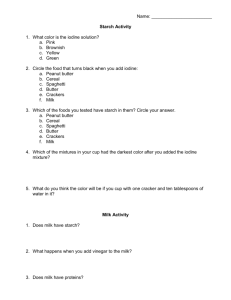

School of Science FST1800 Fundamentals of Food and Sensory Science Laboratory Manual Semester 1, 2021 FST1800 Fundamentals of Food Science Laboratory Manual Laboratory coordinator : Dr Lee Yee Ying Location : School of Science Block 4, Level 8 Room 4810 Contact No. : 03-5515 9716 Email lee.yeeying@monash.edu Laboratory technician Location Contact No. Email 1 Miss Kanakeswary Room 3507A 03-55161623 Kanakeswary.Mani@monash.edu Laboratory technician Location Contact No. Email 2 Mr Fadzly Adzhar Kamarulzaman Room 3507A 03-55161623 fadzly.adzhar@monash.edu Laboratory demonstrators Email 1. Ooi Teng Sim teng.ooi@monash.edu Email 2. Rex Quek Wei Ping wei.quek@monash.edu Laboratories Food Science and Sensory Lab (Room 47-16) 2 FST1800 Fundamentals of Food Science Laboratory Manual Laboratory Schedule Week Experiments Page No. 2 (Online) Exp. 1: Physical Properties of Water 1. To understand factors affecting boiling rate and boiling point of water. 11 Venue: Zoom 4 Exp. 2: Starch ** (Online) 1. To identify starch in food. 2. To study the microscopic appearances of raw and heated starch. 14 Venue: Zoom 5 (16/4) Venue: Zoom 8 (30/4) Venue: FS/ Zoom 9 (7/5) Venue: FS Exp. 3: Milk** 1. To study the effect of acid on milk protein coagulation. 2. To determine the effect of salt on milk protein coagulation. 3. To examine changes in colour and flavour of milk during heating. 17 Exp. 4: Confectionery (Group A & Group B) 1. To understand the processes of making crystalline and noncrystalline candies. 2. To demonstrate the role of glucose syrup in controlling crystallization of hard candy. 20 Exp. 5: Baked Products + Sensory (Group A & Group B) 1. To study the effect of flour type on the sensory attributes of baked products. 2. To determine the sensory acceptance test of baked products. 21 /Zoom 12 SWOT VAC ** A full report is required FS – Food Science and Sensory Lab (Room 4-7-16) 3 FST1800 Fundamentals of Food Science Laboratory Manual General 1. Laboratory class is compulsory for all students. 2. Lab reports should be handed in during the following lab session. The penalty for assignments submitted late is 10% of the maximum mark per day late or part thereof. Please inform the lab supervisor if submission is not during the lab session. Any submission after 2pm on the day with lab session is considered as late submission. 3. Be punctual to attend laboratory classes. Unless provided with solid evidence for late lab attendance, students are not allowed to enter the lab after 15 minutes of the commencement time of the lab. Use of laboratory 1. Apparatus • Each student is responsible for the care and cleanliness of the apparatus in the bench and cupboard allocated. • Always keep the laboratory clean and tidy. 2. Benches and reagents • Each student is responsible for the cleanliness and tidiness of their own bench and sink. Sinks should be flushed out after the use of concentrated reagents, and should not be left with rubbish in them. • Reagents and equipment should be returned to their proper place after use. • Spillages must be wiped up immediately. 3. Broken glassware and waste paper • Place all broken glass in a labeled bin or inform the laboratory technicians. • Make sure the working area is free from broken glass. 4. Lab coats & lockers • Lab coats (blue color) will be provided to students. The students MUST wear only blue color lab coat in Food Science and Sensory Laboratory. • The blue color lab coats are NOT ALLOWED in other laboratory. Please also bring your own white lab coat every time when there is a lab session in case you need to enter those labs. • Students are responsible to take a good care of the lab coats. RM50.00 penalty will be charged if the lab coats are missing/misplaced/damage. • Students can rent a locker where RM10 deposit need to be paid during lab coat collection. The deposit will be refunded at the end of semester when students return the key for the locker. No deposit will be refunded if the key for locker is missing/misplaced. Note: You will need to bring EXACT RM10 on the first week of lab session (Friday) if you wish to rent a locker. 4 FST1800 Fundamentals of Food Science Laboratory Manual Safety 1. Smoking, drinking and eating in the laboratory are strictly forbidden, with an exception in food science and sensory laboratory. 2. Always wear long-sleeved and long legged clothing; do not wear short trousers or short skirts. 3. Laboratory coat, closed in shoes and safety spectacles MUST always be worn during class. Laboratory coat is to be worn at its full length, without rolling up the sleeves. While in the food science and sensory laboratory, please wear the provided laboratory coat. Clean laboratory coat is to be worn in all the laboratories. The lab coats are not to be worn outside the laboratory, especially in rest room. 4. Laboratory clothing is to be kept clean and replaced when necessary. 5. Long hair must be tied back. 6. Never pipette by mouth. Always use a bulb to pipette. 7. Fire or accidents: Students must familiarize themselves with the following on their first visit to the laboratory: a) the location of ALL fire extinguishers in the laboratory b) the location of the nearest fire alarm c) the procedure in the event of a fire or a disaster d) the position of the First Aid Box 8. All accidents and all fires must be reported to the supervisor and/or laboratory staff immediately. 