CARNEGIE MELLON UNIVERSITY

INDENTATION METHODS

FOR ADHESION MEASUREMENT IN THERMAL

BARRIER COATING SYSTEMS

A DISSERTATION

SUBMITTED TO THE CARNEGIE INSTITUTE OF TECHNOLOGY

IN PARTIAL FULFILLMENT OF THE REQUIREMENTS

for the degree of

DOCTOR OF PHILOSOPHY

in

MECHANICAL ENGINEERING

by

QIN MA

Pittsburgh, Pennsylvania

M ay 24, 2004

Reproduced with permission of the copyright owner. Further reproduction prohibited without permission.

UMI Number: 3126927

INFORMATION TO USERS

The quality of this reproduction is dependent upon the quality of the copy

submitted. Broken or indistinct print, colored or poor quality illustrations and

photographs, print bleed-through, substandard margins, and improper

alignment can adversely affect reproduction.

In the unlikely event that the author did not send a complete manuscript

and there are missing pages, these will be noted. Also, if unauthorized

copyright material had to be removed, a note will indicate the deletion.

UMI

UMI Microform 3126927

Copyright 2004 by ProQuest Information and Learning Company.

All rights reserved. This microform edition is protected against

unauthorized copying under Title 17, United States Code.

ProQuest Information and Learning Company

300 North Zeeb Road

P.O. Box 1346

Ann Arbor, Ml 48106-1346

Reproduced with permission of the copyright owner. Further reproduction prohibited without permission.

Carnegie Mellon University

C a r n e g i e In s t i t u t e

of

T echnology

THESIS

Submitted in Partial Fulfillment o f the Requirements

For the Degree o f Doctor o f Philosophy

TITLE

INDENTATION METHODS

FOR ADHESION MEASUREMENT IN

THERMAL BARRIER COATING SYSTEMS

P r esen ted B y

QIN MA

VA c c e p t e d

b y the

D epartm ent

of

M e c h a n ic a l E n g in e e r in g

^/■2.C / z o o ^

'

M a

A jTo

Or

R 1P r o f e s s o r

M

D ate

D epartm ent H ea d

D ate

A ppro ved

D ean

b y the

C o l l e g e C o u n c il

D ate

Reproduced with permission of the copyright owner. Further reproduction prohibited without permission.

ABSTRACT

This thesis investigates the fundamentals of indentation-induced delamination of

electron beam physical vapor deposition thermal barrier coatings (EB-PVD TBCs).

Thermal barrier coatings are thin ceramic coatings used to insulate gas turbine

components. In the as-proeessed state, TBCs are well-bonded to the metallic substrate

they are deposited upon. However, as these coatings are exposed to high temperatures

during turbine operation, they lose their adhesion. The goal of this thesis is to determine

how to use indentation testing techniques, coupled with fracture mechanics principles, to

track this loss of adhesion and to identify mechanisms causing it.

This thesis addresses four primary topics. First, a detailed fracture mechanics

analysis of indentation-induced delamination is made, including the quantification of

energy release rates, interfacial toughnesses and mode mix. The second topic addressed

is application of the indentation test to track toughness losses in TBC systems subjected

to a variety of thermal exposures. Three subtopics are included: 1) mechanism-based tests

for the isothermal dry air exposures; 2) mechanism-based tests for exposures with water

vapor and 3) meehanism-based tests for cyclic thermal exposures. In the first subtopic,

TGO thickening and TBC sintering are modeled. Various mechanisms that lead to

toughness degradation are discussed and analyzed quantitatively. An Arrhenius analysis

has been performed to understand accelerated testing methods. The second subtopic

presents the results of toughness degradation and the evolution of microstructures due to

isothermal exposure with water vapor. The third subtopic investigates the toughness

degradation for cyclic thermal exposures in dry air. Piezospectroscopy method has been

applied to track the evolution of residual stresses in the TGO layer with thermal cycles.

Quantitative analysis has been provided to give insights into the effects of oxide damage

during thermal cycling. The final two topics of this thesis relate to extensions of the

indentation test to make it applicable to a wider variety of TBC systems. These include

the use of different indenter shapes and the indentation of TBCs deposited onto curved

substrates.

Reproduced with permission of the copyright owner. Further reproduction prohibited without permission.

ACKNOWLEDGMENTS

This thesis could not have been completed without a great deal of assistance from

others. First and foremost, I would like to take this opportunity to thank my advisor, Prof.

Jack L. Beuth, for his invaluable input, guidance and support during my graduate study at

CMU and in the course of the eompletion of this thesis. I have benefited from many

discussions with him, from his strict academic attitude and his attempts to approach a

problem in more than one way, from his encouragement and academic direction, from his

expertise and mentoring, which have allowed me to reach this point in my academic

career.

I would also like to take this opportunity to thank the members of my thesis

committee. Prof. Paul S Steif, Prof. Philip R. LeDuc, Prof. Frederick S. Pettit, and Prof.

Gerald H. Meier for their invaluable input and mentoring, and for their comments and

criticism of this thesis.

I would also like to give my special appreciation to Matt Stiger (University of

Pittsburgh) for his help on starting the experimental work (including the SEM work), and

for his valuable suggestions during this research program.

My appreciation goes out to many of the staff in the Mechanical Engineering

Department for their assistance beyond the scope of their respective job duties. I would

like to give my thanks especially to Jim Dillinger and John Fulmer for their help in the

Mechanical Engineering Machine Shop, and for their consistently excellent and

expeditious work in machining my test samples; I thank Gary Novay and Rich Tourville

for their help on computing setups and networking problems. Michael Scampone, I thank

you for your help on purchasing and other matters relating to this research. Kate

McClintock, I thank you for proof reading a part of this thesis. I wish to thank Chris Zeise

for her advice and help with all the paper work.

I have also benefited from the friendship and resources of my colleagues. I would

like to thank Aditad (Tom) Vasinonta, Roy Flandoko and Raymond Ong for their warm

welcome to join their research group when I first arrived here, and for their help early on

in this research topic. I would like to thank Huang Tang, Pruk Aggarangsi, Andrew

Bimbaum, Steve Bianculli, and Nandhini Dhanaraj for their friendly support and for

111

Reproduced with permission of the copyright owner. Further reproduction prohibited without permission.

making my graduate experience more enjoyable. Thanks also go to N. Meltem Yanar,

Monica Maris-Sida and Kivilcim Onal (University of Pittsburgh) for their kind

collaboration during this research project, and their help on the oxidation and material

processing matters in the Department of Materials Science, University of Pittsburgh.

My appreciation also goes to Albert Stewart (Materials Science Department,

University of Pittsburgh) for his expert advice and assistance related to my work in the

SEM laboratory. And I would like to thank Tom Nuhfer for his training course and help

in the SEM laboratory, in the Material Science Department of Carnegie Mellon

University.

I would like also to take this opportunity to express my deep appreciation for all

the collaborators from the industrial institutes, national laboratories and universities

during this research project. I am grateful to GE Aircraft Engines and the Howmet

Corporation for providing the TBC specimens. I would like to thank Dr. Ken Wright and

Dr. Ram Darolia of the GE Aircraft Engines for their interactions in this research. Thank

you. Dr. Michael Lance of ORNL for performing the piezospectroscopic stress

measurements. My thanks to you Dr. William Ellingson of ANL for performing optical

backscatter experiments on the destructive vs. non-destructive TBC testing specimens.

My appreciation goes to Dr. Marion Bartsch and her co-workers, in the Institut fiir

Werkstoffforschung (Institute for Materials Research) of Deutsches Zentrum fiir Luftund Raumfahrt (German Aerospace Center), Linder Hohe, for their helpful information

regarding the thermal gradient mechanical fatigue (TGMF) tests and the indentation

images on their cylindrical EB-PVD TBC specimen. I wish to thank Dr. Christopher

Mercer, University of California at Santa Barbara, for providing the NiCoCrAlY burner

rig specimen to realize our delamination analysis on a curved substrate from the

experimental point of view.

