A PROJECT REPORT ON

SMART AGRICULTURE FIELD

SUBMITTED BY

KRISHAN YADAV

UNDER THE GUIDANCE OF

MR. PUSHPERDRA SINGH

SCIENTIST ‘D’, DIPR, Delhi

DEFENCE INSTITUTE OF PSYCHOLOGICAL RESEARCH

DEFENCE RESEARCH AND DEVELOPMENT ORGANISATION

LUCKNOW ROAD, TIMARPUR, DELHI - 110054

1

Declaration

I declare that this written submission represents my ideas in my own words and others’

ideas and words have been included, I have adequately cited the original sources. I also

declare that I have adhered to all principles of academic honesty and integrity and have

not misrepresented or fabricated or falsified any idea/data/fact/source in my submission. I

understand that any violation will be cause for disciplinary action by the institute and also

evoke penal action from the source which have thus not been properly cited or from whom

proper permission has not been taken when needed.

Signature

Krishan Yadav

Date:

2

Acknowledgement

Foremost, I would like to express my sincere thanks to my mentor, Mr. Pushperdra

Singh, who offered his time, expertise, wisdom and continuous encouragement in guiding

me and mentoring me throughout the whole process. His instructions not merely helped

me in shaping this project but also provided abundant suggestions for future projects.

Without his guidance this project would not have come into being. I would also like to

give regards and gratitude to Dr K. Ramachandran, Director DIPR, for providing me the

opportunity to undergo my training at their prestigious organization.

I am also indebted to a number of friends and well-wishers who have extended

their co-operation and help in the preparation of the project.

Date: July 22, 2019

Place: Delhi

Krishan yadav

3

Certificate

I hereby certify that the work which is being presented in the Summer Internship,

project entitled Smart Agriculture Field, in partial fulfillment of the requirements for

the award of the Certificate for summer internship at DIPR, Delhi and submitted to the

Defence Institute of Psychological Research (DIPR), Delhi, which is an authentic record

of my own work carried out during a period from 22nd May 2019 to 22nd July 2019 under

the supervision of Mr. Pushperdra Singh, Scientist “D”, DIPR Delhi.

The work presented in this report has not been submitted by me for the award of

any other degree elsewhere.

Krishan Yadav

This is to certify that the above statement made by the candidate is correct to the

best of my knowledge.

Date: ……………..

Mr. Pushperdra Singh

Scientist ‘D’

DIPR, Delhi-11054

(PROJECT SUPERVISOR)

4

Abstract

A “Smart Agriculture Field” Using Arduino Microcontroller proposes an automated irrigation using

Arduino microcontroller system which is cost effective and can be used farm field or average home

garden. The proposed system is developed to automatically water the plants when the soil moisture

sensor has detected the soil is insufficient of water by using the Arduino as the center core. The

automated irrigation system is a fully functional prototype which consists of a soil moisture sensor;

a radar system to ward off animals from field; a relay module which used to control the on and off

switch of the water pump; and a water pump. When the soil moisture sensor sense the dry soil, it

will send signal to the relay, and the relay module will switch on the water pump automatically to

start the watering process, or vice versa. This system will continue to take the inputs from the

sensors until there is sufficient amount of moisture in the soil and then it will automatically turn the

pump off. This irrigation system will reduce the hardship of farmers, save the time and enhance

accuracy and effectiveness in relatively minimal cost.

5

Table of Contents

Declaration

2

Acknowledgement

3

Certificate

4

Abstract

5

Chapter 1.. ........................................................................................................................... 8

Introduction ......................................................................................................................... 8

1.1 Introduction…………. ..................................................................................................... 8

1.2 Purpose of the project ..................................................................................................... 9

CHAPTER 2 ...................................................................................................................... 10

METHODOLOGY ........................................................................................................... 10

2.1 Smart Irrigation System ................................................................................................ 10

2.2 Farm Radar System….. ..................................................................... ……………………10

Chapter 3… ....................................................................................................................... 11

Proposed Work.................................................................................................................. 11

3.1 Hardware Working…11

3.2 Components used…….12

3.3 Hardware Specifications12

Chapter 4.. ................................................................................................................ …….20

6

Circuit Diagram and Code ............................................................................................... 20

