of opportunity” for construction to take advantage of offsite, with the chance to “grow a new sector and retain the gross value add within the UK economy”. There are, of course, a number of challenges to the growth of offsite. However, one of the biggest potential drags on the UK fully capitalising on the rise of offsite construction would be an inadequately trained workforce. We need a more flexible skillset across construction to One of the biggest drags on the rise of offsite would be an inadequately trained workforce adapt to the dynamic demands of offsite construction. The growth of offsite has seen a blurring of the lines between manufacturing, engineering and construction, creating the need for new skills and redefining existing ones. We need to not only train new entrants in a range of new skills, but also upskill our existing workforce. The digitalisation of the construction industry and the link that provides to offsite also offers a chance to attract a new cohort of skilled workers. This report summarises detailed research into the offsite sector and its skill needs, produced by Pye Tait for CITB. It also recommends a number of actions for CITB to which we respond. It is based on a comprehensive survey of 100 clients, data from CITB’s panel of 1,248 employers and in-depth interviews with over 50 employers, manufacturers, training providers, industry stakeholders and clients. 4 Clients and employers expecting growth Clients The research identified a rapidly developing appetite for offsite construction among clients but also a number of barriers to growth. These include higher upfront capital costs and public perception that offsite construction results in poorer quality products, possibly due to an association with post-war ‘pre-fab’ housing. The survey of 100 construction industry clients found that nearly one in five (18%) expected the proportion of work that includes some element of offsite construction to increase a lot over the next five years, and a third for it to increase a little. That compares with only 1% who said work would decrease a lot and 3% that it would decrease a little (see figure 1). Figure 1: Over the next 5 years, do you expect the percentage of all your construction work that comprises offsite construction to: Increase a lot 18% Increase a little 31% No change 42% Decrease a little Decrease a lot Nearly half of clients expect the use of offsite construction to increase 3% 1% Cannot say/don’t know 0% 5% 10% 20% 30% 40% 50% % of client respondants It should be noted, however, that the survey only questioned those clients with existing experience of commissioning offsite. That said, these so-called ‘informed’ clients tend to represent larger companies, suggesting that among the bigger employers, offsite is far more likely to grow than shrink. In this context, there is an opportunity for offsite. Not only does it have the potential to drive efficiencies for contractors, digitalisation and the relative comfort and safety of factory working could make the sector more attractive to new entrants. The drivers for growth appear to be strongest in the housing and commercial sub-sectors, where there is clear appetite for innovation. The growing use of certain products - such as light steel frames - in both the commercial and residential markets have helped boost the use of and appetite for offsite. The vast majority of respondents to the survey also expected much greater use of There is a clear appetite for innovation in the housing and commercial sectors offsite produced precast concrete panels and concrete frames over the next five years (see figure 2 overleaf). 5 The infrastructure and industrial sub-sectors have been somewhat slower to adopt the offsite agenda, but there is huge scope for growth here too, with a number of major projects, including HS2 and the Hinkley Point nuclear plant, set to come on stream in the near future. On both projects contractors have indicated the intention to use offsite methods to address regional skills shortages. Figure 2: Of the types of offsite construction materials and products used on your work, do you expect the level of use over the next 5 years to: Precast concrete panels 100% Precast concrete frame 91% Cross-laminated timber 80% Hybrid 75% Structural insulated panels (SIPS) 76% High technology glazing 67% Steel frame 66% 20% 25% 18% 6% 17% Pods 45% Modular 36% 0% 20% No change 17% 31% 59% Timber frame Increase 9% 33% 3% 8% 55% 3% 61% 40% 60% 80% 100% Decrease Employers 42% of firms with over 100 staff expect to use offsite in 3-5 years’ time Of the employers surveyed, around 16% are currently using offsite approaches. But this is almost certainly set to grow in the coming years. The use of offsite is expected to grow more quickly for larger employers. Of the respondents surveyed with more than 100 employees, 42% said they expect their business to use offsite methods in three to five years’ time. That figure drops to just 17% for firms who employ fewer than 10 staff. This discrepancy could impact the supply chain, with even smaller companies forced to upskill, given the high use of sub-contracting in the sector. Personas During the research for this report, a set of six ‘key functions’ were identified, covering multiple job roles that are key to offsite construction. These functions – or personas as they are described here – work in harness with each other in a more holistic, collaborative way (see figure 3). See the Persona Supplement for the full persona examples. 