I could have not reached this point in my academic career without the assistance

and support from my dear friends. Especially, I would like to express my deep

appreciation to Mrs. Eileen Lapree for providing us a home when we first arrived here,

for all her hospitality and family-like love, and for her unwavering support during all

these years of my studies in the United States of America. I would like to express my

Reproduced with permission of the copyright owner. Further reproduction prohibited without permission.

deep appreciation to Dr. Chengxian Lin and Jing Wu for their steadfast friendship, for

their recommendation and for supporting me in my plans to come to the US. I would like

to express my many thanks to Leora DeWitt, Pastor Wayne and Jean Johnson, Jean and

Albert Durica, Dr. Dominic Alfonso, Sinai Jun and Eric Flottman, Harold Pangbum,

Lauren and Robert Painter, Margaret and Max Davidson, and Ruby and Henry Davidson.

I wish to express all my heart felt appreciation and gratitude for their friendship and

support.

Last but not least I want to thank my family. I thank my parents, Zhengyang Ma

and Xiuhua Liu, and my parents-in-law, Yongqin Wu and Xuefen Yang, for their untiring

support in all o f my professional aspirations. I would like to thank my wife, Zheng Wu,

and my son, Matthew JunXiang M a for their loving support and sacrifice.

Reproduced with permission of the copyright owner. Further reproduction prohibited without permission.

CONTENTS

ABSTRACT.................................................................................................................................. ii

ACKNOW LEDGEM ENTS.....................................................................................................iii

C O N T EN T S................................................................................................................................ vi

NOM ENC LA TUR E................................................................................................................... x

LIST OF FIG U R ES..................................................................................................................xii

LIST OF TA BLES................................................................................................................... xxi

1. INTRODUCTION

1

1.1 Background........................................................................................................................ 1

1.2 Existing W ork................................................................................................................... 4

1.3 Motivation ........................................................................................................................9

1.4 Organization ..................................................................................................................10

2. FRACTURE ANALYSIS OF INDENTATION TESTS IN EB-PVD TBC

SYSTEMS

14

2.1 Chapter Overview ..........................................................................................................14

2.2 Energy Release Rate for Delamination o f an Annular Plate Subject to Equi-biaxial

Residual Stresses............................................................................................................. 16

2.3 Energy Release Rate for Delamination due to Indentation.......................................21

2.3.1 Delamination o f a Single L ayer..........................................................................22

2.3.2 Delamination o f a Composite P la te ................................................................... 23

2.4 Mechanics o f Interfacial Cracks....................................................................................32

2.5 Finite Element Modeling ............................................................................................. 35

2.5.1 Model Description and V alidation.................................................................... 35

2.5.2 Stress Intensity Factor K vs. R/a .......................................................................41

2.5.3 Mode Mixity v|/ vs. R/a .......................................................................................43

2.6 Chapter Summary ......................................................................................................... 46

3. APPLICATIONS OF CONICAL INDENTATION TESTS

47

3.1 Chapter Overview ........................................................................................................ 47

3.2 Effects o f Unloading on Indentation-Induced Stress Intensity F a c to rs.................. 49

vi

Reproduced with permission of the copyright owner. Further reproduction prohibited without permission.

3.2.1

Unloading on a Homogeneous S u b strate...................................................... 50

3.2.2

Unloading Effects for a PtAl/N5 TBC Specim en......................................... 53

3.3 Mechanism-Based Tests for Isothermal Dry Air E xposures....................................55

3.3.1 Introduction...........................................................................................................55

3.3.2 Toughness Loss vs. Isothermal Exposure Timein Dry A ir............................. 56

3.3.3 Measurements and Model o f Oxide Thickening..............................................58

3.3.4 Measurements and Model o f TBC Stiffness Modulus Due to Sintering .....64

3.3.5 Toughness Measurements from Indentation Including Changes in Oxide

Thickness and TBC Sintering ........................................................................... 69

3.3.6 Model o f TBC Duration and Arrhenius Plotfor Accelerated Tests................ 80

3.3.7 Concluding Remarks............................................................................................ 83

3.4 Mechanism-Based Tests for Exposures with Water Vapor .....................................84

3.4.1 Introduction...........................................................................................................84

3.4.2 Experimental Procedure...................................................................................... 85

3.4.3 Results and Discussion ....................................................................................... 89

3.4.3.1 Initial Tests on Steam-Exposed Specim ens......................................... 89

3.4.3.2 An In-Depth Study o f Toughness Degradation Including AsProcessed Toughness Values ................................................................ 92

3.4.3.3 Fracture Surfaces and Structure o f the Alumina S cale.....................102

3.4.4 Concluding R em ark s..........................................................................................106

3.5 Mechanism-Based Tests for Cyclic Thermal Exposures ....................................... 107

3.5.1 Introduction.........................................................................................................107

3.5.2 A Preliminary Investigation............................................................................... 108

3.5.2.1 Indentation Tests and Toughness M easurements.............................. 108

3.5.2.2 Toughness Degradation Compared to the Isothermal Dry Air

112

3.5.2.3 Fracture Surfaces and Structure o f the Alumina S cale.....................114

3.5.3 An In-depth Study by Integrating Improved Non-destructive M ethods...... 119

3.5.3.1 Toughness Measurements from Indentation Assuming No Changes

in the TBC S y ste m ................................................................................119

3.5.3.2 Optical Backscattering R esults............................................................ 123

Vll

Reproduced with permission of the copyright owner. Further reproduction prohibited without permission.

3.5.3.3 Toughness Measurements from Indentation Including Changes in

Oxide Thickness and Stress................................................................ 127

3.5.4 Concluding Remarks........................................................................................ 132

3.6 Chapter Sum m ary...................................................................................................... 133

4. INDENTER SHAPE EFFECTS ON THE DELAMINATION MECHANICS OF

INTERFACIAL FRACTURE

135

4.1 Chapter Overview ........................................................................................................135

4.2 Limitations o f the Existing Conical Indentation T est..............................................136

4.3 Constitutive Behavior and Finite Element M o d el................................................... 139

4.3.1 Constitutive B ehav io r........................................................................................ 139

4.3.2 Finite Element M o d e l........................................................................................ 146

4.4 Mechanics o f Conical Indentation............................................................................. 151

4.4.1 Loading Curves vs. Contact S iz e s ................................................................... 151

4.4.2 Surface Displacement P ro file s......................................................................... 161

4.4.3 Surface Strain Profiles ...................................................................................... 163

4.5 Mechanics o f Spherical Indentation.......................................................................... 168

4.5.1 Loading Curves vs. Contact Sizes.....................................................................168

4.5.2 Surface Displacement P ro file s......................................................................... 175

4.6 Interfacial Stress Intensity Factor Distribution due to Various Shapes o f Indenters

........................................................................................................................................ 179

4.6.1 K vs. R/a due to Conical Indentation............................................................... 179

4.6.2 K vs. R/a due to Spherical Im pression............................................................ 183

4.7 Effects o f Unloading for Various Indenter Shapes ................................................. 187

4.7.1 Effects o f Unloading for Various Conical Indentations.................................187

4.7.2 Effects o f Unloading for Spherical Indentations.............................................189

4.8 Quantification o f Interfacial T oughness....................................................................191

4.8.1 Results due to the Conical Indentation T e s ts ................................................. 191

4.8.2 Results due to the Spherical Indentation T e sts...............................................195

4.9 Chapter Summary ........................................................................................................197

Vlll

Reproduced with permission of the copyright owner. Further reproduction prohibited without permission.

