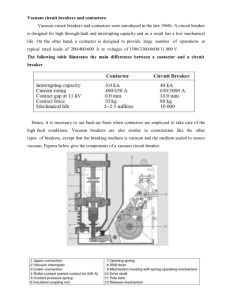

Application Paper AP020006EN Effective September 2020 Benefits of contactors vs. breakers for medium-voltage motor control applications Reduced footprint, clearances, and front accessibility Presently used MV MCCs, measure about 36 inches wide by 30 inches deep and only require a front clearance of 36 inches. They are front accessible and commonly available in a single-high 800 A or a two-high 400 A starter configuration, which can be installed against a wall, back to back, or in a corner. Introduction With both power circuit breakers and contactors able to start and stop a motor, how do you decide which option makes the most sense? The availability of fully rated 800 A contactors has been a great advantage for medium-voltage (MV) motor control. With contactors available at this higher amperage, there is a reason to assess the typical approach for motor control and understand what are the advantages a contactor provides over a circuit breaker. Full-voltage starters are the most commonly used method of MV motor control. Also known as across-the-line starters, this equipment applies line voltage to the motor in a single action via contactors rated to connect and disconnect motor in-rush currents. An assembly of motor controllers under a common bus is often called a motor control center (MCC). On the other hand, an MV circuit breaker is a power distribution protection equipment designed to interrupt high levels of short-circuit current. These devices are commonly found installed in assemblies called switchgear. This application paper will discuss common application considerations when choosing a motor starting method including: size of equipment, endurance, impact on other equipment, and safety. Here is the upshot—the contactor-based motor starter solution comes out substantially ahead in each of these parameters. The following pages will describe the benefits of using contactors for motor starting applications. MV switchgear on the other hand, requires rear access, is 96 inches deep, and has clearance requirements of 70 inches at the front, 32 inches on the side, and 36 inches at the rear. This increased footprint and additional access requirements can become costly, particularly when the equipment is installed in locations such as prefabricated electrical houses where the cost per square foot is very significant. For example, a typical MV MCC lineup with ten 400 A starters will measure 180 inches in width and would require about 83 square feet of floor space, including front clearances. Using circuit breakers in MV switchgear for the same application would more than triple the overall required footprint and clearances to 253 square feet. This increase in footprint, clearances, and overall cost is not necessary especially for motors below 6000 horsepower (hp), which can be controlled by a fully rated 800 A contactorbased starter. Lower chopping current means there’s less chance for adverse impact on your motor When a vacuum interrupter opens, the level of current produced by the arcing between the interrupter’s contacts almost instantly falls to zero instead of following a nominal current zero decrease of the fundamental 60 Hz waveform. This sudden interruption in current is defined as current chop and depending on its magnitude and frequency, it can cause serious insulation degradation over the lifetime of a motor. By design, vacuum interrupters in contactors have a lower interrupting rating and are constructed to operate more frequently than the ones used in breakers. Vacuum interrupters in contactors are manufactured using different metallurgy, which allows them to exhibit a lower chop current (about 1 A) than the chop current produced by a breaker interrupter (about 5 A). See Figure 1. Application Paper AP020006EN Effective September 2020 Depending on the characteristic impedance of the electrical system, the transient voltage created by the chopping current could be detrimental to equipment insulation. Figure 2 presents the transient voltage created by a 1 A and 5 A chopping current in a simulated circuit with a characteristic impedance of 3000 ohms. As shown, the 1 per unit overvoltage condition created by the 1 A current chop of a vacuum contactor is well within the rating of most MV insulation Figure 1. 1 A and 5 A chopping current waveforms Figure 2. 1 A and 5 A voltage transient waveform (Z0 = 3000 ohms) 2 EATON www.eaton.com Benefits of contactors vs. breakers for medium-voltage motor control applications systems and will not compel design engineers to use surge arresters. Vacuum interrupters in circuit breakers, on the other hand, have a 5 A current chop, increasing the voltage transient to levels above four times the system voltage. These higher levels of transient voltages often require the use of surge arresters as a mitigator to protect insulation systems. Application Paper AP020006EN Benefits of contactors vs. breakers for medium-voltage motor control applications Effective September 2020 Higher mechanical and electrical endurance Motor starters using contactors have extended mechanical and electrical life when compared to breakers used in the same application. The impact here is substantial. For motor starting applications, contactors can require little, if any, maintenance for decades. In contrast, breaker-based solutions for motor starting could require repeated maintenance beginning within a year of operation. As seen in Table 1, vacuum breakers have a mechanical endurance of 10,000 operations with a manufacturer recommended maintenance period of 500 operations. Vacuum contactors are commonly rated for 25,000 electrical operations before maintenance is recommended and a total electrical life up to 300,000 operations. Table 1. Vacuum breaker and contactor rated operations and maintenance Device