9. If acids or bases are accidentally spilled on your skin, wash the affected area with plenty of water. HOWEVER, IF THE SPILL INVOLVES SIZEABLE QUANTITIES OF CONCENTRATED SULFURIC ACID, DO NOT WASH WITH WATER IMMEDIATELY. In this case, brush off the majority of the acid with a cloth or paper towel before washing with water. This avoids deep-seated burns and scarring which would otherwise occur as heat is liberated when concentrated sulfuric acid and water mix. 10. Switch off the power of electrical appliances when they are not in used. For more detailed information on laboratory safety, please refer to the following website: http://intranet.monash.edu.my/osh/File%20Server/School%20Documents/Science/ Laboratory%20Safety%20Manual/Safety%20Manual%20May%202015.pdf 5 FST1800 Fundamentals of Food Science Laboratory Manual Laboratory Report Format Laboratory reports must be written using a word processor. Graphs must be plotted using a graphing software program (e.g. Excel). Only laboratory sessions 2 and 3 would require full report that must comprise of each of the following sections as stated below whilst others are half reports (title of the experiment, aims/objectives, results, discussion questions, conclusion and references only). Appendix can be included in either half or full report if it is applicable. Lab report is to be submitted one week (half report) and two weeks (full report) after the lab session, respectively. 1. Title of experiment 2. Aims/Objectives This should be a simple statement on what the experiments are set out to achieve. e.g. to determine the moisture content and water activity of bread, cracker, carrot and apple; to differentiate between moisture content and water activity. 3. Introduction (5 marks) This section should not be more than one page. This section should include: a) Summary of literature search for the past 10 years in relation to the investigated topic (no more than 3 papers) e.g. It has been suggested that texture variations in several commercial biscuits cannot be explained by differences in moisture content at a specific relative humidity. Water activities at which the crispiness of biscuits was ideal for consumer varied from the type of biscuits. This result suggested that moisture content of each biscuits should be adjusted to meet the consumer’s preferences (Hough et al., 2001). In a study that involves blanched and unblanched freeze-dried carrots, the rate of carotenoid degradation was minimum at water activity of 0.310.54, which corresponds to 6-11% moisture (Lavelli et al., 2007). Hence, it was suggested that partial removal of water in carrots are necessary to preserve the carotenoid content of carrots instead of complete dehydration (Lavelli et al., 2007). b) The significance of the study e.g. Moisture content is an important physical property in food research as it determines the shelf life of food. It also influences the sensory attributes of food such as food texture. 4. Materials and methods (5 marks) List out the materials used in the practical. Describe the methods used during the practical. Do not rewrite methods in the laboratory manual but noted any changes you have made. Do not use personal pronouns and write in past tense. You may include diagrams (flow chart etc.) where appropriate. 6 FST1800 Fundamentals of Food Science Laboratory Manual 5. Results (10 marks) This is a statement of the results. Where appropriate, present your data in tables or figures. Show in step by step, all calculations involved in getting the final value and include any necessary written explanations. Describe all the important aspects of the experiment that you observe, both what are requested in the laboratory manual and those that are interesting and important but not requested in the laboratory manual. 6. Discussion (20 marks) This section is used to discuss your results. You can also compare your results with literatures (properly cited). e.g. It was observed that chips have the lowest water activity among all the samples. Snack food products lost their crispiness and became unacceptable at water activity (aw) between 0.35 and 0.50 (Katz and Labuza, 1981). a. Explain any factors in the method you adopted that may influence the result e.g. Although carrots were cut immediately prior to the measurement, moisture loss from the carrots was inevitable. This may result in a falsely low result. b. Explain errors integral to the experimental design e.g. Variation in the texture of biscuits that changed with water activity could be due to differences in their microstructure, degree of starch gelatinization and development of gluten (Hough et al., 2001). c. Advantages and disadvantages of this method should be included e.g. The drying method used in this study is time consuming but it is a basic method to determine moisture content. *you may combine both results and discussion if you wish. 7. Discussion questions (according to mark allocated for each question) Answer all the questions. 8. Conclusion (5 marks) Summarize your main findings. Link your conclusion to your objectives. 9. References (5 marks) Any article or reference text used in the report MUST be referenced in full. e.g. in the text of your report, your might cite the following reference. Carrots are good source of carotene (El-Arab et al., 2002; Lavelli et al., 2007). In the reference section at the end of the document, include the above mentioned reference in your list. Arrange the list of literatures according to an alphabetical order of the last name of the first author. Use a consistent reference style. 7 FST1800 Fundamentals of Food Science Laboratory Manual References El-Arab, A. E., Khalil, F. and Hussein, L. (2002). Vitamin A deficiency among preschool children in a rural area of Egypt. The results of dietary assessment and biochemical assay. International Journal of Food Science and Nutrition, 53(6), 465-474. Lavelli, V., Zanoni, B. and Zaniboni, A. (2007). Effect of water activity on carotenoid degradation in dehydrated carrots. Food Chemistry, 104(4), 1705-1711. Remain consistent in your reference format throughout the report. DO NOT use any internet websites or lab manual as source of references. 10. Appendix Include raw data, statistical analysis etc. in which your results are based. This section will not be graded. 