5. CONTACT AND FRACTURE ANALYSIS OF DELAMINATION ON

CURVED SUBSTRATES

198

5.1 Chapter O v erv iew ........................................................................................................198

5.2 Indentation Mechanics on a Curved Substrate......................................................... 201

5.2.1 Geometrical Consideration............................................................................... 201

5.2.2 Dimensional Analysis for Surface Strains ..................................................... 207

5.2.3 Energy Release Rate ......................................................................................... 208

5.3 Finite Element Modeling .......................................................................................... 209

5.3.1 Model Description for Contact on 3-D Curved S u b strates..........................209

5.3.2 Model Verification for Contact on a 3-D Flat Substrate .............................214

5.3.3 Model Verification for Contact on 3-D Hollow Cylinders...........................217

5.4 Numerical Results and Discussion ........................................................................... 221

5.4.1 Indentation Results on Hollow Cylinders without Roller Constraints

221

5.4.2 Indentation Results on Hollow Cylinders with Roller Constraints............. 230

5.4.3 Indentation Results on a Solid C ylinder......................................................... 243

5.5 Guidelines for Indentation Tests on Curved Substrates ........................................ 249

5.5.1 Onset Buckling and Valid Indentation Load Range.......................................249

5.5.2 Effects o f Unloading on the Toughness M easurem ent................................. 256

5.6 Toughness o f a Typical EB-PVD TBC Fabricated on a Curved Substrate ........ 258

5.6.1 Specimen A n aly sis............................................................................................ 258

5.6.2 Indentation Tests ...............................................................................................262

5.6.3 Critical Energy Release Rate and Interfacial Fracture T o u g h n ess............. 266

5.7 Chapter Summery ....................................................................................................... 268

6. CONCLUSIONS

270

6.1 Contributions o f This T h e sis......................................................................................270

6.2 Recommendations for Future W o rk ..........................................................................273

REFERENCES

275

APPENDIX

285

IX

Reproduced with permission of the copyright owner. Further reproduction prohibited without permission.

NOMENCLATURE

a, ac

Ideal and actual contact radius in the 2-D analysis

az, ae

Ideal contact radius in the axial and circumferential directions

A

Area

b, bo

Half width, critical half width

E

Young’s modulus

Ea, Q

Activation Energy

Eeff

Effective Young’s modulus

H, H bc, H s

Hardness

K, K u/l

Stress intensity factor

Kc, Gc

Interfacial fracture toughness; critical energy release rate

kp , Ks

Parabolic rate constant

G

Energy release rate

Ic

Transformed moment of inertia per unit width

r

Conical indenter tip round radius

R, Reff

Debond radius, effective debond radius

Re, Rz

Debond radius in the circumferential and axial directions

Rb

Ball radius

M

Net moment per unit width

N

Hardening exponent

Pm

Mean pressure

P

Load

t

Thickness

T , Tq

Temperature

Ur, ue.

Displacement

U

Elastic strain energy; radial surface displacement

U’^

Elastic unloading displacement

Vf

Columnar volume density

Reproduced with permission of the copyright owner. Further reproduction prohibited without permission.

a

Hardening parameter; Dundurs’ parameter

P

Inclination of the cone surface; Dundurs’ parameter

5

Penetration depth; relative crack face displacements

8

Strain; bi-material mismatch parameter

£' 8*

Indentation induced strain

Effective residual strain

£rr, £ee

Strain

V

Poisson Ratio

p

Shear modulus; friction coefficient

Gyy, Qxy

Stress components

( 7 o , <7 t b c , ( 7 t g o

Residual stress

o

Effective residual stress

Oy, CTys, CTybc

Yield stress

P i, p o

Inner radius and outer radius of the cylindrical specimen

T

Time

\(/

Phase angle

Reproduced with permission of the copyright owner. Further reproduction prohibited without permission.

LIST OF FIGURES

Figure 1.1: A Standard TBC Button Specimen and Cross Section Schematic

of the

Individual L ayers................................................................................................... 2

Figure 1.2: Schematic Diagram of the Indentation Test for TBC S y stem s..........................5

Figure 2.1: Delamination of an Annular Plate Driven by Equi-biaxial Residual Stresses

................................................................................................................................... 17

Figure 2.2: Energy Release Rate Formulation due to the Combination of Residual Stress

and Indentation Induced S tress.............................................................................26

Figure 2.3: U/a vs. R/a due to a Standard Conical Indentation with Major Load Levels

................................................................................................................................ 30

Figure 2.4: Energy Release Rate vs. TGO Thickness for Bending Contribution due to

Different Form ulations....................................................................................... 31

Figure 2.5: Interface Crack between Two Isotropic M e d ia .......................................... 32

Figure 2.6: Finite Element Model Used for the Combined Indentation and Fracture

A nalysis................................................................................................................ 40

Figure 2.7: Result Comparison for K vs. R/a due to the Formulation with Contact

Analysis and the Fracture and Contact Model with Rj/R=0.9 under Asprocessed Properties in the EB-PVD TBC system s..........................................42

Figure 2.8: Phase A n g l e , v s . R/a Using As-processed Properties with Two Oxide

Thickness Obtained From Numerical Solutions...............................................45

Figure 3.1: A Sectioned SEM Micrograph of an As-Processed EB-PVD TBC System...49

Figure 3.2.1: K l/u vs. R/a due to a Standard Conical Indentation on a Homogeneous

Substrate Including Unloading Effects............................................................... 52

Figure 3.2.2: K l/u vs. R/a due to a Standard Conical Indentation with Major Load Levels

Including Unloading Effects.................................................................. ............54

Figure 3.3.1: Apparent Toughness as a Function of Exposure Time for TBC Systems at

Various Temperatures..............................................................................

57

Figure 3.3.2: Least Square Correlation of TGO Thickness (pm) vs. Square Root of

Exposure Time (s)......................................................................................

Reproduced with permission of the copyright owner. Further reproduction prohibited without permission.

...60

Figure 3.3.3 Oxide Thickness vs. Exposure Time between the Measurement and Model

Prediction.................................................................................................................63

Figure 3.3.4: Young’s Modulus of EBPVD TBC vs. Thermal Exposure Time (hr) based

on Thermally Activated Mechanisms Considering As-Processed E to be

44GPa and 175GPa in Fully Densed C ondition................................................ 66

Figure 3.3.5: Toughness Loss vs. Isothermal Exposure Time at 1100 °C Assuming No

Changes Both in the Alumina Layer and in the TBC Layer (same results as in

Figure 3.3.1) and Taking Into Account Measured Alumina Layer Thickening

.................................................................................................................................. 71

Figure 3.3.6: Toughness Loss vs. Isothermal Exposure Time at 1100 °C Assuming No

Changes Both in the Alumina Layer and in the TBC Layer (same results as in

Figure 3.3.1) and Taking Into Account the TBC Sintering Properties

72

Figure 3.3.7: Toughness Loss vs. Isothermal Exposure Time at 1100 °C Assuming No

Changes Both in the Alumina Layer and in the TBC Layer (same results as in

Figure 3.3.1) and Taking Into Account the Changes Both in Oxide

Thickening and TBC Sintering............................................................................73

Figure 3.3.8: Toughness Loss vs. Isothermal Exposure Time at 1200 °C Assuming No

Changes Both in the Alumina Layer and in the TBC Layer (same results as in

Figure 3.3.1) and Taking Into Account Measured Alumina Layer Thickening

.................................................................................................................................. 77

Figure 3.3.9: Toughness Loss vs. Isothermal Exposure Time at 1200 °C Assuming No

Changes Both in the Alumina Layer and in the TBC Layer (same results as in

Figure 3.3.1) and Taking Into Account the TBC Sintering Properties

78

Figure 3.3.10: Toughness Loss vs. Isothermal Exposure Time at 1200 °C Assuming No

Changes Both in the Alumina Layer and in the TBC Layer (same results as in

Figure 3.3.1) and Taking Into Account the Changes Both in Oxide

Thickening and TBC S intering............................................................................79

Figure 3.3.11: Arhennius Plot of Toughness D egradation.................................................. 82

Reproduced with permission of the copyright owner. Further reproduction prohibited without permission.