6 Figure 3: Key offsite functions Digital design Site management & integration Offsite requires a more collaborative and integrated approach between functions. Onsite assembly & placement All functions depend on some shared skills, knowledge and behaviours in order to effectively deliver offsite projects. Estimating/ commercial Logistics Offsite manufacture Digital Design (Roles include: BIM Technician, Architect, Design Engineer) Designers will need a new range of digital capabilities. Arguably the most important is the adoption of 3D digital models with rich data (using Building Information Modelling) so that designs can be robustly tested and agreed in advance of manufacture to avoid costly errors and modifications at later stages. Aligned to this is the need to integrate the design function into early stage planning with the contractor and client. This is a significant break from the norm and challenges designers to adopt a more holistic approach to their role. Besides adapting to new technologies, those working in digital design should develop knowledge skills including a deeper understanding of the materials and systems used in offsite construction and how they can be optimally manufactured, transported and assembled. It is also important for digital designers to engage with clients and facility managers during and at the end of projects to get feedback, learn lessons and continually improve approaches. Relevant digital design skills, particularly BIM and offsite-specific knowledge, must be embedded in further and higher education programmes. It is also advised that training Digital skills and knowledge of offsite materials and processes is crucial for this function includes how to generate and use data in models such as sequencing, quantities, product information and task data to help drive efficiencies in design, planning and collaboration. A key barrier to the delivery of training is a shortage of tutors with the relevant knowledge and experience in the emerging area of design for manufacture and assembly. 7 Being able to make the business case for offsite is vital but “no-one is training estimators in offsite methods” Estimating/Commercial (Roles include: Commercial Manager, Quantity Surveyor, Estimator) Given that cost saving is one of the key advantages of offsite, the estimating function becomes an even more crucial one in the sector. Estimators must account for – and have an understanding of – materials used, transportation costs and risk factors. For offsite projects, the costing model often puts a far higher proportion of the cost at the outset (i.e. before being onsite). This can deter clients. Being able to make the case for an alternative value proposition is, therefore, vital. The technical skills required include developing whole-life cycle costs, analysing tender documents and contracts, developing tenders, and understanding the use of BIM. Knowledge of contract law, quality assurance and an appreciation of how pre-manufactured buildings are physically put together are also important in this function. To be effective in this function, estimators must have both commercial nous and a keen understanding of design and materials. There is a notable shortage of estimators with the right skills for offsite construction or, as one offsite company put it to our researchers: “No-one is training estimators.” Respondents believed some form of specific training in offsite construction is required – via CPD, but say this does not exist, and have concerns about the supply of tutors available to deliver bespoke training. 8 Logistics (Roles include: Signallers, Despatch Leader, Logistics/ Plant Manager) In the context of offsite construction, logistics covers planning, transportation, scheduling, goods monitoring and supply chain management. Most of those surveyed view the function as a crossover between onsite and offsite. But as one offsite house builder put it, offsite logistics requires more patience and control, with the traditional function “more chaotic”. Much of this function revolves around coordination and integration, so it is important that those involved develop soft skills such as listening and distilling information, as well as problem-solving capabilities. As with other functions, skills in understanding and using digital models and data become vital here, particularly with regard to planning and project management. Understanding different offsite methods and materials is important for enabling effective decision making and planning. Often the logistics function needs to take account of larger loads for moving and storing and correct sequencing, for example when placing finished pods in-situ. Planning and coordination between offsite and onsite requires new skills and knowledge Appropriate training for this function should include a blend of existing methods and new knowledge and behaviours, which cover offsite processes and materials. According to respondents, what’s missing are training and qualifications