8 FST1800 Fundamentals of Food Science Laboratory Manual Marking criteria High Distinction (HD, 80+) The report has included all the graded sections stated in page 7-9 and each section is well-written/presented. Data is presented using a perfect choice of illustrative materials. In the discussion section, the report shows clear evidence of critical analysis and excellent arguments. Quality professional reading is evident as relevant supporting material and example are used throughout the essay to enrich the discussion and critique of the reviewed work. All scientific-writing requirements are met to the highest standard (e.g. presentation, coherency, clarity spelling, referencing, and grammar). This report is of professional standard in both content and presentation. Distinction (D, 70-79) The report has included all the graded sections stated in page 7-9 and some sections are well-written/presented. Data is presented using appropriate illustrative materials. In the discussion section, the report shows clear evidence of critical analysis. Professional reading on this topic is used to enrich the discussion. All scientific-writing requirements are of a very good standard (e.g. presentation, coherency, clarity spelling, referencing, and grammar). The report is wellpresented. Credit (C, 60-69) The report has not included all the graded sections stated in page 7-9. The report is focused on description although there is some attempt to critically analyse the published works. Professional reading on the topic is evident but limited in scope and quality. While the discussion shows that there is a good understanding of the chosen topic, there is a lack of originality of thinking and coherency in linking the ideas. Guidelines for scientific-writing have been met at a satisfactory standard. Pass (P, 50-59) The report has not included all the graded sections stated in page 7-9. Overall the report is focused on description with scant evidence of critical analysis. The discussion reveals a limited understanding of the elements involved in the given topic. There is little evidence of professional reading on the chosen topic. Guidelines for scientific-writing have been met at the satisfactory level. Fail (N, less than 50) The report shows little or no evidence of preparation, understanding of material or ability to structure or present material. The content is wholly irrelevant. 9 FST1800 Fundamentals of Food Science Laboratory Manual Experiment 1: Physical properties of water Venue: Food Analysis Lab 3508 Objectives 1. To understand factors affecting boiling rate and boiling point of water. Introduction Water is a main component in many foods. Water plays the role as a solvent and dispersing medium in foods. It is important to understand the physical properties of water in order to understand their behavior in various food systems. Physical properties of water Boiling point Boiling point is the temperature at which vapour pressure has just exceeded the atmospheric pressure. At low vapour pressure, liquid does not vaporize easily, leading to high boiling point. Conversely, at high vapour pressure, many molecules exist in the vapour state; the boiling point is low. Vapour pressure increases as increasing temperatures. This is because of molecules have more energy to vaporize at higher temperatures compared to low temperatures. Vapour pressure is also affected by the addition of solutes as the presence of solutes may decrease the availability of water molecules to vaporize, thus reducing the vapour pressure. a) Boiling rate of the various amounts of water Materials 250 mL beaker (x1), magnetic stirring hot plate (x1), magnetic stirrer, thermometer (x1), timer/stop watch (x1), safety goggles (x1 for each student). Procedures Part a(i) 1. Turn on the heat on the hot plate at no. “8” for 10 minutes. Be careful of the hot surface after turning on the hot plate. 2. Pour 200 mL of water into a 250 mL beaker. Put the beaker of water on the hot plate and put a thermometer inside the beaker. 3. Record the temperature of water every 30 seconds until the water boils. Then record the temperature every 1 minute for 6 minutes. Subsequently record the temperature every 2 minutes until there is 150 mL of water left in the beaker. 4. Record the data in a template table as shown Table 1. Part a(ii) Repeat steps 1-4 in part 1a (i) with 150 mL of water and heating is continued until there is 100 mL of water left in the beaker. Part a(iii) 1. Repeat steps 1-4 in part 1a (i) with 100 mL of water and heating is continued until there is 50 mL of water left in the beaker. 2. Plot a graph of temperature against time until heating is stopped for data collected in part 1a (i), (ii) and (iii). 10 FST1800 Fundamentals of Food Science Laboratory Manual Results Table 1. Time required to boil 200 mL of water. Time (s) Temperature (°C) Discussion questions 1. Do the curves in part a(i), (ii) and (iii) have a flat section? Is so, explain the flat section. (3 marks) 2. Does the boiling point of water depend on the amount of water? Please explain your answer. (3 marks) 3. Which of the samples boil faster? Why? (2 marks) b) Effect of solutes on boiling point of water Part b(i) 1. Turn on the heater at no. “8” for 10 minutes. Be careful of the hot surface after turning on the hot plate. 2. Put 10 g of sodium chloride (NaCl) in a beaker. Pour 200 mL of water into the beaker followed by putting a thermometer in the beaker. Stir the solution using a magnetic stirrer. 3. Record the temperature of water every 30 seconds until the water boils. Then record the temperature every 1 minute for 6 minutes. Subsequently record the temperature every 2 minutes until there is 150 mL of water left in the beaker. 4. Record the data in a template table as shown in Table 1. Part b(ii) 1. Repeat steps 1-4 in part b(i) with 10 g of sucrose. 2. Plot a graph of temperature against time until heating is stopped for data collected in part a(i), b(i) and b(ii). Discussion questions 1. Compare the graph that consists of experimental work of part a(i), b (i) and b (ii), which of the sample has the highest boiling point? What can you conclude on the boiling point of water and a solution? (3 marks) 2. Comparing NaCl and sucrose, which of this solute increases more on the boiling point of water? Give reason(s). (3 marks) References 1. McWilliams, M. (2008). Water. In Foods: Experimental Perspectives 6th edition (pp. 93-105). New Jersey: Pearson Prentice Hall. 11 FST1800 Fundamentals of Food Science Laboratory Manual 2. Mehas, K. Y. and Rodgers, S. L. (2002). The Boiling Point of Water. In Food Science: The Biochemistry of Food and Nutrition (pp.79-80). Glencoe, McGraw-Hill, USA,. 