Figure 3.4.1; A Typical SEM Charging Image of the Debonded TBC After Indentation

using a Major Load of 100 kg (Steam Pressure O.IO atm with 120 hrs

Isothermal Exposure)..............................................................................................86

Figure 3.4.2: UHDR Method for Determination of Debonding Radii; Unaxisymmetric

with Undebonded Gaps Observed in 5D Specimen (a) and 4B Specimen (b)

at I50Kg Indentation Load Under As-Processed Conditions........................... 88

Figure 3.4.3: Apparent Toughness vs. Exposure Time for TBC Systems in Dry Air and

the First Specimen at IIOO°C with O.IO atm. Vapor Pressure of Steam

(Dashed L in e ).........................................................................................................91

Figure 3.4.4: Indentation Test Locations on Specimen 5D: O.IO atm Vapor Isotherm ....97

Figure 3.4.5: 4B Specimen Surface at Different Exposure History Before and at its Final

Failure due to Indentation and Thermal Exposure Events................................ 98

Figure 3.4.6:

Toughness Loss vs. Exposure Time for Specimens with Measured As-

Processed Toughnesses....................................................................................... lOI

Figure 3.4.7:

SEM Photographs for Fracture Surfaces of Specimen 7C, Exposed

Isothermally at I IOO°C with 0.30atm W ater Vapor.........................................102

Figure 3.4.8: SEM Images of Fracture Surfaces for Two Different Exposure Conditions

After 120 hrs at I I 0 0 ° C ......................................................................................103

Figure 3.4.9:

Sectioned Views of TBC and Oxide Scale Morphology under Different

Exposure C onditions........................................................................................... 104

Figure 3.4.10: Oxide Thickness vs. Time IIOO°C under Different Isothermal Exposures

.......................................................................................................................

105

Figure 3.5.1: 4A Specimen Surface at Different Exposure History Before and at its Final

Failure due to Indentation and Thermal Exposure Events.....................

Figure 3.5.2:

112

Toughness Loss vs. Exposure Time for Specimens with Measured As

Processed Toughnesses for Cyclic and Isothermal Dry A ir ........................... 113

Figure 3.5.3: SEM Photographs for Fracture Surfaces of Specimen 4A and 7C under

Different Exposure Conditions after Experiencing the Same Equivalent

Isothermal Exposure Time of I20hrs....................................................

XIV

Reproduced with permission of the copyright owner. Further reproduction prohibited without permission.

114

Figure 3.5.4: SEM Photographs for Fracture Surface of Specimen 4A and 4B at 350hrs

................................................................................................................................ 115

Figure 3.5.5: Fracture Surface Analysis as a Function of Exposure Time for Different

S pecim ens............................................................................................................. 116

Figure 3.5.6: Sectioned Views of TBC and Oxide Scale Morphology in Failed Specimens

118

Figure 3.5.7: Plot of TBC Interfacial Toughness vs. Exposure Time for Specimens #2

and # 3 ...................................................................................................................... 122

Figure 3.5.8: Composite Figure Showing Micrograph, Backscatter and SEM Charging

Images after 170 Cycles. Center Indent was Performed before any Thermal

Exposure, Left Indent was after 50 Cycles and the Right Indent was after 170

Cycles..................................................................................................................... 123

Figure 3.5.9: Backscatter (a and b) and SEM Charging (e) Images of TBC Indent after

270 Cycles. Backscatter (a) is Constructed by Establishing the Ratio of the

Signals from the Two Detectors and (b) by Summing the Output of Both

Detector S ig n als...................................................................................................124

Figure 3.5.10: Toughness Loss vs. Number of Cycles Assuming No Changes in the

Alumina Layer (Same Results as in Figure 3.5.7) and Taking Into Account

Measured

Alumina

Layer

Thickening

and

Reductions

in

............................................................................................................................

Stress

130

Figure 3.5.11: Toughness Loss vs. Number of Cycles Assuming Debonding of the

Alumina and TBC (Same Results as in Figure 3.5.7) and Debonding of the

TBC o n ly ...............................................................................................................131

Figure 4.1:

Illustration of Problems Observed in Previous Indentation Tests of the

EBPVD T B C s ...........................................................................................

138

Figure 4.2: Tensile Stress vs. Strain Behavior for Mar-M200 in the [100] Direction Used

in Vasinonta and Beuth (2001) and the Modified Ramberg-Osgood Relation

by Setting N=2 and 0^=14.................................................................................... 144

Reproduced with permission of the copyright owner. Further reproduction prohibited without permission.

Figure 4.3: Tensile Stress vs. Strain Behavior for Polycrystalline NiAl Used in Vasinonta

and Beuth (2001) and the Modified Ramberg-Osgood Relation by Setting

N=2.87 and a=1.7

145

Figure 4.4: Schematic of the Indentation Models (a) by a Rigid Conical Indenter; (b) by a

Rigid Spherical Indenter..................................................................................... 150

Figure 4.5: Indent Load vs. Contact Radius Compared with the Analytical Predictions

due to a Standard Conical Indentation, Illustrating the Role of Hardening

Behavior on the Effects of load vs. contact radius a ..................................... 154

Figure 4.6: Indent Load vs. Contact Radius Compared with the Analytical Predictions

due to a 90° Conical Indentation, Illustrating the Role of Hardening Behavior

on the Effects of load vs. contact radius a ........................................................ 155

Figure 4.7: P vs. a due to Various Conical Indentation Geometries Considering Typical

EB-PVD TBC Properties....................................................................................159

Figure 4.8: P vs. 5 due to Various Conical Indentation Geometries Considering Typical

EB-PVD TBC Properties...............................................................

160

Figure 4.9: U/a vs. R/a due to Various Conical Indentation Geometries Considering

Typical EB-PVD TBC Properties.......................................................................162

Figure 4.10: Axial Compressive Strain vs. R/a as a Function of Conical Indenter

Geometry Compared with the Analytical Solution for a Single Material

(Substrate Properties o n ly )................................................................................. 166

Figure 4.11: Circumferential Strain vs. R/a as a Function of Conical Indenter Geometry

Compared with the Analytical Solution for a Single Material (Substrate

Properties o n ly ).................................................................................................... 167

Figure 4.12: H vs. a/Rb due to the Spherical Indentation of Various Diameters on a

Typical EB-PVD TBC System without TBC on T o p ..................................... 173

Figure 4.13: P/trdRb vs. 5/Rb due to the Spherical Indentation of Various Diameters on a

Typical EB-PVD TBC System without TBC on t o p .............................

174

Figure 4.14: U/a vs. R/a as a Function of a/Rb for the Spherical Indentation on a Large

Single Material (nickel based superalloy properties) to Illustrate its Size or

Load Dependence (3 sizes of ball used: 0.79mm, 1.59mm and 3.18mmin

XV I

Reproduced with permission of the copyright owner. Further reproduction prohibited without permission.

diameter and U/a vs. R/a overlaps at the same a/Rb of different size ball)

................................................................................................................................. 177

Figure 4.15: U/a vs. R/a as a Function of a/Rb for the Spherical Indentation on a Standard

EB-PVD TBC System without Bondcoat on Top (3 sizes of ball used:

0.79mm, 1.59mm and 3.18mm in diameter at the same load level of 150Kg)

.................................................................................................................

