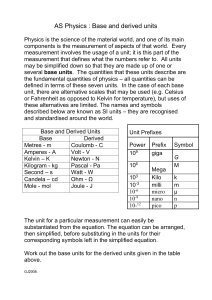

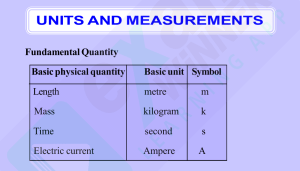

DEBRE BERHAN UNIVERSITY SCHOOL OF MECHANICAL ENGINEERING INSTRUMENTATION & MEASUREMENT UNIT – I CONCEPT OF MEASUREMENT BY, V.DINESH KUMAR Contents: • • • • • General concepts of Measurement Need for Measurement Methods of Measurements UnitsTypes of units Fundamental Units Supplementary Units Derived Units • Standards • Types of standards International Standards Primary Standards Secondary Standards Working Standards. GENERAL CONCEPT OF MEASUREMENT • Measurement is a comparison of a given unknown quantity with one of its predetermined standard values adopted as a unit. • Measurement provides is with means of describing various phenomena in quantitative terms. • It plays an important role in all branches of engineering and science. IMPORTANT REQUIREMENT OF THE MEASUREMENT The standard used for comparison must be accurate and internationally accepted. The apparatus or instrument and the process used for comparison must be provable. FUNDAMENTAL MEASURING PROCESS FUNDAMENTAL MEASURING PROCESS • The word measurand is used to designate the particular physical parameter being observed, unknown quantity which is to measured. It is the input quantity to the measuring process. • This unknown quantity is compared with the available standard quantities such length, mass, time, and it produces a result. APPLICATION OF MEASUREMENT: • Measurement Provides the Fundamentals basis for research and development activities. In research activity, the experimental part is based on measurement. • Measurement is a fundamental element of any automatic control system. In control system, discrepancy or error between the actual value and described value of a variable is to be determined. • Measurement is used to evaluate the performance of any plant or a process. For eg: in a modern power plant, temperature pressure, vibrational amplitude, etc, must be constantly monitored by the measurement to ensure the proper performance of the system. • Measurement is also the basis for commercial activities such as production, prizing, sale, and purchase. • Measurement is used to monitor data in the interest of health and safety, eg: forecasting wheather and predicting the one set of earthquakes. • It establish the validity of design and determines data for new and improved design. NEED FOR MEASUREMENT: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. To determine the true dimensions of part. To increase our knowledge and understanding of the world. To ensure public health and human health. To convert physical parameters into meaningful numbers. To test whether the element that constitute the system function as per the design. To evaluate the performance of a system. To study some basic law of nature. To ensure interchangeability with a view for promoting mass production. To evaluate the response of the system to a particular point. To check the limitations of theory in practical situations. To establish the validity of design and for finding new data and new designs. METHODS OF MEASUREMENT There are two different methods for measurement 1. Direct comparison with primary or secondary standard. 2. Indirect comparison with a standard through calibration system. 3. Comparative method 4. Coincidence method 5. Fundamental method 6. Contact method 7. Transposition method 8. Complementary method 9. Deflection method DIRECT METHOD • In direct comparison the parameter to be measured is directly compared with either a primary standard or a secondary standard. In this method, the comparison is done with a standard with the help of calibrated system. • Direct method are quite common for the measurement of physical quantities like length, mass and time. • For eg: if we want to measure the length of the rod with the standard length, and finding the bar which is so many times long because that many units on the standard have the same length as the bar. Thus, we have determined the length by direct comparison. Generally, the direct comparison is not always the most accurate or the best, it is not sensitive enough also. CLASSIFICATION OF DIRECT MEASUREMENT: • Measurement may be classified as primary, secondary and tertiary based on the complexity of the measurement system. • In primary measurement, any physical parameters are measured by comparing directly with reference standards. For eg: 1. matching of two lengths when determining the length of an object with a meter rod. 2. matching of two weights when determining the mass of grossary items. – The primary measurement provides subjective information only. Here, the observer indicates only the one rod is longer than the other rod. One object contains more or less mass than the other. The primary measurement is under the category of direct measurement. SECONDARY MEASUREMENT: • A secondary measurement involves