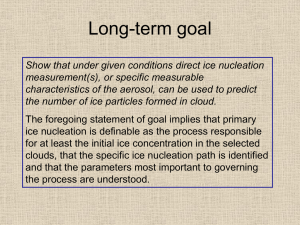

See discussions, stats, and author profiles for this publication at: https://www.researchgate.net/publication/291346619 LECTURE 2 HOMOGENEOUS NUCLEATION Chapter · January 2016 CITATION READS 1 17,124 1 author: Alaa Abdulhasan Atiyah University of Technology, Iraq 62 PUBLICATIONS 75 CITATIONS SEE PROFILE Some of the authors of this publication are also working on these related projects: new approach in 3-dimensional simulation of Functionally graded materials View project Synthesis ceramic parts by electrophoretic deposition technique View project All content following this page was uploaded by Alaa Abdulhasan Atiyah on 21 January 2016. The user has requested enhancement of the downloaded file. Solidification of Metals & Alloys Course /MSc Course Assist. Prof. Dr. Alaa A. Atiyah ــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــ LECTURE 2 HOMOGENEOUS NUCLEATION 2.1 Generals This chapter deals with the simplest nucleation event, namely the homogeneous nucleation of solid crystals during the freezing of a pure metal. On completion, the student should be able to: Explain the term homogeneous, as applied to nucleation events, Understand the concept of a critical size or radius, r* and a critical free energy to nucleation, ΔG*, Differentiate between unstable clusters (or embryos) and stable nuclei, Derive expressions for r* and ΔG* in terms of volume free energy, ΔGv and undercooling, ΔT. Recall that r* ∞ 1/ΔT and ΔG* ∞ 1/ΔT 2. The chapter starts by explaining that a driving force for solidification, ΔGv exists below the equilibrium melting temperature, Tm and that this is approximately proportional to the degree of undercooling ΔT. Solidification and melting can be defined as “Transformation between crystallographic and non-crystallographic states of a metal and alloy”. These transformations are of course basic to such technological applications as: 1. Ingot casting. 2. Foundry casting. 3. Continuous casting. 4. Single-crystal growth for semiconductors. 5. Directionally solidified composite alloys, and more recently rapidly solidified alloys and glasses. Another important and complex solidification and melting process, often neglected in textbooks on solidification, concerns the process of fusion welding. An understanding of the mechanism of solidification and how it is affected by such parameters such as: a. Temperature distribution. b. Cooling rate and alloying. Are important in the control of mechanical properties of cast metals and fusion welds? It is the objective of this chapter to develop some of the basic concepts of solidification and apply these to some of the most important practical processes such as ingot casting, continuous casting and fusion welding. We then consider a few practical examples illustrating the casting or welding of engineering alloys in the light of the theoretical introduction. 1 Solidification of Metals & Alloys Course /MSc Course Assist. Prof. Dr. Alaa A. Atiyah ــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــ 2.2 Nucleation in Pure Metals If a liquid is cooled below its equilibrium melting temperature (Tm) there is a driving force for solidification (GL - GS) and it might be expected that the liquid phase would spontaneously solidify. However, this is not always the case. For example under suitable conditions liquid nickel can be under cooled (or supercooled) to 250° K below Tm (1453 °C) and held there indefinitely without any transformation occurring. The reason for this behavior is that the transformation begins with the formation of very small solid particles or nuclei. Normally undercoolings as large as 250 K are not observed, since in practice the walls of the liquid container and solid impurity particles in the liquid catalyze the nucleation of solid at undercoolings of only -1° K. This is known as heterogeneous nucleation. The large undercoolings mentioned above are only obtained when no heterogeneous nucleation sites are available, i.e. When solid nuclei must form homogeneously from the liquid. Experimentally this can be achieved by dividing the liquid into tiny droplets, many of which remain impurity-free and do not solidify until very large undercoolings are reached. 2.1.1 Homogeneous Nucleation Consider a given volume of liquid at a temperature ΔT below Tm with a free energy G1 as shown in Fig. 2.la. If some of the atoms of the liquid cluster together to form a small sphere of solid, Fig. 4.1b, the free energy of the system will change to G2, given by: Liquid Solid Liquid (G1) (G2=G1 + ΔG) Figure (2.1): Homogeneous nucleation. G2 = VSGsv + VLGvL + ASLγSL Where, Vs is the volume of the solid sphere, VL the volume of liquid, ASL, is the solid/liquid interfacial area, Gsv and GvL are the free energies per unit volume of solid and liquid respectively and γSL the solid/liquid interfacial free energy. The free energy of the system without any solid present is given by: G1 = (Vs + Vl) GvL 2 Solidification of Metals & Alloys Course /MSc Course Assist. Prof. Dr. Alaa A. Atiyah ــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــ The formation of solid therefore results in a free