4.1 Irrigation part

20

4.2 Radar system part

21

4.2.3 Code

22

4.3 Overall code

23

Chapter 5.. ......................................................................................................................... 25

Result Analysis .................................................................................................................. 25

Chapter 6.. ......................................................................................................................... 26

Novelty…… ....................................................................................................................... 26

Chapter 7…. ...................................................................................................................... 27

Conclusion and Future Scope .......................................................................................... 27

7.1 Conclusion

27

7.2 Future Scope

27

Chapter 7.. ......................................................................................................................... 28

References .......................................................................................................................... 28

7

Chapter 1

Introduction

1.1 Introduction

In developing countries the economy is highly based on agriculture but we lack in proper

utilization of resources available to us. This is mainly because of the unplanned use of

water for irrigation. Although there are many modern irrigation techniques like drip

irrigation and sprinkler irrigation farmers have to visit the farms in person regularly in

order to water their crops. i.e. it is manually controlled. All these problems results in

wastage of human and agricultural resources as well as time. Hence, there is a need for

making an automatic irrigation system. Literature reports different techniques

implemented for automatic irrigation systems.

As man is cutting down forest with a very high rate due to which the habitat of animals is

reducing day by day, as the population is growing and with increasing population the

demand for food is also increasing. The size of agriculture land is decreasing, which lead

to moving of farms towards forest, which leads to conflict between man and animals.

Animals destroy the agriculture field and sometimes loss of human and animal life also

occurs. There is an urgent need of solution for this problem. Farm Radar system can act as

a solution to this problem. Life of both human and animals is equally important. The only

way to deal with this situation is to prevent animal and human confrontation. There is a

need of system which will make the wild animals run towards the forest as soon as they

approach the agriculture field.

Therefore to improve the life of farmers and to implement ease of living formula of current

government, I thought that India needs not only smart cities but smarts farms as well.

8

1.2 Purpose of the project

The automatic irrigation system shows a well-established combination of Arduino Uno,

Soil Moisture Sensor, Water Pump, Servo motor, Ultraviolet Sensor and their

interconnection. This system has been designed to achieve the following properties:

To increase the production by using better irrigation system.

To manage the water supply for proper cultivation of plants.

To reduce man power.

To take proper action regarding the condition of the soil through the proposed

system.

To reduce annual crop damage by wild animals.

To reduce the loss of animal and human life.

To increase ease of living of farmers and to achieve the goal of government of

doubling the income of farmers by 2022.

9

CHAPTER 2

METHODOLOGY

2.1 Smart Irrigation System

In this project of automatic water irrigation system, we have used one moisture sensor which

will read the moisture value of the soil with the two electrodes connected to it. We have used

the sensors in analogue mode so it will read the values from 0-1024. The value read by the

sensor will be then compared to the threshold value. Arduino will turn on the pump high and

low according to the value received. If the value read by the sensors satisfies the condition for

dryness, the relay will turn on water pump. If the value read by the sensor satisfies the

condition for wetness, the relay will turn off the water pump.

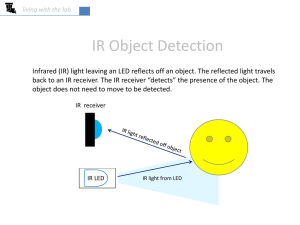

2.2 Farm Radar System

In case of farm radar system the ultrasonic sensor has two parts ultrasonic transmitter and

ultrasonic receiver. Ultrasonic sensors emit short, high-frequency sound pulses at regular

intervals. These propagate in the air at the velocity of sound. If they strike an object, then

they are reflected back as echo signals to the sensor, which itself computes the distance to the

target based on the time-span between emitting the signal and receiving the echo.

The Arduino will calculate the distance using these waves using the formula between speed,

distance and time. Accordingly the buzzer would be set to high and low. Servo motor is

programmed to rotate from 0 to 180 degree with 30 degree one time shift.

10

Chapter 3

Proposed Work

3.1 Hardware Working

3.1.1 Smart irrigation System

Soil moisture sensor is put inside the soil near the plant, to prevent it from damage to

electrodes are connected to it. Water pump is put inside a water container. After turning on

the system and connecting 5 volt water pump the soil moisture sensor will send the reading to

the Arduino. If the soil is dry Arduino will set high the pin of relay, which is directly

connected to the water pump. Water pump will turn on when relay is high and water will flow

in the field. Water pump will turn off when relay is low and water will stop flowing in the

field.

