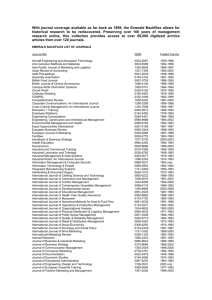

BUCHAREST UNIVERSITY OF ECONOMIC STUDIES TRANSPORTATION-Managing the flow of the Supply Chain Members: Andreea Constantin Cosmin Balazsfi Group: 1735, D. Keywords: transportation; supply chain; flow managing; Contents Introduction ............................................................................................................................................. 3 What is Logistics ? .............................................................................................................................. 3 What is the supply chain ? .................................................................................................................. 3 What is Transportation ? ..................................................................................................................... 4 Transportation Decision-Making Framework ......................................................................................... 4 Differential effects of transportation in supply chain modelling ............................................................ 7 Critical application of TMS .................................................................................................................... 7 Modal Selection of TMS ......................................................................................................................... 8 Conclusion .............................................................................................................................................. 9 Reference list ........................................................................................................................................ 10 2 Introduction What is Logistics ? Every manufacturer in order to be succesful and to grow his business into profit he needs to move materials, in order to produce, to have what to sell to the curstomers. There are multiple ways of collecting materials and delivering fnished goods, like retail shops which have regular deliveries from wholesalers, manufacturer who build factories that collect raw materials and deliver finished goods to customers. Even your daily routine involves logistics, the fact that you can buy from a store everything you need, that you can rent a DVD or order clothes online, all of this actions means that someone is responsible for fulfilling your „wishes and desires” and delivered to you. Logistics is the function that is responsible for this movement and for the transport and storage of the materials from the suppliers to the customers. These products can be cathegorized as goods or services and they can be either tangible(Samsung, Heineken) or intangible (Orange, Telekom) but on a more detailed analysis they are a complex package which is not limited only to these attributes but are rather a combination of these 2. What is the supply chain ? The supply chain represent the activities and organisations that material move through on their journey from the first supplier to it’s customers. For example, due to the fact that every product has its own unique supply chain, for example for bread its start with the grains growing in a field and ends with you buying the product from the supermarket. The supply chain for chocolate start with the cocoa beans growing in the field and end with the table of chocolate being available for sale in the shop. The supply chain has different names in the literature according to which attributes they emphasise more: -emphasise on the marketing, logistic channel; -emphasise on the operations; process; -emphasise on the value added, value chain; -emphasise on customers if they are satisfied, demand chain; 3 What is Transportation ? When we talk about logistics, one of the more important characteristics is the Transportation part because if this part is not established in detail for every product, from buying from the suppliers until delivering them to the customers than the whole business would collapse because it relies on this component a lot. When a company knows exactly how and when to deliver their product and by which methods, than that company is destined for success, but when the transportation part is not very clear in the company this can lead to delayed orders, unsatisfied customers and lost of clients and profit. Challenges to carrying out this role: • Supply chain complexity; • Competing goals among supply chain partners; • Changing customer requirements; • Limited information availability; • Synchronizing transportation with other supply chain activities; • Transportation capacity constraints pose a challenge; • Rising transportation rates present another major concern for organizations; • The transportation industry is impacted by governmental requirements that affect cost structures and service capabilities; • Regulation is growing in areas where the transportation industry has the potential to impact the quality of life, the safety of citizens, and the growth of commerce. Modes of Transportation: • Truck; • Rail; • Air; • Water; • Pipeline; • Intermodal transportation. Transportation Decision-Making Framework During this times the transportation and logistics managers face a very different environment than they did a few years ago, this due to the continuous economical change of the environment and of the customers expectations, increased globalization and improved technologies bring them not only a bunch of new opportunities but also a lot of challenges which if they do not know how to overcome and adapt their needs to it they will remain behind the times and trends. 4 One of the most important challenge is the transportation one, because its important to leverage this function as critical for the company and make it a critical strategic element in the logistics function. Managers who do not adapt to these times and they don’t consider transportation a critical function in the company results in performance shortcomings and missed opportunities. Transportation services play a central role in seamless supply chain operations, moving inbound materials from supply sites to manufacturing facilities, repositioning inventory among different plants and distribution centers, and delivering finished products to customers. Benefits accruing from world class operations at the points of supply, production, and customer locations are pointless without the accompaniment of excellent transportation planning and execution. Having inventory positioned and available for delivery is not enough if it cannot be delivered when and where needed in a cost-efficient manner, that’s why recently more and more managers in order to meet ever-increasing expectations of their customers the basic work of transportation is no longer viewed as just a simple delivery job, but has changed to providing a strategic edge by simultaneously increasingly lower costs and meeting elevated service requirements. We can think of the concept of Transportation as a machine, having different gear, each gears representing the multiple supply chains entities in a channel and each gear it’s dependent on the other in order to keep the “machine” working properly. The supply chain in this function, in this machine is only as strong as its weakest component or gear, that’s why we don’t have to look at transportation as a single and independent value because if its managed independently of other gear in the machine, like value added supply chain operations than this entire function will fail. Transportation decisions made in cooperation with related functions alleviate its weaknesses. When taking the decision of choosing the transportation mode we need to analyse each possibility and route; air, motor vehicles, railroads, pipelines and intermodal. 