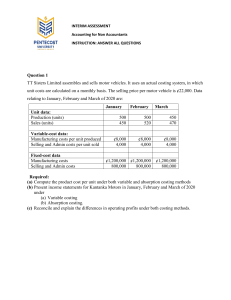

BSR Long Question Summary LA 5: Cost Behaviour 1. High – Low Method Find the lowest and highest levels of ACTIVITY and their associated costs. Do not use highest and lowest costs. To get the variable cost per unit of activity, divide the difference between the highest and lowest cost by the difference in the activity levels. We can now determine the fixed cost. We take either the high value and associated cost or the low value and associated cost. Fixed Cost = Total Cost – (Variable cost per unit of activity x Amount of activity) Using the formula y = a + bx a = total fixed cost b = variable cost per unit of activity 2. Scatter graph method Plot all points. Activity on the x axis, cost on the y axis Draw a regression line so that there is approximately the same number of points on either side of the line. It is easier if your line bisects one of these points. Slope of line represents average variable cost per unit of activity. The fixed cost is represented by where the regression line intersects the cost/y axis. Variable cost = Total cost – fixed cost Major setbacks are that no one will ever draw the same line. The estimate of the fixed cost is not as precise as other methods. 3. Least squares regression method More objective and precise. Uses mathematical formulas to fit the regression line. Computes the regression line that minimises the sum of these squared errors. 𝑅2 Additional information provided by this method. Measure’s goodness of fit of regression line to data points. Tells us what percentage of variation in cost (dependant variable) that is explained by variation in the independent variable (activity). 4. Contribution Approach (costs organized by behaviour) Separates costs into fixed and variable, first deducting variable expenses from revenue to obtain contribution margin (amount of remaining from sales revenue after variable expenses have been deducted). Revenue Less variable Expenses: Cost of goods sold Variable selling Variable admin 12000 UNITS X VC/unit (2000) (600) (400) Contribution Margin: Less fixed Expenses: Fixed manufacturing Fixed selling Fixed admin Net profit: = 9000 (4000) (2500) (1500) = 1000 5. Fixed and Variable costs Important to remember: Summary of Variable and fixed cost behaviour Cost In total Per unit Total variable Variable cost per Variable cost changes unit remains the when activity same level changes Fixed Total fixed cost remains the same even when activity levels change. Fixed cost per unit goes down as activity levels go up Sales commission, shipping, DM, DL, VMOH, COGS Taxes, insurance, salaries, depreciation, advertising In identifying if a cost is mixed, fixed or variable use the rules above. Step 1; Identify fixed costs FIRST, they are the easiest. Fixed cost remains the same in total even if activity changes. Step 2: Identify mixed and variable costs. If we calculate a cost per unit at various levels, & we get the same answer, that is a VC. If we calculate a cost per unit at vario us levels & we DO NOT get the same answer, that must be a MC. LA 6: Variable and Absorption costing Product Costs Period Costs Absorption Costing Direct Materials Direct Labour Variable Manufacturing Overhead Fixed Manufacturing Overhead (divide by prod units) Selling and administrative expenses Product Costs Variable Costing DO FIRST Direct Materials Direct Labour Variable Manufacturing Overhead Fixed Manufacturing Overhead Selling and administrative expenses Period Costs Calculating Unit Product Costs Use the rules above to determine which costs are used in each method. Always calculate beginning inventory of the month they ask for. Take revenue of previous month divided by the cost per unit. This gives the number of products sold. If they produced 40000 and you find only 35000 sold then the next months BI is 5000. Beginning Inventory + Units Produced = Total Units Available Units sold Closing Inventory Jan 0 40000 40000 35000 5000 Feb 5000 50000 55000 40000 15000 E.g. Variable Costing Profit and loss Statement Sales = 40 000 x R30 per unit = R1 200 000 1. Variable COGS: Opening Balance 5000 x (R5 cost to produce unit in jan, variable costing) COGM 50 000 x R5.5 Less Closing Balance (15 000 x R5.5) 2. Variable admin and selling expenses 40 000 x R2 (R2 times by units SOLD) 3. Total Variable costs = 1 + 2 = 297500 4. Contribution Margin = revenue – total variable costs = 902500 