that consider onsite and offsite together, allowing people to develop skills and knowledge that are transferrable between the two. 9 Offsite manufacture (Roles include: Multi-skilled trades, Welding Fabricator, Machinist, Project Manager, Factory Manager) Offsite manufacturing encompasses the creation of components, modules or entire buildings in a factory setting, which are then assembled on site. The offsite manufacturing function requires technical skills, like welding, joinery, pre-casting and steel fixing, already present in the construction workforce, plus product and process knowledge. Product knowledge of concrete, light gauge steel, hot rolled steel, open and closed timber frame, cross laminated timber and structural insulated panels (SIPs) would be suitable for most factories in the current market. Many factories use traditional trades, meaning there is still a healthy market for these skills and those who train them. However, the research found that a growing number of respondents are moving towards having multi-skilled operatives who are comfortable with a wider variety of tasks and responsible for quality assurance of finished components. This In addition to any technical skills, trades and multiskilled operatives in factories need training in the right behaviours means that machinists and other multi-skilled operatives would benefit from basic design knowledge to understand what a finished output should look like and to address any issues that might affect assembly onsite. The key to developing a skilled workforce in this function is about supplementing existing skills as much as training a new generation. Respondents said there was a lack of offsite specific training available meaning many companies are conducting training in-house. There is also a need for traditional training courses to include a general overview of offsite which could also lay the basis for training in multi-skilling. The collaborative process of offsite requires a major cultural shift, and so, as much as skills are important, having the right behaviours and attitudes is equally crucial. These soft skills should be embedded into training programmes and qualifications. Onsite placement and assembly (Roles include: Groundworks, Crane Operator, Assembly Technician, Site Manager) Onsite assembly often relies on pre-existing core ‘tradespeople’ skills. However, additional skills, both technical and soft, are also required, together with those traditional ones. For instance, a crane operator needs new skills in handling much larger, unstable pre-manufactured loads. Similarly, ground workers need to work to much tighter tolerances so that foundations match precisely the dimensions of the components being assembled. Technical understanding of products and materials is a key requirement across all roles. 10 Quality assurance, process management and problem-solving skills are also crucial competencies for both assemblers and site supervisors. As one onsite construction company questioned in the research put it, “it’s like Lego for grown-ups.” This function relies largely on existing training for traditional onsite operatives. Those who have done this training can often transition relatively easily to offsite, as long as their training is supplemented by an understanding of the specific needs of offsite. New training should therefore focus on providing an overview of offsite, helping to develop knowledge of materials, basic design and quality assurance testing. Site management and integration (Roles include: Site Manager, Project Manager. Logistics Manager) Adaptability and communication are the key skills for the site management function when it comes to offsite construction. The role hinges on being able to integrate onsite and offsite functions in one project. In this sense, soft skills, such as time management, attitudes and behaviours are arguably as important as technical skills. Digital skills are required in reading and using BIM models, to help with correct sequencing and installation. Quality assurance skills and behaviours are also important. Respondents agree, on the whole, that project and site managers should have a generic skillset in construction, aided by training in specifics such as products and materials and digital software. Current training for managers also needs to include coverage of the right attitudes and behaviours. Managers need offsite specific knowledge, especially if they manage all stages of production Some respondents anticipate a transition to a more highly skilled and knowledgeable programme/project manager who would oversee everything from design to completion, requiring a new qualification pathway. Supply of offsite training The research suggests there is a lack of appropriate training for offsite construction at a time when demand is growing. Of businesses expecting to use offsite over the next three to five years, 38% said they believed they will need new or significantly improved skills within their workforces. Handling and assembly skills are those most in demand, with 81% of employers citing them. Seven in ten also mentioned skills relating to the operation of powered equipment, health, safety and welfare, site preparation, disposal of waste, team working and quality control. And yet this clear demand is not being met. Offsite training is rarely, if ever, embedded into existing courses, meaning training is piecemeal across the sector. 