178

Figure 4.16: K vs. R/a for Different Shapes of Conical Indenters Based on the Indentation

Simulation on a Standard EB-PVD TBC system ............................................ 181

Figure 4.17: K vs. R/5 for Different Shapes of Conical Indenters Based on the Indentation

Simulation on a Standard EB-PVD TBC system ............................................ 182

Figure 4.18: K vs. R/a for a Spherical Indentation on a Standard EB-PVD TBC System(3

sizes of ball used: 0.79mm, 1.59mm and 3.18mm in diameter at the same

load level of 150K g)............................................................................................185

Figure 4.19: K vs. R/6 for a Spherical Indentation on a Standard EB-PVD TBC System (3

sizes of ball used: 0.79mm, 1.59mm and 3.18mm in diameter at the same

load level of 150K g)............................................................................................186

Figure 4.20: K vs. R/a for Different Shapes of Conieal Indenters Ineluding Unloading

E ffe ets...................................................................................................................188

Figure 4.21: K vs. R/a for Spherical Indentations Including Unloading Effects at the Same

Load Level of 150 k g ..........................................................................................190

Figure 4.22: Debonding Behavior Upon the Same Indentation Depth of 0.1mm Caused

by Different Shapes of Indenters. Debonding Size and Pattern Are Seen

Differently for Different Cones at the Same Penetration D e p th ....................192

Figure 4.23: Debonding Behavior Upon the Same Indentation Load of 150KgDebonding

Size and Pattern Are Seen Differently for Different Cones at the Same Indent

Load L e v e l..................................................................................................

194

Figure 4.24: Backseattered SEM Photographs to Illustrate the Debonding Behavior for

Different Spherieal Indenters at the Load Level of 150K g............................ 196

Figure 4.25: Debonding Behavior Upon upon a 1.588mm Diameter Spherical Rigid

Indenter at the Load Level of 150Kg............................................................ ....196

X V ll

Reproduced with permission of the copyright owner. Further reproduction prohibited without permission.

Figure 5.1: Delamination Pattern of TBC Coating on a Cylindrical Specimen with Outer

Diameter = 14.7mm, Inner Diameter = 6mm, NiCoCrAlY Bond Coat

Thickness = llO pm , and EB-PVD TBC Thickness = 220pm.

Indentation

Performed with a Rockwell Hardness Tester by a Standard Brale C Diamond

Conical Indenter (Bartsch, et.al, 2 0 0 2 )............................................................ 199

Figure 5.2: Schematic of Indentation on a 3-D Curved Substrate...................................... 203

Figure 5.3: Schematics of Indentation Geometry on Determination of Contact Radius

in the Axial Direction

and Circumferential Direction a e ...........................204

Figure 5.4: Curvature Effect of Contact Radii ae Compared with

at the Same

Penetration D e p th ................................................................................................ 206

Figure 5.5: A Simplified 3-D FEA Contact Model of a Hollow Cylindrical Specimen .212

Figure 5.6: FEA Contact Analysis of a Sharp 90° Conical Indentation on the UCSB

Specimen with Bondcoat/Substrate S y stem .....................................................213

Figure 5.7: Contact on a 3-D Flat Substrate with Results Compared to the 2-D Standard

Analysis to Show the Validation of 3-D Mesh R esolution....................

215

Figure 5.8: Compressive Strain vs. RJa^ for a Standard Conical Indentation on a Flat

Substrate with Comparison to Standard 2-D Results..............................

216

Figure 5.9: Compressive Strain vs. R/a for a Standard Conical Indenter Contact on

Hollow Cylindrical Substrates with Roller Constraints at Inner Surfaces and

at the Same ae/po in the Circumferential Direction and the Same az/po in the

Axial D irection............................................................................................

219

Figure 5.10: Tensile Strain vs. R/a for a Standard Conical Indenter Contact on Hollow

Cylindrical Substrates with Roller Constraints at Inner Surfaces and at the

Same ae/po in the Circumferential Direction and the Same az/po in the Axial

Direction.......................................................................................................................220

Figure 5.11: Compressive Strain vs. R/a for a Standard Conical Indenter Contact on a

Hollow

Cylinder

(po=5.11mm,

Pi=3.00mm)

Traction-free

at

Inner

Surface................................................................................................................ 223

xvm

Reproduced with permission of the copyright owner. Further reproduction prohibited without permission.

Figure 5.12: K vs. R/a for a Standard Conical Indenter Contact on a Hollow Cylinder

(po=5.11mm, pi=3.00mm) in the As-processed Condition and Traction- free

at the Inner Surface..........................................................................................

224

Figure 5.13: Compressive Strain vs. R/a for a Standard Conical Indenter Contact on a

Hollow Cylinder (po=3.08mm, Pi=0.97mm), Traction-free at the Inner

S urface................................................................................................................ 226

Figure 5.14: K vs. R/a for Contact on the Small Cylinder at the As-processed Condition

for a Standard Conical Indenter Contact on a Hollow Cylinder (po=3.08mm,

Pi=0.97mm), Traction-free at the Inner Surface..........................................

227

Figure 5.15: Indentation Load as a Function of Contact Size for a Standard Conical

Indenter Contact on a Hollow Cylinder (po=5.IImm, Pi=3.00mm), with

Roller Constraints at the Inner S u rface............................................................ 233

Figure 5.16: Compressive Strain vs. R/a for a Standard Conical Indenter Contact on a

Hollow Cylinder (po=5.IImm, Pi=3.00mm), with Roller Constraints at the

Inner Surface......................................................................................................... 234

Figure 5.17: Tensile Strain vs. R/a for a Standard Conical Indenter Contact on a Hollow

Cylinder (po=5.IImm, Pi=3.00mm), with Roller Constraints at the Inner

S urface.................................................................................................................. 235

Figure 5.18: K vs. R/a for a Standard Conical Indenter Contact on a Hollow Cylinder

(po=5.IImm, Pi=3.00mm) At the As-processed Condition with Roller

Constraints at the Inner Surface........................................................................ 236

Figure 5.19: Indentation Load as a Function of Contact Size for a Standard Conical

Indenter Contact on a Hollow Cylinder (po=3.08mm, pi=0.97mm), with

Roller Constraints at the Inner Surface..............................................................239

Figure 5.20: Compressive Strain vs. R/a for a Standard Conical Indenter Contact on a

Hollow Cylinder (po=3.08mm, Pi=0.97mm), with Roller Constraints at the

Inner Surface.................................................................................................

240

Figure 5.21: Tensile Strain vs. R/a for a Standard Conical Indenter Contact on a Hollow

Cylinder (po=3.08mm, pi=0.97mm), with Roller Constraints at the Inner

Surface................................................................................................................ 241

XIX

Reproduced with permission of the copyright owner. Further reproduction prohibited without permission.