energy change (ΔG = G2 - G1) where: ΔG = -VsΔGv + ASLγSL (2.1) And ΔGv = GvL- Gsv (2.2) For an undercoolings ΔT, ΔG, is given by Equation 1.17 (see 2) as: ΔGv = LvΔT / Tm (2.3) Where, Lv is the latent heat of fusion per unit volume. Below Tm, ΔG is positive so that the free energy change associated with the formation of a small volume of solid has a negative contribution due to the lower free energy of a bulk solid, but there is also a positive contribution due to the creation of a solid/liquid interface. The excess free energy associated with the solid particle can be minimized by the correct choice of particle shape. If γSL is isotropic this is a sphere of radius r. Equation 1.1 then becomes: ΔGv = -4/3 πr3ΔGv + 4 π r2γSL (2.4) This is illustrated in Fig. 2.2. Since the interfacial term increases as r2whereas the volume free energy released only increases as r3the creation of small particles of solid always leads to a free energy increase. It is this increase that is able to maintain the liquid phase in a meta-stable state almost indefinitely at temperatures below Tm. It can be seen from Fig. 2.2 that for a given under cooling there is a certain radius, r*, which is associated with a maximum excess free energy. If r < r* the system can lower its free energy by dissolution of the solid, whereas when r > r* the free energy of the system decreases if the solid grows. Unstable solid particles with r < r* are known as clusters or embryos while stable particles with r > r* are referred to as nuclei* is known as the critical nucleus size. Since dG = 0 when r = r* the critical nucleus is effectively in (unstable) equilibrium with the surrounding liquid. 3 Solidification of Metals & Alloys Course /MSc Course Assist. Prof. Dr. Alaa A. Atiyah ــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــ Figure (2.2): The free energy change associated with homogeneous nucleation of a sphere of radius r. It can easily be shown by differentiation of the equation (2.4) that: r*=2γSL/ΔGv (2.5) And ΔGv* = 16 πγ3SL / 3 (ΔGv) ² (2.6) Substituting equation 1.3 for ΔGv gives: r*= (2γSLTm/Lv) 1/ΔT (2.7) ΔG* = (16π γ 3SL /3 L 2v)1/(ΔT) 2 (2.8) And Note how r* and ΔG* decrease with increasing under cooling (ΔT). Equation 2.3 could also have been obtained from the Gibbs-Thomson equation. Since r*is the radius of the solid sphere that is in (unstable.) equilibrium with the surrounding liquid. The solidified sphere and liquid must then have the same free energy. From Equation 1.58 (see 1) a solid sphere of radius r will have three free energies greater than that of 4 Solidification of Metals & Alloys Course /MSc Course Assist. Prof. Dr. Alaa A. Atiyah ــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــ bulk solid by 2γVm/r per mole or 2γ/r per unit volume. Therefore, it can be seen from Fig. 1.3 that equality of free energy implies: ΔGv = 2γSL/r* (2.9) Which is identical to Equation 2.5? Figure (2.3): Volume free energy as a function of temperature for solid and liquid phases. To understand how it is possible for a stable, solid nucleus to form homogeneously from the liquid it is first necessary to examine the atomic structure of the liquid phase. From dilatometric measurements it is known that at the melting point the liquid phase has a volume 4% greater than the solid. Therefore, there is a great deal more freedom of movement of atoms in the liquid and when a period of time. The atom positions appear completely random averaged over. However, an instantaneous picture of the liquid would reveal the presence of many small, close-packed clusters of atoms which are temporary in the same crystalline array as in the solid, Fig. 2.4. On average the number of spherical clusters of radius r is given by: nr = no exp (-Δ Gr/KT) (2.10) Where, no is the total number of atoms in the system, ΔG, is the excess free energy associated with the cluster, Equation 1.4, and k is Boltzmann's constant. For a liquid above T, this relationship applies for all values of r. Below Tm it only applies for r 5 r* because clusters greater than the critical size are stable nuclei of solid and no longer part of the liquid. Since nr decreases exponentially with ΔGr (which itself increases rapidly with r) the probability of finding a given cluster decreases very rapidly as the cluster size increases. For example, by combining Equations 2.4 and 2.10 it can be shown that 1 mm3 of copper at its melting point (~ 1020 atoms) should on average contain ~ 1014 clusters of 5 Solidification of Metals & Alloys Course /MSc Course Assist. Prof. Dr. Alaa A. Atiyah ــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــ 0.3 nm radius (i.e. ~10 atoms) but only-10 clusters with a radius of 0.6 nm (i.e. -60 atoms). These numbers are of course only approximate. Such small clusters of atoms cannot be considered to be spherical, and even more important the effective value of y used in calculating ΔGr, (equation 2.4) is very probably a function of the cluster size. However the above calculations do illustrate how sensitively cluster density depends on their size. Also, it can be seen that there is effectively a maximum cluster size, ~100 atoms, which has