11 Sector training and qualifications remain mostly generic, with a lack of specific content on the offsite element. In particular, these traditional training models do not focus sufficiently on behaviours and attitudes; these are seen as essential in changing the mindset around offsite. Awareness of training that does exist is limited. As a result, many companies are undertaking in-house training, meaning that best practice is less likely to be shared across the sector. The third major hurdle is a shortage of both tutors and assessors with the necessary knowledge, understanding and experience to meet the demand for expert offsite training. Recommendations and activities Future activity – following the development CITB proposes the following response to the report’s of standards: recommendations for it to support the delivery of • Ensure support is in place for the delivery of training for on site elements, including: offsite training. Immediate activity: • In partnership with employers, lead a review of National Occupation Standards (NOS) to identify the • Work with industry to develop new qualification units and standalone knowledge courses. • Link new standards and qualifications to the CITB training grants. • Support the development of bespoke teaching materials for schools, FE and HE. • Promote offsite training to encourage the uptake of standardised courses. • Fund industry experts to deliver training and assessments. need for new standards for roles that are core to the CITB scope (i.e. predominately site based). • Work with the design, engineering and manufacturing sectors to apply the standards developed in these areas to a construction context, to support key offsite functions. • Work with industry to develop a competency framework for offsite construction, focusing on attitudes and behaviours, to embed in training for all functions. • Help to promote career opportunities in offsite using existing avenues such as Go Construct. • Work alongside other bodies, such as the Construction • Recognising the integration between offsite functions, consider options to support training for the design, engineering and manufacturing sectors, along with on site training, such as establishing training/resource Leadership Council, to drive innovation and create hubs that provide curriculum delivery materials, ‘centres of excellence’ for skills and knowledge. expertise and facilities. This is the first of CITB’s Research White Papers on Productivity and Future Skills. The next is on the application of digital learning technologies in construction training. 12 Personas The following personas list all the skills and knowledge needs identified which are applicable to that particular function. They also show training and qualifications available and the gaps in relation to these, as well as the preferred methods of training delivery identified via the research. They are intended to provide a useful reference for assessing the suitability of training provision and the development of new content that meets the competency requirements. Digital design The critical difference between design for traditional construction and design for offsite, is that the latter needs to design specifically for manufacture and subsequent assembly, using appropriate technology and digital skills. Technical skills Knowledge Soft Skills BIM-enabled design Creating 3D models Developing a value proposition (cost, durability, low carbon, aesthetic) Digital design software use e.g. AutoCAD, Revit Digital skills (e.g. scheduling and specific IT) Generating 2D fabrication drawings and site drawings Obtaining prices and dealing with variations Producing product/service specifications Reading technical drawings Risk assessment Appreciation of how buildings are constructed Current and emerging technologies Degrees of tolerance/accuracy IT tools Lean methodologies New technologies e.g. 3D printing Order of sequence Processes used to assemble buildings Quality assurance Relevant design codes and standards Understanding of full range of materials and products used (weights, volumes, dimensions etc.) Understanding of relevant products and systems Understanding of the materials being produced and energy efficiency ratings, U-values etc. Waste management Weight and robustness of materials Accuracy Attention to detail Business case for offsite Effective and on-going communication Problem-solving Team-working Working to tight deadlines Sector specific House-building regulations and planning Commercial building regulations and planning Job roles Skilled worker Supervisor Manager 3D Visualiser CAD Modeller Architectural Technician BIM Technician Pre-Construction Designer Building Services Engineer Electrical Engineer Senior ManagerProfessional Architect Design Engineer Structural Engineer Available qualifications Available training Modern Methods of Construction (MMC) Level 2 Specialist design software e.g. AutoCAD, Tekla BIM training Steel Construction Institute courses/webinars in steel design HNC/D (e.g. Architectural Technology) HNC/FdSc Sustainable