3. Murano, P. S. (2003). Food Chemistry I: Functional groups and properties, water and acids. In: Understanding Food Science and Technology (pp. 91111). USA: Thomson Learning, Inc. 4. Reid, D. S. and Fennema, O. R. (2008). Water and Ice. In S. Damodaran, K. L. Parkin and O. R. Fennema (eds.), Fennema’s Food Chemistry 4th edition (pp. 17-82). Boca Raton: CRC Press. 5. Vaclavik, V. A. and Christian, E. W. (2008). Water. In Essentials of Food Science 3rd edition (pp. 21-31). USA: Springer. Recommended readings 1. http://www.decagon.com/food_science/literature/app_notes.php 2. Fontana, A. J. (1998). Water activity: Why it is important for food safety, First NSF International Conference on Food Safety, November 16-18, Albuquerque, NM. 3. Lowe, J. A. and Kershaw, S. J. (1995). Water activity-moisture content relationship as a predictive indicator for control spoilage in commercial pet diet components. Animal Feed Science Technology, 56(3-4), 187-194. 4. Nelson, K. A. and Labuza, T. P. (1994). Water activity and food polymer science: Implications of state on Arrhenius and WLT models in predicting shelf life. Journal of Food Engineering, 22(1-4), 271-289. 12 FST1800 Fundamentals of Food Science Laboratory Manual Experiment 2: Starch Venue: Food Analysis Lab 3508 Objectives 1. To identify starch in food. 2. To study the microscopic appearances of raw and heated starch. Introduction Starch is a complex carbohydrate stored in roots and seeds of plants. For a grain kernel, starch is stored in the endosperm of a grain kernel. Starch is important in food pyramid as it provides human with energy. Starch granules are made up of two fractions, amylose and amylopectin. Amylose is the linear fraction of starch with 1,4-α-glucosidic linkages. The other starch fraction, amylopectin, consists of 1,4-α-glucosidic linkages and 1,6-α-glucosidic linkages. The 1,6-α-glucosidic linkages result in branches in amylopectin, hence amylopectin is a non linear molecule. Uncooked starch granule swells slightly when it absorbs water and it forms a suspension as it is insoluble in water. Another feature of uncooked starch granule is that it exhibits a maltese cross formation, or birefringence, when the granule is viewed under polarized light. This is because of the highly ordered crystalline structure and light is refracted in two directions. As heating begins, starch granules start to uptake water, or is commonly termed as swelling. Further heating will result in the leaching out of the short chain amylose from the starch granule. This process is known as gelatinization, which is unique for the thickening characteristic of starch. The “thickness” of a starch solution is a measure of the resistance of the starch solution to flow. This “thickness” is called viscosity in rheological study. A thicker starch solution is more resistance to flow compared to a thinner starch solution. Viscosity is mathematically defined by the following formula: τ η ……..……………………………………(1) The fundamental unit of viscosity measurement is “poise”. The International System for viscosity unit is expressed as pascal-seconds (Pa•s). Viscosity measurement can be determined using a Brookfield viscometer. 13 FST1800 Fundamentals of Food Science Laboratory Manual 1. Identify starch in foods Materials Iodine solution (20 mL), 10% (w/w) tapioca starch solution (20 mL), 10% (w/w) corn starch solution (20 mL), 10% (w/w) potato starch solution (20 mL), 10% (w/w) rice starch solution (20 mL), bread (x1/4 slice), rice (a few granules), ripe and unripe banana (x1/2 banana each), Pasteur pipette (x5), glass slides (x5), blade (x1), glass rod (x1). Procedures 1. Put one drop of starch solution on a glass slide and smear the droplet into a thin layer on the glass slide using a glass rod. 2. Put a few drops of iodine onto the smeared starch solution and record the observation. 3. Cut the banana into thin slices and place the banana slices on a paper towel. Put a few drops of iodine onto the banana slices and record the observation. 4. Place the bread and rice granule on a paper towel. Put a few drops of iodine solution onto the bread and rice and record the observation. Discussion questions 1. What was the colour change when iodine solution was added to the starch solution, bread and rice? Please explain your answer. (3 marks) 2. Which of the banana consists of more starch? Please illustrate your answer. (3 marks) 2. Microscopic examination of raw and heated starch Materials Iodine solution (20 mL), 10% (w/w) tapioca starch solution (200 mL), 10% (w/w) corn starch solution (200 mL), 10% (w/w) potato starch solution (200 mL), 10% (w/w) rice starch solution (200 mL), light microscope (x1), magnetic stirring hot plate (x1), thermometer (x1), 500mL beaker (x4), Pasteur pipette (x4), cover slip (x1 box), glass slide (x10), glass rod (x1). Procedures 1. Examine starch solution that was stained with iodine (prepared in part 1) under a light microscope. 2. Sketch the shape and size of the starch granules. 3. Heat 200 mL of tapioca starch solution up to 85°C. Put a few drops of the starch solution on a slide and smear a thin layer of the starch solution using a glass rod. Examine the starch granules under a light microscope. 4. Repeat step 3 & 4 for corn, potato and rice starch with the final heating temperature of 95°C, 70°C and 98°C, respectively. 5. Sketch the shape and size of the starch granules. Compare the raw and heated starch. 6. Cool the heated gel. Note the appearance of the gel whether the gel is translucent or opaque. 