5 There are a few steps to take into consideration when choosing the transportation plan: 1. Total Network and Lane Decisions: -studying the possible network of distribution, supplier, plant, customer locations, the various movements among them and choosing the best one for your company and focus on long term planning, which primary mode of transportation is appropriate for each general flow (interfacility, inbound, outbound) by product or location. 2. Lane Operation Decisions: -the second level of decision making regards transportation, the first one was for long term planning, but this one is for daily operational freight transactions such as managers who have real date about what products are needed at various system nodes and must coordinate product movements along inbound, outbound and interfacility shipping lanes to meet service requirements at lowest total costs. 3. Carrier Assignment Decisions: -this step is about the information that is needed in order to deploy different techniques, goods and products in order to stay in trend with the market and to be able to offer your customer the best experience. In order to offer this you need large amounts of data and decisions made upon product, market service and cost criteria. 4. Service Negotiations: -this step present the fact that managers are increasingly managing relationships with transportation service providers and that nowadays managers need to posses a vast knowledge of strategic and tactical business in order to understand the customer and the transportation firm and to be able to establish a threshold point to satisfy both parts but to also make profit. 5. Dock Level Decisions: -this final step involves dock level operations such as loading, planning, routing and scheduling. 6 Differential effects of transportation in supply chain modelling Transportation management systems are widely used information technologies that support the effective planning, execution, and analysis of transportation processes. This process must be included in supply chain strategy development, network design, and total cost management. Managing the transportation process for maximum supply chain impact requires considerable knowledge of transportation options, planning, decision making, analytical skills, and information sharing capabilities. Businesses seek to increase value through efficient SCM, and one of the easiest ways to increase value is through increasing volume while reducing waste through the lowering of operating costs. They have to try to overcome numerous obstacles like global expansion of supply chains, rising costs, limited capacity, and government regulation in order to synchronize transportation with other supply chain processes. Transportation, from the planner’s perspective, is only one of the elements in the supply chain – representing about 36 percent of total distribution costs; the other 64 percent of cost is consumed by other elements in the supply chain, which the logistician will take into account when making decisions about channel relationships. Successful SCM, however, generally requires good transportation resources, because the transportation system becomes the warehouse, with orders consolidated in the computer and carriers coordinated for JIT delivery. Transportation Management Systems Critical application of TMS include the following: 1. Routing and scheduling • proper planning of delivery routes has a major impact on customer satisfaction, supply chain performance and organizational success 2. Load planning • effective preparation of safe and efficient deliveries 3. Load tendering • consists of requesting a load tender from a carrier and giving them the ability to respond by rejection or acceptance. 4. Status tracking • helps the supervisors to know exactly when the shipping will arrive in order to arrange future steps 7 5. Appointment scheduling • allows the supervisors to use you load space as best you can without having drivers waiting. Certainly, transportation can play a key integrative role in supply chain structures, since carriers may be in an ideal position to integrate and coordinate flows throughout the supply chain. This suggests a close consideration of the role that transportation plays in the integrated SCM scenario. Modal Selection of TMS 1. Product Safety • Safety advantage: Air transportation and motor carriage • Safety disadvantage: Rail and water 2. Cost • Cost advantage: The cost of transportation service varies greatly between and within the modes • Cost disadvantage: Motor carriage and air transportation The significant differences between model versions suggests that transportation costs play a significant role in this particular simulation. Supply chain information flow strategiesSupply chain management takes a systems view regarding all processes needed to bring a product to the final customer. This view recognizes that the value creation process extends beyond the boundaries of the firm, and 8 involves integrated business processes among the entities of the chain, such as suppliers, manufacturers, and customers. . This requires the supply chain ultimately to be managed as one complete system and asks for integration practices that strengthen linkages across individual firm functions as well as throughout the supply chain. Some of the main benefits of this type of relationship are the increase in the synchronization of the Supply Chain, the reduction of total costs, improvement of quality and cycle time, as well as a strong competitive position which exceeds any possible contribution from traditional relationships. The information flow is the foundation for integration in the strategic alliance which we can describe by 3 characteristic 1. Level of information sharing 2. Information quality 3. IT supply chain applications Information sharing is the sharing of knowledge among partners to serve downstream customers effectively and efficiently. This knowledge includes information on the production status and the planning process, but also on changes in the business environment and the goals of the companies Information quality is measured by the degree to which the information shared between supply chain partners meets the needs of the different partners. The use of IT systems in inter-firm integration is supported by transaction cost economics, which generally posits that IT reduces transaction costs. Conclusion Transportation involves the physical movement of goods between origin and destination points. The transportation system links geographically separated partners and facilities in a company’s supply. Transportation facilitates the creation of time and place utility in the supply chain, also has a major economic impact on the financial performance of businesses. 9 Reference list 1. Huq, F., Stafford, T., Bhutta, M.K. and Kanungo, S., (2009) An examination of the differential effects of transportation in supply chain optimization modelling, [ejournal]. Available through Emerald Insight (database) https://www.emerald.com/insight/publication/issn/1741-038X [Accessed 26 March 2020]. 2. Vanpoucke, E., Boyer, K.K. and Vereecke, A., (2009) Supply chain information flow strategies: an empirical taxonomy, [e-journal]. Available through Emerald Insight (database) https://www.emerald.com/insight/publication/issn/0144-3577 [Accessed 26 March 2020]. 3. Ballou, H.R., (2007) The evolution and future of logistics and supply chain management, [e-journal]. Available through Emerald Insight (database) https://www.emerald.com/insight/publication/issn/0955-534X [Accessed 26 March 220] 4. Stank, T.P. and Goldsby, T.J., (2000) A framework for transportation decision making in an integrated supply chain, [e-journal]. Available through Emerald Insight (database) http://www.emerald-library.com [Accessed 26 March 2020] 5. Waters, D., (2003) Logistics: An Introduction to Supply Chain Management, PALGRAVE MACMILLAN 10