Construction & Built Environment BIM and Integrated Design MSc/PgDip/PgCert SVQ (e.g. Built Environment Design) Modern Apprenticeships (e.g. Timber Manufacture Design) Construction Technologies Theory Level 3 Gaps and issues – training & qualifications KEY: Sector specific Mitek (or other timber engineering software) Limited training in design explicitly for manufacture and assembly Software training does not typically cater for offsite specifically Limited coverage of offsite construction in most degree design courses Shortage of tutors able to deliver offsite specific design courses Very little or no content directly aimed at offsite construction Some content directly aimed at for offsite construction Good amount of content directly aimed at offsite construction Preferred training delivery methods Online KEY: 14 Work-based /on-the-job Very few or no employers expressed a preference Classroom delivery Some employers expressed a preference Blended learning Most or all employers expressed a preference Estimating/commercial Estimating is a crucial element of delivering the fundamental cost savings of offsite (compared with traditional) construction, but is subject to substantial skills shortages. Technical skills Knowledge Soft Skills Analysis of tender documents/contract terms and conditions BIM-enabled design Costing/developing whole life cycle costs Developing sub-contract terms and conditions Developing a value proposition (cost, durability, low carbon, aesthetic) Developing tenders Obtaining prices and dealing with variations Planning Producing product/service specifications Reading technical drawings Risk assessment Appreciation of how buildings are constructed Contract law Current and emerging technologies IT tools Lean methodologies Quality assurance Typical associate costs Understanding of full range of materials and products used (weights, volumes, dimensions etc.) Waste management Accuracy Attention to detail Business case for offsite Commercial awareness Effective and on-going communication Problem-solving Team-working Working to tight deadlines Sector specific Differences between Scotland and England for timber frame costing Job roles Skilled worker Supervisor Manager Contracts Manager Commercial Manager Risk Manager Business Development Manager Sales Manager Senior ManagerProfessional Estimator Quantity Surveyor Planner Available qualifications Available training BSc Quantity Surveying BTEC Level 3 Advanced Certificate in Surveying and Estimating Level 3 NVQ Diploma in Construction Contracting Operations – Estimating Level 6 NVQ Diploma in Construction Contracting Operations Management - Estimating Specialist estimating software e.g. Swiftest Forecasting tools e.g. spreadsheets Gaps and issues – training & qualifications 19 KEY: No training readily available to offer ‘overview’ or introduction to offsite for estimators/ commercial roles Existing training is available in estimating but does not typically cater for offsite specifically Limited coverage of offsite construction in most quantity surveying courses Shortage of tutors able to deliver offsite specific estimating courses Very little or no content directly aimed at offsite construction Some content directly aimed at for offsite construction Good amount of content directly aimed at offsite construction Preferred training delivery methods Online KEY: 15 Work-based /on-the-job Very few or no employers expressed a preference Classroom delivery Some employers expressed a preference Blended learning Most or all employers expressed a preference Logistics Logistics in this context spans the product: planning, transportation, scheduling, goods in/goods out, and also supply chain management. This function spans offsite and onsite. Technical skills Knowledge Soft Skills Budget and financial management Control and management of inventory Digital skills (e.g. scheduling and specific IT) Health & safety Lifting and handling Planning Process management Project management Quality control Reading technical drawings Risk assessment Supply chain management (“re-engineering the supply chain”) Time management Working at heights Appreciation of how buildings are constructed Degrees of tolerance/accuracy Integrating onsite and offsite IT tools Lean methodologies Low carbon agenda Offsite manufacturing processes Order of sequence Processes used to assemble buildings Quality assurance Safe lifting and handling Scheduling Site specifics Understanding of the materials being produced and energy efficiency ratings, U-values etc. Waste management Weight and robustness of materials Accuracy Attention to detail Business case for offsite Commercial awareness Customer service Effective and on-going communication Negotiation Problem-solving Process improvement Team-working Working to tight deadlines Sector specific Potential issues for education and healthcare deliveries to site, notably to minimise disruption Job roles Skilled worker Supervisor Administrator Banksman/Signaller Dispatch Leader Crane Specialist Plant Support Services Coordinator Site Supervisor Manager Logistics/Plant Manager Dispatch Manager Transport Manager Construction Manager Sales Manager HR/Training Manager Senior ManagerProfessional Available qualifications Available training