a reasonable probability of occurring in the liquid. The same sort of calculations can be made at temperatures other than Tm below Tm there is an increasing contribution from ΔGv in Equation 1.4as the solid becomes progressively more stable and this has the effect of increasing the 'maximum' cluster size somewhat. Figure 4.5 shows schematically how rmax varies with ΔT. Of course larger clusters than rmax are possible in large enough systems or given sufficient time, but the probability of finding clusters only slightly larger than rmax is extremely small. The critical nucleus size r* is also shown in Fig. 2.5. It can be seen that at small undercooling, r* is so large that there will be virtually no chance of forming a stable nucleus. But as ΔT increases r* and ΔG* decrease, and for supercooling of ΔTN or greater there is a very good chance of some clusters reaching r* and growing into stable solid particles. In the small droplet experiment, therefore, homogeneous nucleation should occur when the liquids under cooled by - ΔTN. Figure (2.4): A two-dimensional representation of an instantaneous picture of the liquid showing the origin of I G , and r* structure. Many close-packed crystal-like clusters (shaded) are present. The critical nucleus size r* is also shown in Fig. 2.5. It can be seen that at small undercooling, r* is so large that there will be virtually no chance of forming a stable nucleus. But as ΔT increases r* and ΔG* decrease, and for supercooling of ΔTN or greater there is a very good chance of some clusters reaching r* and growing into stable solid particles. In the small droplet experiment, therefore, homogeneous nucleation should occur when the liquids under cooled by - ΔTN. The same conclusion can also be reached by an energy approach. The creation of a critical nucleus can be considered to be a thermally activated process. i.e. a solid-like 6 Solidification of Metals & Alloys Course /MSc Course Assist. Prof. Dr. Alaa A. Atiyah ــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــ cluster must be able to cross the nucleation barrier ΔG* before it becomes a stable nucleus. Since the probability of achieving this energy is proportional to exp (ΔG*IkT) nucleation will only become possible when ΔG" is reduced below some critical value which can be shown to be -78 kT (see below). Example 2.1 During the solidification of a pure metal, what are the two energies involved in the transformation? Write the equation for the total free-energy change involved in the transformation of liquid to produce a strain-free solid nucleus by homogeneous nucleation. Also illustrate graphically the energy changes associated with the formation of a nucleus during solidification.. Solution: The two energies involved in the solidification of a pure metal are surface free energy and volume free energy. These energies contribute to the total free energy, ΔGr: ΔGr= ΔGV + ΔGS = (3/4) π r2 ΔGV + 4 π r2γ = Volume free energy + Surface free energy Example 2.2 a. Derive an expression describing the critical nucleus size (d*) for a cubed-shaped nucleus, forming by a homogeneous process, with edge length d in an undercooled liquid metal. (b). Would you expect that (d*) to increase or decrease as the undercooling is increased ? (c). Would you expect that undercooling required for nucleation would increase or decrease if some nucleation catalysts were added to the liquid as it cools below its melting temperature? Solution: Cubic nucleus shown schematically as shown below: V = d3 7 Solidification of Metals & Alloys Course /MSc Course Assist. Prof. Dr. Alaa A. Atiyah ــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــ S= cube surface area = 6 d2 ΔG=d3Δgl-s+ 6 d2σl/s dΔG/dd = 3 d2 Δgl-s+ 12 dσl/s=0 3d2 Δg=-12dσl/s d*= -4 σl/s/ Δgl-s>0 when Δg>0 d Since Δgl-s increases as ΔT = Tm – T increases d* will decrease as T decreases. 2.1.2 The Homogeneous Nucleation Rate Let us consider how fast solid nuclei will appear in the liquid at a given under cooling. If the liquid contains Co atoms per unit volume, the number of clusters that have reached the critical size (C*) can be obtained from Equation 1.10 as: C* = Co exp (- ΔG*hom / KT) cluster m-3 The addition of one more atom to each of these clusters will convert them into -stable nuclei and, if this happens with a frequency fo, the homogeneous nucleation rate will be given by: N = fo Co exp (- ΔG*hom / KT) nuclei m-3 s-1 Where, fo, is a complex function that depends on; the vibration frequency of the atoms and the activation energy for diffusion in the liquid, and the surface area of the critical nuclei. Its exact nature is not important here and it is sufficient to consider it a constant equal to ~l011. * Since Co is typically ~1029 atoms rn-3a reasonable nucleation rate (1 cm-3 s-1) is obtained when AG*~ 78 kT. 8 Solidification of Metals & Alloys Course /MSc Course Assist. Prof. Dr. Alaa A. Atiyah ــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــ Figure (2.5): The variation of r*and rmax with under cooling ΔT. Nhom = fo Co exp (- A / (ΔT)2 Where A is relatively insensitive to temperature and is given by: A = 16 π γ3SLT2m / 3 L2v k T Nhom