14 FST1800 Fundamentals of Food Science Laboratory Manual Discussion questions 1. Are there any differences between starch granules (both raw and heated) of various sources? If so, what are the differences? What can you conclude on the heating temperatures of 85°C, 95°C, 70°C and 98°C for tapioca, corn, potato and rice starch, respectively? (4 marks) 2. Briefly describe steps involved during starch gelatinization. (5 marks) 3. Do the starch granules in heated starch solution return to their original appearance when they are cooled to room temperature? Please explain your answer. (3 marks) References 1. Mehas, K. Y. and Rodgers, S. L. (2002). Thickening Agents. In Food Science: The Biochemistry of Food and Nutrition (pp.127-129). USA: Glencoe, Mc-Graw-Hill. 2. Vaclavik, V. A. and Christian, E. W. (2008). Starches in Food. In Essentials of Food Science 3rd edition (pp. 49-67). USA: Springer. 3. Weaver, C. M. and Daniel, J. R. (2003). Laboratory: Carbohydrates. In The Food Chemistry Laboratory: A Manual of Experimental Foods, Dietetics and Food Scientists 2nd edition (pp. 75-79). Boca Raton: CRC Press. Recommended readings 1. BeMiller, J. N. and Huber, K. C. (2008). Carbohydrates. In S. Damodaran, K. L. Parkin and O. R. Fennema (eds.), Fennema’s Food Chemistry 4th edition (pp. 83-154). Boca Raton: CRC Press. 2. Olkku, J. and Rha, C. K. (1978). Gelatinization of starch and wheat-flour starch – review. Food Chemistry, 3(4), 293-317. 3. Shu, X. L., Shen, S. Q., Bao, J. S., Wu, D. X., Nakamura, Y., Shu, Q. Y. (2006). Molecular and biochemical analysis of the gelatinization temperature characteristics of rice (Oryza sativa L.) starch granules. Journal of Cereal Science, 44(1), 40-48. 4. Tako, M. and Hizukuri, S. (1999). Gelatinization mechanism of rice starch. Journal of Carbohydrate Chemistry, 18(5), 573-584. 5. Tattiyakul, J., Liao, H-J. and Rao, M. A. (2009). Role of structure in the measurement of flow properties of food and starch dispersions: A review. International Journal of Food Properties, 12(1), 2-10. 15 FST1800 Fundamentals of Food Science Laboratory Manual Experiment 3: Milk Venue: Food Analysis Lab 3508 Objectives 1. To study the effect of acid on milk protein coagulation. 2. To determine the effect of salt on milk protein coagulation. 3. To examine changes in colour and flavour of milk during heating. Introduction Milk consists of mainly water. Other components of milk include milk solids non fat (MSNF) such as lactose, caseins, whey proteins and mineral, as well as fat. Casein is the primary milk protein as it comprises of approximately 80% of the milk proteins. Other milk proteins include whey proteins such as α-lactoglobulin and βlactalbumin. In milk, casein associates with each other and with colloidal calcium phosphate to form casein micelles. Casein micelles are coagulated by acid at pH 4.6-5.2. At the isoelectric point of casein, the charge and extend of hydration of micelles are reduced. Κ-casein hairline structures are flattened, thereby reducing steric hindrance and causing aggregation of micelles (Vaclavik and Christian, 2008). Denaturation and coagulation of milk proteins are also influenced by various types of salts. Salt ions interact with electrical charges on the surface of milk proteins, resulting in minimum conflicting charges and favoring denaturation and coagulation of milk proteins (McWilliams, 2008). Upon prolonged heating, α-lactoglobulin and β-lactalbumin are denatured and precipitated. Denatured proteins expose a large number of sulfhydryl (-SH) groups, contributing to “cooked” flavour. During heating, non-enzymatic browning reaction proceeds as the precipitated whey protein interacts with lactose. This results in changes in the colour and flavour of milk (McWilliams, 2008). 1. Effect of acid on milk protein coagulation Materials UHT full cream milk (40 mL), vinegar (20 mL), pH meter, kim wipes, distilled water, 100 mL beaker (x1), glass rod (x1). Procedures 1. Measure 40 mL of milk into a 100 mL beaker. Record the pH and initial appearance of milk. 2. Record the pH of vinegar in another beaker. Add the vinegar into the milk and stir the mixture until the vinegar is well mixed in the milk. 3. Measure the pH of the mixture. 4. Let the mixture stand for 30 minutes and record your observation. 16 FST1800 Fundamentals of Food Science Laboratory Manual 2. Effect of salt on milk protein coagulation Materials UHT full cream milk (40 mL), sodium chloride (NaCl) (10 g), magnetic stirring hot plate, pH meter, paper towel, distilled water, 100 mL beaker (x1), magnetic stirrer. Procedures 1. Measure 40 mL of milk into a 100 mL beaker. 2. Add 10 g of sodium chloride into the milk. Stir until the sodium chloride has completely dissolved in the milk. Record the pH and appearance of the milk. Heat up the milk until the milk is boiling. Let the milk boil for 5 minutes before removing the milk from the heat. 3. Check the pH after the milk has cooled to room temperature. Record your observation. 4. Repeat steps 1-3 for control using another 40 mL of milk without the addition of sodium chloride. Discussion questions 1. What effect did vinegar have on the milk? Explain your answer. (3 marks) 2. Explain the curdling process that may happen when salt is heated with milk. (3 marks) 3. Give one example of dairy product that is important to have curd formation. (1 marks) 3. Changes of milk during heating Materials Sweetened condensed milk (~40 mL), universal bottles (10 mL, x4), test tube rack (x1), timer (x1), 90°C water bath (x2), pH meter (x1), distilled water (x1), kim wipes (x1 box), pipette (x1), Colourflex spectrophotometer. Procedures 1. Pipette 2 mL of sweetened condensed milk into a universal bottle and dilute the milk with 4 mL of water. Record pH of the diluted milk and label this sample specifically for pH measurement. 2. Pipette 10 mL of sweetened condensed milk into a universal bottle and close the universal bottle with a lid. Prepare a total of 2 samples and label each sample. 3. Record the colour and flavour of the sample. Measure the colour of milk using a Colourflex spectrophotometer (Please refer to Appendix 2 for a brief description on colour). This is conducted by filling the sample cup with ¼ full of sample and measure the L*, a* and b* readings. Determine the flavour of milk by sniffing the milk. 4. Put all the universal bottles (3 tubes) in a rack and then put the rack in a 90°C water bath. 5. Remove the sample from the water bath after 90 minutes and check the changes in pH, colour and flavour when the sample is cooled to room temperature. Record the pH, colour and flavour of the sample. 