Figure 5.22: K vs. R/a for a Standard Conical Indenter Contact on a Hollow Cylinder

(po=3.08mm, Pi=0.97mm), with Roller Constraints at the Inner Surface

.............................................................................................................................. 242

Figure 5.23: Indentation Load as a Function of Contact Size for a 90° Conical Indenter

Contact on a Solid Cylinder (po=5.50mm) (UCSB Specim en)..................... 245

Figure 5.24: Compressive Strain vs. R/a for UCSB Specimen for a 90° Conical Indenter

Contact on a Solid Cylinder (po=5.50mm)...................................................... 246

Figure 5.25; Tensile Strain vs. R/a for UCSB Specimen for a 90° Conical Indenter

Contact on a Solid Cylinder (po=5.50mm)...................................................... 247

Figure 5.26: K vs. R/a for UCSB Specimen at the As-processed Condition for a 90,o

Conical Indenter Contact on a Solid Cylinder (po=5.50mm)........................ 248

Figure 5.27: Convention for Delamination in the Circumferential Direetion...................251

Figure 5.28: Critical Half-width for Buckle-driven as a Function of TGO thickness

................................................................................................................................ 252

Figure 5.29: K vs. R/a for the 90° and 120° Conical Indentation on a Flat EB-PVD TBC

System with 110pm Bondcoat Thickness Including Unloading Effects

257

Figure 5.30: TBC Specimen from UCSB, for Interfacial Toughness Measurement

260

Figure 5.31: Typical TGO Morphology and TBC Thickness M easurem ent....................260

Figure 5.32: Typical TGO Morphology and Bondcoat Thickness M easurem ent............261

Figure 5.33: Typical TGO Thickness M easurem ent........................................................... 261

Figure 5.34: Typical SEM Images for Delamination Patterns and Contact Regions due to

the Indentation at Three Standard Load Levels, Available from a Rockwell

Hardness Tester.................................................................................................... 263

Figure 5.35: SEM Images Reveal Cracking Interface is at or Near to the Interface of TBC

and TGO................................................................................................................ 265

Reproduced with permission of the copyright owner. Further reproduction prohibited without permission.

LIST OF TABLES

Table 3.3.1: TBC Sintering and TGO Thickening as a Function of Exposure Time and

Tem perature............................................................................................................68

Table 3.3.2: Properties of Each Layer in an EB-PVD TBC System Under As-processed

C onditions...............................................................................................................68

Table 3.4.1:

Summary of Measured Data and Kc Values from Indentation Tests

Performed on a TBC Specimen Exposed at 1100°C, with Vapor Pressure =

O .la tm ..........................

90

Table 3.4.2: Specimen Exposure Conditions and T im e s.................................................... 92

Table 3.4.3: Results for the As-Processed Interfacial Toughnesses................................... 94

Table3.4.4:

Summary of Measured Data and Kc Values from Indentation Tests

Performed on 5D TBC Specimen Exposed at 1100°C, with Vapor Pressure =

O.latm and 1C TBC Specimen Exposed at 1100°C, with Vapor Pressure =

0 .3 a tm ......................................................................................................................96

Table 3.4.5: Summary of Measured Data and Kc Values from Indentation Test Performed

on 4B TBC Specimen Exposed at 1100°C under Dry Air Isothermal

conditions...............................................................................................................99

Table 3.5.1: Summary of Measured Data and Kc Values from Indentation Tests

Performed on 4A TBC Specimen Exposed at I100°C under I hr Cyclic Dry

A ir .......................................................................................................................... I l l

Table 3.5.2: First Round Tests of TBC Specim ens..............................................................120

Table 3.5.3: SEM Charging vs. Optical Backscattering Measurements of Debond Size

after 170 Cycles (Specimen # 3 ) ....................................................................... 126

Table 3.5.4: SEM Charging vs. Optical Backscattering Measurements of Debond Size

after 270 Cycles (Specimen # 3 ) ....................................................................... 126

Table 4.1: Conelated Coefficients for Eqn. (4.7) due to Different Conical Indenters ....162

Table 4.2: Measurements of Interfacial Toughness due to the 90 Degree Conical

Indentation and Comparison with the Results of the Standard Conical

Indentation......................................................................................................... 192

Reproduced with permission of the copyright owner. Further reproduction prohibited without permission.

Table 4.3: Measurements of Interfacial Toughness due to the 150 Degree Conical

Indentation and Comparison with the Result of the Standard Conical

Indentation.......................................................................................................... 194

Table 4.4: Summary of the Measurements of Interfacial Toughness due to Various Shapes

of Indenters at the Indent Load Level of ISOKg..............................................196

Table 5. T. Cases Considered in the FEA Sim ulations..................................................... 211

Table 5.2: Indentation Depth as a Function of Cone Type and Bondcoat Thickness at the

Loads of 60Kg, lOOKg and I5 0 K g ................................................................... 255

Table 5.3: Half-width Determination at a Certain Toughness Level with bo=2.58mm by a

Standard Conical Indentation...............................................................................255

Table 5.4: Characterization of the UCSB Solid Cylindrical Specim en............................ 259

Table 5.5: Contact Radius due to 90 Degree Cone at Various Load L e v e ls.................... 265

Table 5.6; Effective Delamination Sizes from the Tests on the UCSB Specimen

267

Table 5.7: Kc and Go at the Final Unloading State for the UCSB Specimen................... 267

xxn

Reproduced with permission of the copyright owner. Further reproduction prohibited without permission.

Chapter 1. Introduction

CHAPTER 1.

NTRODUCTION

1.1 Background

Ceramic thermal barrier coatings (TBCs) have been used to increase the creep

resistance of gas turbine components for more than two decades. Although their first uses

were primarily for thermal protection of combustor and after burner components in

aircraft engine applications, TBCs are now used to insulate rotating components such as

blades and vanes.

They are also being used in land-based turbines used for power

generation. As compared to new alloy development, the use of TBCs can be a low-cost

approach for allowing increases in turbine operating temperatures and turbine efficiency.

As the applications of TBCs increase, designers want to fully exploit them in

turbine designs. However, because of problems with the durability of TBCs, they cannot

be relied upon to provide thermal protection for the life of a turbine or until scheduled

turbine rebuilds.

Initially, in the as-deposited state, TBCs are well-bonded to the

superalloy component upon which they are deposited. As the coating system is exposed

to operating temperatures, however, its adherence degrades. Poor adhesion can lead to

the spontaneous debonding or spallation of the coating, which is driven by compressive

residual stresses. In addition, in actual gas turbine environments, small-scale impacts of

moving components by particles ingested into the gas turbine (termed foreign object

damage) can help initiate and drive coating debonds.

Improving the life of thermal barrier coatings is a key goal of gas turbine design

and it requires an in-depth understanding of the mechanisms leading to loss of TBC

adhesion leading to spallation failures. The ultimate goal of this research is to help to

quantify the contribution of various mechanisms leading to TBC adhesion loss under

simulative environmental exposures. That goal will be achieved through the analysis and

implementation of indentation tests for tracking fracture toughness losses in exposed

TBC systems.

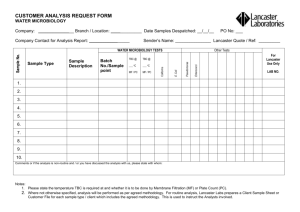

Figure I.l shows a TBC "button" specimen, which is the standard specimen

geometry used in the gas turbine industry. The button specimen is 25.4 mm in diameter,

with a thickness of 3.18 mm. The two principal methods of depositing thermal barrier

Reproduced with permission of the copyright owner. Further reproduction prohibited without permission.

Chapter 1. Introduction

coatings are plasma spray and electron beam physical vapor deposition (EBPVD).

Though the work of this thesis may be applicable to plasma sprayed TBC systems, this

thesis will focus on EBPVD TBC systems. Furthermore, two types of bond coats are

commonly used in TBC systems: platinum aluminide (PtAl) alloys and nickel-cobaltchromium-aluminum-yttrium (NiCoCrAlY) alloys. This thesis will address PtAl bond

coat systems directly. The EBPVD specimens considered in this study were provided by

the General Electric (GE) and Howmet Corporations, and were fabricated using identical

processing standards.

25.4 mm3.18 mm

100 |j.m

0.25-5 jL im

50 ) L im

TBC

i'CK.)

_

Figure l.I: A Standard TBC Button Specimen and Cross Section Schematic

of the Individual Layers.

Figure 1.1 also gives a schematic of the cross section of this type of multi-layered

EBPVD TBC system.