is plotted as a function of ΔT in Fig. 2.6. As a result of the (ΔT)* term, inside the exponential Nhom changes by orders of magnitude from essentially zero to very high values over a very narrow temperature range, i.e. there is effectively a critical under cooling for nucleation ΔTN. This is the same as ΔTN in Fig. 4.5, but Fig. 1.6 demonstrates more vividly how virtually no nuclei are I formed until ΔTN is reached after which there is an 'explosion' of nuclei. The small droplet experiments of Turnbull et al. ' have shown that ΔTN is I-0.2 T, for most metals (i.e. -200 K). The measured values of ΔTN have in fact been used along with Equation 2.13 to derive the values of interfacial1 free energy given in related references2. In practice homogeneous nucleation is rarely encountered in solidification. 9 Solidification of Metals & Alloys Course /MSc Course Assist. Prof. Dr. Alaa A. Atiyah ــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــ Figure (2.6): The homogeneous nucleation rate as a function of under cooling ΔT. ΔTN is the critical under cooling for homogeneous nucleation. Example 2.3 Calculate the critical radius r* and the activation free energy ΔG* for a body-centered cubic beta phase nucleus in a superheated alpha titanium matrix at 1165 K. Assume a spherical nucleus (homogeneous nucleation), ΔGv (1165 K) = -0.095 J/m3, and σsl = γ = 0.2 J/m2. Solution: NOTE: For the surface energy term, I changed σsl to γ in the following solution. For homogeneous nucleation of β-Ti in superheated β-Ti, r * = -2γ/ΔGV = -2(0.2 J/m2)/-0.095 J/m3 = 4.2 m ΔGhom* = (16π/3) (γ 3/ΔGV= (16π/3) (0.2 J/m2) 3/(-0.095 J/m3 ) 2=14.9 J Questions (2-2) 1. Answer by T or F for each question below: a. Nucleation becomes easier at higher temperatures because there is more thermal energy. b. Homogeneous nucleation requires a large amount of under-cooling. c. The Avrami equation describes the time dependence of the phase transformation process. d. The size of a critical nucleus gets larger as the temperature decreases. e. Nucleation becomes easier at lower temperatures because there is more undercooling. f. Nucleation theory only applies to solids forming from a liquid. g. The energy barrier for nucleation gets smaller as the temperature decreases. h. Heterogeneous nucleation is much less common than homogeneous nucleation. 10 Solidification of Metals & Alloys Course /MSc Course Assist. Prof. Dr. Alaa A. Atiyah ــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــ 2. 3. 4. 5. 6. i. A hypo-eutectic alloy is one with a composition to the right of the eutectic composition. j. Alloys generally melt over a range of temperatures, while pure metals melt at a single temperature. Calculate the size (radius) of the critically sized nucleus for pure platinum when the homogeneous nucleation takes place. Calculate the number of atoms in a critically sized nucleus for the homogeneous nucleation of pure platinum. Consider an alloy containing 70 wt% Ni and 30 wt% Cu. At 1350°C make a phase analysis assuming equilibrium conditions. In the phase analysis include the following: a. What phases are present? b. What is the chemical composition of each phase? c. What amount of each phase is present? d. Make a similar phase analysis at 1500°C. Define the following terms: a. Nucleation b. Embryo c. Heterogeneous nucleation d. Homogeneous nucleation e. inoculants Consider the nucleation of a spherical solid nucleus in a liquid and a temperature T1 < Tm. Write down the general analytical expression for the change in the Gibbs free energy of the system (DG) associated with the formation of this solid nucleus. Specifically define and explain each of the terms in this expression. Based on this expression DG, calculate the analytical expression for the critical radius, r*, of the solid nucleus as well as critical activation energy for nucleation DG*. 7. Consider the planar solidification of an elemental liquid (planar solid/liquid interface). If the solidification proceeds by conduction of the latent heat of fusion into the solid do you expect the planar interface to be stable or not? Explain your answer. Is a planar solid/liquid interface stable if solidification proceeds by heat conduction of into the supercooled liquid ahead of the growing solid? Explain your answer. Based on these two cases, explain under what condition you would expect dendritic solidification. 8. (Challenging question) In terms of the change in the Gibbs free energy of the system (DG) what is the basic difference between the nucleation of a solid spherical nucleus of radius (r) in a liquid versus the nucleation of a solid spherical nucleus of radius (r) of a b phase within a solid a matrix. If the driving force for nucleation (DGV) is the same in both cases and the interfacial energy (g) between the solid and the liquid is the same as that between the a and b phases, what do you expect the relative values of r* and DG* will be in the two cases described above. Explain your answer. 11 Assist. Prof. Dr. Alaa A. Atiyah Solidification of Metals & Alloys Course /MSc Course ــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــ 12 View publication stats