17 FST1800 Fundamentals of Food Science Laboratory Manual Discussion questions 1. What are the changes in terms of pH, colour and flavour of heated sweetened condensed milk? Explain your answer. (4 marks) 2. Name a compound that may attribute to the cooked flavour of heated milk. (2 marks) References 1. McWilliams, M. (2008). Dairy Products. In Experimental Foods: Laboratory Manual 7th Edition (pp. 131-170). New Jersey: Pearson Prentice Hall. 2. McWilliams, M. (2008). Milk and Milk Products. In Foods: Experimental Perspectives 6th edition (pp. 293-323). New Jersey: Pearson Prentice Hall. 3. Vaclavik, V. A. and Christian, E. W. (2008). Milk and Milk Products. In Essentials of Food Science 3rd edition (pp. 237-268). USA: Springer. Recommended readings 1. Culbertson, J. D. (2006). Food Protein Functionality. In Handbook of Food Science, Technology and Engineering, Volume 1 (pp. 7-1 to 7-13). Boca Raton: Taylor & Francis. 2. Damodaran, S. (2008). Amino Acids, Peptides, and Proteins. In S. Damodaran, K. L. Parkin and O. R. Fennema (eds.), Fennema’s Food Chemistry 4th edition (pp. 217-329). Boca Raton: CRC Press. 3. Guyomarc’h, F. (2006). Formation of heat-induced protein aggregates in milk as a means to recover the whey protein fraction in cheese manufacture, and potential of heat-treating milk at alkaline pH values in order to keep its rennet coagulation properties, a review. Lait, 86(1), 1-20. 4. Swaisgood, H. E. (2008). Characteristics of Milk. In S. Damodaran, K. L. Parkin and O. R. Fennema (eds.), Fennema’s Food Chemistry 4th edition (pp. 885-921). Boca Raton: CRC Press. 18 FST1800 Fundamentals of Food Science Laboratory Manual Experiment 4: Confectionery Venue: Food Science and Sensory Lab 4716 Objectives 1. To understand the processes of making crystalline and non-crystalline candies. 2. To demonstrate the role of glucose syrup in controlling crystallization of hard candy. Introduction Candies are classified into two different types, crystalline or non-crystalline. The main ingredients in candies are sucrose and water. Most candies consist of other ingredients such as glucose syrup, cream of tartar, butter and nuts in order to improve the quality of candies. The presence of ingredients other than sucrose molecules interfere with the sucrose crystal lattice, thereby preventing crystallization. Heating temperature is important to make sure the sugar solution reaches supersaturation. This will either promote crystallization or result in extremely viscous sugar syrup that prevents the arrangement of sucrose molecules (glassy candy). Care should be taken to make sure that no sugar crystals are present on the side of the pot during the heating of sugar solution as any nuclei could act as seeds for crystallization. Beating of sugar solution is initiated when the desired degree of supersaturation is reached. This is important to break the aggregation of sucrose crystals in order to ensure smooth texture of crystalline candies (McWilliams, 2008). Safety reminder: This lab involves high temperature sugar syrup. Please make sure you wear the safety googles, lab coat and appropriate gloves throughout the lab session. 1. Crystalline candy – fondant (Demonstration) Materials Sugar (200 g), hot water (120 mL), candy thermometer (x1), beaker (x1), analytical balance, 100-mL measuring cylinder (x1), wooden spoon (x1), safety goggles, aluminum foil, ice bath. Procedures Control 1. Put sugar and hot water in a beaker over medium heat. 2. Suspend a thermometer in the beaker so that the bulb of thermometer is completely immersed in sugar solution but not touching the bottom of the beaker. 3. Boil the sugar solution until the temperature reaches 114°C. 4. Remove the beaker from heat and cool the solution undisturbed until the temperature drops to 40°C. 19 FST1800 Fundamentals of Food Science Laboratory Manual 5. Mix/beat the mixture vigorously with a wooden spoon until the mixture becomes a creamy white mass. 6. When the fondant has cooled down to room temperature, taste a small sample of fondant and record their feel on tongue. Use the list of descriptions below the table to help your description. Table 1. Physical appearance and mouthfeel of crystalline and non-crystalline candies. Sample Appearance Crystalline candy (Fondant) Non-crystalline candy (with glucose syrup) *Mouthfeel of crystals on tongue “Non-crystalline candy (without glucose syrup) *smooth; gritty; sandy; easily melt; in solution Discussion questions 1. What is the purpose of undisturbed cooling? (1 mark) 2. Why beating is required in making fondant? (1 mark) 2. Non-crystalline candy – hard candy Materials Sucrose (180 or 300 g), glucose syrup (120 g), citric acid, ice water bath, colours, flavours, beaker (x1), wooden spoon (x1), candy thermometer (x1), pastry brush (x1), lollipop sticks, disposable pipettes, non-stick spray, safety goggles. Table 2. Weight of glucose syrup, sucrose and volume of water for hard candy. Ingredients Recipe 1 Recipe 2 Sucrose (g) 180 300 Glucose syrup (g) 120 Water (mL) 60 120 A. Flavour & colour premix preparation 1. Two 100 mL beakers containing 10g of powdered sugar are weighed out for you. These are the two colour and flavor premixes that you are going to use for candy in recipe 1 and 2, respectively. 2. To each of the 10 g of premix, add 5g citric acid (depending on your flavor choice), 3-4 drops of colour solution and 4-6 drops of flavour solution. Mix together with a glass rod until the colour is evenly mixed through and cover with an aluminum foil. 20 FST1800 Fundamentals of Food Science Laboratory Manual B. Candy preparation Procedures 1. Combine the pre-weighed sucrose, glucose syrup and water into a beaker. Suspend a candy thermometer in the beaker so that the bulb of the thermometer is completely immersed in sugar solution but not touching the bottom of the beaker. 