3.1.2 Smart radar system

When the circuit is powered on the servo motor starts to rotate. The ultrasonic sensor has

Ultrasonic transmitter and Ultrasonic receiver.

Ultrasonic transmitter uses a piezoceramic crystal attached with a conical metal sheet. When

an electrical voltage is applied to the piezoceramic, it vibrates with continuous expansion and

contraction. Resultantly, as per the property of piezoelectric material, ultrasonic waves are

generated which propagates straight because of the conical shape of the resonator.

Ultrasonic receiver works on the just reverse concept. When ultrasonic waves strike with the

resonator, the attached vibrator (metal plate) vibrates. With the vibration of the piezoceramic

disc pasted on the vibrator, an electric current is produced as per the property of piezoceramic

material. This electric current is further taken out from the two external leads.

If anyone comes near the radar than a specified distance the buzzer will start beeping. As the

ultraviolet sensor is mounted on the servo motor, the ultraviolet sensor will cover 180 degree

field view. The servo motor will along with Ultraviolet Sensor and Buzzer will act as a radar

system for the field.

11

3.2 Components used

Arduino UNO

Relay

Breadboard

Soil moisture sensor

Water pump

9V Battery

Servo motor

Ultrasonic Sensor

Jumper wires

Voltage regulator (7805)

3.3 Hardware Specifications

3.3.1 Arduino UNO

12

The Arduino UNO is a microcontroller which is based on the ATmega328 datasheet. It has

14 digital inputs /output pins. It is an open source microcontroller which is used to control

relay, simply connect to a computer with a USB cable or power it with a AC-to-DC adapter

or battery to get started. It is large assortment of included libraries for interfacing to wide

range of hardware. The Uno differs from all preceding boards in that it does not use the FTDI

USB-to-serial driver chip.

General pin function

LED: There is a built-in LED driven by digital pin 13. When the pin is high value, the

LED is on, when the pin is low, it's off.

VIN: The input voltage to the Arduino/Genuino board when it's using an external

power source (as opposed to 5 volts from the USB connection or other regulated

power source). You can supply voltage through this pin, or, if supplying voltage via

the power jack, access it through this pin.

5V: This pin outputs a regulated 5V from the regulator on the board. The board can be

supplied with power either from the DC power jack (7 - 20V), the USB connector

(5V), or the VIN pin of the board (7-20V). Supplying voltage via the 5V or 3.3V pins

bypasses the regulator, and can damage the board.

3V3: A 3.3 volt supply generated by the on-board regulator. Maximum current draw

is 50 mA.

GND: Ground pins.

IOREF: This pin on the Arduino/Genuino board provides the voltage reference with

which the microcontroller operates. A properly configured shield can read the IOREF

pin voltage and select the appropriate power source or enable voltage translators on

the outputs to work with the 5V or 3.3V.

Reset: Typically used to add a reset button to shields which block the one on the

board.

Special pin functions

Each of the 14 digital pins and 6 analog pins on the Uno can be used as an input or output,

using pinMode(), digitalWrite(), and digitalRead() functions. They operate at 5 volts. Serial :

pins 0 (RX) and 1 (TX). Used to receive (RX) and transmit (TX) TTL serial data. These pins

are connected to the corresponding pins of the ATmega8U2 USB-to-TTL serial chip.

External interrupts: pins 2 and 3. These pins can be configured to trigger an interrupt on a

low value, a rising or falling edge, or a change in value.

13

PWM (pulse-width modulation): 3, 5, 6, 9, 10, and 11. Can provide 8-bit PWM output with

the analogWrite() function.

SPI (Serial Peripheral Interface): 10 (SS), 11 (MOSI), 12 (MISO), 13 (SCK). These pins

support SPI communication using the SPI library.

TWI (two-wire interface) : A4 or SDA pin and A5 or SCL pin. Support TWI communication

using the Wire library.

AREF (analog reference): Reference voltage for the analog inputs.