Level 2 NVQ Diploma in Site Logistics Operations (Construction) BSc Logistics Management NVQ/SVQ level 2 (Slinging and Signalling, Plant Operations) Level 4 NVQ Diploma in Controlling Lifting Operations Use of specific planning software/other tools Gaps and issues – training & qualifications KEY: Security Industry Authority (SIA) licence Existing training is available in logistics but does not typically cater for offsite specifically or illustrate differences between on and offsite logistics No training readily available to offer ‘overview’ or introduction to offsite for logistics function Shortage of tutors that would be able to deliver offsite specific training Very little or no content directly aimed at offsite construction Some content directly aimed at for offsite construction Good amount of content directly aimed at offsite construction Preferred training delivery methods Online KEY: 16 Work-based /on-the-job Very few or no employers expressed a preference Classroom delivery Some employers expressed a preference Blended learning Most or all employers expressed a preference Offsite manufacture Offsite manufacture refers to the creation of components, modules or entire buildings that are subsequently taken to, and assembled/installed onsite. Technical skills Knowledge Soft Skills BIM-enabled design Health & safety Relevant trade skills (joinery, plastering, operating site machinery, welding) Lifting and handling Machine plant operation Measuring to precise specifications Multiskilling (e.g. combination of various technical skills) Process management Project management Quality control Reading technical drawings Risk assessment Supply chain management (“re-engineering the supply chain”) Time management Use of hand tools Working at heights Appreciation of how buildings are constructed Basic design Degrees of tolerance/accuracy Impacts for site if manufacture is at fault Lean methodologies New technologies e.g. 3D printing Offsite manufacturing processes Order of sequence Processes used to assemble buildings Quality assurance Relevant design codes and standards Safe lifting and handling Scheduling Understanding of full range of materials and products used (weights, volumes, dimensions etc.) Understanding of relevant products and systems Waste management Weight and robustness of materials Accuracy Adaptability Attention to detail Effective and on-going communication Problem-solving Process improvement Team-working Working to tight deadlines Job roles Skilled worker Supervisor Wood Machinist, Multi-Skilled Operative, Steel Fixer, Welding Fabricator, Trades: Joiner; Kitchen Fitter, Forklift driver Trades: Plumber; Electrician; Painter & Decorator; Floorlayer/Tiler; Cavity Insulation Installer Manager Factory Supervisor Project Manager Factory Manager Plant Manager Senior ManagerProfessional Available qualifications Available training Modern Methods of Construction (MMC) level 2 NVQ in Modular Construction level 2 Level 2 NVQ Diploma in Innovative/MMC – Modular/Portable Buildings Steel frame assembly/construction Trailblazer Construction Assembly Technician (multi-skilled) Scottish Modern Apprenticeship Timber Frame Manufacture Level 3 Diploma Engineering Technical Certification Level 3 NVQ Diploma Engineering Technical Support Modular and portable building association in-company training (bespoke) Timber Frame Competency Award Scheme (Structural Timber Association) Scottish Adult Upskilling Programme Timber Frame Manufacturing Steel Construction Institute (SCI) courses and webinars Gaps and issues – training & qualifications KEY: Offsite manufacture specific training (e.g. specific to a material or product such as steel, some of which is developed by federations) not taken up/offered by providers who cannot get funding to run these courses Traditional training in ‘silos’ not multi-skilling Employers largely unaware of relevant training that exists Difficult for employers to release operatives for training; preference for On-site Assessment and Training (OSAT) Shortage of assessors and tutors Very little or no content directly aimed at offsite construction Some content directly aimed at for offsite construction Good amount of content directly aimed at offsite construction Preferred training delivery methods Online KEY: 17 Work-based /on-the-job Very few or no employers expressed a preference Classroom delivery Some employers expressed a preference Blended learning Most or all employers expressed a preference Onsite placement and assembly Onsite construction requires precise, accurate placement of components, modules and buildings prior to full assembly. This level of precision is the nucleus of a successful project. Technical skills Knowledge Soft Skills Health & safety Relevant trade skills (joinery, plastering, operating site machinery, welding) Laying groundworks Lifting and handling Machine plant operation Measuring to precise specifications Multiskilling (e.g. combination of various technical skills) Process management Project management Quality control Reading technical drawings Risk assessment Time management Use of hand tools Working at heights Degrees of tolerance/accuracy Impacts for site if manufacture is at fault Integrating onsite and offsite Lean methodologies Order of