2. Heat the sugar mixture on low heat (No. 5) with constant stirring until all the sugar crystals have melted. 3. Increase the heat to No. 10. Constantly wash down the side of the beaker with water using the pastry brush, to remove any loose, undissolved crystals. 4. Heat the sugar syrup until 144°C and then remove the beaker from the stove. 5. Place one piece of aluminum foil on an oven tray and spray the aluminum foil with non-stick spray. 6. Cool the syrup to 100°C and add the prepared colour and flavor premix. Stir quickly to mix thoroughly. 7. Pour the syrup onto the greased aluminum foil. Wait for it to harden. 8. Compile the data in table 1. Discussion questions 1. What is the reason of adding glucose syrup in making hard candy? (2 marks) 2. What is the reason to add flavour and colour to the sugar syrup when the syrup has slightly been cooled down to 120°C? (2 marks) 3. Give reason(s) why it is important to remove any loose, undissolved crystals during the hard candy making process. (2 marks) References 1. McWilliams, M. (2008). Crystallization. In Experimental Foods: Laboratory Manual 7th edition (pp. 33-45). New Jersey: Pearson Prentice Hall. 2. McWilliams, M. (2008). Monosaccharides, Disaccharides, and Sweeteners. In Foods: Experimental Perspectives 6th edition (pp. 143-167). New Jersey: Pearson Prentice Hall. 3. Mehas, K. Y. and Rodgers, S. L. (2002). Making fondant. In Lab Manual: Food Science, The Biochemistry of Food and Nutrition (pp. 131-133). USA: Glencoe McGraw-Hill. Recommended readings 1. Hartel, R. W. (2001).Controlling Crystallization. In R. W. Hartel (ed.), Crystallization in Foods (pp.233-283). Maryland: Aspen publication. 2. Labuza, T. P. and Labuza, P. S. (2004). Influence of temperature and relative humidity on the physical states of cotton candy. Journal of Food Processing and Preservation, 28(4), 274-287. 21 Experiment 5: Baked Products Venue: Food Science and Sensory Lab 4716 Objectives 1. To study the effect of flour type on the sensory attributes of baked products. 2. To determine the consumer sensory acceptance of the baked products Introduction Most of the baked products are made of flour, eggs, fats and sugar. Flour provides structure to baked products due to the gluten-forming proteins in flour. Eggs play several roles in baked products including binding of ingredients, emulsifying fat in the batter and providing colour and flavour to the baked products. Fats and oils tenderize baked products by interfering with gluten development. This also results in a “short” texture in baked products (Vaclavik and Christian, 2008). Sensory evaluation employed human five senses which are sight, smell, taste, touch and hearing to evaluate consumer products. Sensory analysis is conducted individually in sensory booth or in group via discussion using score cards. Sensory analysis can be categories into three subcategories which are discriminating testing, descriptive testing and acceptance testing depending on the purpose of the sensory test. For example: acceptance testing is performed to determine the degree of liking of the products by the consumer. Materials Mixing bowl (x1), cake tin (x1), baking paper (x1 roll), electric cake mixer (x1), wooden spoon (x2), oven (x1), several tea and table spoons and forks, bowl (x1), timer (x1), toothpicks (1 box), tray (x1), paper cup (x2), maker pen (x1), small plastic cup (x1), score card (x1) Basic shortened cake formula 56 g butter 150 g granulated sugar 3 mL vanilla 2 eggs, beated **150 g cake flour Variables **replace cake flour with either high gluten bread flour or all purpose flour or rice flour 5.4 g baking powder 120 mL milk Group _____& ______ Cake flour Group ______& _____ High gluten bread flour Group _____& ______ All purpose flour Group_____& ______ Rice flour FST1800 Fundamentals of Food Science Laboratory Manual Procedures Part A 1. Preheat an oven to 180°C. 2. Sift the flour and baking powder. 3. Beat the eggs in a bowl using an electric mixer until the eggs become soft peaks stage. 4. Cream the fat, sugar and vanilla together for 5 minutes using an electric mixer set at a low speed. 5. Pour the eggs into the mixture and beat the mixture until it is light and fluffy. 6. Stop the mixer and scrape the mixer blades with a spoon. 7. Add one-third of flour and baking powder into the mixture. Stir the batter 50 strokes using a wooden spoon. 8. Add half of the milk into the batter and stir 25 strokes. 9. Add the second third of the flour mixture and stir 50 strokes. Add the last half of milk and stir 25 strokes. 10. Finally add the last third of the flour mixture and stir 75 strokes. 11. Line a cake tin with baking paper. Label the cake tin accordingly and pour the cake batter into the tin. 12. Bake the batter at 180°C in the preheated oven for about 25 minutes until a toothpick inserted in the center comes out clean. 13. Place the cake in a plate to cool down before evaluation. Discussion Questions 1. Are there any reasons sugar, fat and vanilla are creamed together before the addition of flour mixture? Would there be any advantages for creaming prior to the addition of flour compared to mixing of butter, sugar, vanilla and flour all in one go? (4 marks) 2. Discuss the effect of flour type on the texture and overall preference of cake. (4 marks) Part B 1. Cut each of the freshly made cake sample into the size of 3 cm x 3 cm x 3 cm. 2. Place each of the freshly cut cake sample into paper cup. 3. Label each of the sample cup with three coded number. 4. Serve the sample in tray together with 100 ml of water for mouth rinsing purpose. 5. Perform a sensory evaluation test on the texture and overall preference of the cake using a nine-point hedonic scale, ranging from extremely hard/like extremely (score 9) to extremely soft/dislike extremely (score 1). Scores between 9 and 1 signify intermediate attributes. Score 5 signifies neither like nor dislike in sensory booth. 6. Record the acceptance test on the score card prepared below. 