3.3.2 Relay

One-channel relay board which operates on 5-6V is used here. The relay board consists of

three pins which are normally open (NO), normally closed (NC) and common (C). The

common pin is connected to NC pin when the relay is off and to the NO pin when the relay is

on. The input pin receives logic high from Arduino Uno and in turn switches on the relay,

thus common are connected to NO which turns the device on till the relay is on. The “VCC”

and “GND” pins of the relay are connected to 5V supply and ground respectively.

3.3.3 Breadboard

A breadboard is a solderless device for temporary prototype with electronics and test circuit

designs. Most electronic components in electronic circuits can be interconnected by inserting

their leads or terminals into the holes and then making connections through wires where

appropriate.

14

3.3.4 Soil moisture sensor

The soil Moisture sensor FC-28 has four pins

VCC: For power

A0: Analog output

D0: Digital output

GND: Ground

The Module also contains a potentiometer which will set the threshold value and then this

threshold value will be compared by the LM393 comparator. The output LED will light up

and down according to this threshold value.

A soil moisture sensor measures the water content in soil by measuring the dielectric

permittivity of the soil as a function of water content. The volumetric water content is

measured by the soil moisture sensor indirectly by properties like electrical resistance and

dielectric constant. Using this we can reduce manpower, save water to improve production

and gravimetric method

FLOW CHART AND WORKING

The Figure depicts the flow chart of automatic water irrigation system. The Arduino Uno

is a link between the soil moisture sensor and pumping motor. Arduino is supplied with a

power of 7V to 12V. The pump motor is given a separate supply of 9V. The soil moisture

sensor is used in this project because it has to check soil moisture to measure the electrical

conductivity of soil. The moisture sensor provides an analogue output which can be easily

interfaced with Arduino. The system receives a signal from the soil moisture sensor and

compares with the preset threshold value. If the value detected by the sensor is below the

threshold value, the Arduino sends a message signal to the motor to fetch water. But when

the value detected by the sensor is above the pre set value, the motor doesn’t rotate. The

Arduino always accepts the signal from the sensor and keeps updating its data.

15

Fig: Flow chart of the working of irrigation system.

Fig: Block diagram of the irrigation system.

16

3.3.5 Servo Motor

A servo motor is an electrical device which can push or rotate an object with great precision.

If you want to rotate and object at some specific angles or distance, then you use servo motor.

It is just made up of simple motor which run through servo mechanism. If motor is used is

DC powered then it is called DC servo motor, and if it is AC powered motor then it is called

AC servo motor. We can get a very high torque servo motor in a small and light weight

packages. Dur to these features they are being used in many applications like toy car, RC

helicopters and planes, Robotics, Machine etc.

Working principle of Servo Motors

A servo consists of a Motor (DC or AC), a potentiometer, gear assembly and a controlling

circuit. First of all we use gear assembly to reduce RPM and to increase torque of motor. Say

at initial position of servo motor shaft, the position of the potentiometer knob is such that

there is no electrical signal generated at the output port of the potentiometer. Now an

electrical signal is given to another input terminal of the error detector amplifier. Now

difference between these two signals, one comes from potentiometer and another comes from

other source, will be processed in feedback mechanism and output will be provided in term of

error signal. This error signal acts as the input for motor and motor starts rotating. Now motor

shaft is connected with potentiometer and as motor rotates so the potentiometer and it will

generate a signal. So as the potentiometer’s angular position changes, its output feedback

signal changes. After sometime the position of potentiometer reaches at a position that the

output of potentiometer is same as external signal provided. At this condition, there will be

no output signal from the amplifier to the motor input as there is no difference between

external applied signal and the signal generated at potentiometer, and in this situation motor

stops rotating.

17

3.3.6 Ultrasonic Sensor

Ultrasonic sensors are devices that use electrical–mechanical energy transformation to

measure distance from the sensor to the target object. Ultrasonic waves are longitudinal

mechanical waves which travel as a sequence of compressions and rarefactions along the

direction of wave propagation through the medium. Apart from distance measurement, they

are also used in ultrasonic material testing (to detect cracks, air bubbles, and other flaws in

the products), Object detection, position detection, ultrasonic mouse, etc.

Ultrasonic principle:

Ultrasonic sensors emit short, high-frequency sound pulses at regular intervals. These

propagate in the air at the velocity of sound. If they strike an object, then they are reflected

back as echo signals to the sensor, which itself computes the distance to the target based on

the time-span between emitting the signal and receiving the echo.