Rated electrical operations Recommended maintenance operations Vacuum breaker 400 A vacuum contactor 800 A vacuum contactor 10,000 300,000 200,000 500 25,000 25,000 Breakers are constructed to stop high levels of current in the event of a fault. They are excellent interrupters, and as such, they are better suited for power distribution applications instead of motor starting applications where the number of operations significantly increases. For example, an application where only four motor starting operations are required per day would lead to maintenance periods of four months if a breaker-based controller is applied. Using the same scenario, we find that the contactor will not require any recommended maintenance for more than ten years. Breakers can be used in this context, but it’s important to understand manufacturers’ maintenance recommendations in order to implement maintenance schedules that accommodate for this usage. Enhanced safety: faster clearing times and lower let-through currents Breaker-based motor controller short-circuit protection is usually provided by the instantaneous overcurrent setting of the motor protection relay. Although this type of protection operates with no intentional time delay, it is important to note that inherit delays exist due to relay and breaker operations or total clearing time. To obtain the relay operating time, the protection engineer must account for the relay’s output contact and instantaneous protection operating time. Relays typically have an 8 msec contact operation time with a 30 msec maximum pickup time. This means the relay’s total operating time is about 38 msec or about 2¼ cycles. Once the relay picks up and closes its output contact to trip the breaker, it will take an additional 50 to 83 msec (3 to 5 cycles) in order to fully open its contacts and clear the fault. Adding both the relay’s and the breaker’s operating times, the total clearing time is 88–121 msec (5–7 cycles). Class E2 motor controllers use a main contactor to make and break load and overload currents, in addition to MV current-limiting fuses for interrupting fault currents that exceed the breaking capacity of the main contactor. Most 400 A MV contactors have interrupting ratings between 6000 A and 8500 A; and 800 A MV contactors have interrupting ratings of 7200 A to 12,500 A. In order to obtain higher interrupting ratings, current-limiting fuses are supplied as backup protection to interrupt and limit short-circuit currents higher than the contactor’s rating. The motor starter design must ensure the contactor does not open above its interrupting rating, and instead allow the fuse to clear this fault. Table 2 tabulates the minimum and total clearing times as well as the let-through current of common fuses used in 400 A and 800 A MV motor starters. As seen in this table, the higher the levels of prospective short-circuit current at the fuse location, the faster the fuse takes to clear and limit the let-through fault current feeding the fault. This current-limiting feature clears a fault within ½ cycle or at least 10 times faster than a breaker’s instantaneous protection, greatly reducing the amount of arc-flash energy produced during a fault, making it safer for its users. Table 2. 400 A and 800 A MV starter fuse characteristics [1] 400 A—24R Prospective short-circuit current rms (A) 12,000 15,000 20,000 25,000 30,000 35,000 40,000 45,000 50,000 Minimum melt (cycle) 2 1 Let-through region Let-through region Let-through region Let-through region Let-through region Let-through region Let-through region 800 A—44R Total clearing (cycle) Peak let through (A) 2.6 1.2 <0.5 800 A—57X Minimum melt (cycle) Total clearing (cycle) Peak let through (A) Minimum melt (cycle) Total clearing (cycle) Peak let through (A) 33,000 15 18 N/A 18 60 N/A 35,000 37,000 6 2 9 4 N/A N/A 4.8 1.4 16 4.7 N/A N/A <0.5 40,000 1 2 N/A 0.6 2.4 N/A <0.5 43,000 1 N/A 76,000 45,000 0.9 82,000 1.1 80,000 <0.5 47,000 <0.5 87,000 0.8 83,000 <0.5 50,000 <0.5 90,000 <0.5 86,500 <0.5 51,000 <0.5 93,000 Let-through region Let-through region Let-through region Let-through region Let-through region 1.5 <0.5 Let-through region Let-through region Let-through region Let-through region Let-through region <0.5 90,000 EATON www.eaton.com 3 Application Paper AP020006EN Effective September 2020 Benefits of contactors vs. breakers for medium-voltage motor control applications Conclusion With the ability to pair a fully rated 800 A starter with an 800 A induction motor, there’s an opportunity for an optimum solution to starting and stopping MV motors. Applying a fully rated 800 A starter instead of a 1200 A circuit breaker not only right-sizes the equipment for the application but also translates to other benefits: reduced footprint, lower chopping currents, higher endurance, and faster clearing times. The contactor-based solution provides significant advantages along each of these parameters: 1. One-third less footprint and clearance requirements. 2. Lower chopping current means reduced likelihood of adverse impact on downstream equipment. 3. 20 times higher mechanical and electrical endurance and 50 times operations between maintenance intervals. 4. Faster clearing time, which further enhances safety. All that said, the traditional approach can work, and equipment can last until it becomes too expensive and too difficult to find replacement parts. When that happens, there’s an opportunity to assess the best approach available today. References [1] Eaton Corp., R-Rated Medium-Voltage fuses for Motor Circuit Protection, 2018. Eaton 1000 Eaton Boulevard Cleveland, OH 44122 United States Eaton.com © 2020 Eaton All Rights Reserved Printed in USA Publication No. AP020006EN / Z24197 September 2020 Eaton is a registered trademark. All other trademarks are property of their respective owners.