5. Fixed Expenses: Fixed manufacturing overhead 600 000 Fixed selling and admin expense 300 000 – 80 000(40 000x2) Net Income = 82500 Reconcile (Compare Absorp and CM Profit and Loss totals) : Take calculated operating profit from profit and loss statement for each year/month. Add : Fixed manufacturing overhead cost deferred in stock under absorption costing (this is the closing balance of stock x the difference in unit cost between variable and absorption costing) Deduct FMOH cost released from stock under absorption costing (this is the opening balance stock x the difference in unit cost between variable costing and absorption costing.) When asked about why, under absorption costing, the operating profit for year 2 is higher than year 1 although the same amount of products have been sold: The increase in production in year 2 led to a build-up of stock and a deferral of a portion of the fixed manufacturing overheads to the next year. By increasing production, and thereby building up stock the company was able to increase profits without increasing sales. Major criticism. Difference if JIT had been used: Two differences, production would have been geared to sales. The unit production cost for year 2 would be the same as year 1 as the same number of products would be produced. ** Absorption costing is not in line with breakeven analysis LA 7: Cost – Volume – Profit relationships Contribution margin = Revenue – variable expenses Contribution margin ratio = (contribution margin)/(revenue) CMpu = SPpu – Vcpu Variable expense ratio = 100% - CM ratio Using CM ratio to calculate breakeven point: Break even point in units sold = (fixed expenses)/(CMpu) Break even point in total revenue = (fixed expenses)/(CM ratio) TARGET PROFIT: How many units much be sold to earn a profit of x? -> BE = (fixed exp + x)/(CM per unit) High breakeven point = BAD Low net income = BAD MoS = Actual Sales – Breakeven Sales (higher the better) Can also be expressed as % of sales = MoS/Sales Application of CVP: Change in sales volume and fixed cost: First add extra sales to original sales. Divide by the selling price per unit to see the number of sales. From this you can multiply the number of products by the variable cost per unit to get variable expense cost Add any fixed cost they mention. Change in selling price, increase in fixed costs. “Would increase the sales by 1/3”: We test the saying “would increase sales by.” First calculate proposed sales by adding 1/3 to original sales (units sold). Add the value to fixed expense. Calculate normally and compare the profits of each. Degree of operating leverage (DoL): CM / net profit You can use the degree of operating leverage to calculate increase in net income/profit. For example, 20% increase in sales. 0.2 x 4(degree of operating leverage) 80% increase in net income. 60 x 180% = 108000 -> new net income amount When asked “if they sell 12000 pairs (UNITS) what will the profit be”: Take the break even amount minus the stated amount sold, multiply the remainder by the CM per unit. Or take the selling price per unit, multiply by the number of units stated. Subtract the variable costs and fixed costs. If they ask what the profit will be and they give you increased sales value you times this by CM RATIO. Incremental contribution margin (SALES INCREASE): Take the sales increase and multiply by the CM ratio for sales. Subtract any added fixed cost. LA 8: Segment Reporting If sales are increased and nothing else changes and they ask for the profit increase, multiply the CM with the given increase in sales. (REMEMBER RATIOS REMIAN UNCHANGED) Net operating profit = net operating income Return on investment = (net operating profit)/(Average operating assets) ROI = margin x turnover Margin = net operating profit/revenue Turnover = revenue/average operating assets Residual income = net operating profit – (average operating assets x minimum required rate of return) If they give a rate of return and ask to compare to the original, check if the original ROI and RI is higher or lower than that stated. OPERATING INCOME IS BEFORE INTEREST AND TAXES Sales increase = Net income increase, ROI increase Expenses decrease = Net income increase, ROI increase Assets decrease = Net income increase, ROI increase If machinery is purchase, add to assets. If money is used to repurchase inventory, subtract from assets. If revenue increases, adjust variable costs as