18

As the distance to an object is determined by measuring the time of flight and not by the

intensity of the sound, ultrasonic sensors are excellent at suppressing background

interference.

Virtually all materials which reflect sound can be detected, regardless of their colour. Even

transparent materials or thin foils represent no problem for an ultrasonic sensor.

microsonic ultrasonic sensors are suitable for target distances from 20 mm to 10 m and as

they measure the time of flight they can ascertain a measurement with pinpoint accuracy.

Some of our sensors can even resolve the signal to an accuracy of 0.025 mm.

Ultrasonic sensors can see through dust-laden air and ink mists. Even thin deposits on the

sensor membrane do not impair its function.

Sensors with a blind zone of only 20 mm and an extremely thin beam spread are making

entirely new applications possible today: Fill level measurement in wells of microtiter plates

and test tubes, as well as the detection of small bottles in the packaging industry, can be

implemented with ease. Even thin wires are reliably detected.

3.3.7 Voltage regulator IC (7805)

Voltage sources in a circuit may have fluctuations resulting in not providing fixed voltage

outputs. A voltage regulator IC maintains the output voltage at a constant value. 7805 IC, a

member of 78xx series of fixed linear voltage regulators used to maintain such fluctuations, is

a popular voltage regulator integrated circuit (IC). The xx in 78xx indicates the output

voltage it provides. 7805 IC provides +5 volts regulated power supply with provisions to add

a heat sink.

19

Chapter 4

Circuit Diagram and Code

Smart field is a combination of two circuits

1. Smart irrigation system

2. Smart radar system

4.1 Irrigation part

4.1.1 Circuit Diagram

Fig: Circuit diagram for Smart irrigation system using Arduino UNO

4.1.2 Connections

1. Connect VCC and GND of Both Relay and soil moisture sensor with Arduino UNO.

2. Connect DO with 8 pin of Arduino UNO.

3. Connect C1 pin of relay with 5 pin of Arduino UNO.

20

4. Connect the 5 volt water pump with the relay and 9 volt battery.

5. To get 5 volt supply from the battery voltage regulator IC 7805 is used.

6. Switch on the power supply.

4.1.3 Code

Irrigation function of code

void irrigation(){

val = digitalRead(8); //Read data from soil moisture sensor

if(val == LOW){

digitalWrite(5,HIGH); //if soil moisture sensor provides HIGH value send HIGHvalue to

relay

}

else {

digitalWrite(5,LOW); //if soil moisture sensor provides LOW value send LOW value to

relay

}

delay(400); //Wait for few second and then continue the loop.

}

4.2 Radar system part

4.2.1 Circuit Diagram

21

4.2.2 Connections

1. Connect the VCC and GND of both servo motor and Ultrasonic sensor to the arduino.

2. Connect the control pin of servo motor with pin 6.

3. Connect the trig pin and echo pin with pin 9 and 10 respectively.

4. Place the ultrasonic sensor on servo motor so that they work together.

5. Connect negative pin of buzzer with GND and Positive with PIN 11.

6. Power on the system.

4.2.3 Code

Radar function of the code

void calculatedistance(){

// Clears the trigPin

digitalWrite(trigPin, LOW);

delayMicroseconds(2);

// Sets the trigPin on HIGH state for 10 micro seconds

digitalWrite(trigPin, HIGH);

delayMicroseconds(10);

digitalWrite(trigPin, LOW);

// Reads the echoPin, returns the sound wave travel time in microseconds

duration = pulseIn(echoPin, HIGH);

// Calculating the distance

distance= duration*0.034/2;

safetyDistance = distance;

if (safetyDistance <= 30 and safetyDistance!=0){

digitalWrite(buzzer, HIGH);

}

else{

digitalWrite(buzzer, LOW);

}

22

Serial.print("Distance: ");

Serial.println(distance);

}

4.3 Overall code

#include <Servo.h>

Servo myservo;

const int trigPin = 9;

const int echoPin = 10;

const int buzzer = 11;

int ACWATERPUMP = 13;

int sensor = 8;

int val;

long duration;

int distance;

int safetyDistance;

int pos = 0;

void setup() {

myservo.attach(6);

pinMode(trigPin, OUTPUT);

pinMode(echoPin, INPUT);

pinMode(buzzer, OUTPUT);

pinMode(5,OUTPUT);

pinMode(8,INPUT);