only one translation to be done on the quantity under the measurement. For eg: if we want to measure the pressure of a gas in a container, it may not be observable. Therefore, it requires, 1. an instrument to convert pressure into displacement and 2. the change in displacement units equivalent to known change in pressure. Therefore, the primary signal is first transmitted to a transducer, where it is effected to transulate into a length change in pressure gauge. Then the secondary signal of length change is transmitted to the observer’s eye. TERTIARY MEASUREMENT • A tertiary measurement involves two translations. The measurement of static pressure by a bourdon tube pressure gauge is a typical example of tertiary measurement. • During the measurement of pressure, the free end deflects slightly. This small deflection is made larger by using rack and pinion arrangement for better displaying and reading. TERITARY ARRANGEMENT INDIRECT METHOD • Indirect comparison makes use of some form of transducing device, which converts the quantity to be measured into an analogous signal. The analogous signal is then processed by intermediate device and displayed on the output device as known function of the input. • Indirect method for measurement are used in those cases where the direst measurement is difficult. • In this method, an empirical relationship is generally established between the measurement mode and result mode that are desired. 3. COMPARATIVE METHOD • In this method, the quantity to be measured is compared with other known value. • For example: comparators 4. COINCIDENCE METHOD • The value of the quantity to be measured is determined is coincided with certain lines and signals. 5. FUNDAMENTAL METHOD • Measuring a quantity is directly related with the definition of that quantity. 6. CONTACT METHOD • The sensor or measuring tip of the instruments touches the area (or) diameter (or) surface to be measured. • For example: Vernier caliper 7. TRANSPOSITION METHOD • In this method, the quantity to be measured is first balanced by known value and then it is balance by other new known value. • For example: determination of mass by balancing methods. 8. COMPLEMENTARY METHOD • The value of quantity to be measured is combination with known value of the same quantity. • For example: volume determination by liquid displacement. 9. DEFLECTION METHOD • The value to be measured is directly indicated by a deflection of pointer. • For example: pressure measurement. QUERIES? THANK YOU UNITS • To specify and perform calculations with physical quantities, the physical quantities must be defined both in kind and magnitude. The standard measuring of each kind of physical quantity is the unit. • In earlier days, the number of system of units has been used at various times in the past days. There are different system of units available in different countries. • The M.K.S and C.G.S. system of units have been used in earlier days. • However, for the sake of uniformity of units all over the world, S.I. have been developed. • Internationally system of units (S.I) is the system established in 1960 by the general conference of weight and measures (CGPM) and abbreviated as S.I ( system international units) in all languages. • This system of units is based on meter (m), kilogram (kg), seconds (s),ampere (A), degree Kelvin (K),and candela (cd). • The S.I, like the traditional metric system, is based on decimal arithmetic. • For each physical quantity, units of different sizes are formed by multiplying or dividing a single base value of powers of 10. therefore, this system offers the great advantage because the change (unit conversions) can be made very simple by adding zeros or shifting decimal points. • The seven base units are established by the general conference of weights and measures (CGPM) are described below. • There are two supplementary units. Other physical quantities are derived from these basic and supplementary units. TYPES OF S.I.UNITS: 1. Fundamental Units 2. Supplementary Units 3. Derived Units FUNDAMENTAL UNITS: • FUNDAMENTAL UNITS ARE INDEPENDENTLY CHOOSEN AND NOT DEPENDENT ON ANY OTHER UNITS. • IT IS ALSO CALLLED AS BASE UNIT. S.NO QUANTITY 1. Length 2. UNIT UNIT SYMBOL Meter m Mass Kilogram Kg 3. Time Second S 4. Temperature Kelvin K 5. Electric current Ampere A 6. Luminous Intensity Candela cd METER (m) • It is the unit of length. • It is the length equal to 1,650,763,73 wavelength of light emitted in vacuum by the atom Kryton-86 on its transition between the levels 2P10 and 5d5. Kilogram (Kg) • It is the fundamental unit of mass. • It is equal to the mass of the international prototype preserved at the IBWNS (international bureau of weights and measures in serves). • The prototype is made of cylinder of 90% platinum and 10% iridium alloy. Second (S) • It is the unit of time. • A second can be defined as the