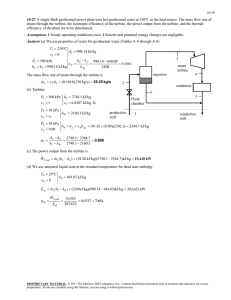

UNIVERSIDAD DE CÓRDOBA FACULTAD DE INGENIERÍAS PROGRAMA INGENIERÍA MECÁNICA Trabajo: Segundo Corte Tema: Primera Ley Estudiantes: Ing. Mecánica. 1. Semestre: 01 de 2021 Profesor: Alonso Perdomo Jiménez Ponderación: 20% Three lb of water is contained in a piston–cylinder assembly, initially occupying a volume V1 = 30 ft3 at T1 = 300°F. The water undergoes two processes in series: Process 1–2: Constant-temperature compression to V2 = 11,19 ft3, during which there is an energy transfer by heat from the water of 1275 Btu. Process 2–3: Constant-volume heating to P3 = 120 lbf/in2 Sketch the two processes in series on a T– v diagram. Neglecting kinetic and potential energy effects, determine the work in Process 1–2 and the heat transfer in Process 2–3, each in Btu. 2. One lb of water contained in a piston–cylinder assembly undergoes the power cycle shown in Figure. For each of the four processes, evaluate the work and heat transfer, each in Btu. For the overall cycle, evaluate the thermal efficiency. 3. A piston–cylinder assembly contains air modeled as an ideal gas with a constant specific heat ratio, k = 1.4. The air undergoes a power cycle consisting of four processes in series: Process 1–2: Constant-temperature expansion at 600 K from P1 = 0,5 MPa to P2 = 0.4 MPa. Process 2–3: Polytropic expansion with n= k to P3 = 0.3 MPa. Process 3–4: Constant-pressure compression to V4 = V1. Process 4–1: Constant-volume heating. Sketch the cycle on a P-v diagram. Determine (a) the work and heat transfer for each process, in kJ/kg, and (d) the thermal efficiency. 4. A system consists of 2 kg of carbon dioxide gas initially at state 1, where P1 = 1 bar, T1 = 300 K. The system undergoes a power cycle consisting of the following processes: Process 1–2: Constant volume to P2 = 4 bar. Process 2–3: Expansion with Pv1,28 = constant. Process 3–1: Constant-pressure compression. Assuming the ideal gas model and neglecting kinetic and potential energy effects, (a) sketch the cycle on a P-v diagram and calculate termal efficiency. (b) plot the thermal efficiency versus P2/P1 ranging from 1,05 to 4. UNIVERSIDAD DE CÓRDOBA FACULTAD DE INGENIERÍAS PROGRAMA INGENIERÍA MECÁNICA 5. The following data are for a simple steam power plant as shown in Figure. State 6 has x6 = 0.92 and velocity of 200 m/s. The rate of steam flow is 25 kg/s, with 300 kW of power input to the pump. Piping diameters are 200 mm from the steam generator to the turbine and 75mm from the condenser to the economizer and steam generator. Determine the velocity at state 5 and the power output of the turbine. For the steam power plant shown in Problem , assume that the cooling water comes from a lake at 15°C and is returned at 25°C. Determine the rate of heat transfer in the condenser and the mass Flow rate of cooling water from the lake. For the steam power plant shown in Problem, determine the rate of heat transfer in the economizer, which is a low-temperature heat exchanger. Also find the rate of heat transfer needed in the steam generator. 6. An R-410a heat pump cycle shown in Figure has an R-410a flow rate of 0.05 kg/s with 5 kW into the compressor. The following data are given: Calculate the heat transfer from the compressor, the heat transfer from the R-410a in the condenser, the heat transfer to the R-410a in the evaporator, and COPHP. UNIVERSIDAD DE CÓRDOBA FACULTAD DE INGENIERÍAS PROGRAMA INGENIERÍA MECÁNICA 7. A modern jet engine has a temperature after combustión of about 1500 K at 3200 kPa as it enters the turbine section (see state 3, Figure). The compressor inlet is at 80 kPa, 260 K (state 1) and the outlet (state 2) is at 3300 kPa, 780 K; the turbine outlet (state 4) into the nozzle is at 400 kPa, 900 K and the nozzle exit (state 5) is at 80 kPa, 640 K. Neglect any heat transfer and neglect kinetic energy except out of the nozzle. Find the compressor and turbine specific work terms and the nozzle exit velocity. 8. A proposal is made to use a geothermal supply of hot water to operate a steam turbine, as shown in Figure. The high-pressure water at 1,5 MPa, 180°C is throttled into a flash evaporator chamber, which forms liquid and vapor at a lower pressure of 400 kPa. The liquid is discarded,while the saturated vapor feeds the turbine and exits at 10 kPa with a 90% quality. If the turbine should produce 1 MW, find the required mass flow rate of hot geotermal water in kilograms per hour. UNIVERSIDAD DE CÓRDOBA FACULTAD DE INGENIERÍAS PROGRAMA INGENIERÍA MECÁNICA 9. A rigid tank whose volume is 0,5 m3, initially containing ammonia at 20°C, 1,5 bar, is connected by a valve to a large supply line carrying ammonia at 12 bar, 60°C. The valve is opened only as long as required to fill the tank with additional ammonia, bringing the total mass of ammonia in the tank to 143,36 kg. Finally, the tank holds a two-phase liquid–vapor mixture at 20°C. Determine the heat transfer between the tank contents and the surroundings, in kJ, ignoring kinetic and potential energy effects. 10. Un dispositivo adiabático de cilindro-émbolo equipado con un resorte mantiene la presión en el interior en 300 kPa, cuando el volumen es 0, y en 3 000 kPa, cuando el volumen es 5 m3. El dispositivo se conecta a una línea de suministro de vapor de agua a 1 500 kPa y 200 °C, y al principio el volumen del cilindro es 0. Determine la temperatura final (y la calidad, si es el caso) cuando se abra la válvula y se deje entrar vapor de agua de la línea de suministro al cilindro, hasta que la presión en el interior sea igual a la que hay en la línea. También determine el trabajo total efectuado durante este proceso de llenado adiabático. Nota: este trabajo deberá ser realizado a mano, luego escaneado y convertido a pdf. Sino se tienen en cuenta las anteriores recomendaciones, no tendrá validez. Créditos: Claus Borgnakke, Richard E. Sonntag. Fundamentals of Thermodynamics. Wiley: USA. Octava Edición, 2013. Michael J. Morán, Howard N. Shapiro. Fundamentals of Engineering Thermodynamics. Wiley. USA. Octava Edición, 2014 Yunus Cengel, Michael Boles. Termodinámica. McGraw-Hill: México. Séptima edición, 2011