Top 6 Benefits of Flexible Rubber Expansion Bellows in Buildings

advertisement

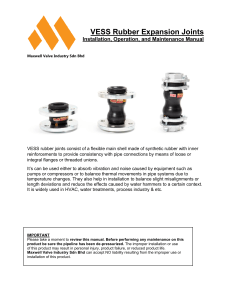

Top 6 Benefits of Flexible Rubber Expansion Bellows in Buildings Overview Rubber, slide-type, and metal-flanged expansion joints can be found in many piping systems, spools, and as flexible pieces of the bellows. The flexible Rubber Expansion Bellows are the connectors that are made of natural elastomers, fluoroplastics, and fabrics that altogether aim to absorb the movement in the piping systems which is caused due to various reasons. Advantages of Using Flexible Rubber Expansion Joints: ❏ ❏ ❏ ❏ ❏ ❏ Absorbs Vibration, Noise, and Shock Easy to Install, Easy to Remove Higher Burst Strength High Efficiency Low Deformation Under Pressure Light and Compact Absorbs Vibration, Noise, and Shock ● The sound that travels through the expansion joints is controlled and stopped by these covers ensuring peacefulness in the building. Water hammers, pumping impulses, and waterborne noises are absorbed by the molded, lightweight, thin-wall structure. Easy to Install, Easy to Remove ● Another benefit of this flexible rubber expansion joints cover is that the elastic spherical body of these joints makes them easy to install and remove whenever required. Loose flanges, no need of gasket or packing, and elastic spherical body make Expansion Joints easy to install or remove. Higher Burst Strength ● This helps in making the expansion joints remain maintenance-free for a longer time and you don’t need to get it repaired or serviced regularly. Additionally, our products are made of the best suitable material, and hence their burst pressure is much higher than those of other makes. High Efficiency ● Expansion Joints have a streamlined, flowing arch to reduce turbulence, sediment build-up, thrust area, and the effects of thrust on the piping system equipment. Low Deformation Under Pressure ● Internal pressure is exerted in all directions distributing forces evenly over a large area. Hence, the deformation of Sure Flow Expansion Joints due to pressure is much lower than that of other makes. Light and Compact ● The space required for the installation of an Expansion Joint is about half of the requirement of a cylindrical joint. Weight is about onethird. THANK YOU https://rzbmco.com/