sequence Processes used to assemble buildings Quality assurance Safe lifting and handling Scheduling Site specifics Understanding of full range of materials and products used (weights, volumes, dimensions etc.) Waste management Weight and robustness of materials Accuracy Adaptability Attention to detail Effective and on-going communication Negotiation Problem-solving Process improvement Team-working Working to tight deadlines Sector specific House-building regulations and planning Commercial building regulations and planning Job roles Skilled worker Supervisor Assembly Technician Erectors: Steel; Precast Concrete Operatives: Groundworks; Roofing, Banksman/ Signaller, Crane Operator, Forklift Driver Trades: Plumber, Electrician, Painter/Decorator, Joiner Tunnelling Operative Manager Chargehand Site supervisor Project Manager Site Manager Site Inspector Senior ManagerProfessional Available qualifications Available training Modern Methods of Construction (MMC) level 2 NVQ in Modular Construction level 2 Level 2 NVQ Diploma in Innovative/MMC – Modular/Portable Buildings Innovative Modern Methods of Construction (Construction): Steel frame assembly/construction NVQ/SVQ level for traditional trades e.g. joinery, plastering Modular and portable building association in-company training (bespoke) Gaps and issues – training & qualifications KEY: Required training for traditional trades: health and safety, working at heights etc. (can be part of qualification) Offsite is not typically covered in traditional trade training Traditional training in ‘silos’ not multi-skilling Employers largely unaware of relevant qualifications such as the NVQ in Modular Construction Shortage of assessors and tutors Very little or no content directly aimed at offsite construction Some content directly aimed at for offsite construction Good amount of content directly aimed at offsite construction Preferred training delivery methods Online KEY: 18 Work-based /on-the-job Very few or no employers expressed a preference Classroom delivery Some employers expressed a preference Blended learning Most or all employers expressed a preference Site management and integration Offsite construction site management hinges on being able to integrate the offsite and onsite functions, which requires a comprehensive understanding of both aspects. Technical skills Knowledge Soft Skills Budget and financial management Digital skills (e.g. scheduling and specific IT) Health & safety Information management (project delivery and design management) Measuring to precise specifications Multiskilling (e.g. combination of various technical skills) Process management Project management Quality control Reading technical drawings Risk assessment Supply chain management (“re-engineering the supply chain”) Time management Degrees of tolerance/accuracy Impacts for site if manufacture is at fault Integrating onsite and offsite IT tools Lean methodologies Order of sequence Processes used to assemble buildings Quality assurance Safe lifting and handling Scheduling Site specifics Understanding of relevant products and systems Waste management Weight and robustness of materials Accuracy Adaptability Attention to detail Effective and on-going communication Negotiation Problem-solving Process improvement Team-working Working to tight deadlines Sector specific House-building regulations and planning Commercial building regulations and planning Job roles Skilled worker Supervisor Manager Site Manager Project Manager Construction Manager Logistics Manager Compliance Manager Senior ManagerProfessional Site Inspector Available qualifications Available training Modern Methods of Construction (MMC) level 2 NVQ in Modular Construction level 2 Level 2 NVQ Diploma in Innovative/MMC – Modular/Portable Buildings Construction Project Management – MSc HNC in Construction & Built Environment Modular and portable building association in-company training (bespoke) Required training for traditional trades: health and safety, working at heights etc. (can be part of qualification) Site safety management HNC in Building Studies Gaps and issues – training & qualifications KEY: Construction project management MSc includes one module on ‘innovation in construction’ i.e. not explicitly covering offsite construction Onsite behaviours and attitudes (e.g. collaborative approach) are not included in traditional training Generic project management qualifications do not have substantial coverage of offsite Shortage of assessors and tutors Very little or no content directly aimed at offsite construction Some content directly aimed at for offsite construction Good amount of content directly aimed at offsite construction Preferred training delivery methods Online KEY: 19 Work-based /on-the-job Very few or no employers expressed a preference Classroom delivery Some employers expressed a preference Blended learning Most or all employers expressed a preference Report Authors Jennifer Brennan and Clare Vokes – Pye Tait Consulting Alan Tanner and Ben Lever - CITB For more information please contact Ben Lever, Future Skills Strategy Manager, CITB ben.lever@citb.co.uk Cover photos: Timber-frame licensed by brizmaker/Shutterstock.com; factory / panel by kind permission of Laing O’Rourke iMedia’