well. Remember ROI is based on average operating assets computed from the beginning of year and end of year balances. / 2 Written off inventory as a loss: Expenses will increase (they are not available for sale) LA 9: Activity based costing Get TOTALS first. Activity rate = (total cost) / (total activity measure) When asked to calculate total cost. Multiply the activity rate by the number of current activities in that poo. E.g. activity rate for ticket bookings is R20, 40 people buy tickets, therefore, R800. Absorption rate is also activity rate. Plantwide Overhead Rate = POHR using direct labour hours or machine hours. Plantwide Overhead rate = (total manufacturing overhead) / (total direct labour hours) Traditional Overhead To work out direct labour hours. Take the cost for labour divided by the rate per hour, this gives you the labour hours per product. Multiply this by sales demand to get direct labour hours in total. Multiply the cost per direct labour hour by the total number of direct labour hours to get the manufacturing overhead. Multiply material cost per kilo by the sales demand to get direct material cost. Multiply the labour cost by the sales demand to get the direct labour cost. Unit product cost – direct materials + direct labour + manufacturing overhead POHR x direct labour hours per unit) ABC Overhead Work on a previous percentage. They will ask for 1st stage allocation of costs to the activity cost pools, multiply the % given by the total for that cost pool. Normally place the Cost pools on the top and the activities on the left-hand side vertically. Once you have worked out the total cost for each cost pool they might ask to calculate the total cost for a specific customer. Here use the costs of the cost pools and multiply by the required units in the given customer requirements. LA 10: Relevant costs Constrained Resources: Usually given some kind of constraint such as a time constraint. For example, Product X 2000 units x 1 min 2000 min Product Y 2200 units x 0.5 min 1100 min Total 3100 min Total available 2400 min (given) Shortage 700 min To see which option is better, work out the CM per unit of the constrained resource. CM per unit (a) X R24 1 min Constrained resource required to produce one unit CM per unit of the R24/1 min constrained resource Y R15 0.5 min R30/min Therefore, Y is better as it has a better CM per constrained resource. If asked to calculate max profits, take the better option (Y). Take planned unit sales and multiply by the time required to produce one unit, the rest of the time is for X. Multiply these times by the CM per unit. Adding and dropping segments: Prepare the analysis asked, usually an analysis to show if the segment is dropped. Start with lost CM as this is lost if the segment is dropped. Here we look for avoidable costs, these are costs that are saved if the segment is dropped, we add this to the lost CM. Avoidable costs are mainly variable costs but beware of allocated fixed costs. Depreciation is a sunk cost. This will give the net increase/decrease in profits if the segment is dropped. Make or buy decision: Compare the make to the buy. Eliminate costs that are not avoidable. (sunk costs and future costs that have no effect). Compare the total variable costs to make and buy, be careful about a joint product, split it up. If the avoidable costs are less than the outside purchase price, then the company should continue to make its own. For make, calculate the total variable make cost and calculate the cost of each product used in the making, use percentages given. For buy, calculate all the variable costs, and add the cost to buy the product. Compare Special Orders: Joint production costs: Keep or replace old equipment: Usually asked to prepare a profit summary for each: Calculate revenue for both the old machine and new machine. Deduct the variable expenses. Calculate the depreciation of each. Given the remaining book value and the disposal value, you can calculate the loss if disposed now for the old machine. This is reported as loss from disposal under the proposed new machine. If asked to determine the desirability, use all the relevant costs. To get relevant costs, eliminate the sunk costs and the future costs that do not differ between the alternatives. To make this easier, calculate the difference in cost between the alternatives. And don’t forget the cost of the new machine/alternative.