Serial.begin(9600); // Starts the serial communication

}

void loop() {

for (pos = 0; pos <= 180; pos += 30) {

myservo.write(pos);

delay(15);

irrigation();

calculatedistance();

}

23

for (pos = 180; pos >= 0; pos -= 30) {

myservo.write(pos);

delay(15);

irrigation();

calculatedistance();

}

}

void calculatedistance(){

digitalWrite(trigPin, LOW);

delayMicroseconds(2);

digitalWrite(trigPin, HIGH);

delayMicroseconds(10);

digitalWrite(trigPin, LOW);

duration = pulseIn(echoPin, HIGH);

distance= duration*0.034/2;

safetyDistance = distance;

if (safetyDistance <= 30 and safetyDistance!=0){

digitalWrite(buzzer, HIGH);

}

else{

digitalWrite(buzzer, LOW);

}

Serial.print("Distance: ");

Serial.println(distance);

}

void irrigation(){

val = digitalRead(8);

if(val == LOW) {

digitalWrite(5,HIGH); }

else{

digitalWrite(5,LOW }

delay(400);

}

24

Chapter 5

Result Analysis

The project is successfully made and all the parts are properly functioning. Both irrigation

system and radar system are performing working well.

The system was tested for black and red soil under the dry and wet conditions. Using these

results a maximum value for the dryness of the soil is set that is 1023 and minimum value is

300.

Maximum value is taken as 1023 since the soil moisture sensor can measure value up to this.

So, if the measured value by the sensor is between 1023 to 300 the motor will turn on

automatically and initiates supply of water to the crops. However, if the measured value is

less than 300 it implies that the soil is wet and hence the motor remains off and no water is

supplied to the crops.

The field radar system is tested for different angles. The radar system covers approx. angle of

160 to 170 degree. The range of radar system 30 cm. The servo motor rotates by 30 degrees

in one go and after 180 degrees retraces its path. It works with even very thin objects

properly.

25

Chapter 6

Novelty

This combination of irrigation and safety for the fields is entirely new. The application of

radar at low level is a new concept which makes this project unique in nature. Today the

condition of Indian farmers is worst in the country, this project is a small step to protect the

interests of our farmers. The country is facing with huge problem of water crises, irrigation

being one of the major sources of water wastage and the smart irrigation system can truly

tackle this problem as this is very cheap and can be purchased even by marginal farmers of

the country. Bringing security and wellbeing of farmer is the main idea behind the working of

this project. This project will help in increasing the ease of living index of farmers and

thereby increasing the overall happiness index of the country.

26

Chapter 7

Conclusion and Future Scope

7.1 Conclusion

The proposed model is easy to use and doesn’t require any special training. Due to its low

price, every section of farmer can afford it. The Arduino based automatic irrigation system

is simple and precise way of irrigation. Hence, this system is very useful as it reduces

manual work of the farmers and also helps in the proper utilization of resources. It

eliminates the manual switching mechanism used by the farmers to ON/OFF the irrigation

system and also ensures there security.

7.2 Future Scope

This project can be extended to greenhouses where manual supervision is less. Fully

automated gardens and farm lands can be created using this principle in the right manner on

large scale.

Automatic Sprinkler irrigation system can also be developed using it and the radar system

can be enhanced by combing it with obstacle avoiding robot. There is lot of requirement of

improvement in agriculture sector and such small technologies can help farmers a lot.

27

Chapter 7

References

1. G. Dearib, Cooperative Automatic Irrigation System using Arduino. International

Journal of Science and Research 6(3) 2017, 1781-1787.

2. S. Rakshak , Prof. R. W. Deshpande, Automated Irrigation System Based on Arduino

Controller Using Sensors. International Journal of Innovative Research in Computer and

Communication Engineering 5(7), 2017, 13394-13400.

3. H.T Ingale, N. Kasat, Automated Irrigation System”, Proceedings of the International

Journal of Engineering Research and Development, 4(11), 2012.

4. www.circuitdigest.com

5. https://www.arduino.cc/en/Main/Docs

28