duration of 9,192,631,770 periods of the radiation corresponding to the transition between the two hyperfine levels of the ground state of the cesium133 atom. Kelvin (K) • It is the fundamental unit of temperature. Kelvin is defined as the fraction 1/273.16 of the thermodynamics temperature of the triple point of water. AMPERE (A) • It is the unit of electric current. • The ampere is the constant current which is produced between the two straight parallel conductors of finite length and negligible cross section placed in vacuum would produce between these conductors a force equal to 2*107 N/m. Candela (Cd ) • It is the fundamental unit of luminous intensity. • Candela is defined as the luminous intensity of a surface of (1/6,00,000 ) m2Of a black body at the temperature of freezing platinum under an atmospheric pressure (1.01325 Mpa). SUPPLEMENTARY UNITS: • There are two supplementary units added to the S.I.Unit system in addition to fundamental units. These two shown in table. S.NO 1. QUANTITY Plane Angel UNIT Radian UNIT SYMBOL rad 2. Solid Angle Steradian sr Radian (rad): • One radian is defined as the plane angel subtended as the center of an arc of unit length at unit radius. Steradian (sr): • one Steradian is defined as the solid angle subtended at the centre by unit area of spherical surface at unit radices. DERIVED UNITS: • The derived unit are expressed in terms of fundamental and supplementary units by defining equations. These derived units can be categorized as follows: • a) mechanical units: units for force, pressure, stress, weight, torque, acceleration, velocity, density, etc. • b) electric and magnetic units: units for power, energy, electric resistance, electric field strength, magnetic flux density. • c) thermal units: units for specific heat capacity, latent heat, sensible heat, etc. S.NO DERIVED UNITS QUANTITY UNIT UNIT SYMBOL 1. AREA m2 A 2. Volume m3 V 3. Density Kg/m3 Ƿ 4. Velocity m/s v 5. Angular velocity rad/s Ѡ 6. Acceleration m/s2 a 7. Angular Acceleration rad/s2 α 8. Force N F 9. Pressure N/m2 P 10. Work, energy Joule W 11. Power Watt p 12. Frequency Hertz f 13. Latent heat KJ/Kg hfg 14. Sensible heat KJ/Kg Hf 15. Specific heat capacity KJ/Kg-K C STANDARDS • Standard is a physical representation of a unit of measurement. A known accurate measure of physical quantity is termed as standard. • These standards are used to determine the values of physical quantities by comparison method. • Different standard have been developed for various units including fundamental as well as derived units. • All these standards are preserved at the international bureau of weight and measures at sever, Paris. • Depending on the function and applications, different types of standards of measurement are classified as follows. TYPES OF STANDARDS: 1. 2. 3. 4. INTERNATIONAL STANDARDS PRIMARY STANDARDS SECONDARY STANDARDS WORKING STANDARDS. INTERNATIONAL STANDARDS • International standards are defined by agreement. they are periodically evaluated and checked by absolute measurement in terms of fundamental units of physics. • They represent certain units of measurement to the closest possible accuracy attainable by the science and technology of measurement. • These international standards are not available to ordinary uses like measurement and calibrations. PRIMARY STANDARDS: • The main function of primary standard is the calibration and verification of secondary standard. Primary standards are maintained at the national standard laboratories in different countries. • The primary standards are not available for the use outside the national laboratory. These primary standards are absolute standard of high accuracy that can be used as ultimate reference standards to check, calibrate and certify the secondary standards. SECONDARY STANDARD: • Secondary standards are basis reference standards used by the measurement and calibration laboratories in industries. These secondary standards are maintained by the particular industry to which they belong. • Each industry has its own secondary standard each laboratory periodically sends its secondary standard to the national standard laboratory for calibration and comparison against the primary standard. • After comparison and calibration, the national standard laboratory returns the secondary standard to the particular industrial laboratory with a certification of measuring accuracy in terms of primary standards. WORKING STANDARDS: • Working standard are the main tools of a measuring laboratory. These standards are used to check and calibrate laboratory instrument for accuracy and performance. • For eg: manufacturing of mechanical components such as shafts, bearings, gears, etc, use a standard called working standard for checking the components dimensions. • For example: plug gauge is used for checking the bore diameter of bearings. QUERIES? THANK YOU