It consists of an N5 single crystal nickel-based superalloy

substrate, a platinum-aluminide bond coat which is applied by chemical vapor deposition

(CVD) with a thickness of approximately 50 |im, a thermally grown oxide (TGO), and

the TBC itself. The TGO is an alumina layer, which is grown on the bond coat before

TBC deposition, to a thickness of approximately 0.25 |im. During exposure the TGO

continues to grow and can become as thick as 4 - 5

|U.m

or more before spallation occurs.

Reproduced with permission of the copyright owner. Further reproduction prohibited without permission.

Chapter 1. Introduction

The TBC itself is yttria stabilized zirconia (YSZ) with a thickness of approximately 100

|im.

The TBC has a columnar microstructure aligned in the vertical direction.

This

structure is not fully dense, which results in a net in-plane stiffness that is a fraction of

that for fully dense zirconia.

During TBC spallation, fracture typically occurs at or near the interface between

the oxide and bond coat layers, although in some cases the fracture path can include the

TBC/oxide interface or even be entirely within the TBC, near the TBC/oxide interface.

From a mechanics standpoint, a number of factors can lead to decreases in the spallation

resistance of a TBC system. First, as the TBC system is exposed at a high temperature

(1000°C is a typical operating temperature), the thickening of the alumina scale increases

the strain energy stored in the system.

Because the oxide scale is highly stressed

(compressive stresses of 3-4 GPa are typical) this can significantly increase the energy

available to drive a debond of the alumina scale and the TBC above it. The ceramic TBC

is also in a state of compression at room temperature (compressive stresses of 10-50 MPa

are typical). Also, as the TBC is exposed to high temperatures it can sinter and densify.

The result is an increase in the effective elastic modulus of the TBC and an increase in the

magnitude of the TBC compressive stress at room temperature. As is true for oxide scale

growth, TBC sintering can significantly increase the energy available to drive a debond

crack.

The two mechanisms for toughness degradation described above can occur

independent of a “true” loss of adhesion or interfacial toughness in the TBC system. A

true reduction in interfacial toughness can be caused by chemical or mechanical damage

near the interface and these are the two final mechanisms which can lead to reductions in

TBC spallation resistance.

Chemical damage can occur due to segregation to the

interface region of elements that weaken or embrittle the interface. For example, if the

sulfur content is not controlled in the bond coat or superalloy, sulfur can segregate to the

interface and weaken it. The same phenomenon can occur if anything other than low

sulfur fuel is used in the gas turbine. Although it can occur during a single thermal cycle,

mechanical damage at the interface is typically seen for cyclic thermal exposures. As a

result of multiple thermal cycles, micro-scale cracking damage can occur in the region

Reproduced with permission of the copyright owner. Further reproduction prohibited without permission.

Chapter 1. Introduction

near the thermally grown oxide, weakening that part of the TBC system.

The

development of this type of damage can be made more prominent by a “ratcheting”

phenomenon (Evans et. al, 2001) where compressive stresses in the oxide scale at high

temperatures cause it to buckle even while it remains bonded to the bond coat alloy

(which has very low creep resistance at high temperatures).

This change in oxide

geometry can lead to substantial crack formation in and near the oxide scale.

Which mechanism dominates the TBC system failure is strongly dependent on the

type of TBC system (e.g. EBPVD vs. plasma spray), the materials used in the system (e.g.

the bond coat alloy used) as well as environmental factors, such as combustion gas

temperature, water vapor content and the presence of small, hard particle impacts. The

goal of this thesis is to use fracture mechanics tests and analyses coupled with insights

from materials science collaborators to help identify dominant mechanisms leading to

failure for an industry-standard TBC system and common exposure conditions. In this

way, we hope to guide TBC system developers, suggesting on what aspects of the TBC

system design they should focus their efforts.

By developing a testing method and

applying it to a key TBC system used in industry, it is also hoped to motivate the

development of similar testing methods for other TBC systems in use and under

development, and in other brittle coating/ductile substrate coating systems.

1.2 Existing Work

1.2.1

Existing Work Involving Indentation to Measure Interfacial Toughness

The mechanics framework for the quantification of the interfacial fracture

toughness for brittle coatings on relatively ductile substrates due to indentation by a

diamond brale “C” conical indenter was established by Drory and Hutchinson (1995).

Their work includes an extensive review of indentation-based interfacial adhesion

measurement techniques and concludes with application of their indentation test to a

diamond-coated titanium alloy.

Their work assumes: (I) the thickness of the film

deposited on the substrate is very small compared to the characteristic size of the

indentation field such that it deforms with the substrate and does not influence the

substrate deformation induced by the indentation, (2) the film is in a state of bi-axial

Reproduced with permission of the copyright owner. Further reproduction prohibited without permission.

Chapter 1. Introduction

compressive stress and (3) linear elastie fracture occurs under mode II conditions. Based

on these assumptions, two formulas for the energy release rate of the debonding coating

are derived, applicable to two types of coating behavior behind the crack front.

Debonding TBC

and TGO Layers

Indenter

Bond Coat

Compressive

Stress a

'Superalloy Substrate

Plastic Zone

3.2 mm

R

a=Contact Radius

R=Debond Radius

Figure 1.2: Schematic Diagram of the Indentation Test for TBC Systems.

Building on the work of Drory and Hutchinson (1995), Vasinonta and Beuth

(2001) developed procedures for using a Rockwell-type indentation test to quantify the

toughness of (TBC) systems (see Fig. 1.2). They used finite element models to quantify

displacement fields caused by a rigid conical indenter on a bond coat/superalloy substrate

system. Indentation displacement fields were then used to determine energy release rates

of debonding oxide scale and thermal barrier coating layers as a function of normalized

distance from the center of the indent. Analysis results were applied to a small number of

indentation tests, yielding some of the first data for interfacial fracture toughness in asprocessed and exposed EBPVD TBC systems. A key aspect of the TBC systems studied

in this work that made use of the indentation test possible is that the TBC and bond coat

layers are relatively thin compared to the depth of the indentation. The comparatively

thin TBC layer is fully penetrated by the indenter and its existence does not alter the

deformation of the substrate (analogous to the assumptions made in the work by Drory

and Hutchinson). The thin bond coat layer also has a limited effect on the indentation

strain field (despite its being part of the indented substrate). This means that accurate

modeling of the elastic-plastic properties of the bond coat (which are not well-known) is

Reproduced with permission of the copyright owner. Further reproduction prohibited without permission.

Chapter 1. Introduction

not critical to the analysis.

The test developed by Vasinonta and Beuth (2001) was

applied to track toughness loss in isothermally exposed TBC systems at three

temperatures by Handoko et al. (2001). In their work, fracture calculations are used to

quantify the relative contribution of oxide thickening, TBC sintering and interfacial

damage to apparent losses of toughness seen in the indentation tests. Analysis of their

tests required the derivation of new energy release rate formulas that take into account the

contribution of a relatively thick oxide scale to the energy release rate of the oxide and

TBC.

Interfacial adhesion of brittle films on ductile substrates has also been quantified

by the use of wedge-shaped indenters.

Indentation by a wedge indenter was first

introduced by Vlassak, Drory and Nix (1997) for measuring the adhesion of diamondcoated titanium. Analogous to a conical indentation test, the plastic deformation of the

Interfacial adhesion of brittle films on ductile substrates has also been quantified by the

use of wedge-shaped indenters. Indentation by a wedge indenter was first introduced by

Vlassak, Drory and Nix (1997) for measuring the adhesion of diamond-coated titanium.

Analogous to a conical indentation test, the plastic deformation of the substrate caused by

the wedge indentation drives the film to delaminate from the substrate and the size of the

delaminated area can be related to the interface toughness.

