Functional Analysis of a Corrugated Cardboard Box Manufacturing System

advertisement

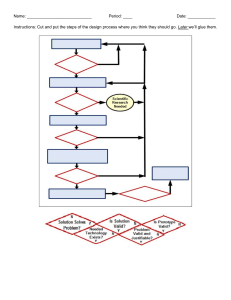

Mech 2503 INTRODUCTION TO DESIGN ASSIGNMENT 2 FUNCTIONAL ANALYSIS OF A CORRUGATED CARDBOARD BOX MANUFACTURING SYSTEM Student Name | Metric ID | Semester | June – September 2020 Program | AME 302 Lecturer | Mdm. Annie Yap Ai Kin Submission Date | 11th of August, 2020 1 | FUNCTIONAL ANALYSIS 1.1 | BLACK BOX SYSTEM MODEL Input Function Virgin Kraft paper Output Corrugated cardboard box (medium and liner) Cardboard offcuts/scraps Dry corn starch powder (glue) Heat + Thermal energies Water Light energy Oxygen Sound energy Coal Wax / Water/Grease resistant coating Electrical energy Electromechanical energy (switches, buttons, levers, relays) Chemical energy Digital signal (control system) Analog signal (heat content) Analog signal (moisture content) Analog signal (intensity of capacitance – electrostatic field based on materials’ dielectric permittivity) Digital signal (light/optical) 1|Page Making corrugated cardboard boxes (sans printing process). Mechanical energy (kinetic energy + potential energy) Digital signal (on/off trigger) Digital signal (information) 1.2 | FUNCTIONAL DECOMPOSITION Chemical energy Air Coal Flame Electrical energy Detect temperature. Corrugate or flute the medium. Convert chemical energy into heat energy. *B Condensed water Heat energy Reel of medium paper Steam-heat at 350 – 365 ˚F. Heat energy Cooling water Remove heat and reduce pressure. A Press by rolling against corrugated profile. Analog signals Analog signals Activate splicer sensing element. Kinetic energy Corrugated/Fluted medium Sound energy Digital signals On or start system. Activate temperature sensing element. Activate pressure sensing element. Detect pressure. Detect presence of paper reel. Digital signals Detect depletion of paper reel. Display real-time information on computer. Digital signal Join the layers. Apply glue to crests of corrugated medium. Bond layer of inner liner to medium. Bond layer of outer liner to board composite. Reload reel. Convert electrical energy into kinetic energy. Corn starch glue Reel of liner sheet *A Steam-heat to cure glue. 2|Page Actuate shaft motor. Heat energy Condensed water Board composite B C Electrical energy Actuate motors. Sort blanks. Actuate saw motor. *C Straight-cut the board to blanks. Kinetic energy Apply wax-coating or water/grease resistant for wet container boxes. Convert electrical energy into kinetic energy. Convert electrical energy into kinetic energy. Wax or water/grease resistant coating Kinetic energy Stack layers to compact predetermined quantities. Inspect for quality. Digital signal Form boxes. Separate blanks into distinctive layers. Conduct warp test to gauge the flatness of blanks. Perform Cobb test to measure moisture content. Trim and punch the boards to subtle shapes for making flaps and handles. Test for glue strength, bursting strength, compression, and dimensional accuracy. Corrugated cardboard boxes Check quality for final time. Trim and perforate intricate slots and holes on cardboards. Cardboard offcuts (to be recycled) Electrical energy 3|Page Convert electrical energy into heat energy. Cardboard offcuts (to be recycled) Fold and join parts. Heat energy Coat hot glue with wax. Condense the overlapping panels to level out thickness. Score and bend parts to be folded. Cold glue Wax Apply glue to sections to be adhered together.