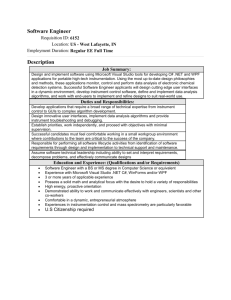

Curriculum – Vitae Instrumentation Engineer MANGESH B. NAIK. Contact No. – 8691956332 At-Post- Pabal, Tal-Pen, Raigad, Maharashtra. pin-402107 mangeshnaik89@gmail.com Objective I am looking for a good position in the field of instruments and automation in a prestigious company where previous skills and capabilities can be put to efficient use. I possess effective organizational skills and the ability to supervise a team and develop the final output. Summery Proficient with an array of Process monitoring and Control Instrumentation, Maintenance, Calibration & Installation. PLC & DCS Programming concepts, Installation & Commissioning of Tobacco process plant with different type of utilities. Currently worked in Carbon black processing plant (230 MT per day capacity with 70 TPH boiler and 23 MW turbine). EDUCATION Diploma in Instrumentation & Control engineering - MSBTE in 2009 with 67 % H.S.C. (Science) - Mumbai University with 51% S.S.C. (Marathi Medium) – Mumbai University with 71.06% WORK EXPERIANCE Birla Carbon India Private Limited 230 MT per Day capacity Carbon black unit with 75 TPH Boiler and 23 MW TG. SR. Technician Instrumentation DEC 2012: Present Formulate a plan, review and analyse preventive maintenance strategy for the equipment instrumentation in order to achieve highest efficiency of the activities for reliable and safe operation. Troubleshooting and corrective action of instrument breakdown or failures to find the root cause and best solution in order to restore the functionality back to normal. Attend to technical query by operation personnel and provide solution according to best engineering practise to address issues which affect the operation. Formulate a plan, execute and analyse calibration schedule of critical and non-critical instrument used in plant to achieve highest quality and efficiency of the product as per customer requirement and satisfaction maintain data for same. Develop the plan, scope and lead the execution of shutdown works for instrumentation to ensure completion within the specified time window. Monitor spare parts and inventory for critical instrumentation to ensure availability when required in order to minimize production interruption. Establish new inventory/cataloguing where necessary. Update information in the inventory to ensure it is relevant for the current operation. Having good exposure of DCS (Emerson Delta V Processor version 10.3.4)., PLC (Allen Bradley) programming, wiring diagram, cable scheduling, loop tracing and fault finding with field instrument i.e. (FF, Analog, Digital). GOOD Knowledge of Telephone Intercom system of Siemens HIPATH 3000. Godfrey Phillips India Tobacco Processing and cigarette manufacturing unit. Officer - Electrical and instrumentation From Nov. 2010 to December 2012 Project Management Checking of database with BOM and BOQ of vendor. Cross checking of I/O assignment with vendor. Installation of all instruments as per P& ID. Hot loop and Cold loop checking. Checked interlocks with vendor. Prepare Spare part list as per critical and non-critical instrument as per data available by vendor. Supervision of installation & commissioning and of Tobacco Process Machinery made for secondary manufacturing. (GD121, Mark8, Mark9, X300, X600) also do trouble shooting and maintenance activity for same Supervision of installation & commissioning and of Tobacco Process Machinery made for primary manufacturing (ASRS, FEEDER, DCCS, CUTTER, DRYER) also do trouble shooting and maintenance activity for same Installation of field instrument. Panel Installation and loop checking with field IO. Familiar with S7300 PLC Other Industrial Training Emerson Delta V Course 7009 carried by Emerson process management Internal training for PLC Step7 software Internal training for PLC micrologix Tobacco Machinery (GD121, X600) operational and electrical and instrument maintenance training from GD in ITALY. Installation and calibration of different instrument PT, DPT, TT, Control Valve, Weighing Scale and Conveyor. Basic training programmed for FESTO Pneumatic Valve. Hand held experience with Different Type of Field Instrument. Control Valves: Samson, Fisher, Unitech, Mascot. Valve Positioner: Siemens, Fisher, Metso. Flow transmitter – Rosemount, Yokogawa, E & H. Pressure transmitter – Rosemount, Yokogawa, E & H. Level Transmitter- DPT, Radio Frequency, Displacer. Temperature transmitter - for (Thermocouple R, K, T and PT100 Type). Analysing instrument - PH & Conductivity meter, Oxygen Analyser, SOX/NOX analyser and Opacity meter. Type of Switches - Pressure, Level, Differential Pressure Type. Weighing Element: Ramsey Weigh belt, Weighing Scale (Metlor Toledo, Jay pan), Weigh BridgeEagle. Personal Profile Nationality Sex Marital Status : - Indian. : - Male. : - Single. D.O.B Passport Place of Issue Date of Issue Date of Expiry :- 08.06.1989 :- J6350168 : - Thane. : - 05-03-2011. : - 04-03-2021. I hereby declare that the above furnished information is true and correct to the fullest. Regards, MANGESH NAIK Date