23 FST1800 Fundamentals of Food Science Laboratory Manual Hedonic score card rating for cake Date: Student name: Sample Code: Please taste the given coded sample and mark (√) how much you like the or dislike it on the point in the scale which best describes your opinion No 1 2 3 4 5 6 Characteristic Taste Texture Color Flavor Crust colour Acceptance Scale 1= 2= 3= 4= 5= 6= 7= 8= 9= ( ) ( Sample Code ) ( ) ( ) Hedonic scale Dislike extremely Dislike very much Dislike moderately Dislike slightly Neither like nor dislike Like slightly Like moderately Like very much Like extremely 7. Work out the average score of the bread (total score/numbers of taster) Organoleptic property Total Score Average Score (total score/no of participant) Sample code Taste Texture Color Flavor Crust color Acceptance Discussion Questions 1. Differentiate between discriminating test, descriptive test and acceptance test. (3 marks) 2. Discuss the overall acceptance of the cake. (4 marks) 3. Correlate the sensory attributes (texture, colour, flavour) to objective evaluation. (4 marks) 4. Explain the purpose of switching on the green light when conducting sensory evaluation. (2 marks) 24 FST1800 Fundamentals of Food Science Laboratory Manual References 1. McWilliams, M. (2008). “Shortened Cakes”. In: Experimental Foods: Laboratory Manual 7th edition, Pearson Prentice Hall, New Jersey, pp. 319338. 2. McWilliams, M. (2008). “Baking Applications”. In: Foods: Experimental Perspectives 6th edition, Pearson Prentice Hall, New Jersey, pp. 427-460. 3. Mehas, K. Y. and Rodgers, S. L. (2002). “Using Baking Powders to Produce Carbon Dioxide”. In: Lab Manual: Food Science, The Biochemistry of Food and Nutrition, Glencoe McGraw-Hill, USA, pp. 165-166. 4. Vaclavik, V. A. and Christian, E. W. (2008). “Baked Products: Batters and Dough”. In: Essentials of Food Science 3rd edition, Springer, USA, pp. 351378. 5. Hildegarde, H and Harry, T.L. “ Discrimination Testing”. In: Sensory evaluation of Food: Principles and Practices, Springer, USA, pp. 116-138 6. Vaclavik, V. A. and Christian, E. W. (2008). “Evaluation of Food Quality”. In: Essentials of Food Science 3rd edition, Springer, USA, pp. 3-15 25 FST1800 Fundamentals of Food Science Laboratory Manual Appendix Sensory evaluation Sensory evaluation uses one or more of the five senses to evaluate foods. Sensory evaluation is important to determine whether foods are differ in their sensory attributes and whether these attributes can be detected by consumer. Through the evaluation, preferences of consumer could also be determined. Descriptive test This type of test involves the rating of particular aspects of particular products on a scale. This test is normally carried out by a group of highly trained panelists. An appropriate vocabulary to describe about samples is developed. This test is useful in product development and research as it gives detailed information on flavour differences between products. Preference test Degree of liking or preference is one of the most important factors in determining the acceptance of a product. A 9-point rating scale has been derived to determine preference of consumers. This 9-point rating scale is given word descriptions ranging from “dislike extremely” at the lower end to “like extremely” at the higher end. This test is useful as a consumer preference test. Appendix 2 Colour Colour can be determined subjectively (visually) or objectively (using instrument such as spectrophotometer or colorimeter). The perception of colour involves the following three components: • Light • An object • An observer Light Light source is an important element in order to allow a precise colour judgment. Thus a standardized illuminant for colour judgment has been developed, which includes • A – incandescent, or tungsten light • C – north sky daylight, or average daylight • D65 – the most commonly-used daylight illuminant; average of noon daylight all over the world • D50 – horizon light (sunlight at sunrise or sunset) • D55 – mid-morning or mid-afternoon daylight • D75 – overcast • F2, Fcw, CWF, F – cool white fluorescent 26 FST1800 Fundamentals of Food Science Laboratory Manual TL4 or TL84 – a custom fluorescent; Philips TL84 fluorescent lamp found in Marks and Spencer stores in Europe • Ultralume 3000 – a custom fluorescent; Westinghouse fluorescent lamp found in many Sears stores in the United States Illuminants are formulas used in colour data. Each illuminant has various wavelengths of visible light. Illuminants are not physical light sources. • Object When an object reflects a particular colour wavelength of light, this allows us to perceive the object at the particular colour. There are four categories of objects that contribute to colour perception. • Opaque nonmetal • Opaque metal • Transparent material • Translucent material Observer This involves a pair of human eye which sees the light and a brain that can interpret the colour. The 10° standard observer is currently best in representing the average spectral response of human observers. CIE L*a*b* Colour Scale The L*a*b* colour scale was recommended in 1976 by Commission Internationale de I’Eclairage, or International Commission on Illumination (CIE) so that everyone can use this standard to compare colours. The L* axis runs from 100 to 0. The maximum for L* is 100, which represents white whilst the minimum for L* is 0, which represents black. The a* axis runs from right to left, with positive a* is red and negative a* is green. The b* axis runs on the z-axis, with positive b* is yellow and negative b* is blue. The following diagram represents the CIE L*a*b* colour scale. White L* = 100 Yellow +b* Red +a* Green -a* Blue -b* Black L* = 0 27 FST1800 Fundamentals of Food Science Laboratory Manual For more detailed information of colour theory, please refer to the following website: http://www.hunterlab.com/ColorEducation/ColorTheory Appendix 3 More information on texture analysis can be obtained from the following website: http://www.stablemicrosystems.com/ Appendix 4 More information on Brookfield viscometer can be obtained from the following website: http://www.brookfieldengineering.com/support/documentation/astms-articlereprints.asp 28