Notable studies on the

application of wedge indentation methods to thermal barrier coating systems were

performed by (Begley et a l, 2000; Mumm and Evans, 2000). Mode mixity for TBC

system debonding was considered in the study of wedge indentation using an approximate

formulation (Hutchinson and Suo, 1991), with the debonding bi-layer of TBC and TGO

converted to an effective single layer. It is important to consider the mode mix in TBC

system fracture testing, because the TGO layer grows with the specimen’s exposure.

With the increase of the TGO thickness, bending deformation may act to open the crack,

making a crack extension under mixed mode instead of under purely mode II. In such

cases, measured changes in toughness may be due to changes in mode mix, so that mode

mix must be accounted for.

Reproduced with permission of the copyright owner. Further reproduction prohibited without permission.

Chapter 1. Introduction

1.2.2

Existing Work on Water Vapor and Cyclic Loading Effects on TBC System

Adherence

The injection o f steam into the combustion stream o f land-based gas turbines can

increase turbine efficiency and reduce emissions; however, there is concern that water

vapor can have a negative effect on the oxidation resistance o f gas turbine alloys and

there is a concern that it could have a similar effect on TBC systems with a growing

alumina scale. Although significant research exists on the effect o f water vapor in the

high temperature corrosion o f metallic alloys (Walter et a l, 1991; Hayashi et a l, 2001;

Fukunoto et a l, 2001; Yu et a l, 2001) as well as ceramics (Geng et a l, 2001; Gogotsi et

a l, 1994; Foerthmann et a l, 1994), work on the influence o f water vapor on the

oxidation o f alumina-forming alloys is not extensive. Moreover, there is little literature

available on the effect o f steam-air mixtures on EB-PVD TBC systems (Tamai et a l,

2000; Janakiraman et a l, 1999).

In tests on superalloys with a-A l 203 scales by

Janakiraman et al. (1999), water vapor was found to increase the spallation o f a-A l 203

scales significantly compared to scales grown on specimens exposed in dry air if the

alumina scales are marginally adherent. However, for alloys with extremely adherent aAI2O 3, water vapor did not manifest significant effect on the spallation and cracking

behavior compared to the scales exposed in dry air even though it was observed that

water vapor had access to the a-A l 203 - alloy interface during cyclic oxidation.

A more recent study by Maris-Sida et al. (2003) shows that the water vapor

affects the oxidation o f alloys in three different ways: (1) The water molecules decrease

the true fracture toughness o f the alumina/alloy interface. (2) Water vapor accelerates the

formation o f transient oxidation to cause thicker oxides to be formed during oxidation in

wet air than dry air. (3) Substantially more spinel phase is formed at the a-A l 203/gas

interface resulting from the outward diffusion o f nickel under water vapor conditions due

to cracking in the oxide scale.

It is well known that the failure o f PtAl EB-PVD TBC systems is strongly

influeneed by the growth o f the TGO layer. Tests described above on alumina scales

without a TBC deposited on top have indicated an effect o f water vapor on scale

adherence. Water vapor may increase the rate o f growth o f an alumina scale. It has been

Reproduced with permission of the copyright owner. Further reproduction prohibited without permission.

Chapter 1. Introduction

found, however, that the presence of water vapor does not significantly affect the residual

stresses in the TGO layer (Janakiraman et al., 1999).

For TBC systems, it remains

unknown if water vapor alters the residual stresses in the TBC layer or stiffness of the

TBC or any other properties of TBC and TGO layers. At this time it is not known if there

are effects of water vapor on adhesion in Pt-Al, EB-PVD TBC systems under various

loading conditions. Part of the research of this thesis will apply indentation tests to study

the degradation of EBPVD TBCs in the presence of water vapor.

1.2.3

Existing Work on the Role o f Indenter Shape

The mechanics of conical and spherical indentation of an elastic-plastic substrate

has been considered by multiple researchers. Early research in this area mainly focused

on determining the mean contact pressure beneath the indenter to obtain insight into

materials hardness testing with various indenter geometries (Tabor, 1951; Johnson, 1970,

1985; Hill, 1950; Bhattacharya and Nix, 1988, 1991). Begley et al. (1999) present a

detailed study of surface strain distributions beneath or near a spherical indenter on an

elastic-plastic substrate with an elastic film on top. Results are given detailing the strain

distributions in the contact region, where non- proportional loading occurs, and insight is

given into the interpretation of elastic thin film cracking patterns beneath the indenter.

However, there are no details given for the field solutions away from the indentation. In

particular, there appears to be no existing literature on the use of spherical indentation to

quantify interfacial toughness in TBC systems. Indenter shape has been considered in the

case of wedge indentation of TBC systems (Begley, et al., 2000; Mumm and Evans,

2000). Their work considers wedges having angles of 90° and 120°, with some model

results compared with those from models of conical indentation.

Despite some existing work looking at the role of indenter shape in the adhesion

testing of coatings, there is a lack of a complete study on the effects of indenter shapes,

especially for substrates that undergo significant work hardening during indentation. In

adherent coating systems such as as-processed TBCs and oxide scale systems (with no

TBC on top) indentation by some indenter shapes is not sufficient to induce interfacial

debonding. Depending on the application, some indenter shapes may be more efficient at

Reproduced with permission of the copyright owner. Further reproduction prohibited without permission.

Chapter 1. Introduction

inducing debonding than others.

These issues serve as the primary motivation for a

detailed study in this thesis on the role of indenter shape in coating toughness testing.

1.2.4

Existing Work on Indentation and Delamination o f Coatings on Curved

Substrates

The subject of delamination of films or coatings on a flat substrate due to a

combination of residual and applied stresses has been richly studied. However, there are

few available studies on the delamination of coatings on a curved substrate. One notable

exception is a recently published article by Hutchinson (2001) regarding thin film

debonding on a curved substrate due to equal biaxial compressive residual stresses in the

film. This paper presents a detailed study of delamination phenomena for thin elastic

films debonding in both axial and circumferential directions of a hollow cylinder using

simple analytical solutions. However, there is no current work considering indentation

toughness testing of films and coatings deposited on a cylindrical surface.

Very recent research involving thermal gradient mechanical fatigue (TGMF) tests

on TBC systems (Bartsch et al., 1999, 2002) has made the consideration of indentation

testing on curved substrates highly relevant. The goal of these tests is to realistically

simulate fatigue loads and thermal gradients imposed on a turbine blade during a service

cycle.

In order to impose specified thermal gradients, hollow cylindrical specimens

coated with EB-PVD TBC are used in performing these tests, with heating applied

externally and cooling air circulated internally, through the hollow cylinder.

In this

research, there is a need to study the degradation of toughness in the TBC system as a

function of exposure. A natural test to achieve this goal is indentation of the cylindrical

substrate. A goal of this thesis is to use analysis results to explain coating cracking paths

and cracking pattems induced by indentation of a curved substrate, to relate delamination

size to fracture toughness, and to assist in the use o f such tests for TBC and other brittle

coating systems.

1.3 Motivation

Reproduced with permission of the copyright owner. Further reproduction prohibited without permission.

Chapter 1. Introduction

This thesis is primarily motivated by existing work by Vasinonta and Beuth

(2001) and Handoko, et al. (2001) developing an indentation test to measure interfacial

toughnesses in thermal barrier coating systems. The test for TBC systems (see Fig. 2)

involves indenting a standard TBC button specimen using a Rockwell hardness tester and

a conically-shaped brale indenter.

The TBC and oxide layers are penetrated by the

indenter and the metallic bond coat and superalloy substrate are plastically deformed.

This plastic deformation induces compressive radial strains in the substrate, which are

transferred to the TBC and oxide layers. This causes an axisymmetric debond, with the

debond crack running at or near the interface between the alumina scale and the metallic

bond coat. The radial extent of the debond is directly related to the fracture toughness of

the interface.